Method and sample frame for testing heat retention of down loose fibers

A test method and down powder technology are applied in the preparation of test samples, measuring devices, instruments, etc., to achieve the effect of simple process, reliable data, and promoting the improvement of test level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Pretreatment of down samples: Take 250g of washed white duck down samples with a bulkiness of 17.0cm and a down content of 90%, spread them one by one and mix them evenly, and use the four-corner halving method to shrink the down samples. For the sample, take two parts of a pair of corners from the sample of the three-time four-corner halving method as the preparatory sample for the test, put the preparatory sample into the pretreatment box, and keep the constant temperature and humidity under the first-level standard atmospheric condition for 24 hours. use;

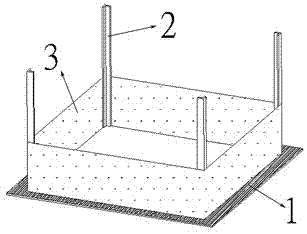

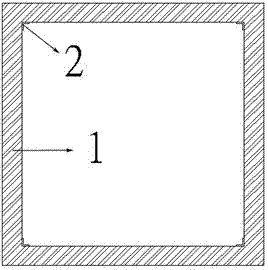

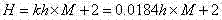

[0047] (2) Preparation of the test sample: take the height of the sample frame cloth curtain as 2.3cm to prepare the sample frame, place the sample frame on a flat-plate thermal instrument, weigh 1g of the pretreated down sample, Put it into the sample frame, spread it evenly with a glass rod, and then cover a piece of cotton standard lining fabric (30cm×30cm) on the top of the down sample to prepare a sample ...

Embodiment 2

[0051] (1) Pretreatment of down samples: Take 250g of washed gray duck down samples with a bulkiness of 16.7cm and a down content of 80%, spread them evenly and mix the samples one by one, and use the four-corner halving method to shrink the down samples. For the sample, take two parts of a pair of corners from the sample of the three-time four-corner halving method as the preparatory sample for the test, put the preparatory sample into the pretreatment box, and keep the constant temperature and humidity under the first-level standard atmospheric condition for 24 hours. use;

[0052](2) Preparation of the test sample: Take the height of the sample frame cloth curtain as 5.0cm to prepare the sample frame, place the sample frame on a flat-plate heat preservation instrument, weigh 10g of the down sample after pretreatment, Put it into the sample frame, spread it evenly with a glass rod, and then cover a piece of cotton standard interlining fabric (30cm×30cm) on the top of the dow...

Embodiment 3

[0056] (1) Pretreatment of down samples: Take 250g of washed white goose down samples with a bulkiness of 15.6cm and a down content of 70%, spread them one by one and mix the samples evenly, and use the four-corner halving method to shrink the down samples. sample, take two parts of a pair of corners from the sample of the three-time four-corner halving method as the preparatory sample for the test, put the preparatory sample into the pretreatment box, and keep the temperature and humidity under the first-level standard atmospheric condition for 24 hours. use;

[0057] (2) Preparation of the test sample: take the height of the sample frame cloth curtain as 7.7cm, make the sample frame, put the sample frame on the flat-plate heat preservation instrument, weigh 20g of the down sample after pretreatment, Put it into the sample frame, spread it evenly with a glass rod, and then cover a piece of cotton standard interlining fabric (30cm×30cm) on the top of the down sample to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com