Patents

Literature

31results about How to "Meet the performance test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residential fire sprinkler

ActiveUS7201234B2Reduce design pressureLow operating pressureSpray nozzlesFire rescueFire protectionEngineering

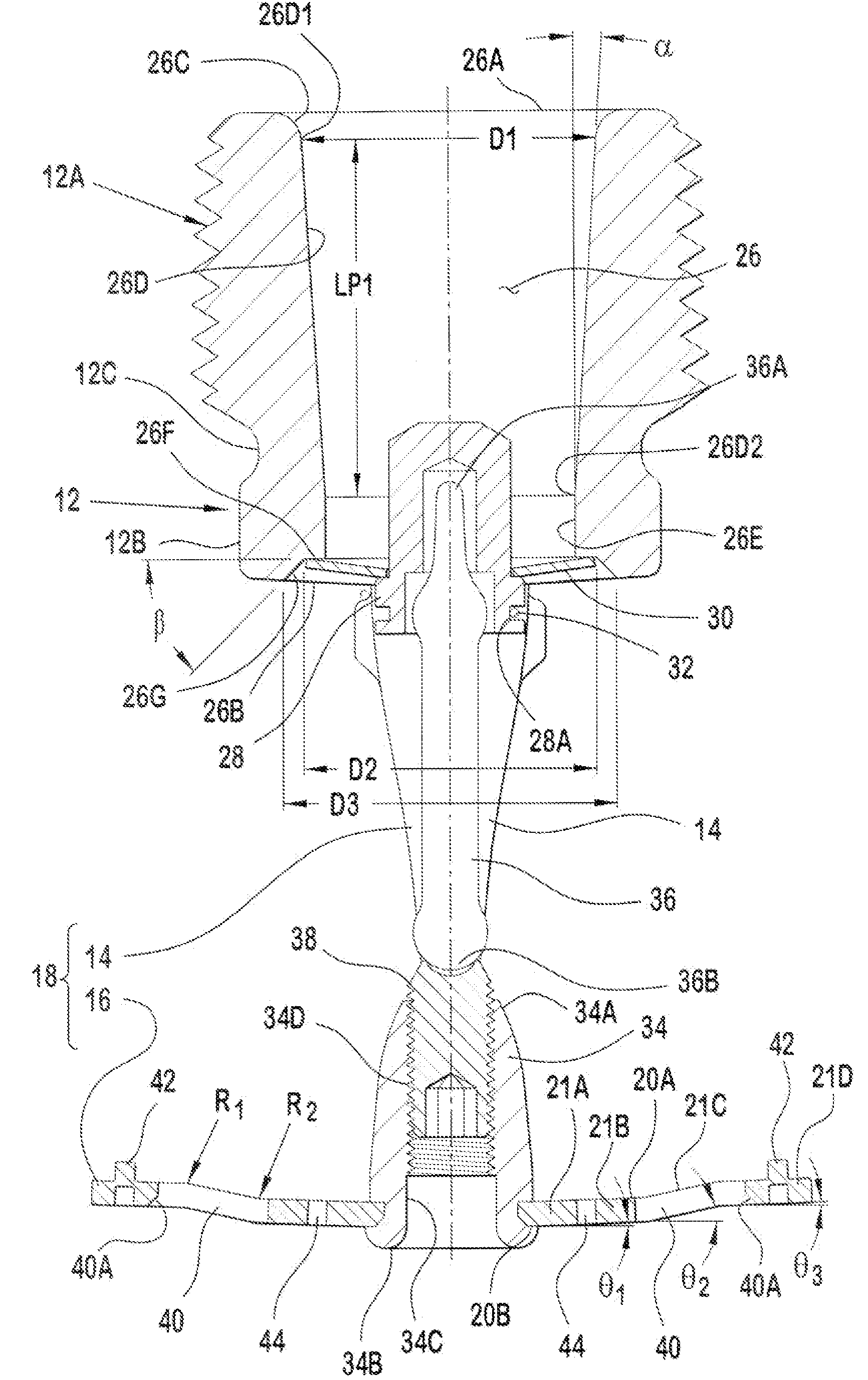

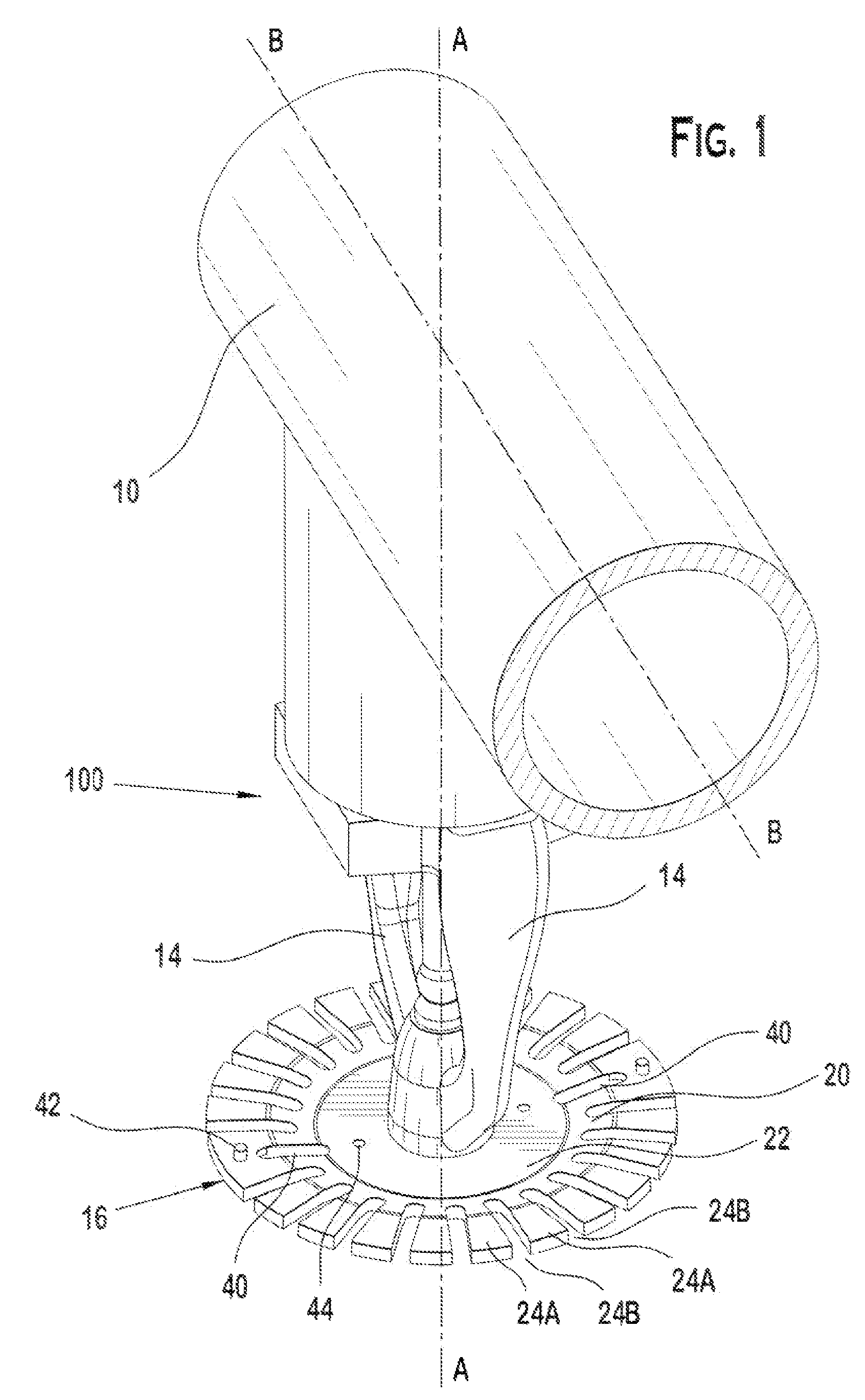

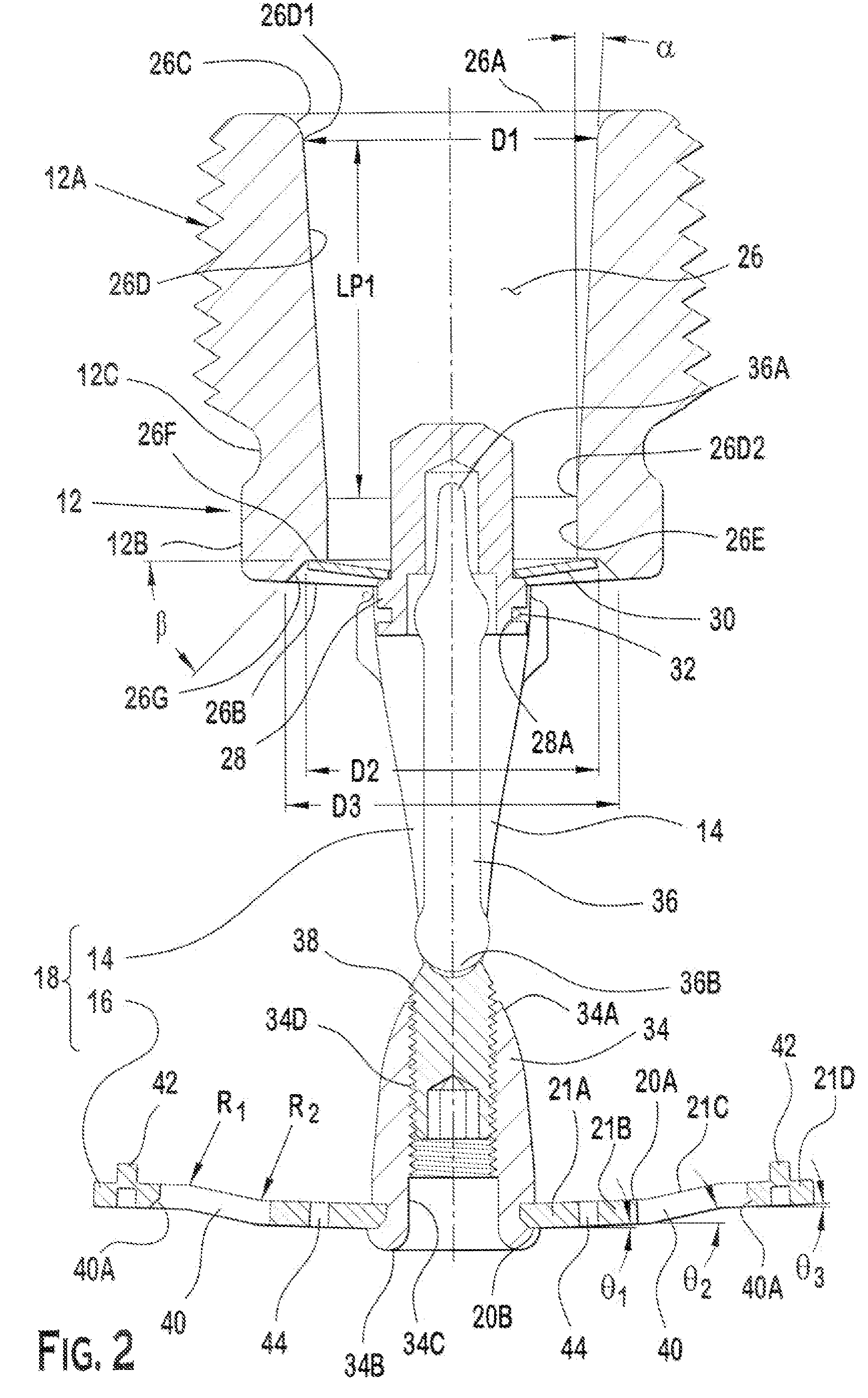

A pendent type residential fire sprinkler is described. The residential fire sprinkler has a body with a K-factor of at least 6 passage coupled to a deflector assembly that distributes fluid flowing through the passage over a coverage area to perform in accordance with Underwriters Laboratory Standard 1626 (October 2003) for listing by Underwriters Laboratory Incorporated so that the body and a heat responsive trigger disposed between the passage and the deflector assembly of the sprinkler can be installed in accordance with the 2002 Edition of National Fire Protection Association Standards 13, 13D, and 13R. Various aspects of the residential fire sprinkler, including a method of protecting a residential dwelling unit are described.

Owner:TYCO FIRE PRODS LP

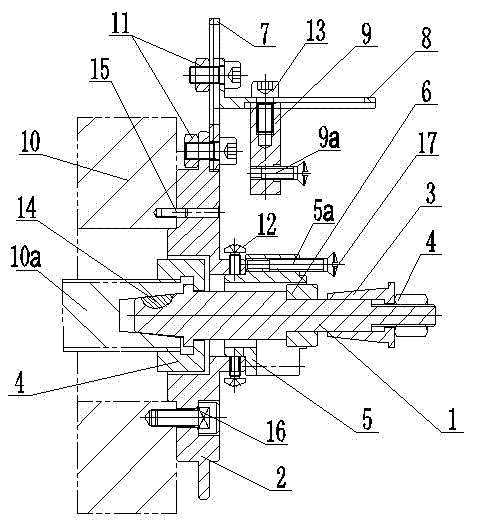

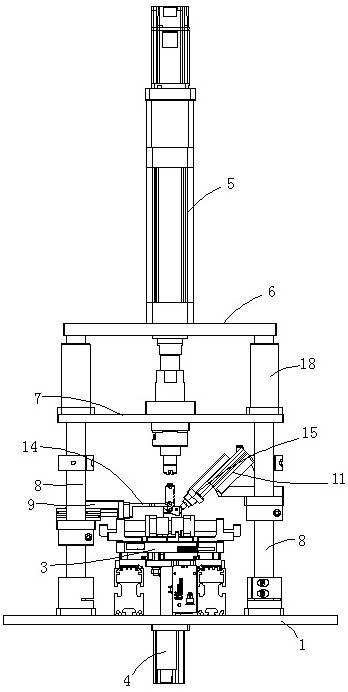

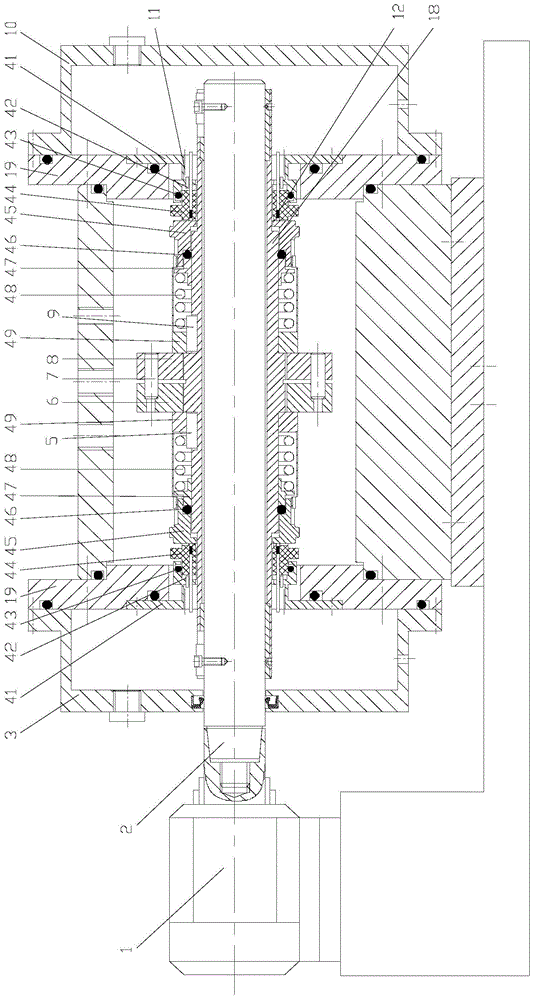

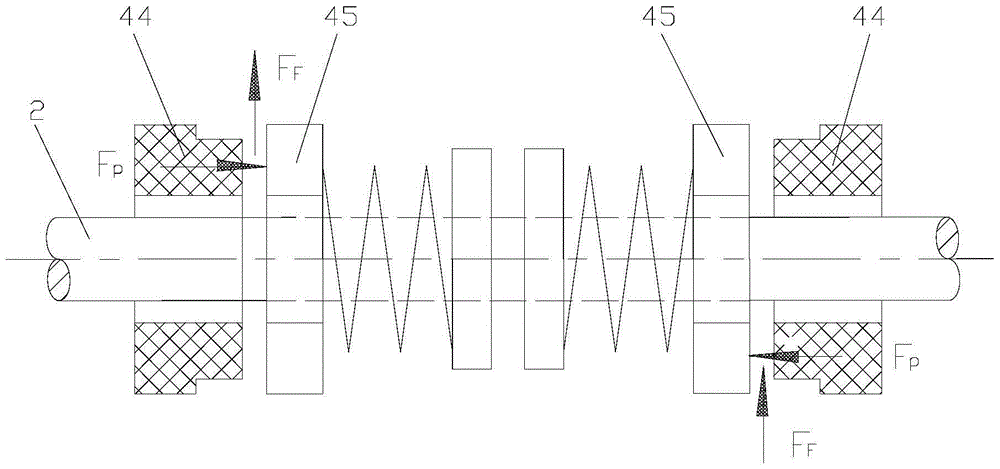

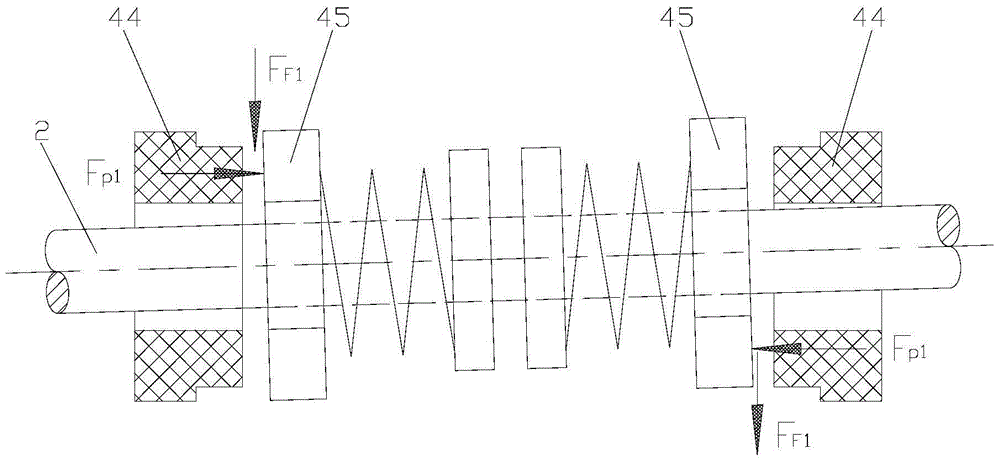

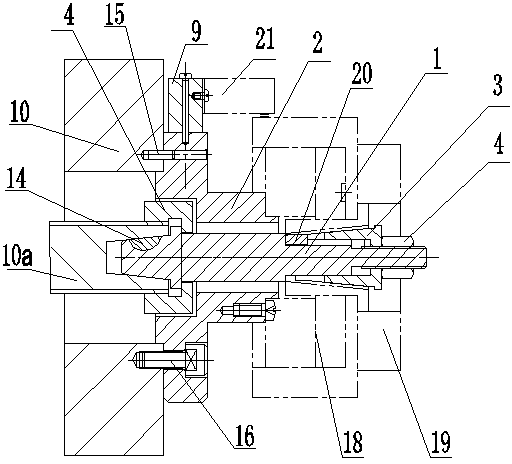

Mechanical sealing property testing device and method for measuring axial force and temperature of sealed end surfaces

ActiveCN104330223AAvoid destructionSimple structureApparatus for force/torque/work measurementPyrometry using electric radation detectorsEngineeringAxial force

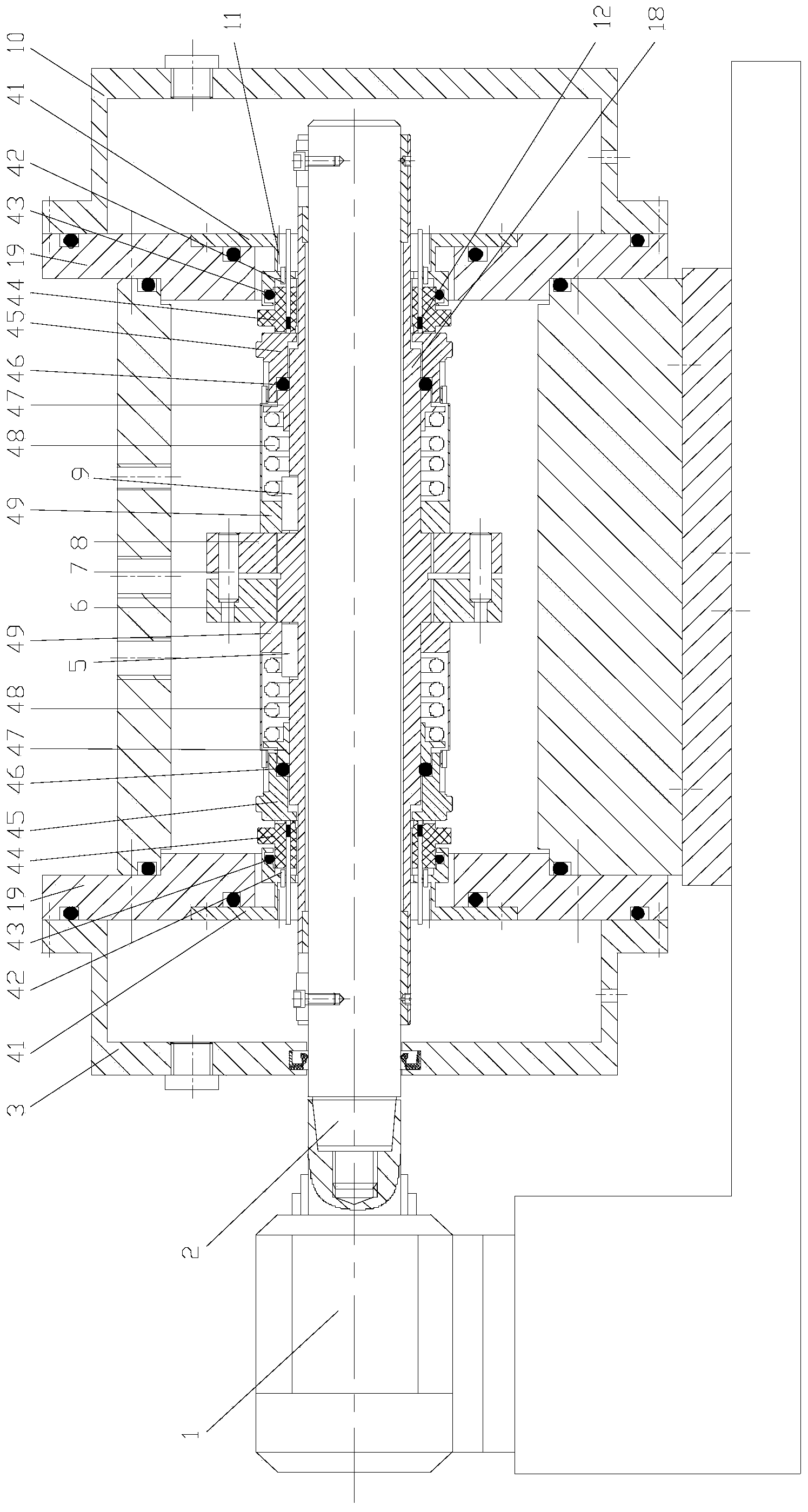

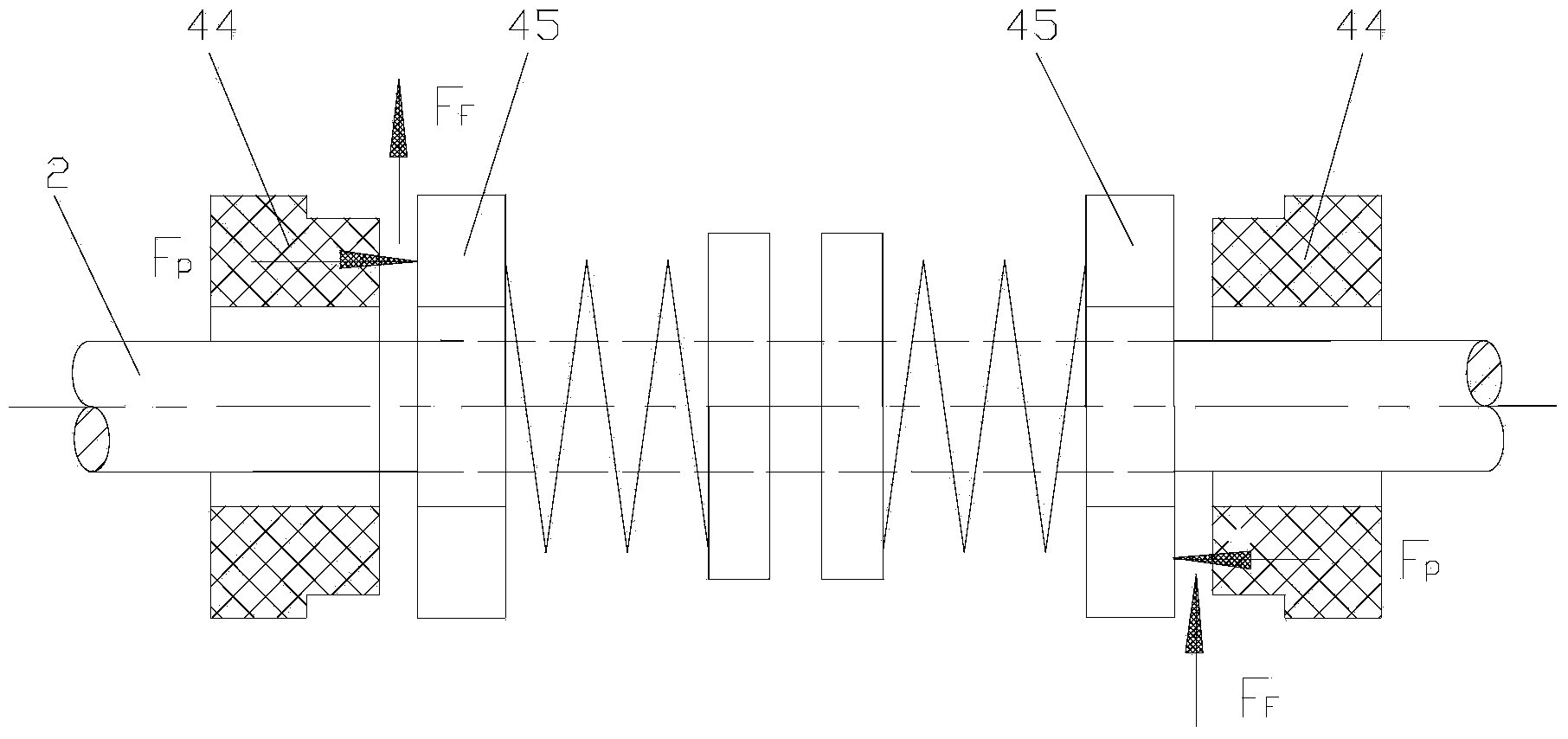

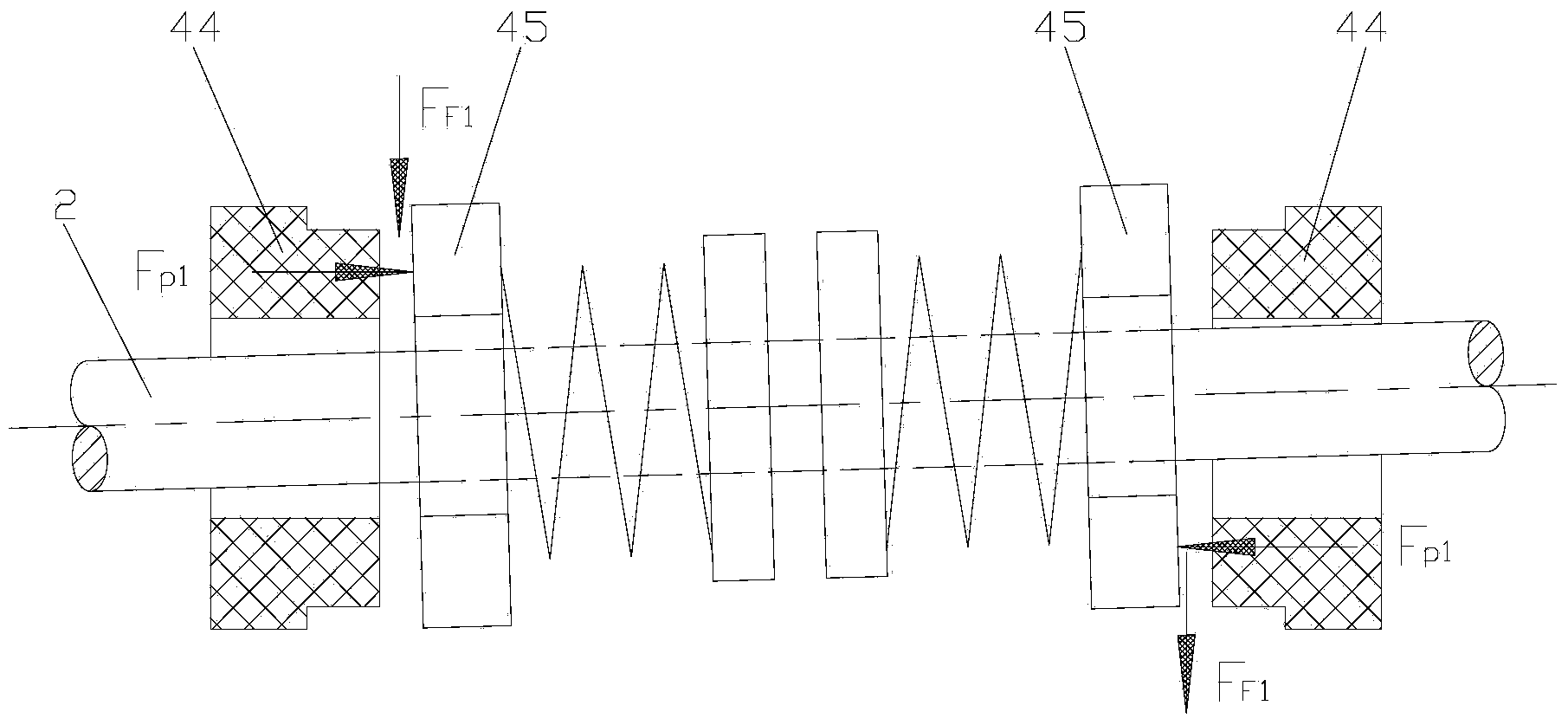

The invention discloses a mechanical sealing property testing device. An electric main shaft is connected with a single cantilever working main shaft; floating support of the single cantilever working main shaft is achieved by virtue of the geometric pressure compressing function of a moving ring end surface and a static ring end surface; the edge end of a force measurement sleeve is of a flange structure; an axial force strain piece is arranged on the force measurement sleeve; a shaft sleeve sleeves the single cantilever working main shaft and penetrates through end covers at the left end and right end of a sealing cavity; the shaft sleeve is slidably connected with the single cantilever working main shaft in a sliding manner in the axial direction and in a positioning manner by using an embedding block in the circumferential direction; two sections of threads of which the screw pitches are equal and the spiral lines are in opposite directions are formed in the shaft sleeve; the threads are respectively screwed with a left screw nut and a right screw nut; the back sides of two push rings respectively contact two moving ring bases; the moving ring bases are connected with the shaft sleeve in an sliding manner in the axial direction and in a positioning manner in the circumferential direction; a through hole which is communicated with a sealed end surface is formed inside a static ring; an infrared probe is arranged inside the through hole. Due to the structural design, measurement on property parameters such as large diameter and high rotation speed of mechanical sealing, particularly the measurement on the axial force and the temperature between sealed end surfaces can be achieved.

Owner:NANJING FORESTRY UNIV

Thermoelectric material thermoelectric conversion performance testing system and method

InactiveCN103323780AGuaranteed cold end environmentGood heat absorption and heat dissipationElectrical testingThermoelectric materialsPower flow

Disclosed is a thermoelectric material thermoelectric conversion performance testing system. The thermoelectric material thermoelectric conversion performance testing system comprises an electrical heating unit, a circulating cooling unit and a data acquisition unit. The electrical heating unit comprises a heat conducting block and a thermoelectric power generation device unit. The thermoelectric power generation device unit comprises thermoelectric materials. The circulating cooling unit comprises a heat absorbing box. The thermoelectric material thermoelectric conversion performance testing system is characterized in that the thermoelectric materials to be tested are placed in the thermoelectric power generation device unit, the electrical heating unit heats a hot end of the thermoelectric materials through the heat conducting block, the circulating cooling unit cools a cold end of the thermoelectric materials through the heat absorbing box, the data acquisition unit records output voltage, output current and cold and hot surface temperatures, and thermoelectric conversion performance of the thermoelectric materials can be accurately tested through real-time data display of the data acquisition unit.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

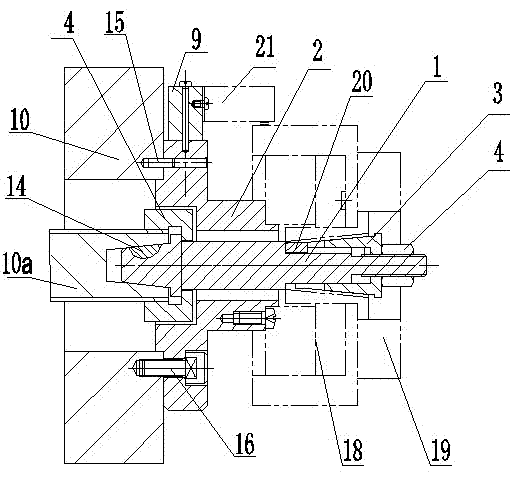

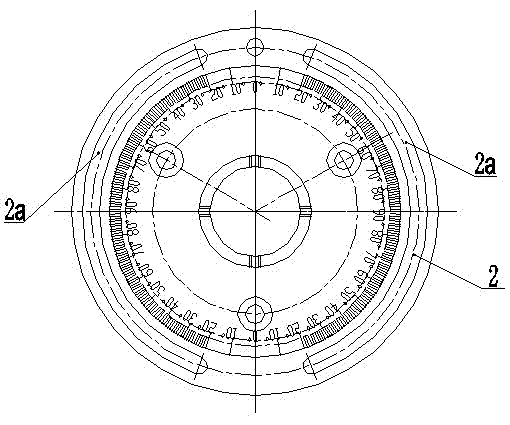

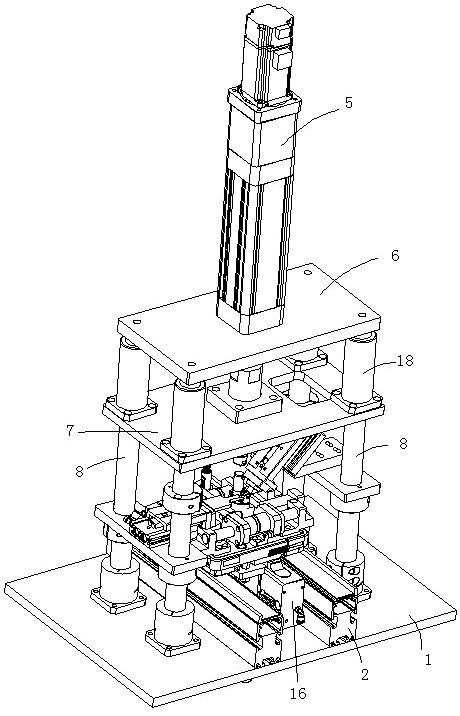

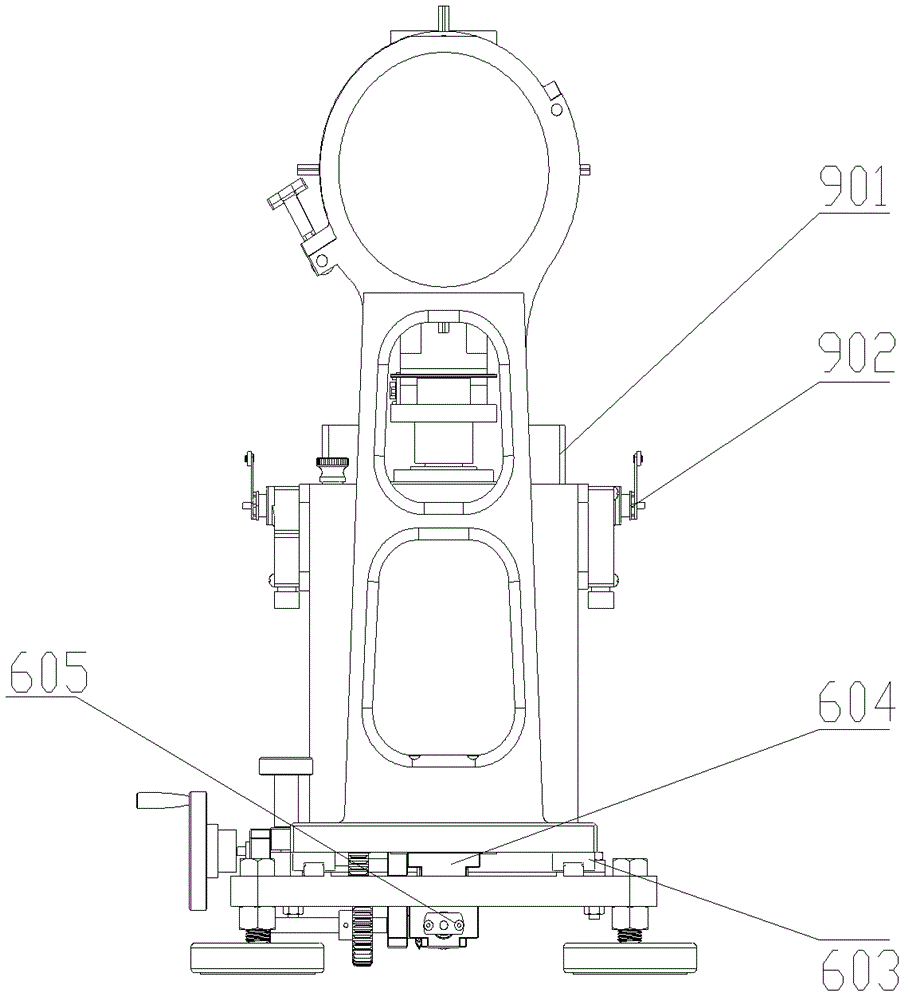

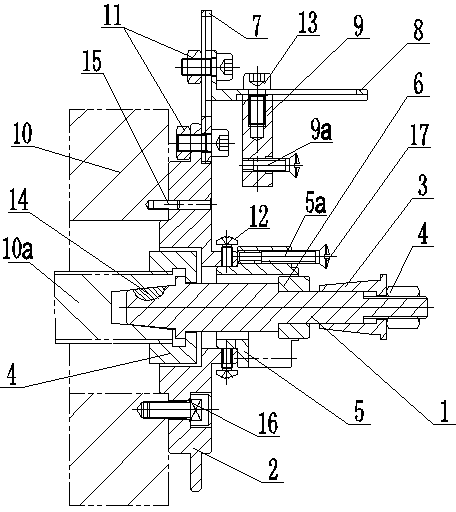

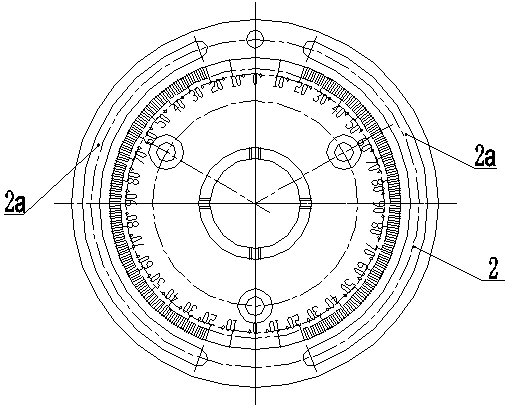

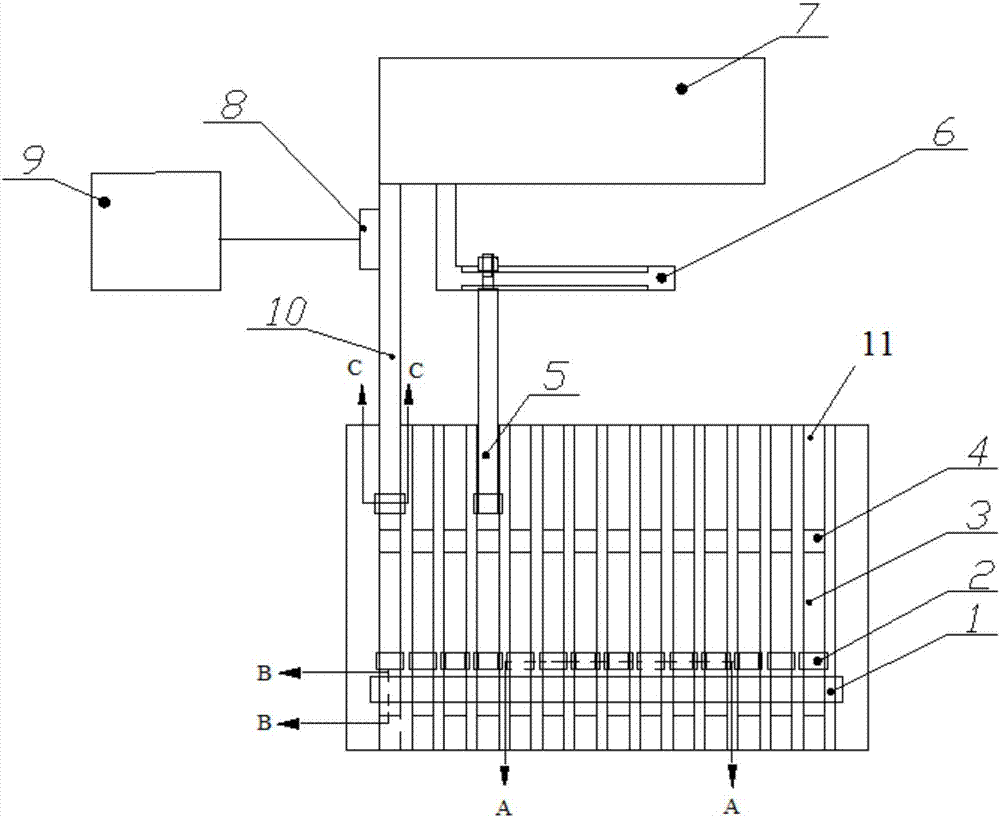

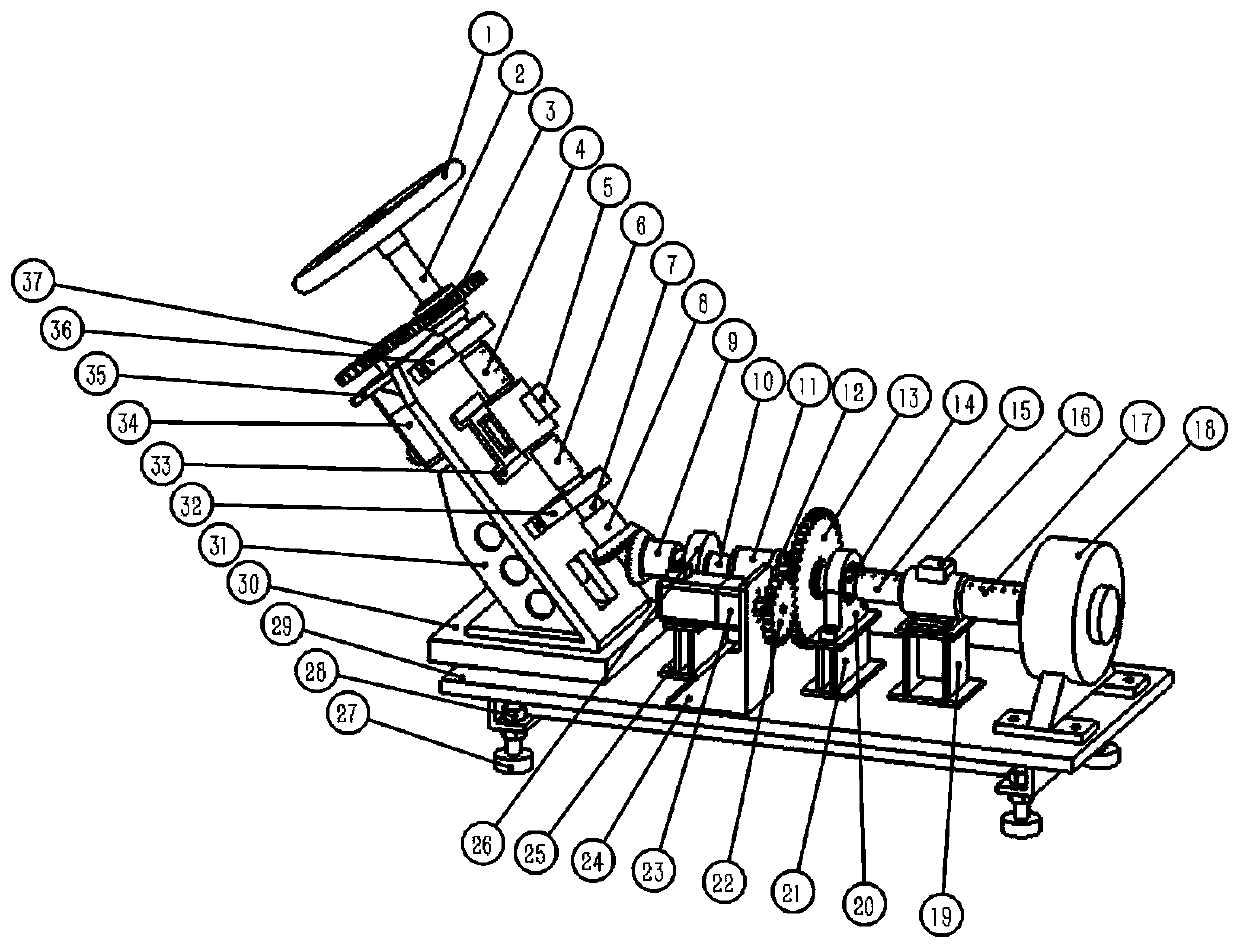

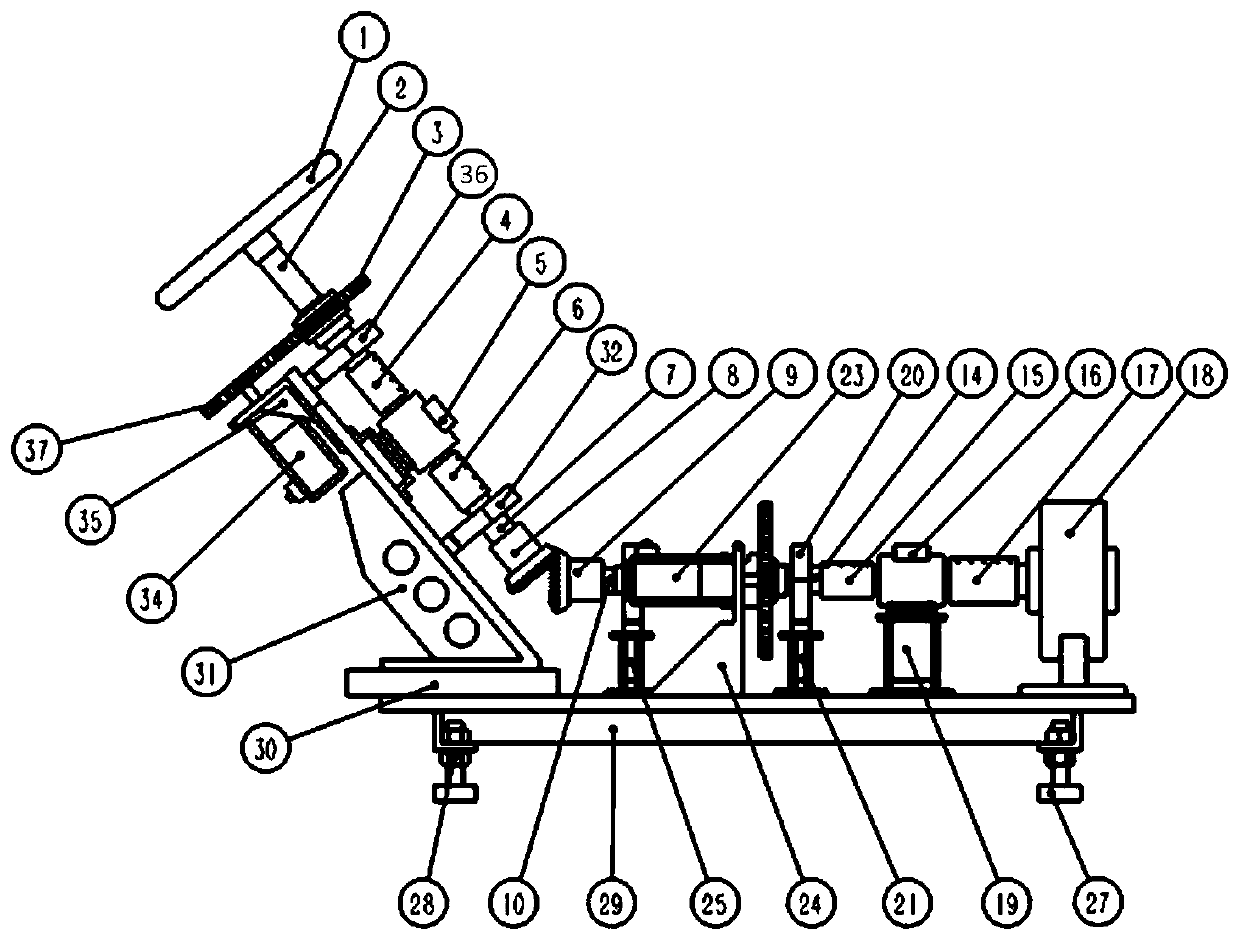

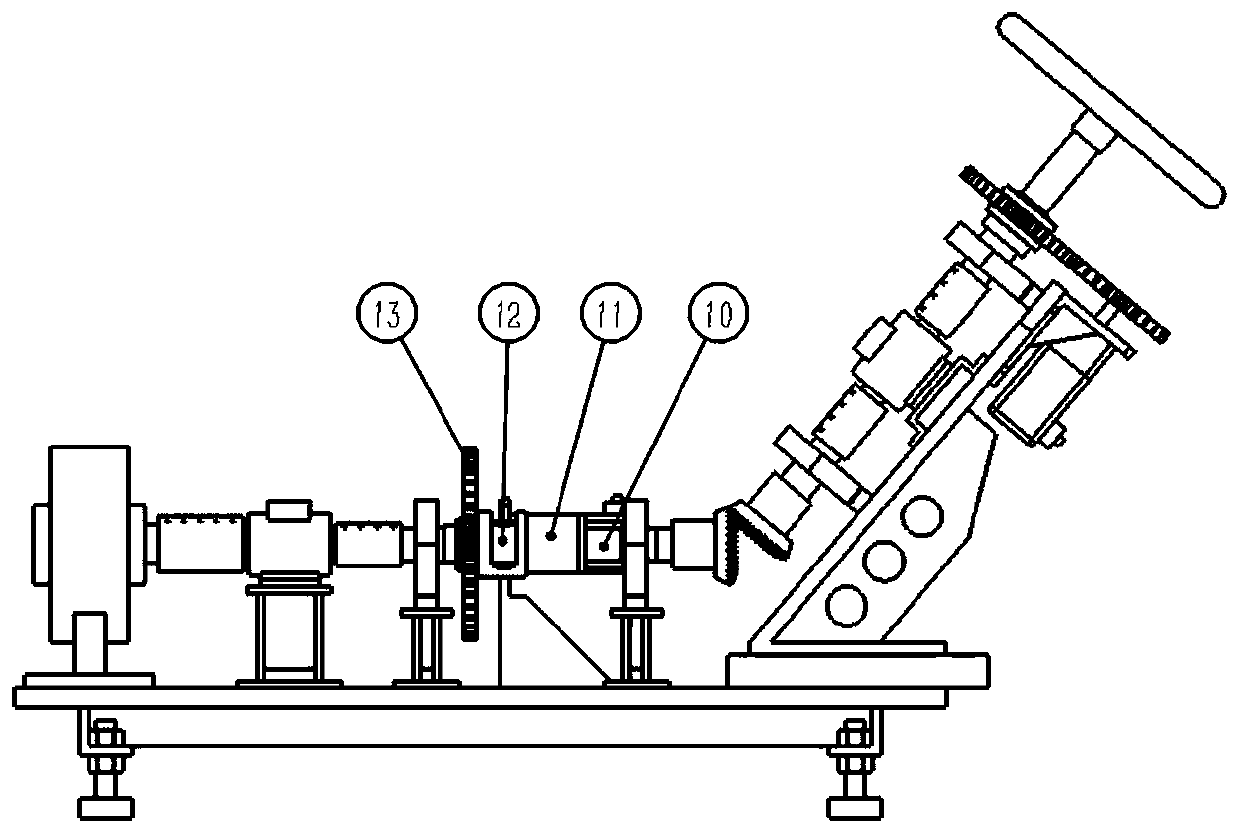

Performance testing fixture for magnetos

InactiveCN102495366AImprove versatilityMeet the test requirementsElectrical measurement instrument detailsDynamo-electric machine testingTest requirementsMagneto

The invention discloses a performance testing fixture for magnetos, which comprises a spindle (1), a flange plate (2) and a taper sleeve (3). The flange plate (2) and the taper sleeve (3) are mounted at two ends of the spindle (1) respectively through locking nuts (4), a stator positioning block (5) is fixedly mounted on the flange plate (2) and positioned on the right of the flange plate (2), anadjusting washer (6) is arranged between the stator positioning block (5) and the taper sleeve (3), an annular groove (2a) is circumferentially distributed along the flange plate (2), a Y-axis sliding rail (7) radially extending along the flange plate (2) is mounted on the annular groove (2a), an X-axis sliding rail (8) axially extending along the flange plate (2) is mounted on the Y-axis slidingrail (7), and a trigger positioning block (9) is mounted on the X-axis sliding rail (8). The performance testing requirements of the magnetos of different structures can be met only by replacing the stator positioning block and the adjusting washer.

Owner:力帆科技(集团)股份有限公司

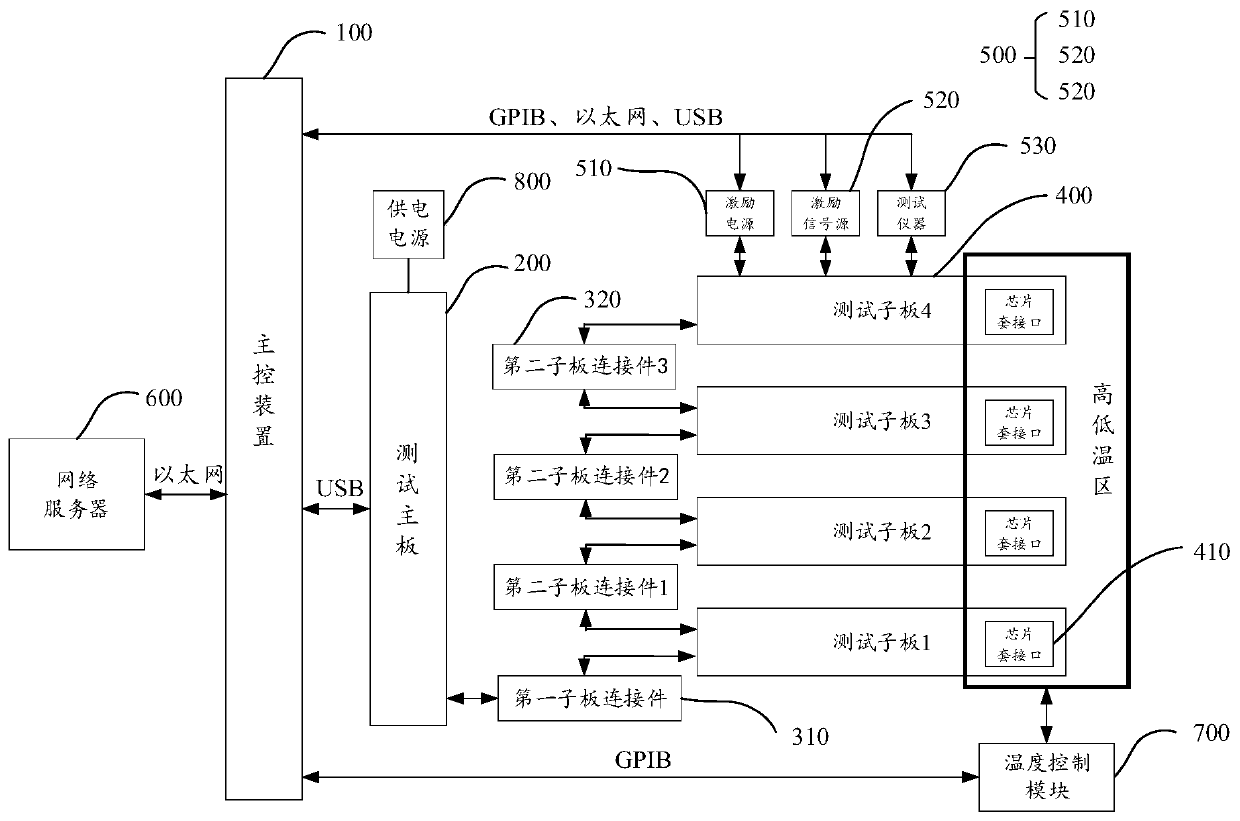

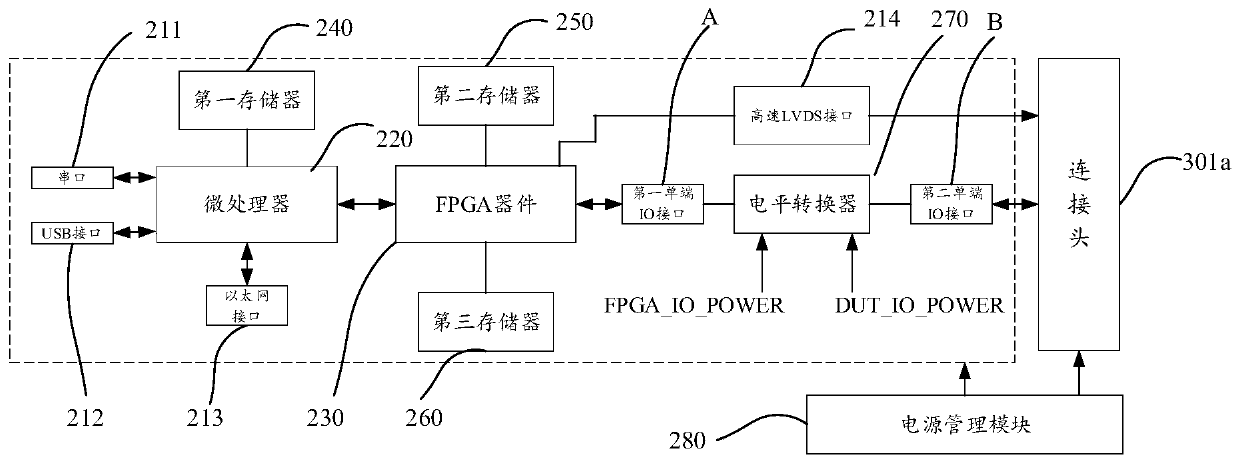

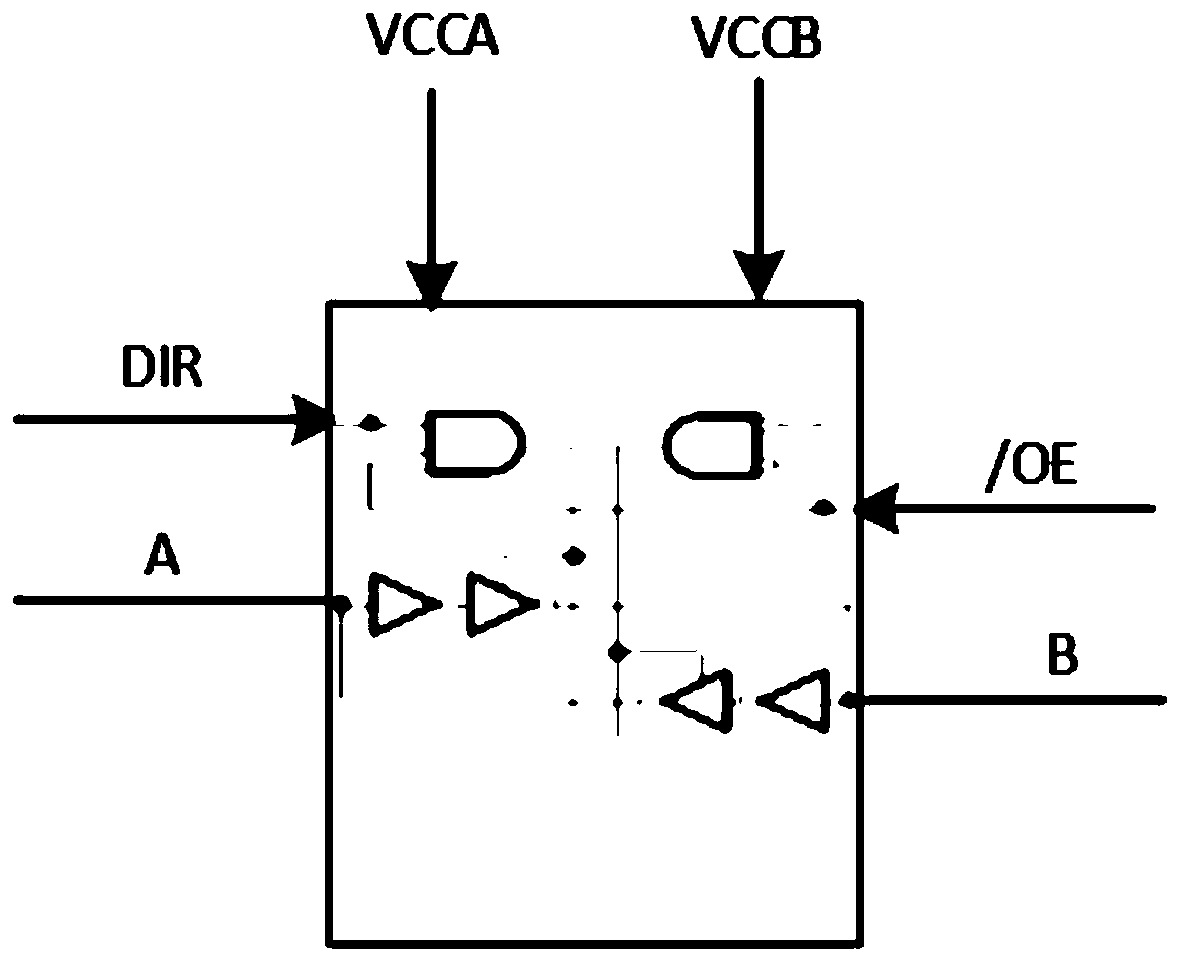

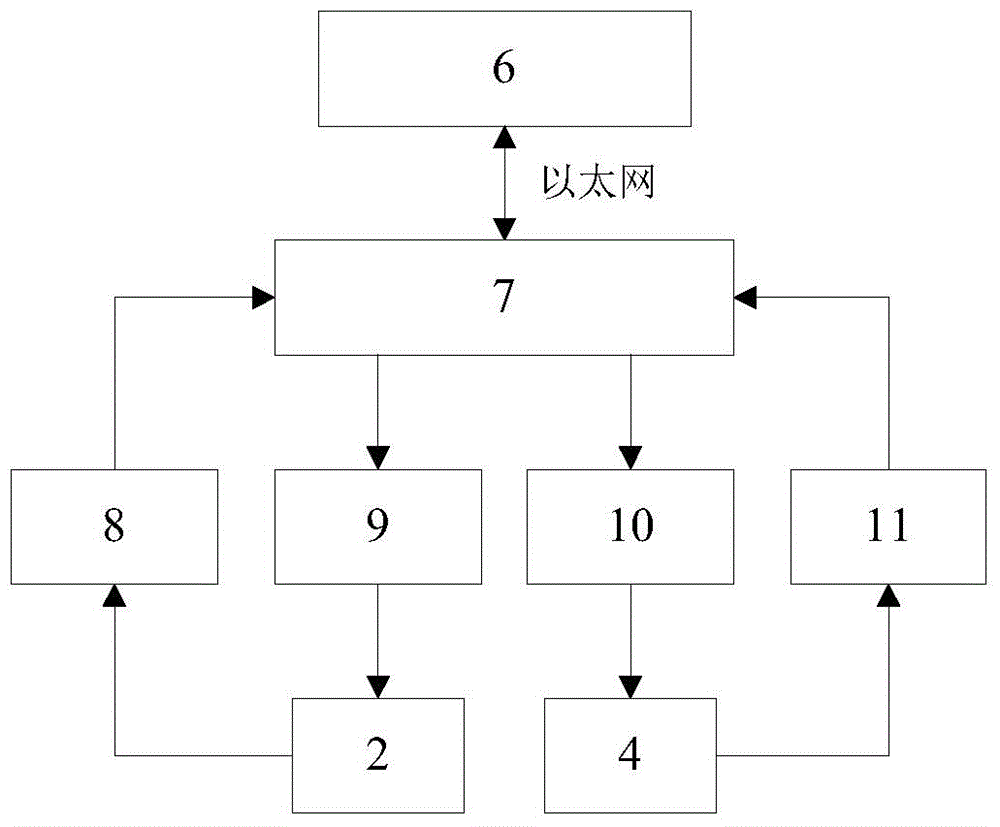

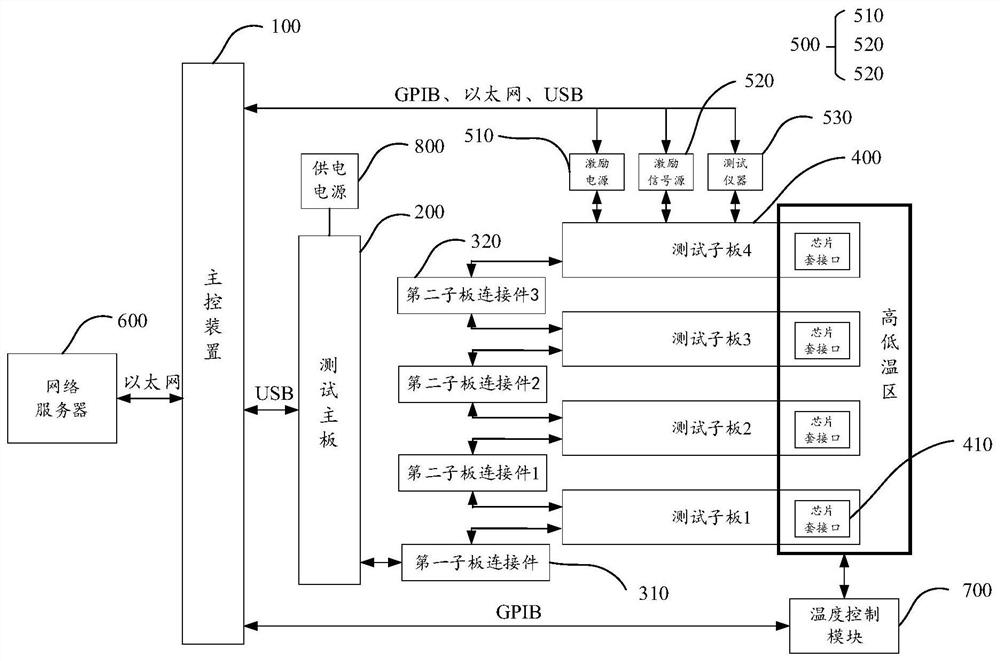

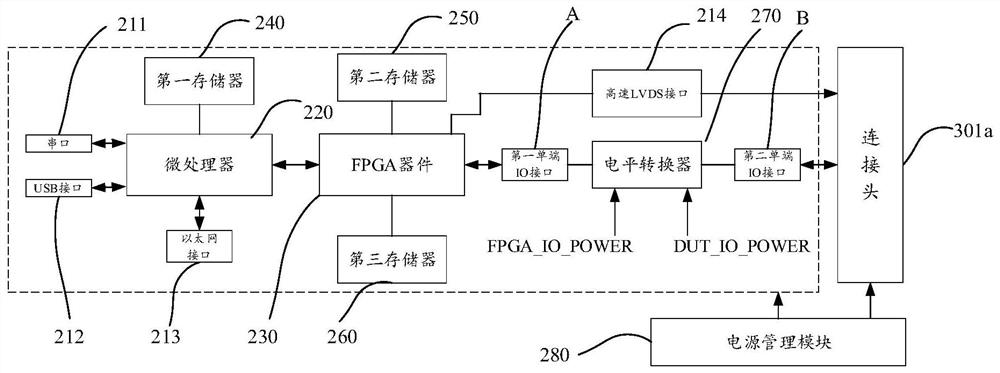

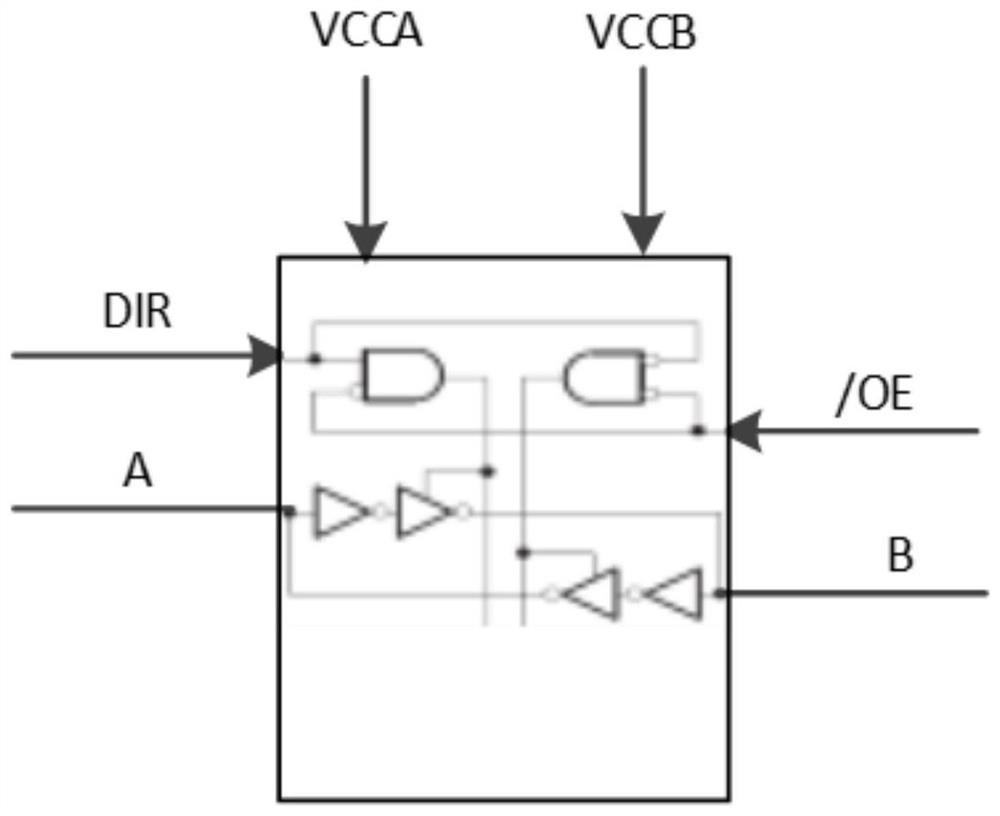

Universal chip test system and test method and storage medium

ActiveCN111487524AImprove construction efficiencyEasy to replaceElectronic circuit testingTest suiteModular design

The invention provides a universal chip test system, a universal chip test method and a storage medium. The chip test system comprises a main control device, a test mainboard, N daughter board connecting pieces, a plurality of test daughter boards and a plurality of test suites. The test mainboard is connected with the main control device, the test suites and the test daughter boards; the test daughter boards match the test suites, and the test daughter boards are connected with the test mainboard through daughter board connecting pieces. The universal chip test system provided by the invention can quickly and accurately verify and test functions and performances before and after chip design, can meet test tasks of function verification, performance test and reliability test before chip manufacturing, adopts a modular design, is high in expandability, and test automation can be realized.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

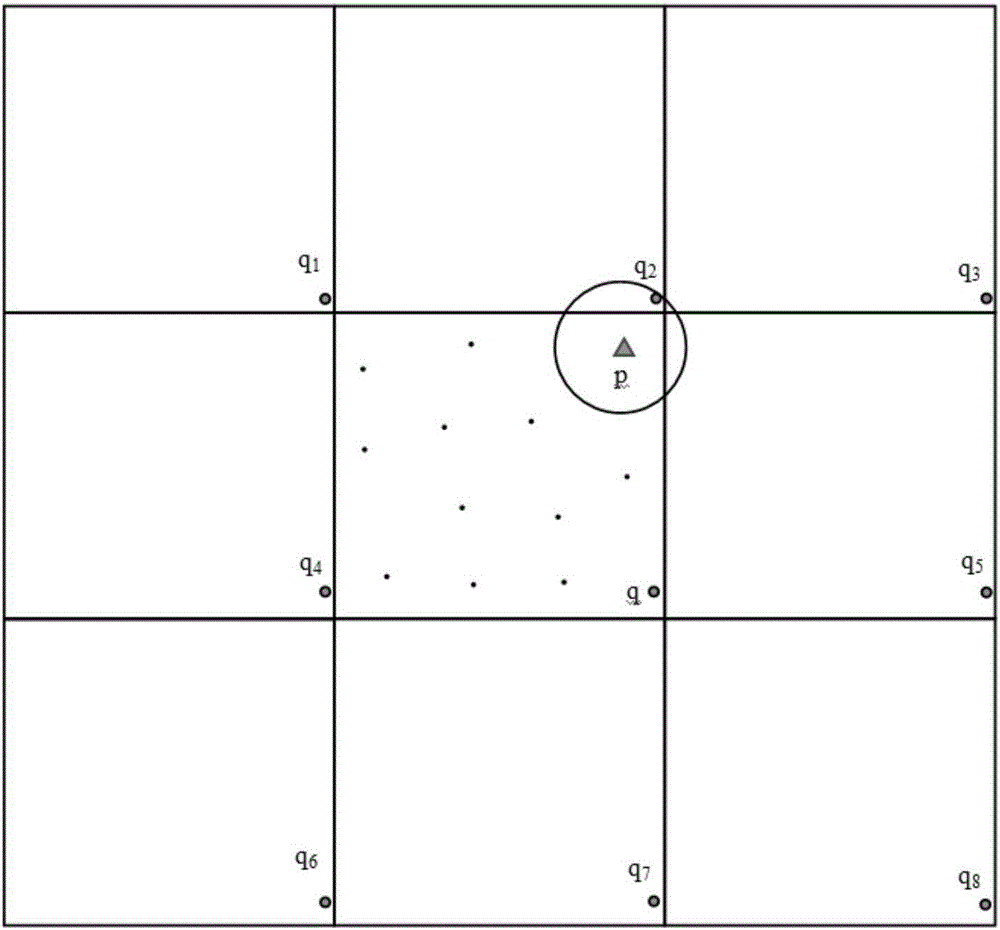

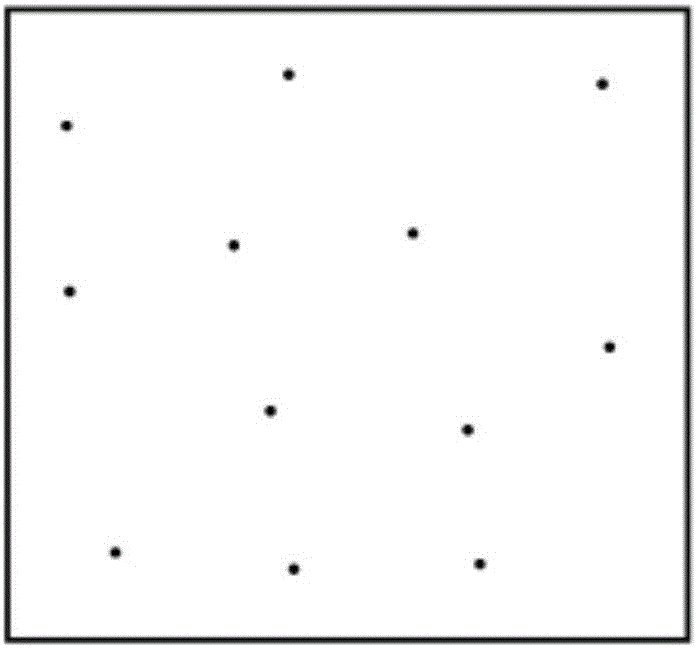

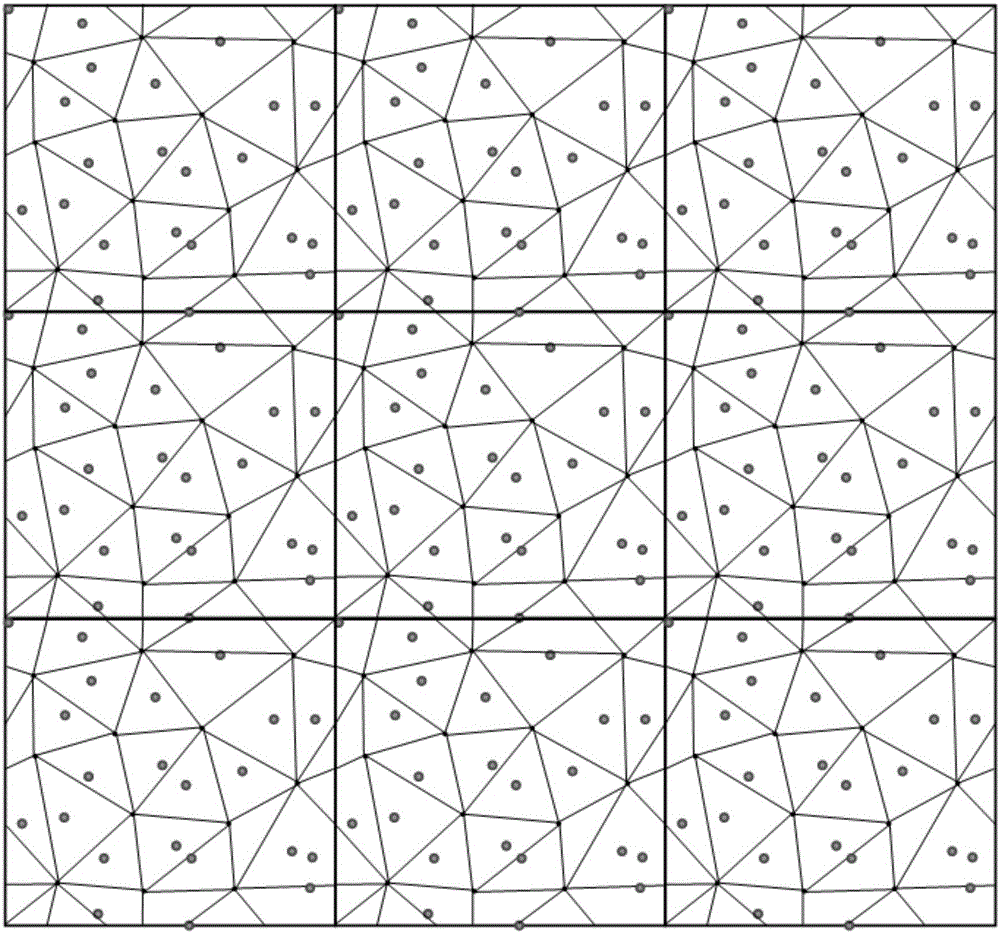

Weighted Voronoi diagram generation method used for big data test

The invention discloses a weighted Voronoi diagram generation method used for a big data test. The method comprises the following steps of constructing a group of randomly and uniformly distributed points in a set region as sites, ensuring a shortest distance between the two sites not to be smaller than a set threshold, and calculating a Voronoi diagram of a set consisting of all the sites; constructing a large-scale data point set in the set region according to the Voronoi diagram of the site set, traversing all Voronoi points, and connecting the Voronoi points to form a Voronoi diagram of the large-scale data point set; randomly selecting any site, modifying all Voronoi edges around the selected site according to a weighted distance function between the sites, and constructing a weighted Voronoi diagram based on an appointed weight set W; and applying the generated weighted Voronoi diagram to the big data test. According to the method, the overall site distribution has randomness and the distribution is relatively uniform, so that the correctness during the big data test is ensured.

Owner:SHANDONG UNIV

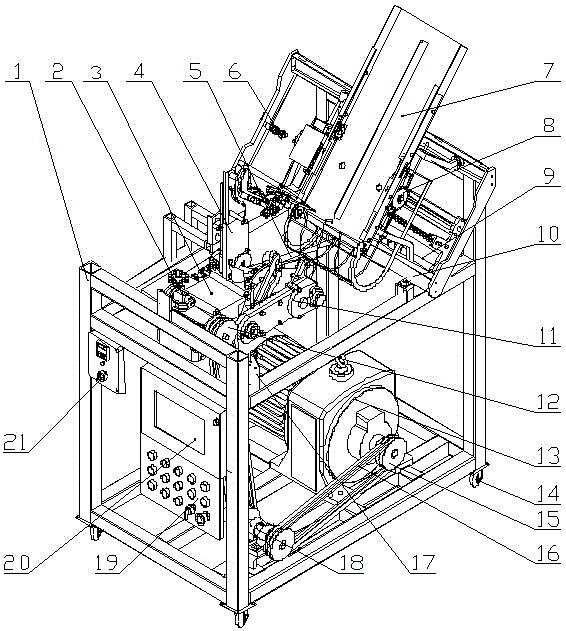

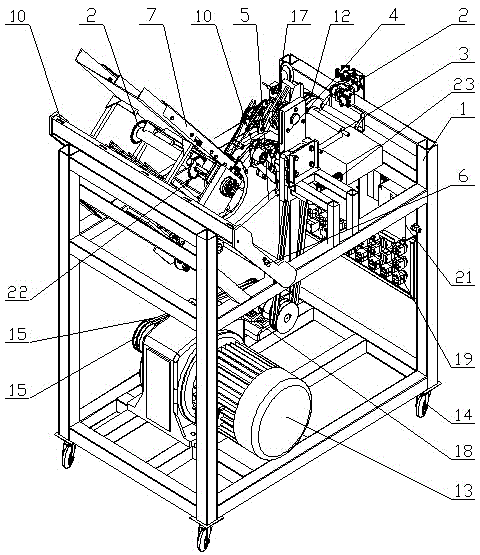

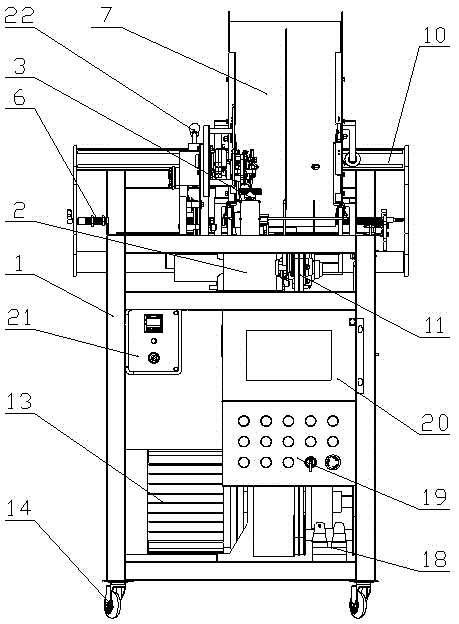

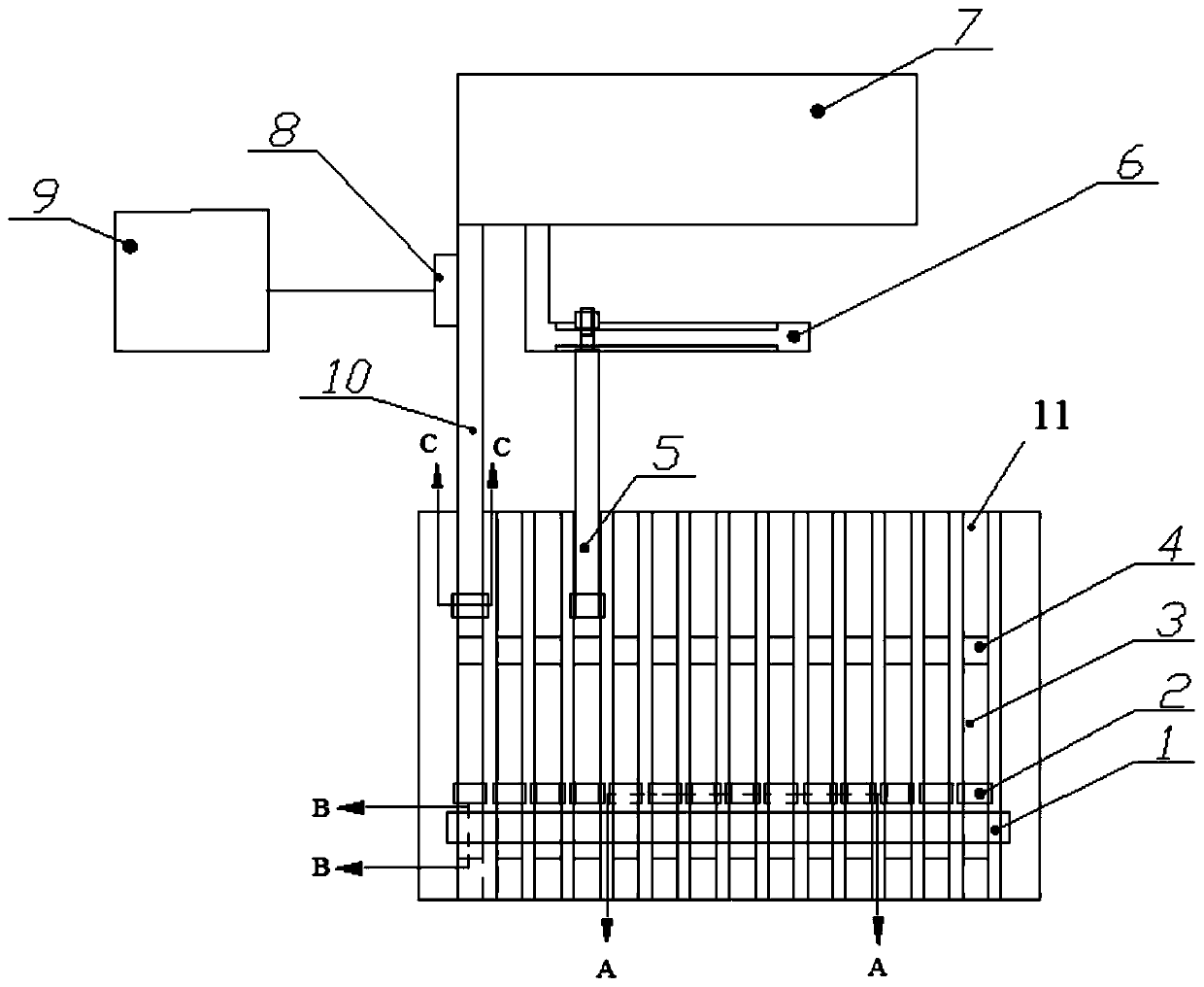

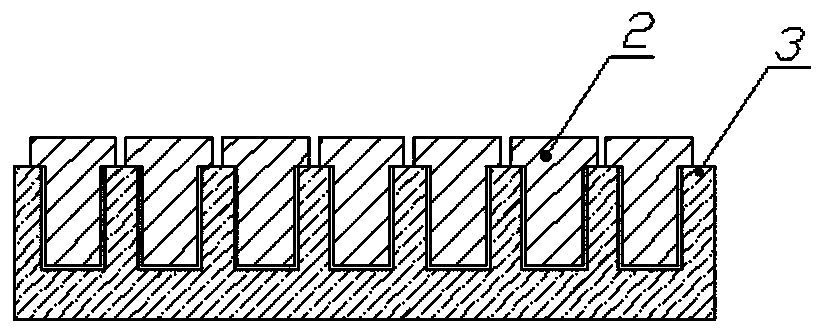

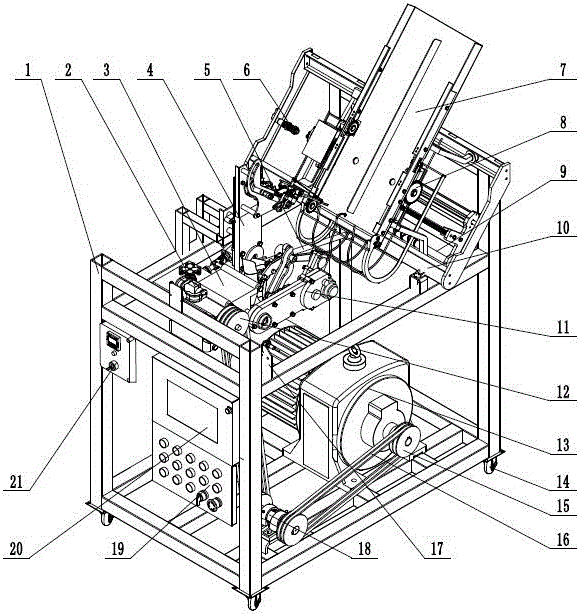

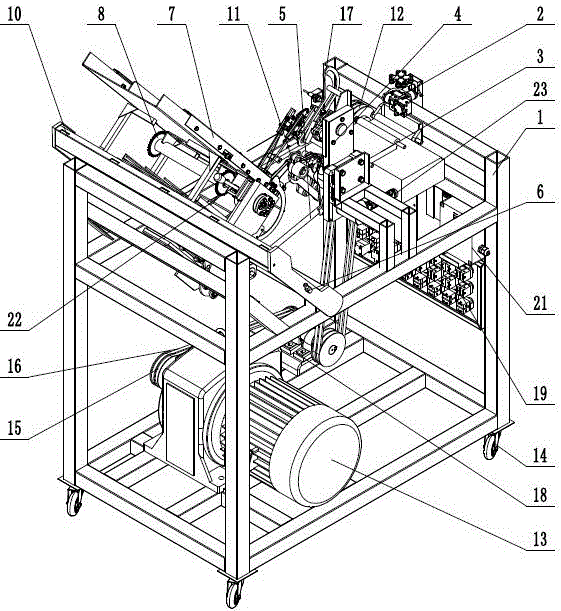

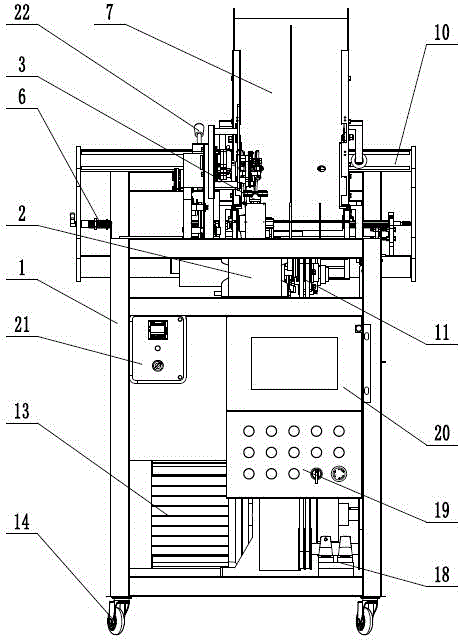

Machine vision-based transplanter test bed

InactiveCN104897427AImprove work efficiencyLow costStructural/machines measurementEngineeringSeedling

The invention relates to a machine vision-based transplanter test bed, and aims to provide a transplanter detection device which is high in detection precision, simple in structure, convenient to use, and high in efficiency. The machine vision-based transplanter test bed includes a test bed rack, an electromagnetic speed regulation motor, a power distribution box, a seedling taking mechanism, a seedling feeding device, a planting mechanism, a computer vision device, a displacement sensor and a speed sensor. The computer vision device adopts an industrial camera to be connected with a microprocessor, the displacement sensor is used for detecting accuracy of transverse reciprocating motion of a disk of the seedling feeding mechanism, the speed sensor is mainly used for detecting the rotating speed of a small belt wheel of the power distribution box, the industrial camera detects a seedling taking process of the seedling taking mechanism, a seedling casting process, a seedling feeding process of the seedling feeding mechanism and a planting process of the planting mechanism, data are sent to the microprocessor to be processed, and a success rate of seedling taking, a success rate of seedling casting, a success rate of planting and an optimal working speed are calculated.

Owner:SHIHEZI UNIVERSITY

Real-virtual interactive comprehensive experiment platform for hydraulic mechanical arm

InactiveCN104867394AVerify accuracyEasy to assemble and disassembleEducational modelsInput controlEngineering

The invention discloses a real-virtual interactive comprehensive experiment platform for a hydraulic mechanism arm, which comprises an upper computer master control system, a motion control system and a hydraulic servo experiment table; wherein the upper computer master control system receives the input control instruction of a user and is connected with the motion control system. Furthermore the upper computer master control system transmits a calculation result to the motion control system. The motion control system receives the instruction of the upper computer mater control system and drives the hydraulic servo experiment table to perform a corresponding action. The real-virtual interactive comprehensive experiment platform performs modular design on an execution mechanism and facilitates detachment. Three-dimensional virtual reality interaction technology is used for realizing real-virtual interaction between the hydraulic experiment table and the mechanical arm. Response characteristics of the servo valve and the execution mechanism can be tested. Execution accuracy of the control algorithm can be verified. The real-virtual interactive comprehensive experiment platform is suitable for research and development of the hydraulic mechanical arm.

Owner:STATE GRID CORP OF CHINA +2

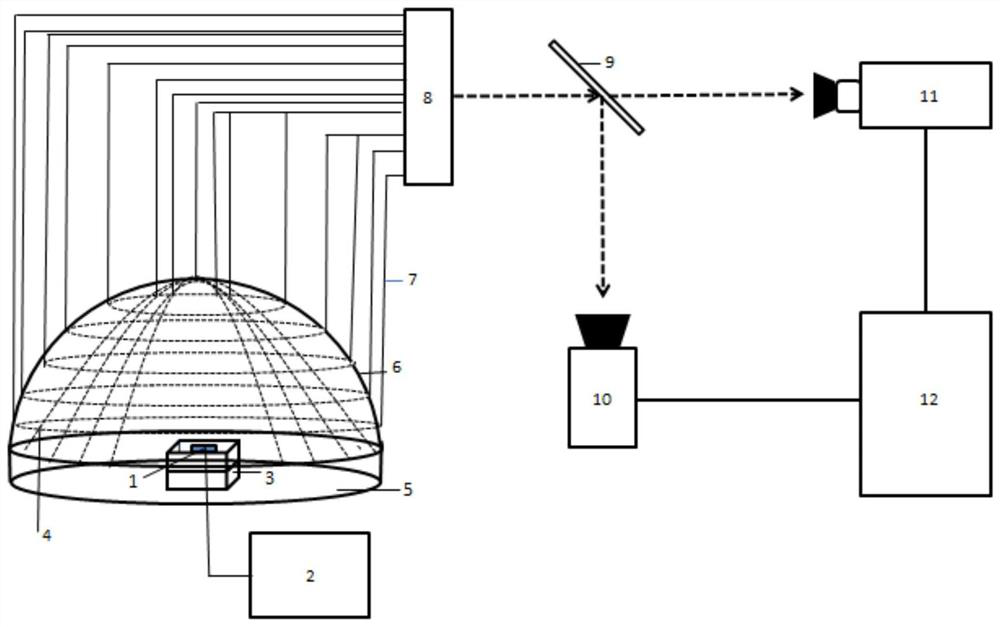

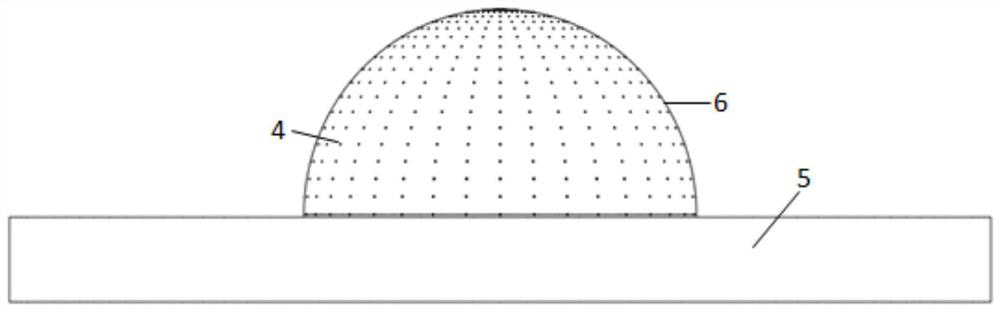

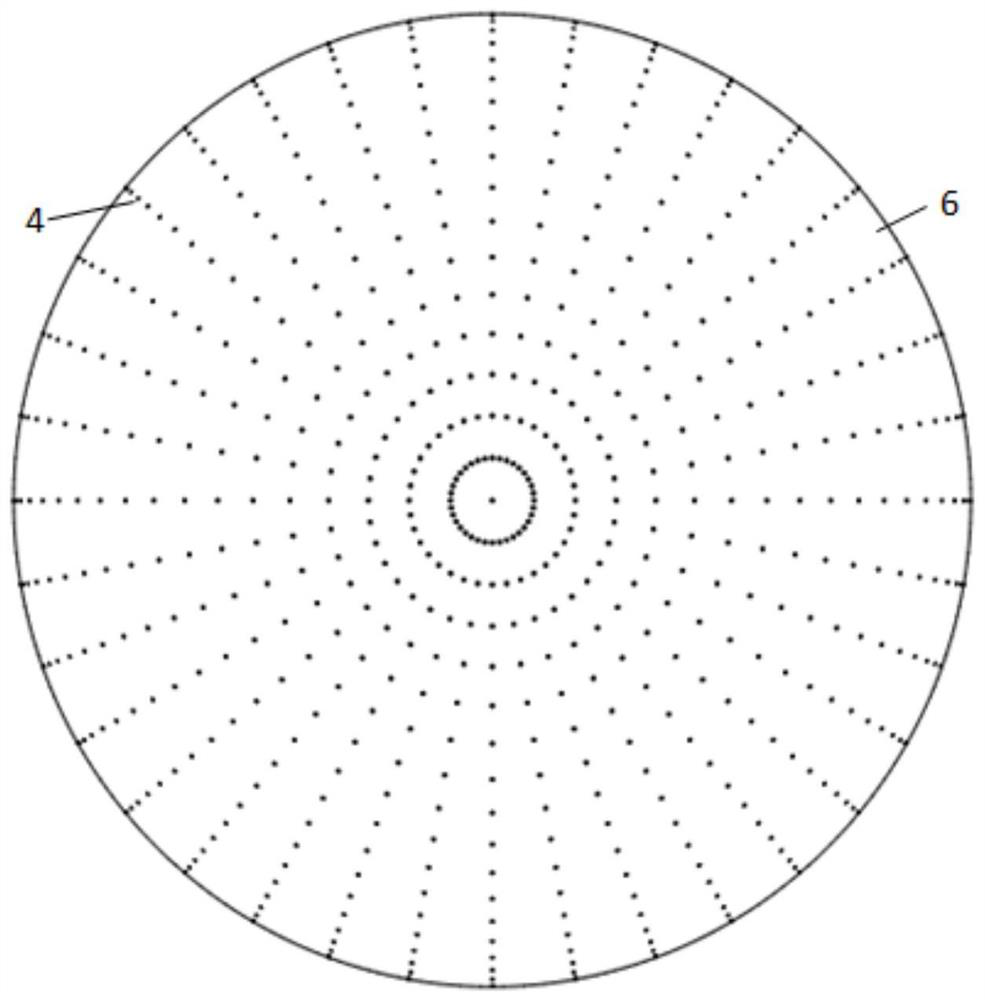

Miniature light-emitting device space light color distribution detection system and detection method thereof

ActiveCN113218628AMeet the performance testSolving Optical Positioning ChallengesTesting optical propertiesCcd cameraHyperspectral imaging

The invention discloses a miniature light-emitting device spatial light color distribution detection system and a detection method thereof, and relates to miniature light-emitting devices. The detection system comprises a hemisphere with a cavity, a bottom plate, a three-dimensional table, a current source, an optical fiber, an optical fiber integrated panel, a beam splitter, a CCD camera, a hyperspectral imaging spectrometer and a computer. The micro light-emitting device is connected with the current source and is arranged at the center of the hemisphere, and the standard light source with known irradiance spectral distribution data is arranged at the center of the hemisphere for system calibration; the optical fiber transmits spatial light distribution to the optical fiber integrated panel, the hyperspectral imaging spectrometer collects two-dimensional images and spectral information, three-dimensional spatial light color distribution of the miniature light-emitting device is obtained through computer data processing, and the luminous flux or luminous power of the miniature light-emitting device is obtained after integration of all optical fiber light distribution. The three-dimensional space light color distribution characteristic of the light-emitting device is converted into the two-dimensional distribution characteristic, and the optical characteristic of the micro light-emitting device can be rapidly and accurately detected.

Owner:XIAMEN UNIV

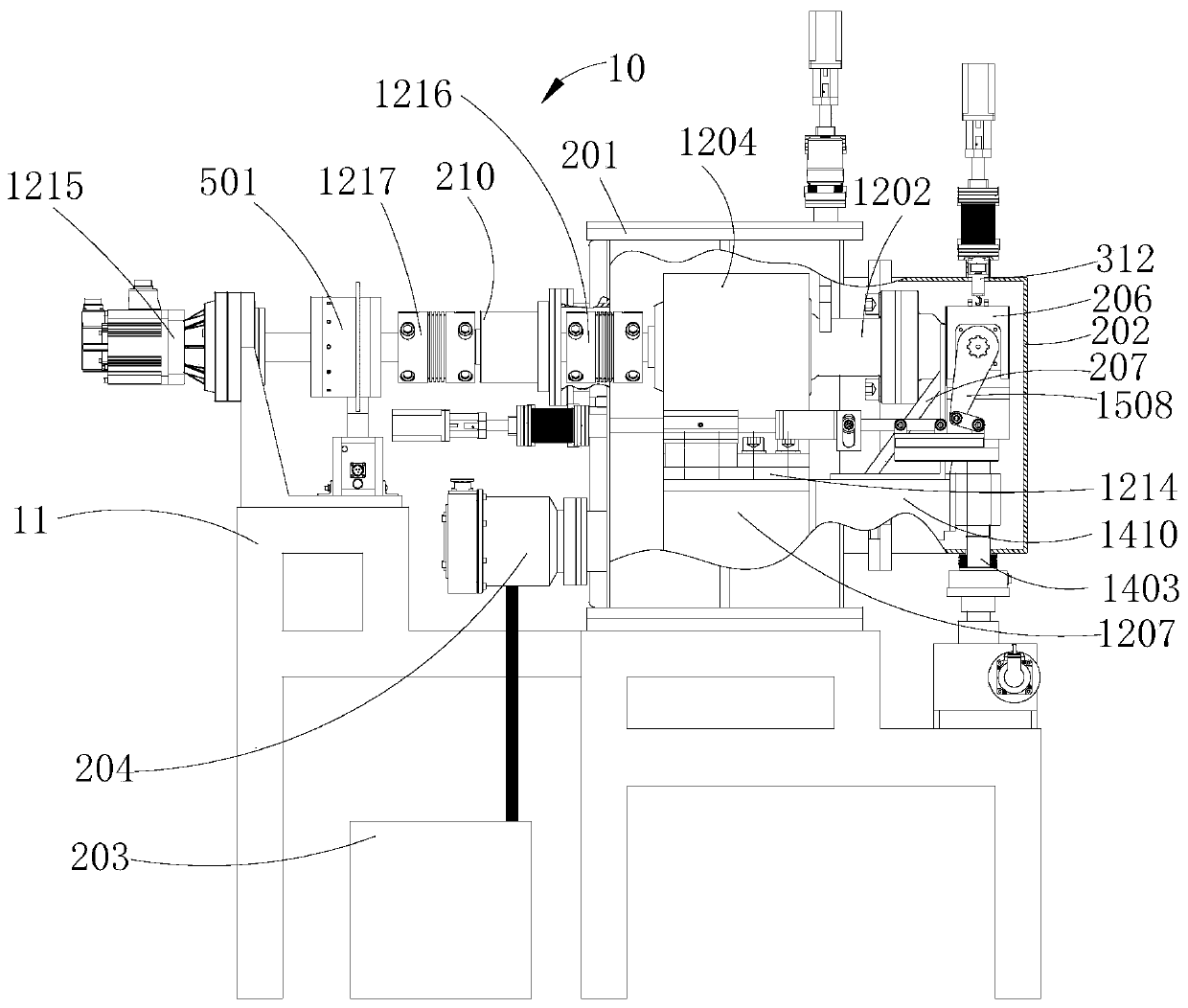

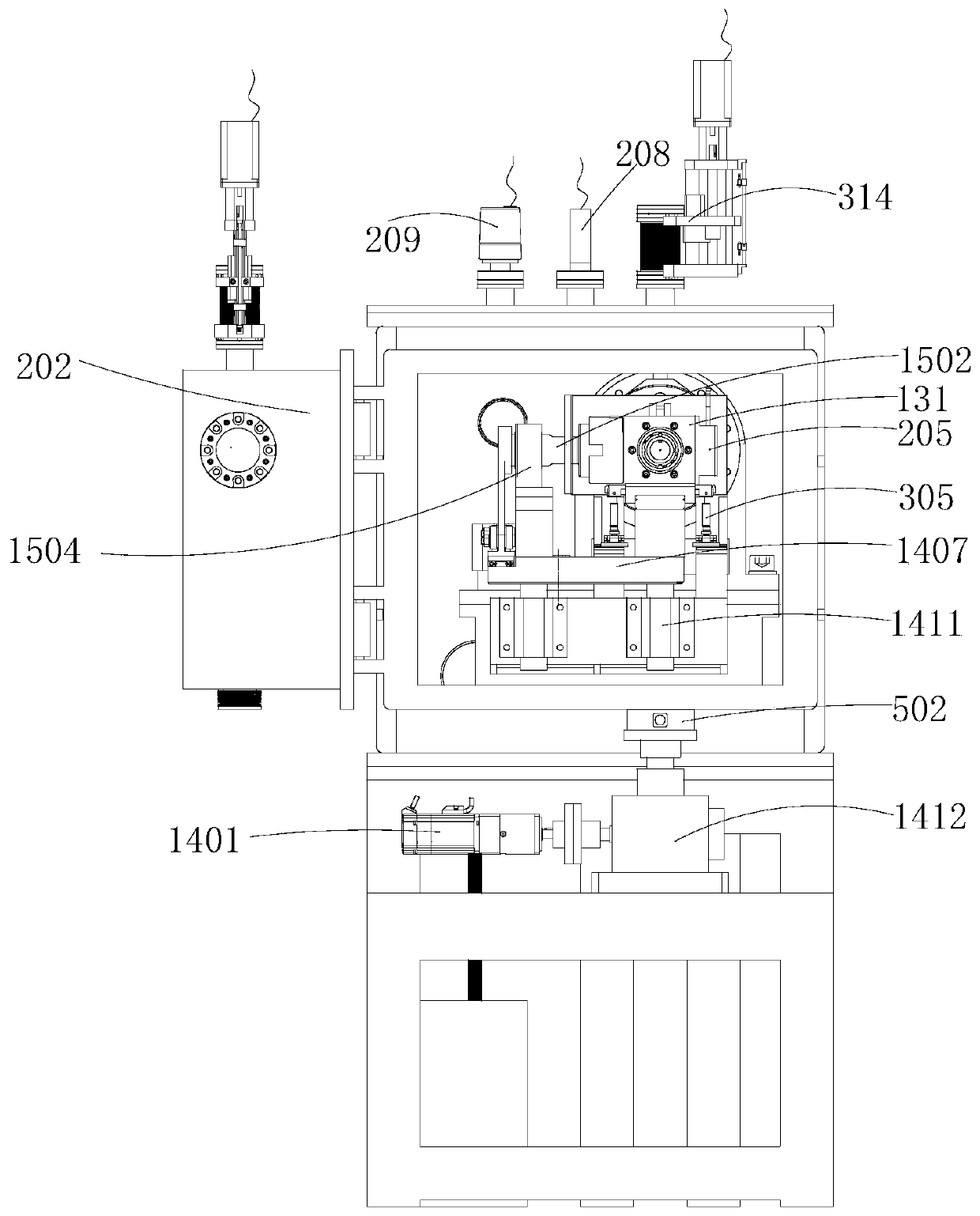

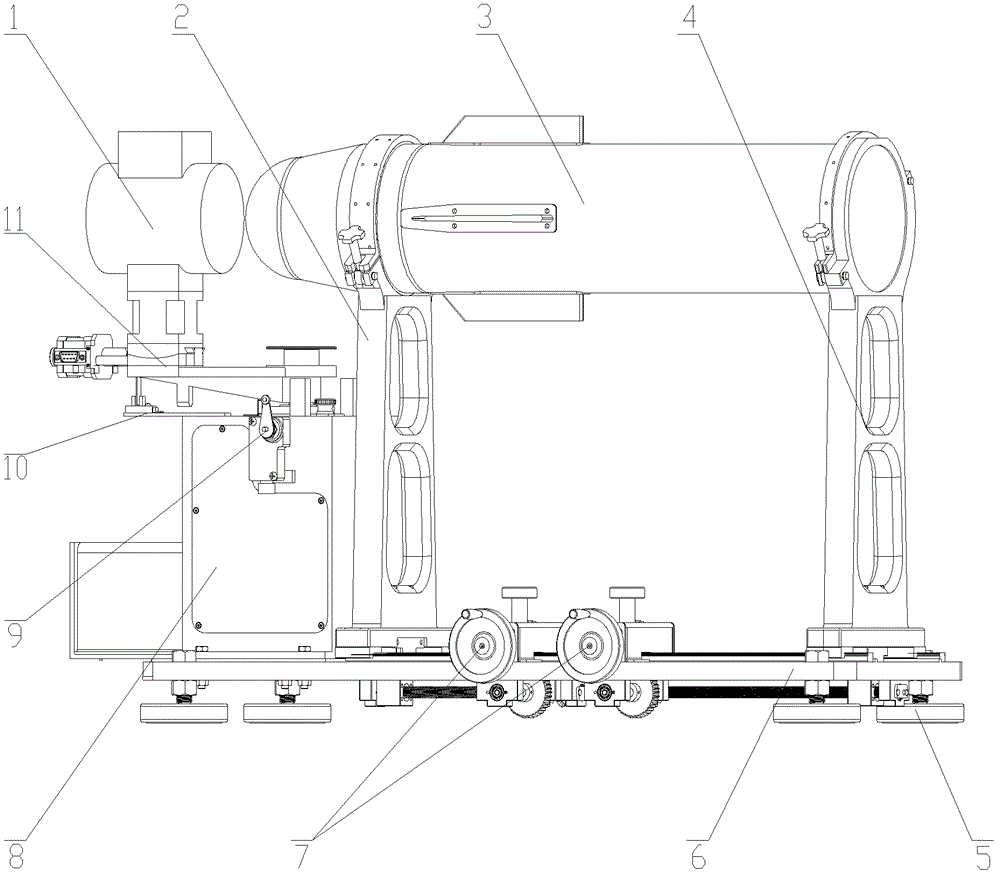

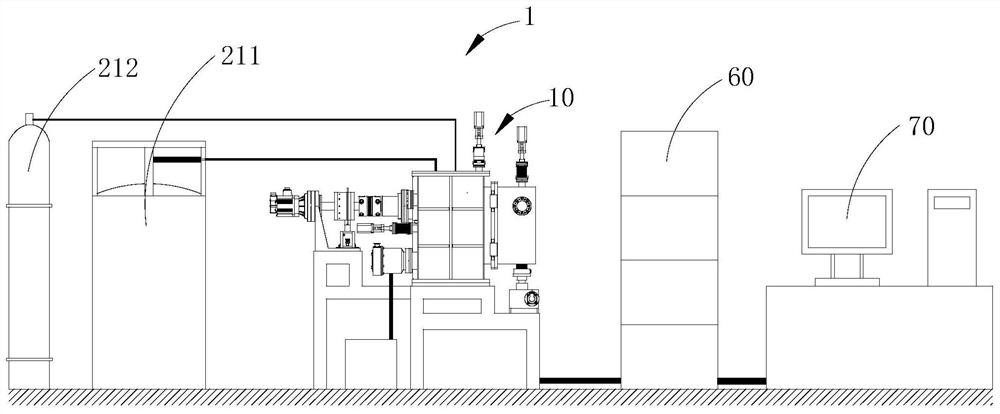

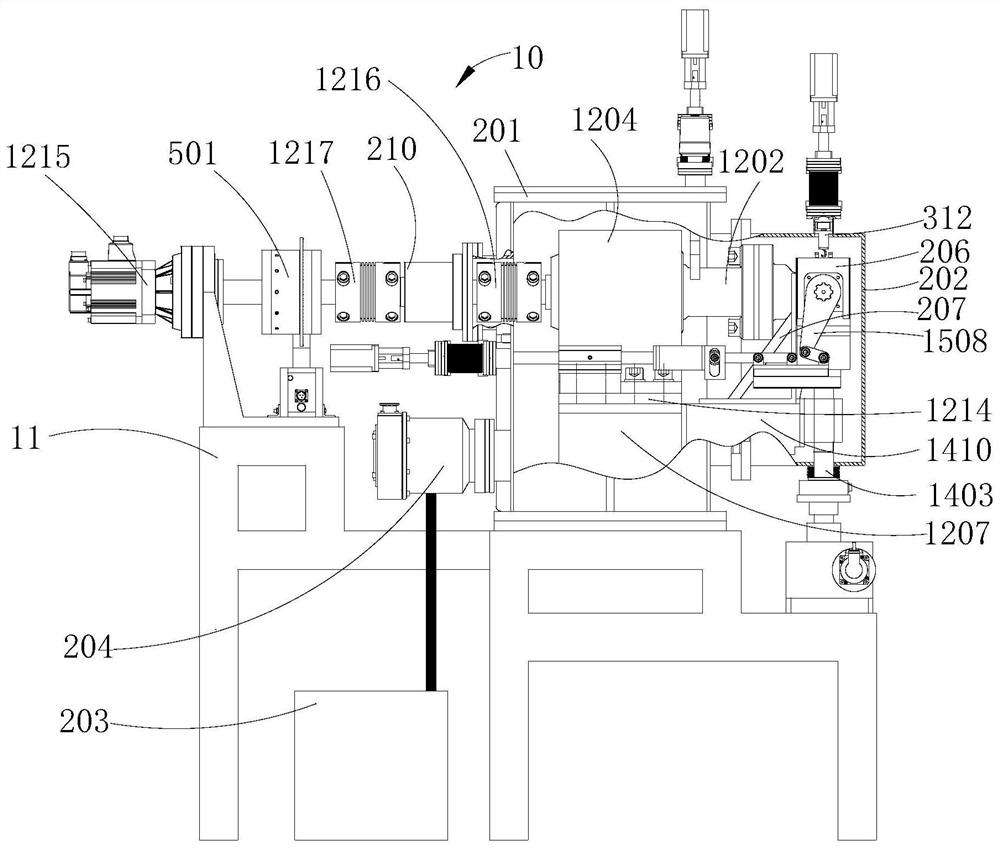

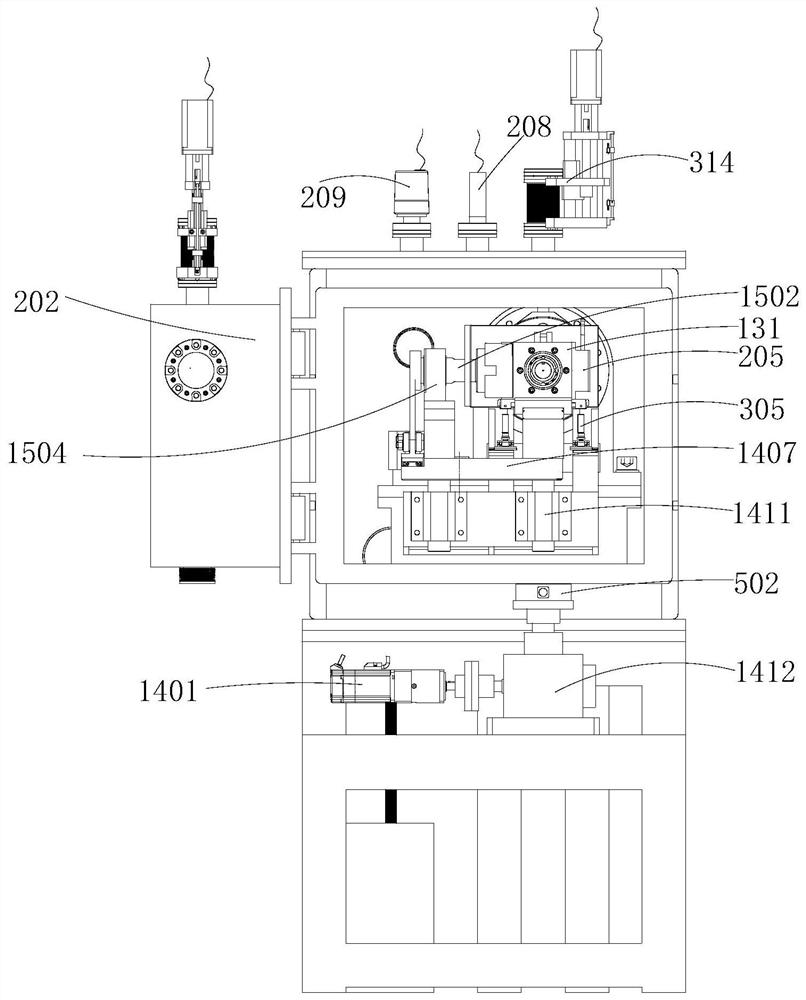

Low-temperature large-temperature variable joint bearing test platform and joint bearing measurement method

ActiveCN110726555AImplement friction testMeet the performance testMachine bearings testingUsing optical meansProgrammable logic controllerControl system

The invention provides a low-temperature large-temperature variable joint bearing test platform and a joint bearing measurement method. The low-temperature large-temperature variable joint bearing test platform comprises a motion and load simulation system; an environment measurement and control system; a programmable logic controller; a host computer; and a measurement and data acquisition system; the measurement and data acquisition system comprises a clearance and wear measuring device; the clearance and wear measuring device is connected with the motion and load simulation system and the environment measurement and control system, and electrically connected with the programmable logic controller; and the measurement and data acquisition system transmits measurement data to the programmable logic controller and is controlled by the programmable logic controller. According to the low-temperature large-temperature variable joint bearing test platform provided by the invention, the wear and in-situ clearance measurement of a joint bearing in a special working condition environment are achieved, a means is provided for researching and inspecting performance parameters and influencing factors of the joint bearing in special working conditions, and designing and optimizing the joint bearing suitable for special working condition environment, thereby ensuring the reliability of thejoint bearing.

Owner:TSINGHUA UNIV

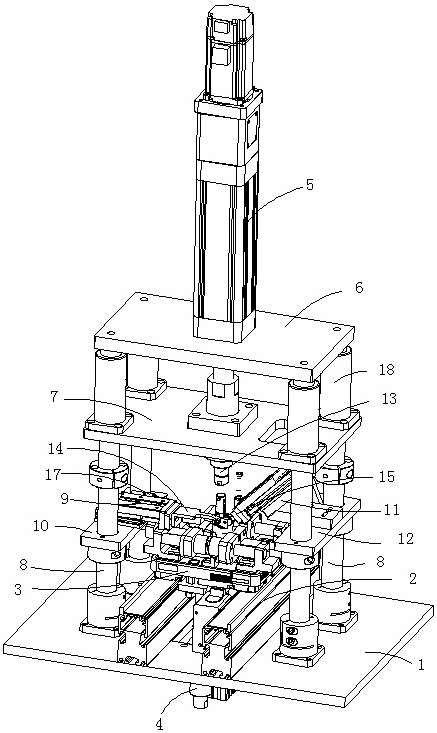

Automobile tensioner assembly performance testing mechanism and working method thereof

PendingCN112710463AMeet the performance testSimple structural designVehicle testingMachine part testingEngineeringServo

The invention relates to an automobile tensioner assembly performance testing mechanism and a working method thereof, and belongs to the field of automobile tensioner performance testing. The testing mechanism comprises a bottom plate, an output line, a tray mechanism, a jacking mechanism, a servo electric cylinder, an electric cylinder fixing plate, a pressure head fixing plate, a first air cylinder, a first air cylinder mounting plate, a second air cylinder, a second air cylinder mounting plate, a force measuring pressure head piece, a hanging component and a jacking pawl mechanism, the output line is mounted on the bottom plate, the tray mechanism is arranged on the output line, the jacking mechanism is connected with the tray mechanism, the servo electric cylinder is arranged on the electric cylinder fixing plate and is connected with the pressure head fixing plate, the first air cylinder is fixed to the first air cylinder mounting plate, the second air cylinder is fixed to the second air cylinder mounting plate, the force measuring pressure head piece is installed on the pressure head fixing plate and connected with the servo electric cylinder, the hanging component is fixed to the first air cylinder, and the pawl ejecting mechanism is connected with the second air cylinder. The testing mechanism is simple and reasonable in structural design, accurate in test, convenient to operate, high in automation degree and capable of meeting performance test requirements.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

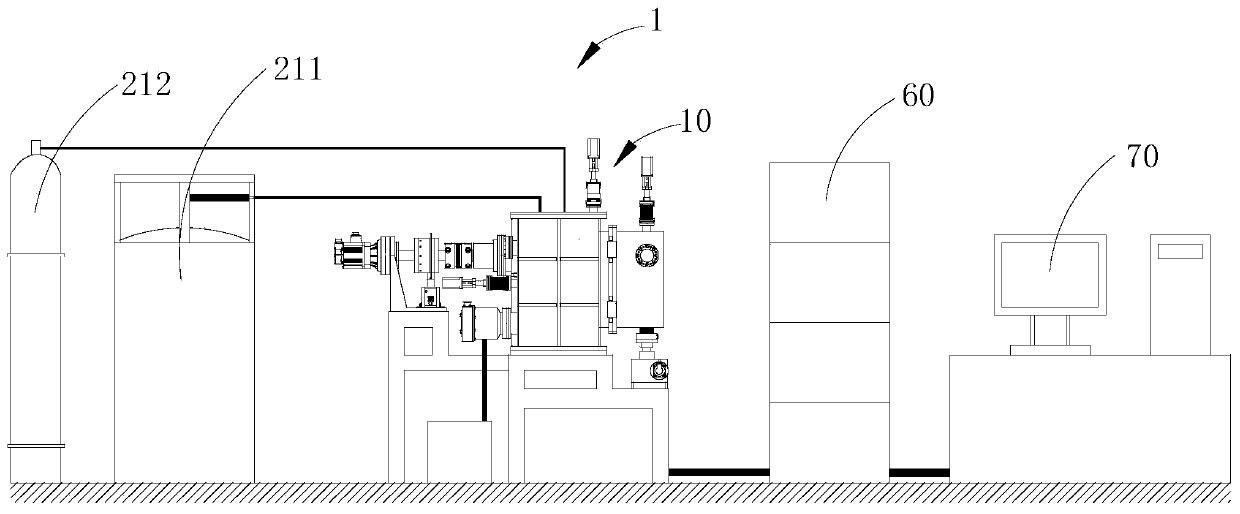

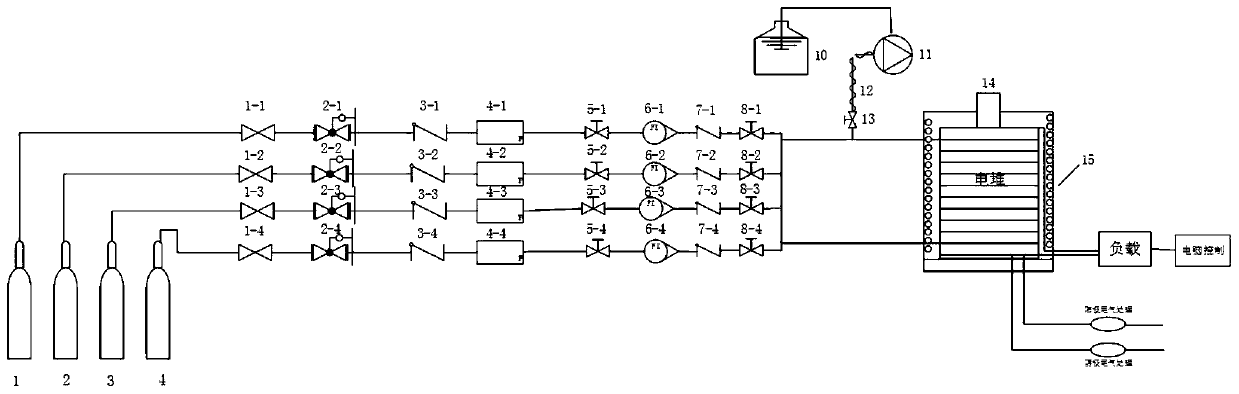

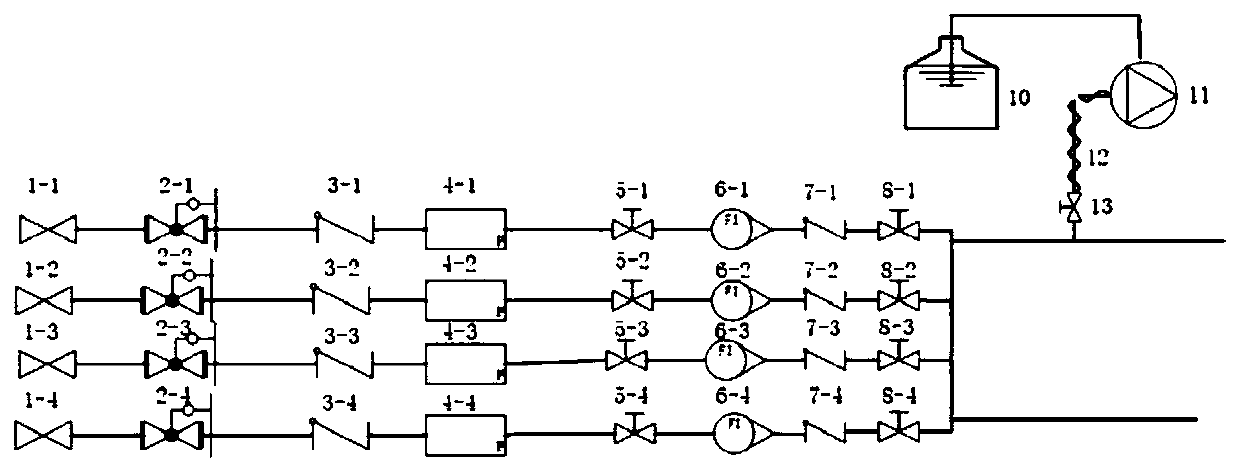

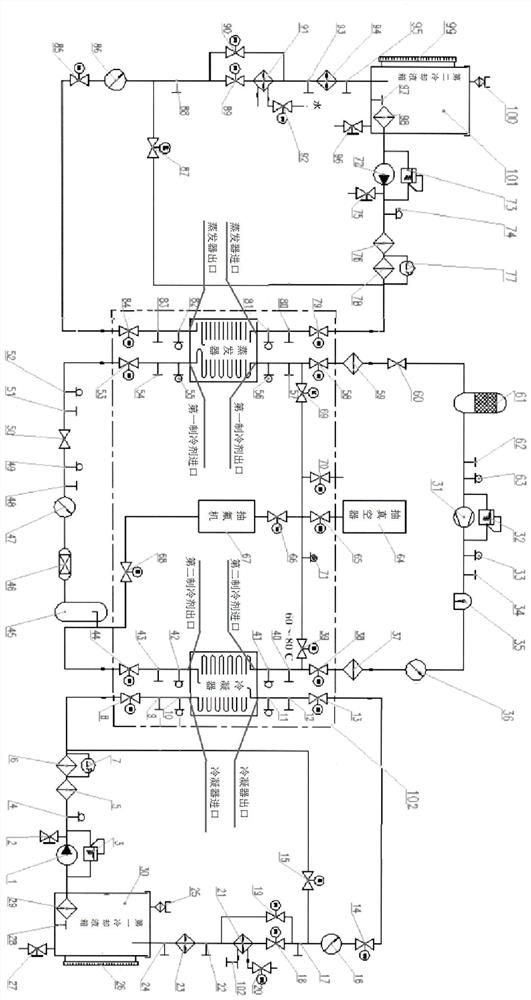

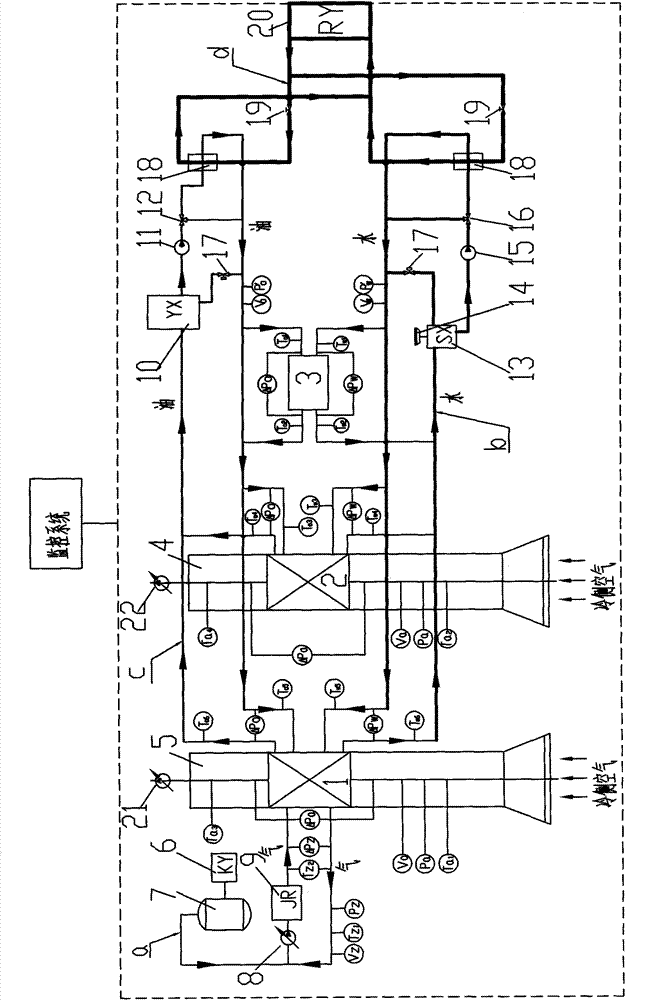

High-temperature fuel cell test system

PendingCN110531273ALow costMeet the performance testElectrical measurement instrument detailsElectrical testingFuel cellsGas cylinder

The invention provides a high-temperature fuel cell test system. The high-temperature fuel cell test system comprises a gas control device for controlling gas types and gas inlet proportions of an anode gas inlet and a cathode gas inlet of a galvanic pile. A plurality of gas cylinders used for testing the performance of the high-temperature fuel cell is set, and a gas outlet of each gas cylinder is connected with the anode gas inlet and the cathode gas inlet of the fuel cell stack. A gas control device is arranged on a connecting pipeline of a gas outlet of each gas cylinder. According to thesystem, the tests of all high-temperature fuel cells and the performance tests of fuel cells with different fuel sources are satisfied, the system has the advantages of simple structure and easy realization, and the problem of high cost caused by the pertinence of a fuel cell testing system in the prior art is solved.

Owner:HUANENG CLEAN ENERGY RES INST

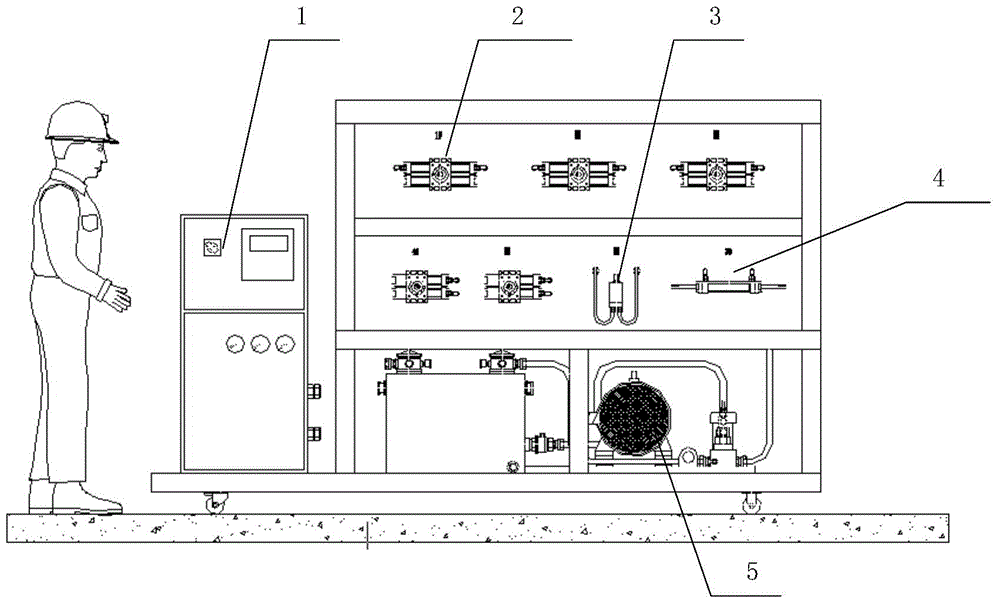

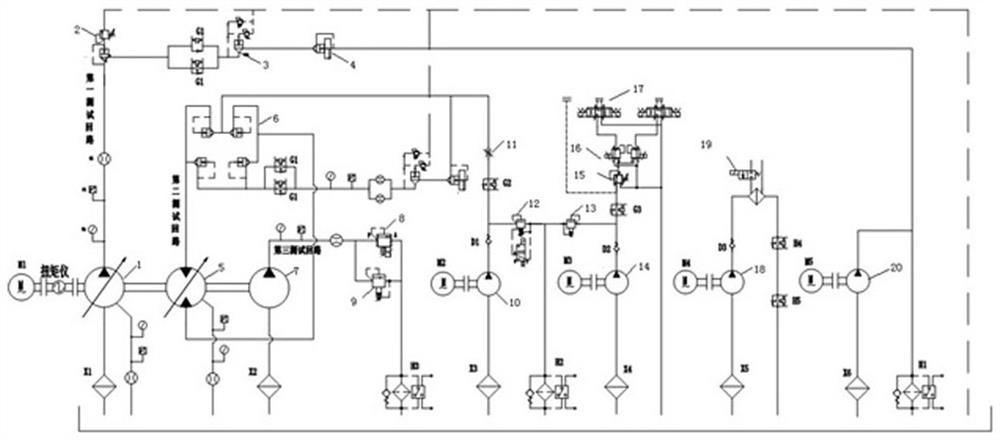

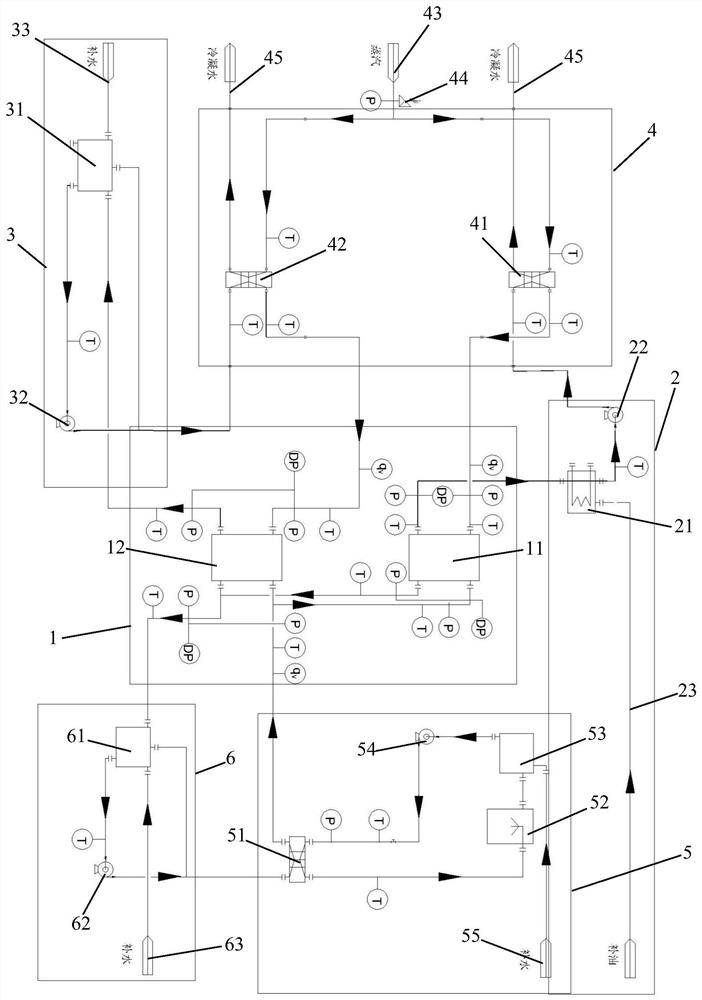

Hydraulic pump comprehensive test system

PendingCN112594178AMeet the performance testSatisfy the loadPump testingPositive displacement pump componentsCombined testHydraulic pump

The invention provides a hydraulic pump comprehensive test system. The hydraulic pump comprehensive test system comprises a main oil tank; the main oil tank communicates with a cooling circulation loop, and further communicates with a series pump set; the series pump set communicates with an oil drainage loop, a first test loop, a second test loop and a third test loop; the second test loop communicates with an oil supplementing loop and a control loop; and the oil supplementing loop and the control loop both communicate with the main oil tank. The hydraulic pump comprehensive test system meets the performance test of a high-flow pump, can realize the automatic loading, meets the load simulation condition test of a high-displacement pump, can further realize the series pump test, meets theperformance test of a triple pump at most, and meets the automatic loading and load simulation condition test of s series pump at the same time.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

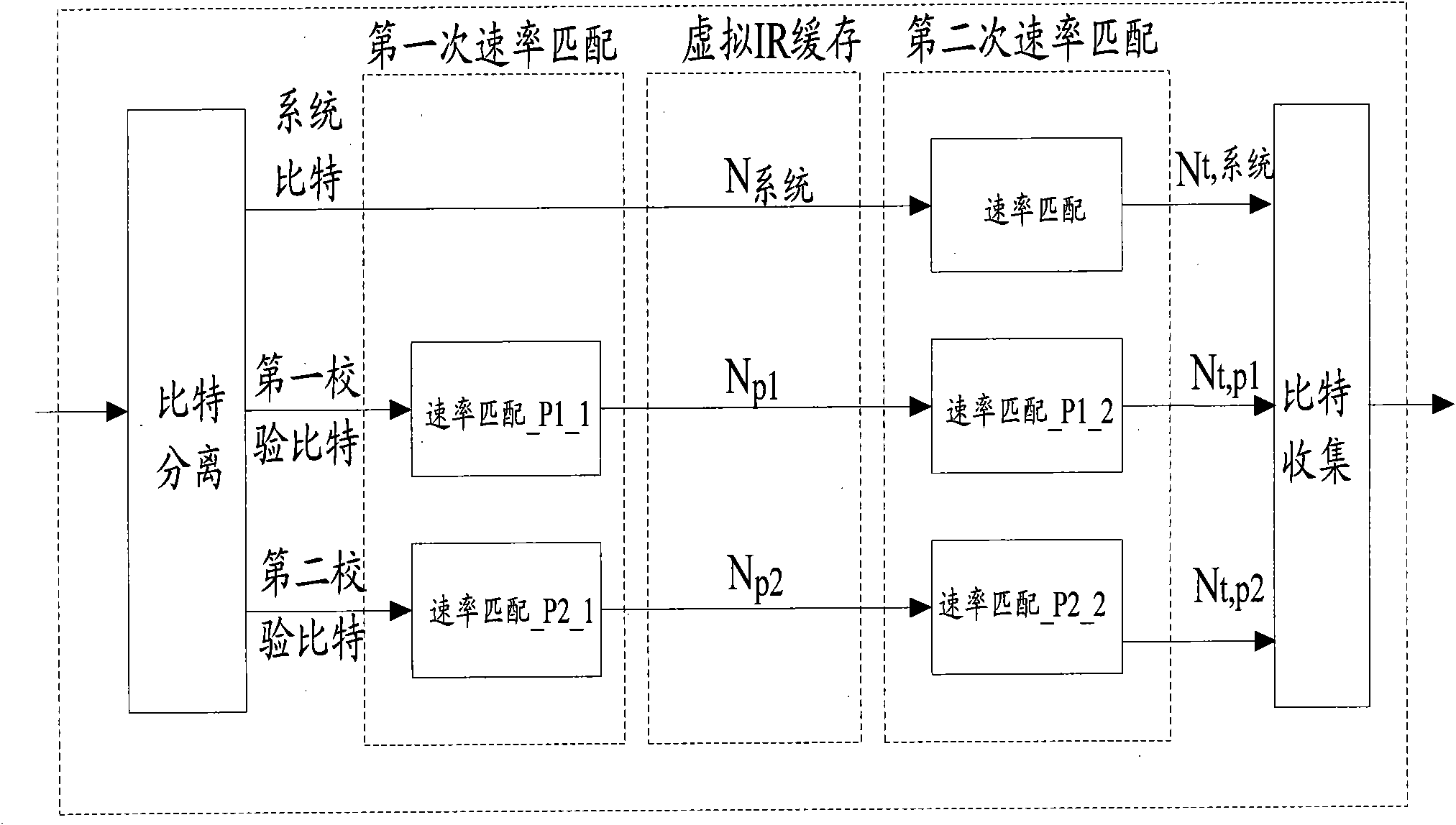

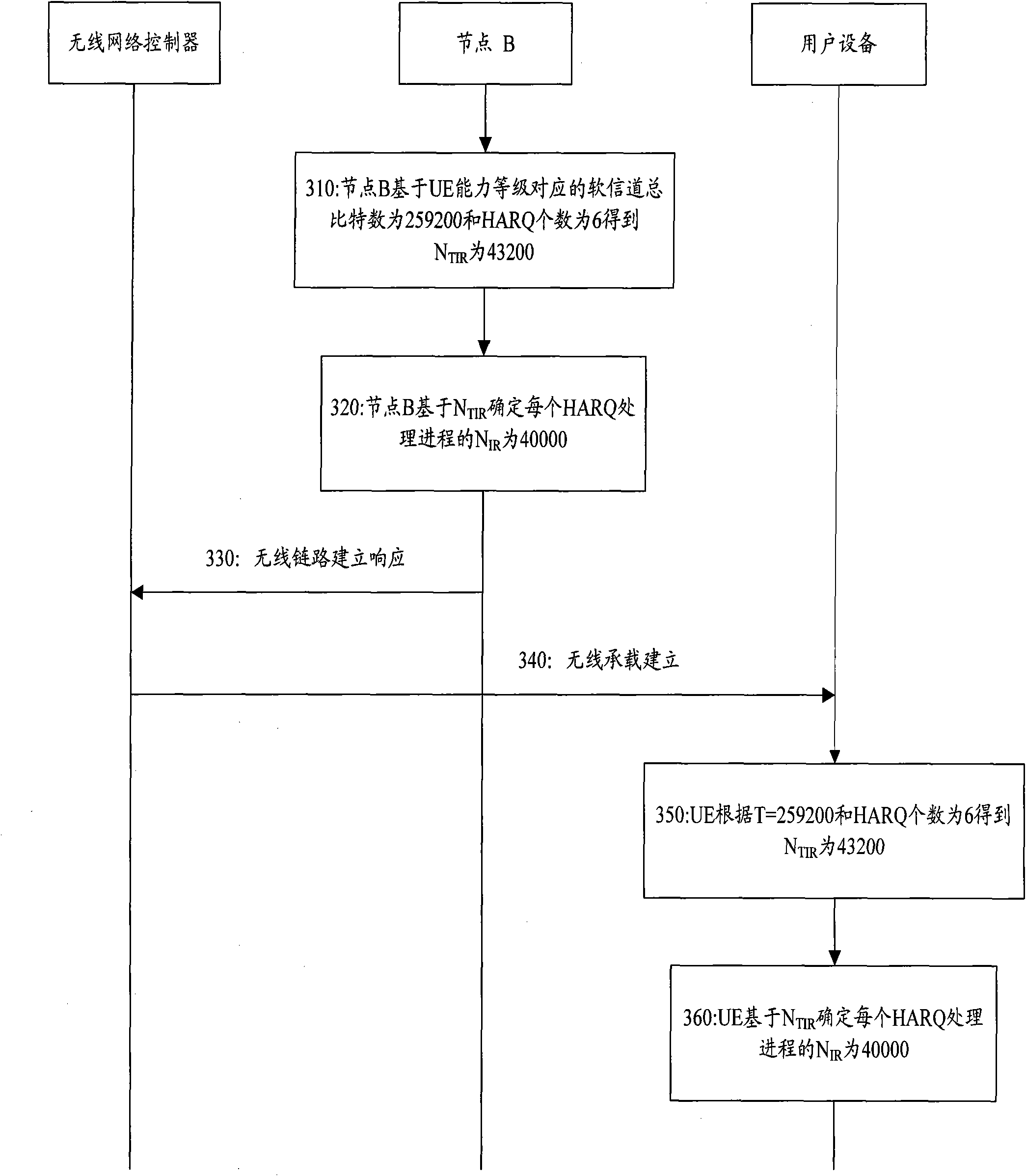

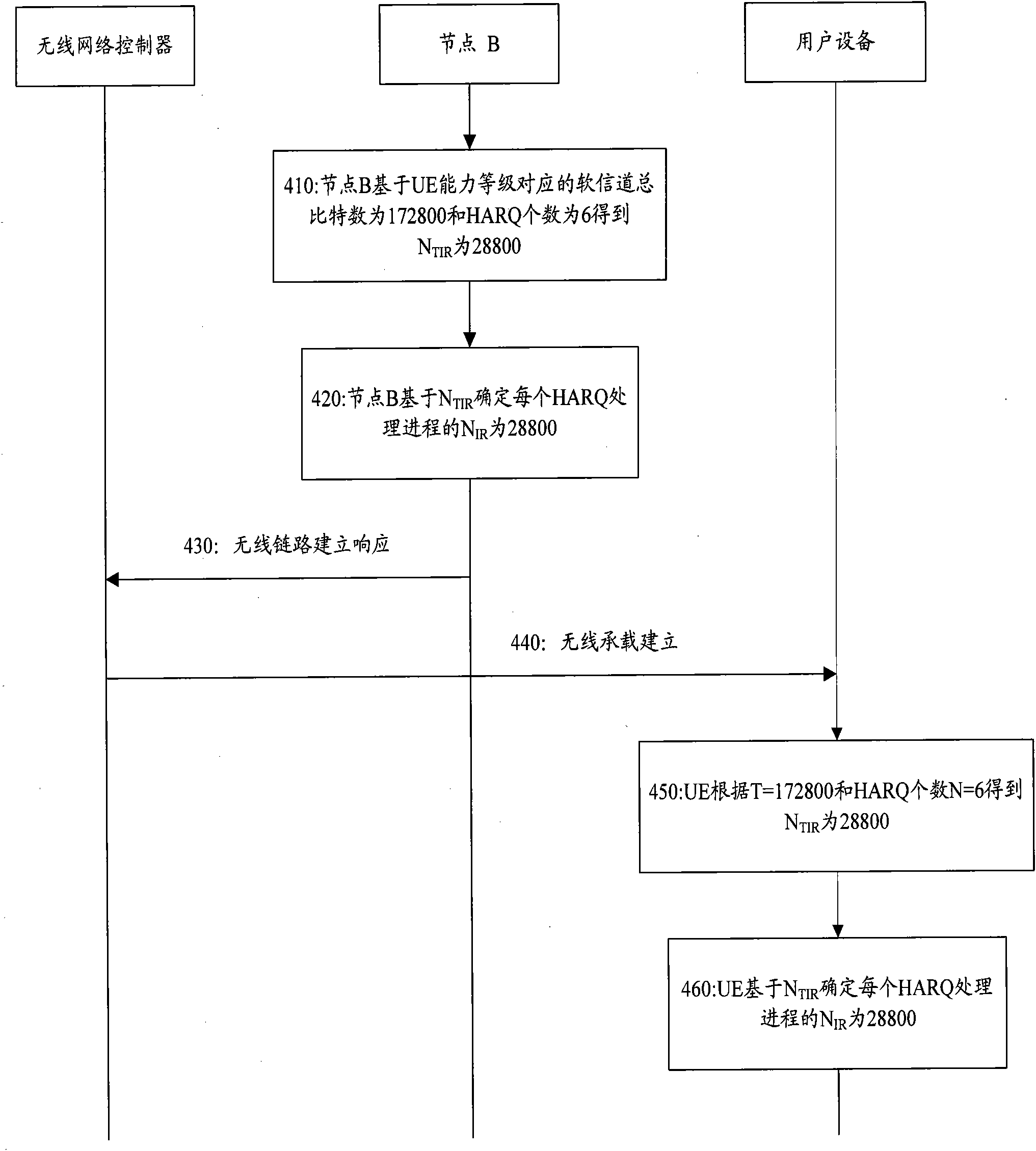

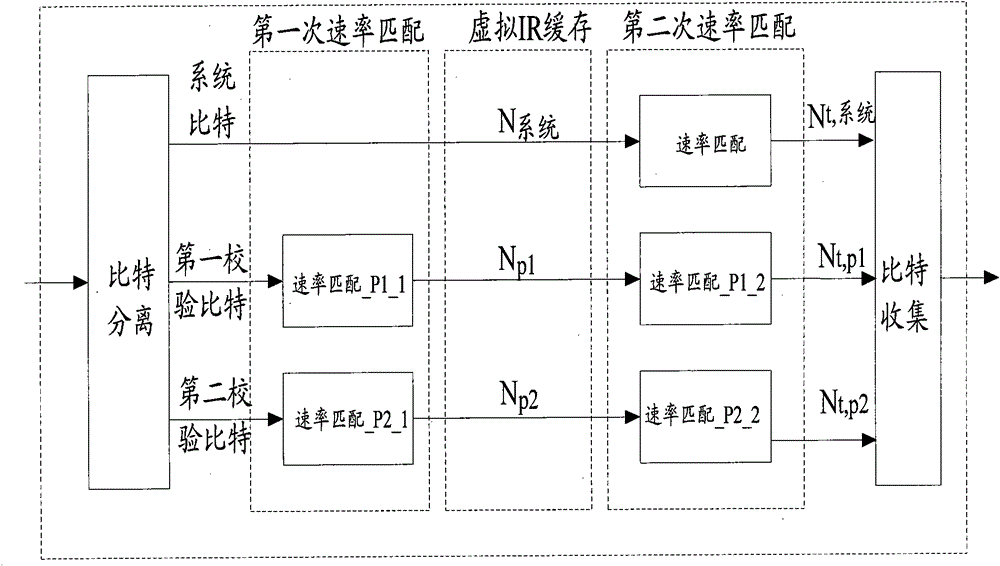

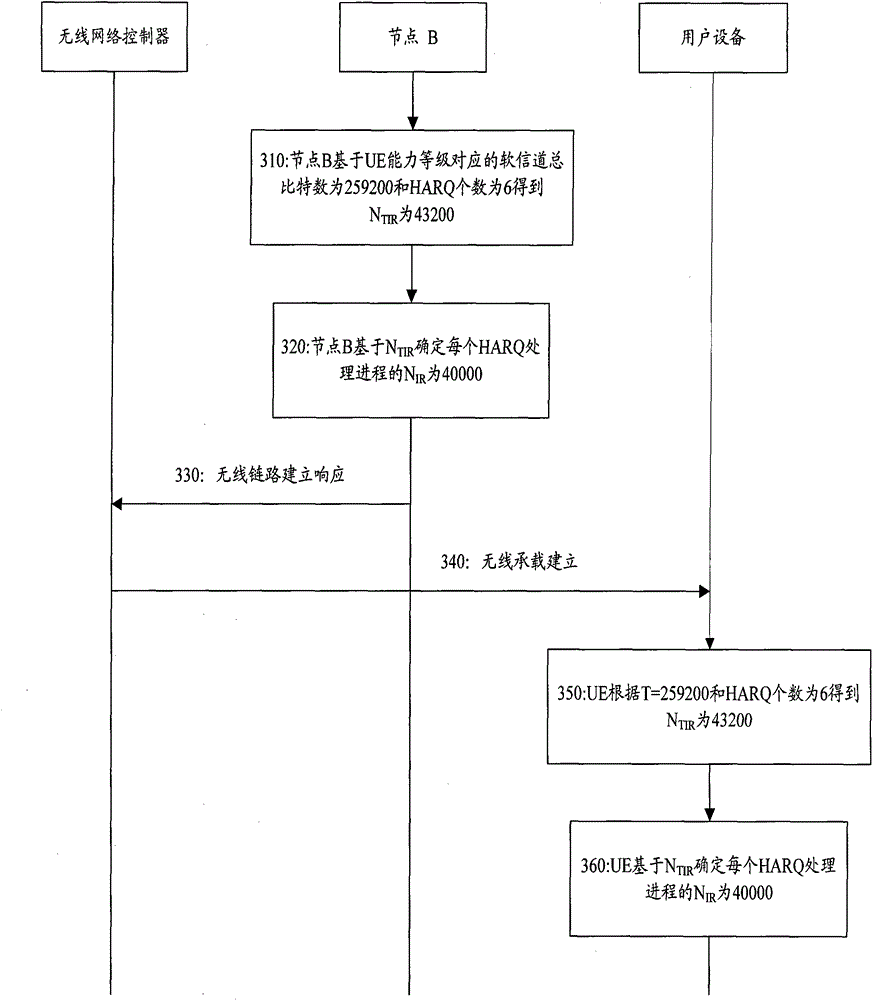

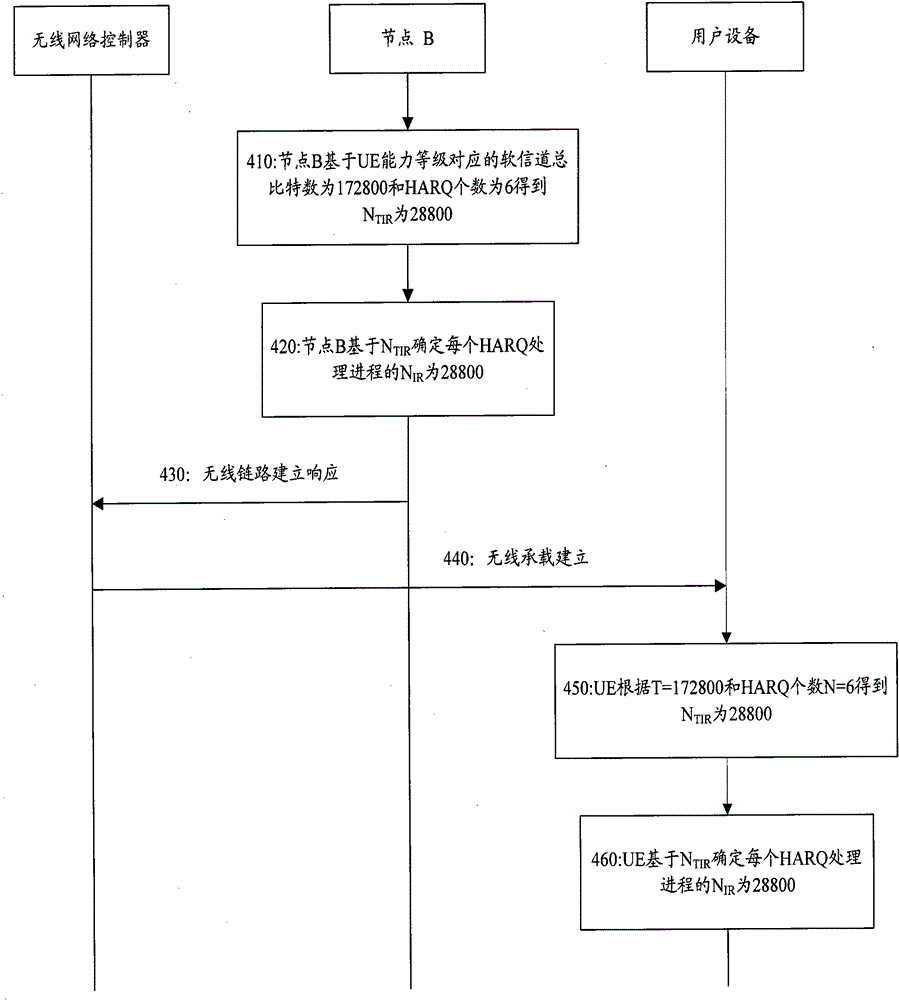

Method and system for distributing available soft channel maximum bit value

InactiveCN102387010AMeet performance needsMeet the performance testError prevention/detection by using return channelNetwork traffic/resource managementTelecommunicationsBit numbering

The invention discloses a method for distributing an available soft channel maximum bit value, which comprises the following steps: a node B sets that NTIR is equal to T / N, wherein T is the total bit number of a soft channel of user equipment (UE), and N is the amount of the processing progress of a hybrid automatic repeat request (HARQ) configured for the UE by the node B; according to the NTIR, the available soft channel maximum bit value NIR of each HARQ processing progress in N HARG processing progresses is determined; and in an implicit mode, the node B notifies the UE to distribute the NIR for the node B. The invention also discloses a system for distributing the available soft channel maximum bit value, and an NIR determining unit on the node B side is used for determining the available soft channel maximum bit value NIR of each HARQ processing progress in N HARG processing progresses according to the NTIR. According to the method and the system disclosed by the invention, an effective solution is provided for aiming at problems caused by distribution in the implicit mode.

Owner:ZTE CORP

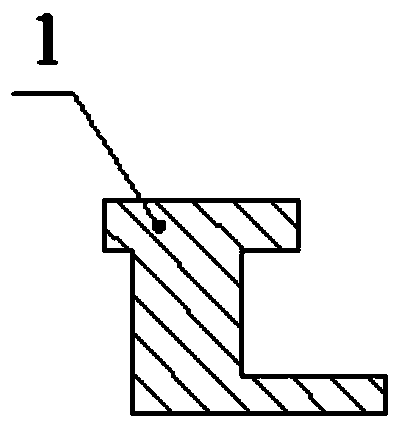

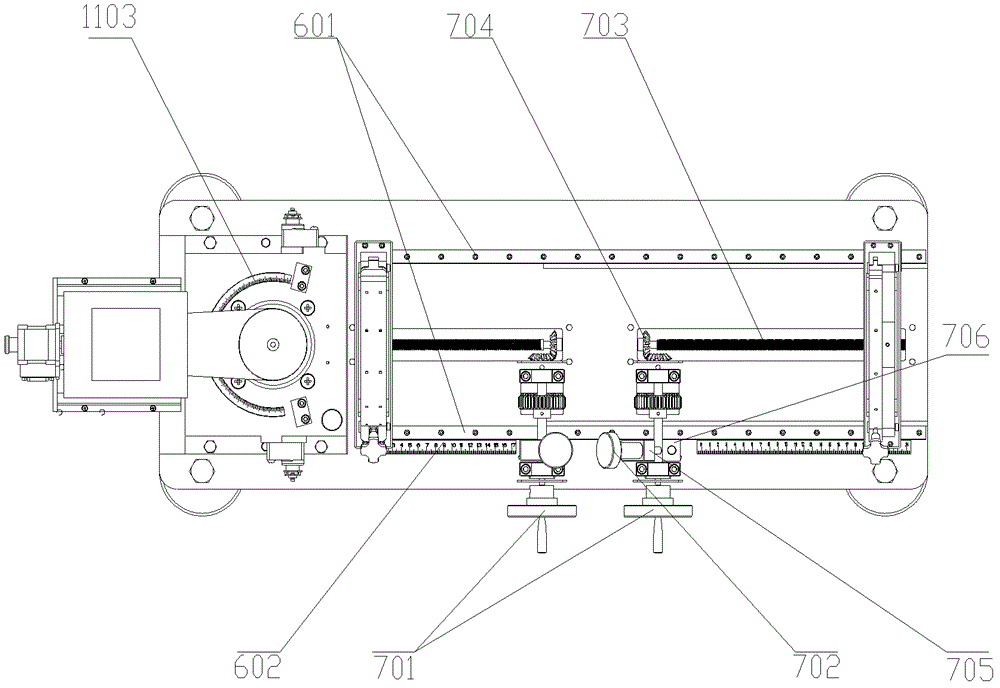

A mechanical performance testing device for micron-sized monofilament fibers

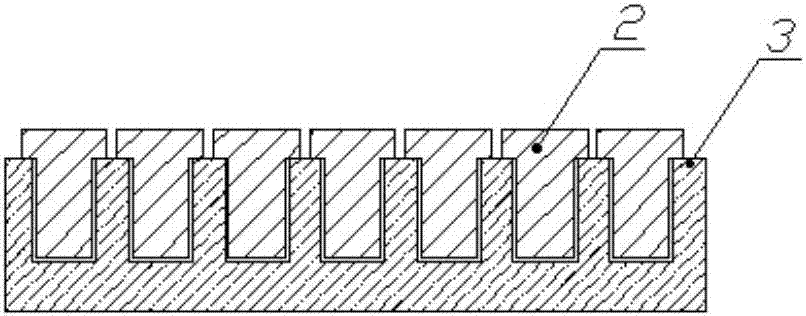

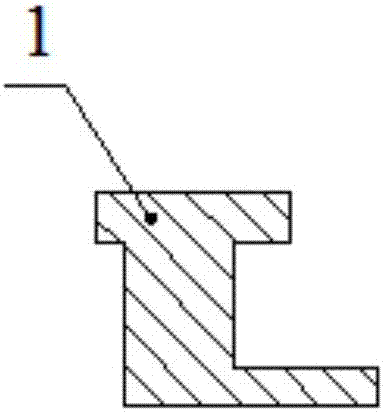

ActiveCN107153027BImprove accuracyImprove efficiencyMaterial strength using tensile/compressive forcesFiberMicrometer

The invention discloses a mechanical property testing device for a micrometer monofilament fiber. The mechanical property testing device comprises a bottom plate, wherein a plurality of grooves are arranged on the bottom plate in parallel; slide blocks and clamp heads are sequentially arranged on the bottom plate from front to back, and are matched with the grooves; the multiple slide blocks are inserted into the grooves to form a row, and can slide in the grooves; the clamp heads comprise first clamp heads and second clamp heads, and the side surface, near one side of each slide block, of each of the first clamp heads and second clamp heads is flush, and is respectively inserted into the corresponding groove; each first clamp head is horizontally moved, the surface of each second clamp head is attached with a strain sensor, and each strain sensor is connected with a mechanical recorder. The mechanical property testing device has the advantages that by adopting the semi-automatic positioning and automatic clamping units, the length of the monofilament fiber can be adjusted, the advanced sample preparation is not needed, and the structure is simple; the testing accuracy and efficiency of the monofilament fiber are improved.

Owner:SHAANXI UNIV OF SCI & TECH

Mechanical seal performance test device and axial force and temperature measurement method between seal faces

ActiveCN104330223BAvoid destructionSimple structureApparatus for force/torque/work measurementPyrometry using electric radation detectorsElectricityAxial force

Owner:NANJING FORESTRY UNIV

A general chip test system, test method and storage medium

ActiveCN111487524BImprove construction efficiencyEasy to replaceElectronic circuit testingTest suiteModular design

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method and system for allocating maximum value of available soft channel bits

InactiveCN102387010BMeet the performance testMeet performance needsError prevention/detection by using return channelNetwork traffic/resource managementEffective solutionTelecommunications

The invention discloses a method for distributing an available soft channel maximum bit value, which comprises the following steps: a node B sets that NTIR is equal to T / N, wherein T is the total bit number of a soft channel of user equipment (UE), and N is the amount of the processing progress of a hybrid automatic repeat request (HARQ) configured for the UE by the node B; according to the NTIR, the available soft channel maximum bit value NIR of each HARQ processing progress in N HARG processing progresses is determined; and in an implicit mode, the node B notifies the UE to distribute the NIR for the node B. The invention also discloses a system for distributing the available soft channel maximum bit value, and an NIR determining unit on the node B side is used for determining the available soft channel maximum bit value NIR of each HARQ processing progress in N HARG processing progresses according to the NTIR. According to the method and the system disclosed by the invention, an effective solution is provided for aiming at problems caused by distribution in the implicit mode.

Owner:ZTE CORP

Evaporator and condenser performance joint test device

ActiveCN114199602AImprove test efficiencyQuick testStructural/machines measurementProcess engineeringControl theory

The invention discloses an evaporator and condenser performance joint testing device, which comprises an environmental chamber, and an evaporator and a condenser which are arranged in the environmental chamber, and is characterized in that the evaporator is connected with an evaporation system and a refrigerant system through an evaporation system interface and a refrigerant system inlet and outlet in the environmental chamber respectively; the condenser is connected with the condensation system and the refrigerant system through the condensation system interface and the refrigerant system inlet and outlet in the environment cabin, the use working conditions of the evaporator and the condenser can be simulated, the performance of the evaporator and the performance of the condenser can be tested independently or jointly, and the testing process is rapid, accurate, safe and environmentally friendly.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

A Motion Simulation System for Infrared Targets

Owner:LUOYANG INST OF SCI & TECH

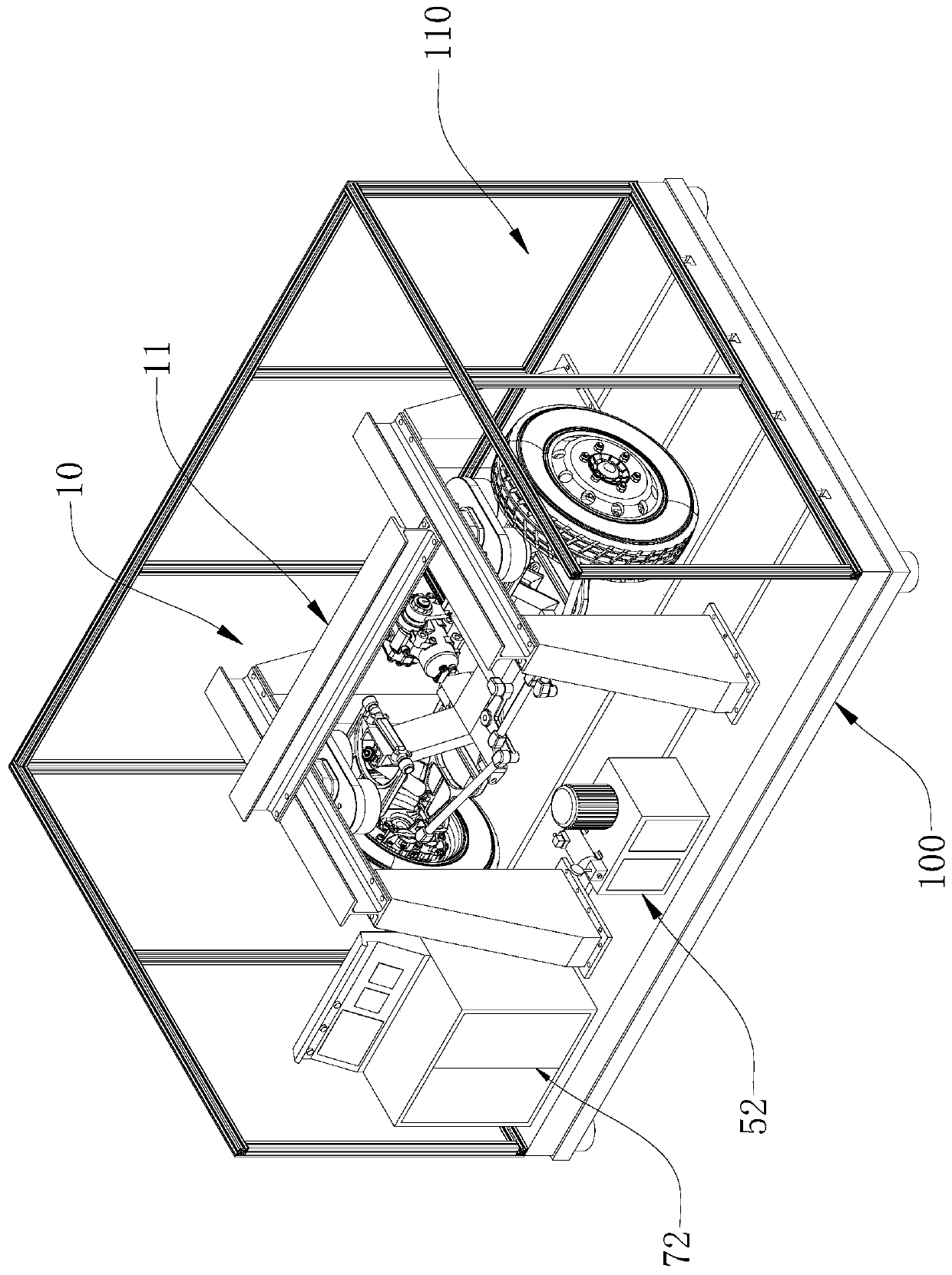

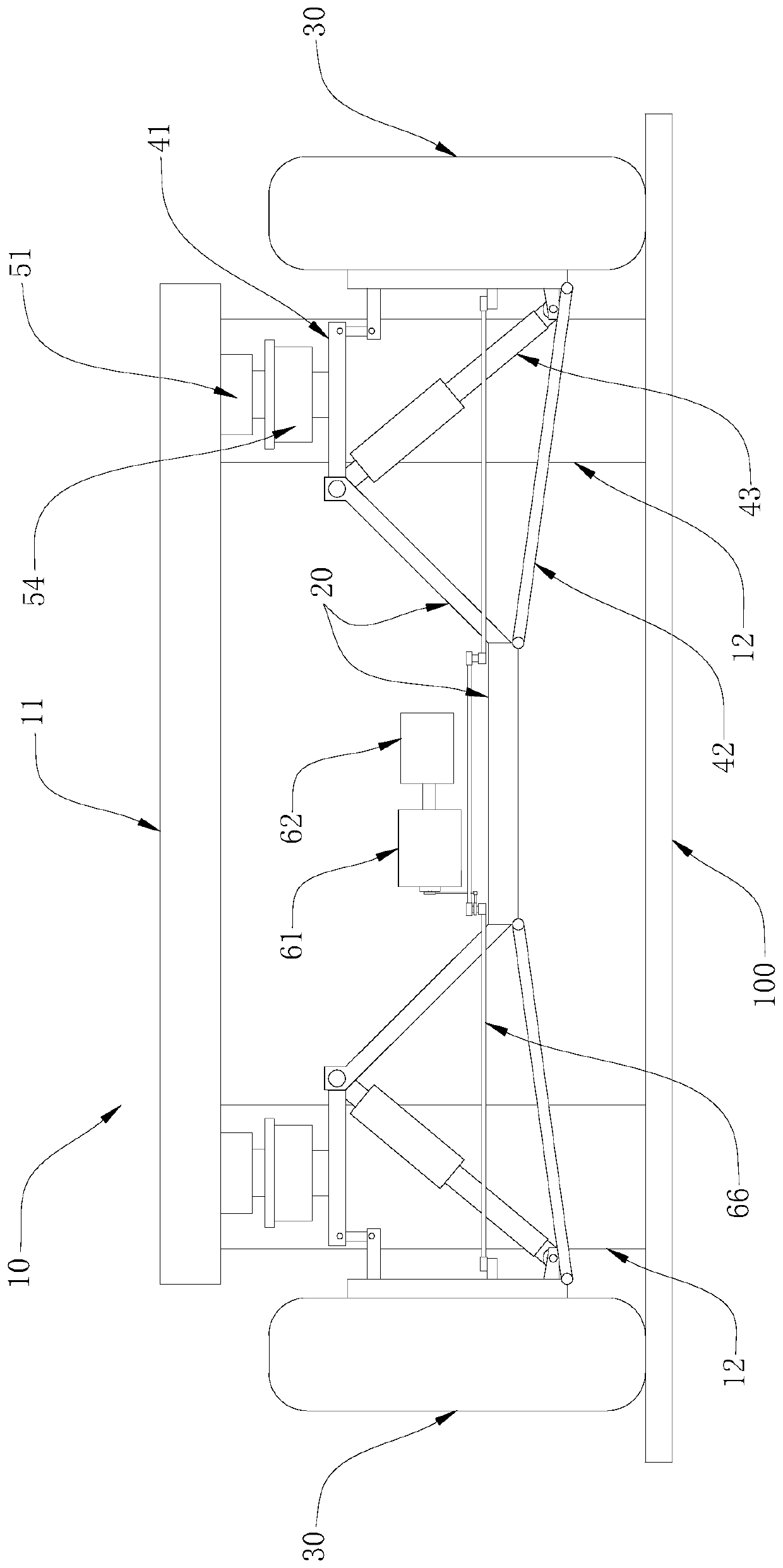

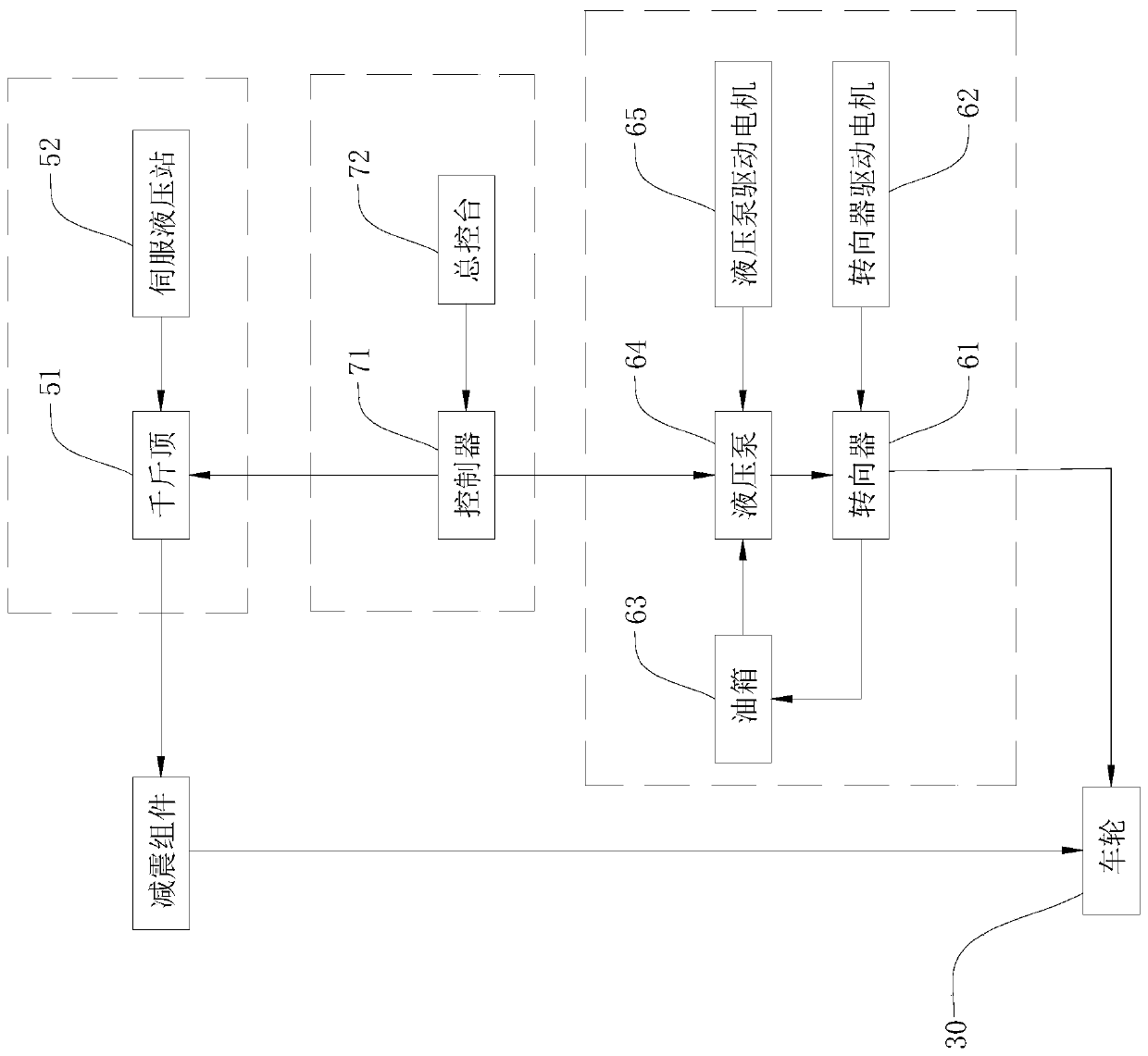

Steering-by-wire system experimental device

PendingCN110186699AMeet the test needsIdeal nonlinear elastic propertiesVehicle steering/rolling behaviourVehicle frameControl system

The invention discloses a steering-by-wire system experimental device, and belongs to the technical field of vehicle experiments. The steering-by-wire system experimental device comprises a bracket, asuspension assembly and a control system, wherein the top of the bracket is provided with a top beam; the suspension assembly comprises a frame and wheels located on both sides of the frame; the frame is connected with the wheels through a damping assembly respectively; the frame is also connected with the wheels through a steering-by-wire system; the top of the damping assembly is connected withthe top beam through a pressing assembly; and the control system communicates with the steering-by-wire system and the pressing assembly respectively. The steering-by-wire system experimental devicecan simulate the load transfer between left and right wheels during curve driving of a vehicle, static steering test under a full load condition, frequency-sweep steering test under a driving condition, steering test under different tire-ground adhesion conditions and performance test of key components of the steering-by-wire system of a heavy-duty vehicle, and can meet the test demand of the steering-by-wire system of a heavy-duty driverless vehicle in the development process of a steering mechanism and an actuation control system.

Owner:SOUTHWEST JIAOTONG UNIV +1

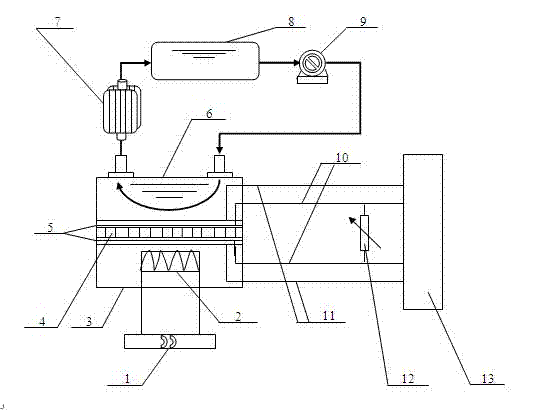

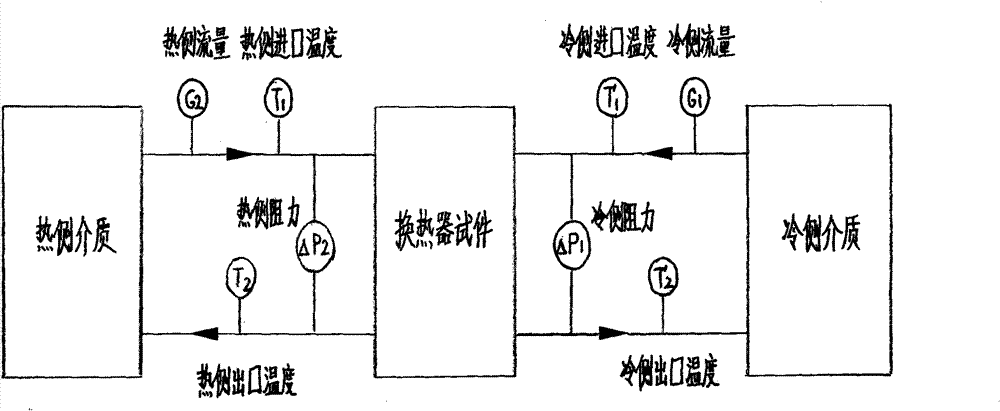

Multi-medium combined heat exchanger test bed

ActiveCN102095447BMeet the performance testImprove the design levelMeasurement devicesCombined testThermal energy

The invention provides a multi-medium combined heat exchanger test bed. The multi-medium combined heat exchanger test bed comprises an intercooler test bed, and a water / oil heat exchanger test bed, wherein the intercooler test bed comprises an air heating system, an air circulation system, an intercooler test bed wind tunnel system, a specimen, a measurement instrument and pipelines; the water / oil heat exchanger test bed comprises a water circulation system, an oil circulation system, a heat supply system, a water / oil heat exchanger test bed wind tunnel system, a specimen, a measurement instrument and pipelines; and the intercooler test bed and the water / oil heat exchanger test bed are connected with each other through the pipeline and are controlled by a monitoring system. The multi-medium combined heat exchanger test bed can meet the requirement for performance testing of various types of heat exchangers, and can improve the single test mode of the original parts to the synchronous comprehensive test mode of the parts and the system, thereby further improving the design strength and the design level of heat radiation systems for the military special vehicles, other vehicles and engineering machines.

Owner:BEIJING FENGKAI HEAT EXCHANGER

A transplanter test bench based on machine vision

InactiveCN104897427BMeet the performance testImprove work efficiencyStructural/machines measurementMachine visionReciprocating motion

Owner:SHIHEZI UNIVERSITY

Performance testing fixture for magnetos

InactiveCN102495366BSimple structureEasy to installElectrical measurement instrument detailsDynamo-electric machine testingTest requirementsEngineering

Owner:力帆科技(集团)股份有限公司

Heat exchanger performance test and energy efficiency evaluation system

PendingCN114034498AMeet the performance testThermal oil meeting the requirements of energy efficiency evaluationStructural/machines measurementCold sideData acquisition

The invention discloses a heat exchanger performance test and energy efficiency evaluation system. A to-be-tested platform is provided with an oil-water to-be-tested heat exchanger and a water-water to-be-tested heat exchanger; inlets of a hot oil loop and a hot water loop are respectively communicated with hot side outlets of the two to-be-tested heat exchangers; the steam loop comprises a steam-oil heat exchanger and a steam-water heat exchanger; the steam-oil heat exchanger and the steam-water heat exchanger provide exchange heat through steam; inlets of the steam-oil heat exchanger and the steam-water heat exchanger are respectively communicated with outlets of the hot oil loop and the hot water loop, and outlets of the steam-oil heat exchanger and the steam-water heat exchanger are respectively communicated with hot side inlets of the two to-be-tested heat exchangers; an outlet of the cooling water loop is communicated with cold side inlets of the two to-be-tested heat exchangers; an inlet of the cold water loop is communicated with cold side outlets of the two to-be-tested heat exchangers, and an outlet of the cold water loop is communicated with an inlet of the cooling water loop; and the data acquisition system comprises a plurality of detection sensors mounted on the pipeline.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Low temperature and large temperature variable joint bearing test platform and measurement method for joint bearings

ActiveCN110726555BImplement friction testMeet the performance testMachine bearings testingUsing optical meansThermodynamicsProgrammable logic controller

The invention provides a low-temperature and large-temperature variable joint bearing test platform and a measurement method for the joint bearing. The low temperature and large temperature variable joint bearing test platform includes: motion and load simulation system; environmental measurement and control system; programmable logic controller; The gap and wear amount measuring device is connected with the motion and load simulation system and the environment measurement and control system, and is electrically connected with the programmable logic controller, and the measurement and data acquisition system transmits the measurement data to the programmable logic controller. A logic controller is programmed and controlled by the programmable logic controller. Realize the wear amount and in-situ clearance measurement of spherical plain bearings under special working conditions, provide means for researching and testing the performance parameters of spherical plain bearings and their influencing factors under special working conditions, and design and optimize spherical plain bearings suitable for special working conditions, ensuring Reliability of spherical plain bearings.

Owner:TSINGHUA UNIV

Mechanical property testing device for micrometer monofilament fiber

ActiveCN107153027AImprove accuracyImprove efficiencyMaterial strength using tensile/compressive forcesFiberMicrometer

The invention discloses a mechanical property testing device for a micrometer monofilament fiber. The mechanical property testing device comprises a bottom plate, wherein a plurality of grooves are arranged on the bottom plate in parallel; slide blocks and clamp heads are sequentially arranged on the bottom plate from front to back, and are matched with the grooves; the multiple slide blocks are inserted into the grooves to form a row, and can slide in the grooves; the clamp heads comprise first clamp heads and second clamp heads, and the side surface, near one side of each slide block, of each of the first clamp heads and second clamp heads is flush, and is respectively inserted into the corresponding groove; each first clamp head is horizontally moved, the surface of each second clamp head is attached with a strain sensor, and each strain sensor is connected with a mechanical recorder. The mechanical property testing device has the advantages that by adopting the semi-automatic positioning and automatic clamping units, the length of the monofilament fiber can be adjusted, the advanced sample preparation is not needed, and the structure is simple; the testing accuracy and efficiency of the monofilament fiber are improved.

Owner:SHAANXI UNIV OF SCI & TECH

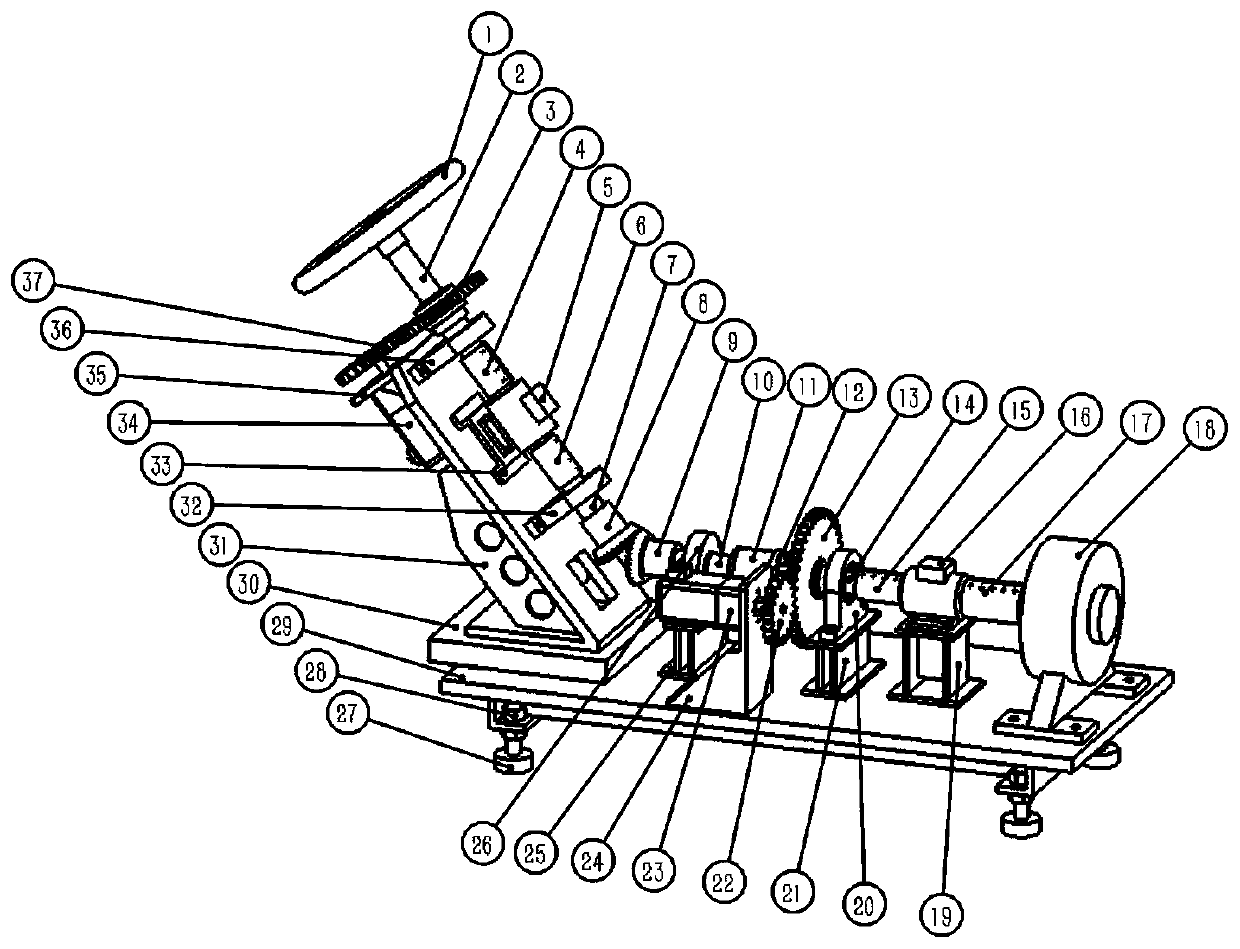

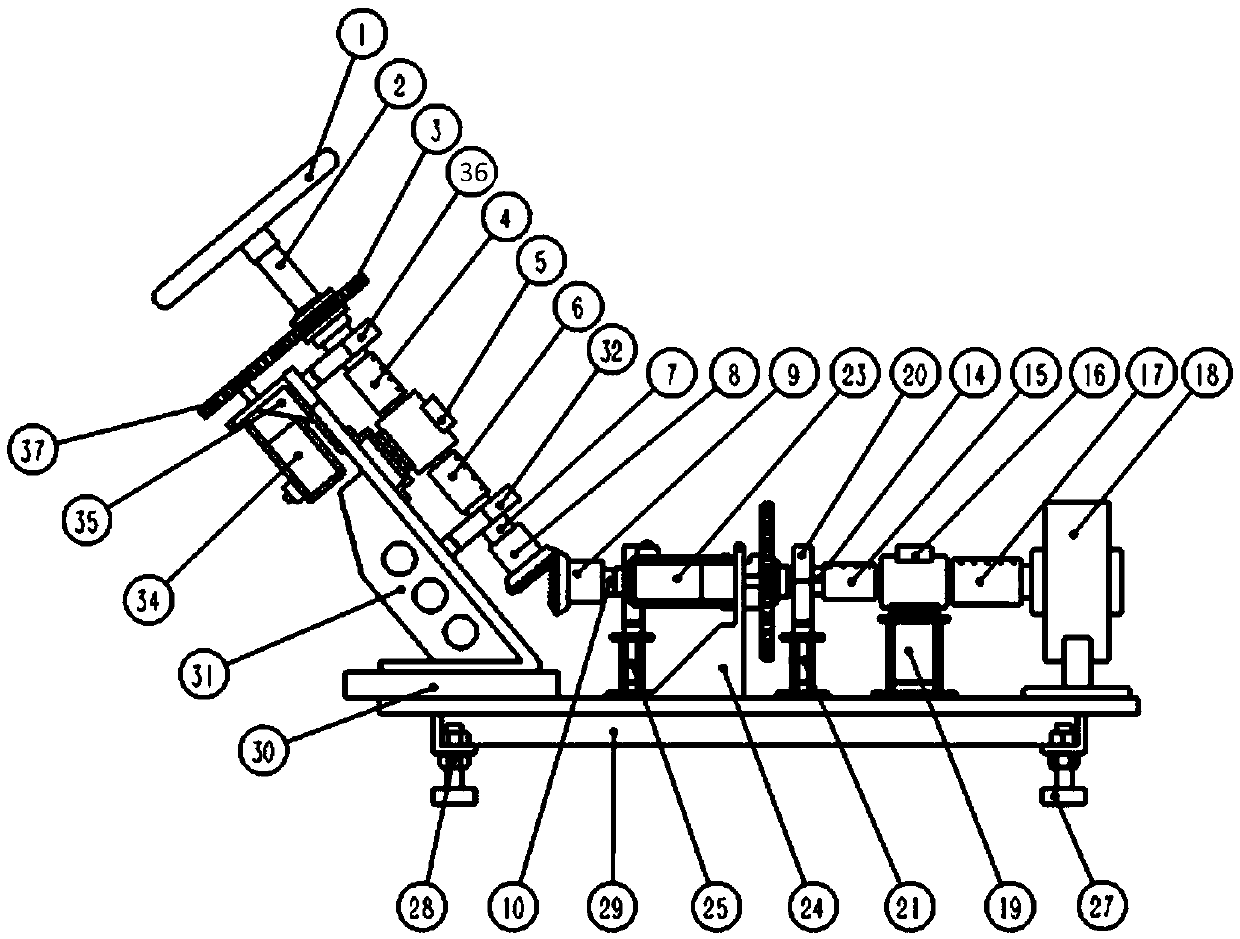

Performance test system of electric power steering system for storage logistics vehicle

PendingCN111060332ADesigned to accurately measureReliable designVehicle steering/rolling behaviourElectric power steeringGear wheel

The invention discloses a performance test system of an electric power steering system for a storage logistics vehicle, which comprises a test bed support, an EPS system assembly and a detection system. The EPS system assembly and the detection system are installed on the test bed support. The test bed support comprises a test bed bottom plate, an inclined support adjusting plate and an inclined support. The detection system comprises a first torque sensor, a torque acquisition device, a second torque sensor, an electronic control unit ECU and an input motor control unit. The torque signal acquisition device connected with the second dynamic torque sensor is provided with an inner rotating shaft and an outer rotating shaft which can rotate relatively, wherein the inner rotating shaft is provided with a first torsion spring compression bar and a second torsion spring compression bar, and the outer rotating shaft is provided with a first torsion spring fixing bar and a second torsion spring fixing bar to compress the torsion spring. The EPS system assembly comprises a steering wheel, an input shaft, a torque input large gear, a first coupling, a second coupling, a first bevel gear shaft, a first bevel gear, a second bevel gear, a second bevel gear shaft, a booster large gear, a large gear shaft, a third coupling, a fourth coupling and a magnetic powder brake connected in sequence.

Owner:ZHEJIANG UNIV OF TECH

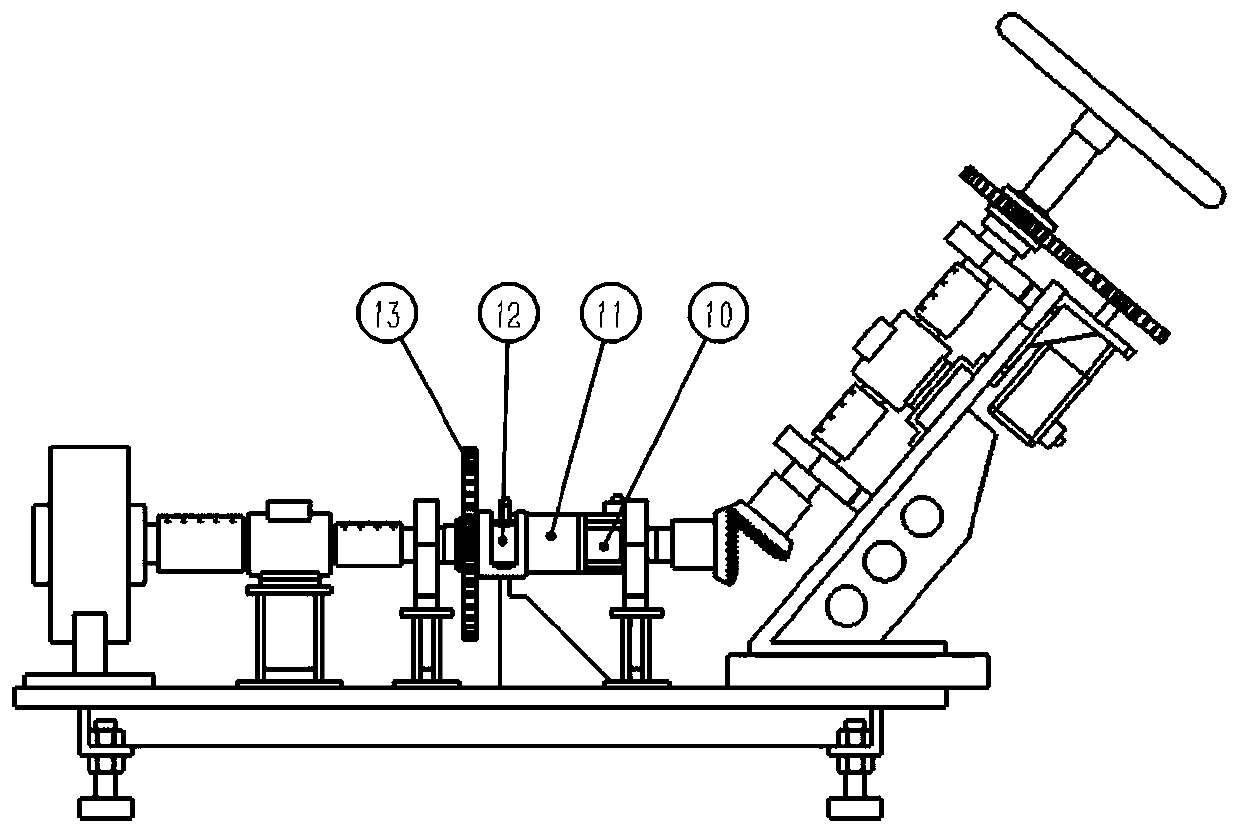

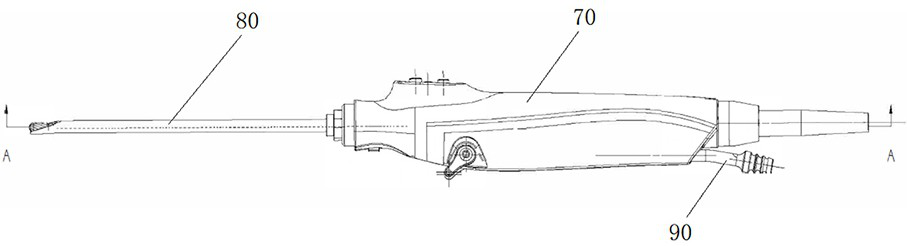

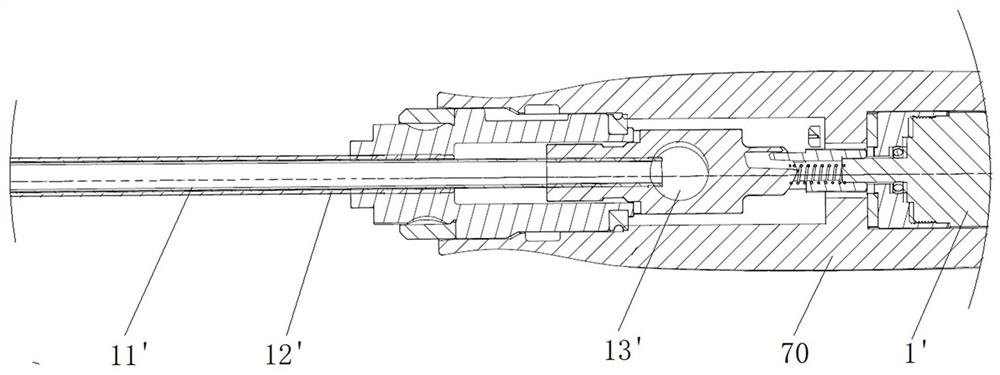

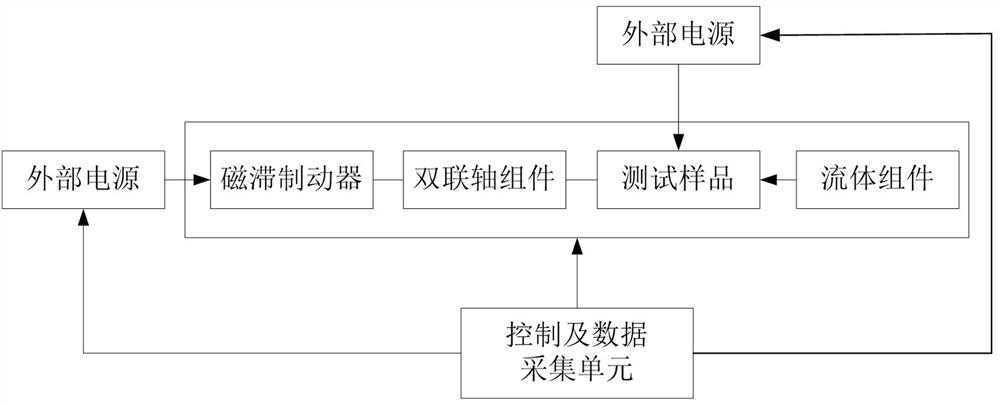

Medical planer test system and test method

ActiveCN113776605BRealize requirementsRealize researchMeasurement devicesTest sampleStructural engineering

A medical planer test system, including a performance test unit and a control and data acquisition unit; the performance test unit includes: a hysteresis brake that provides a simulated load to the test sample, a double-coupling structure, and a temperature rise test and a cooling test The fluid component of the sample; the output end of the hysteresis brake is connected to one end of the double-coupling structure, and the other end of the double-coupling structure is connected to the upper end of the test sample axis; the fluid component communicates with the bottom of the other end of the test sample axis; the control The data acquisition unit is used to provide motion control for the test sample, provide simulated load control for the performance test unit, and collect test data of the performance test unit for storage and processing. A test method based on the test system is also provided. The test system and test method have a wide range of applications and can meet the performance tests of medical planers of different models and different interface sizes.

Owner:SUZHOU YINGTUKANG MEDICAL TECH CO LTD

Performance test platform for electric power steering system of industrial transport vehicle

PendingCN111060331ADesigned to accurately measureReliable designVehicle steering/rolling behaviourElectric power steeringSteering wheel

The invention discloses a performance test platform for an electric power steering system of an industrial transport vehicle, which comprises a test bed support, an EPS system assembly and a detectionsystem, wherein the EPS system assembly and the detection system are both installed on the test bed support; the test bed support comprises a test bed bottom plate, an inclined support adjusting plate and an inclined support; the detection system comprises a torque sensor I, a torque acquisition device, a torque sensor II, an electronic control unit ECU and an input motor control unit; the EPS system assembly comprises a steering wheel, an input shaft, a torque input large gear, a coupler I, a coupler II, a bevel gear shaft I, a bevel gear I, a bevel gear II, a bevel gear shaft II, an assisting large gear, a large gear shaft, a coupler III, a coupler IV and a magnetic powder brake which are connected in sequence. The platform can be suitable for performance test of the electric power steering system of various industrial transport vehicles.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com