Medical planer test system and test method

A test system and planing technology, applied in the field of testing, can solve problems such as low efficiency, inability to meet special test requirements, etc., to achieve a wide range of applications, achieve load characteristics and efficiency testing, and real test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

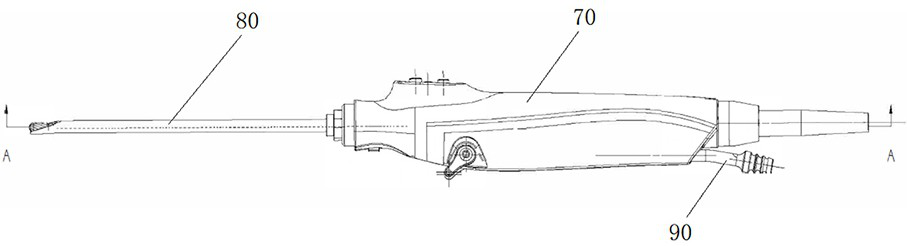

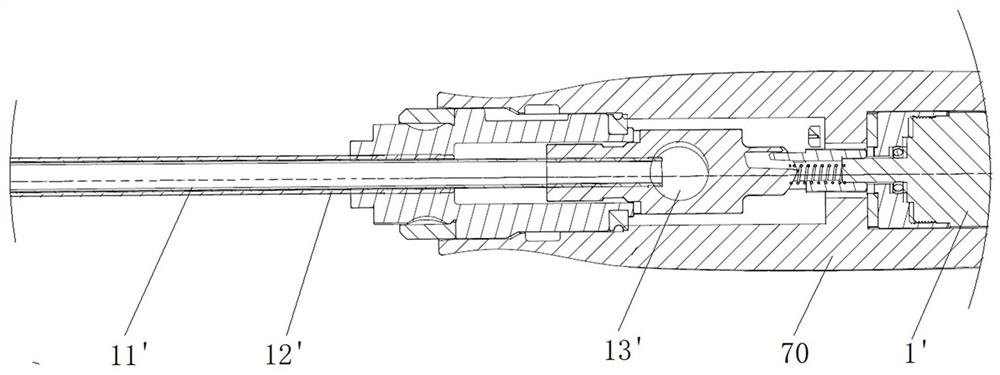

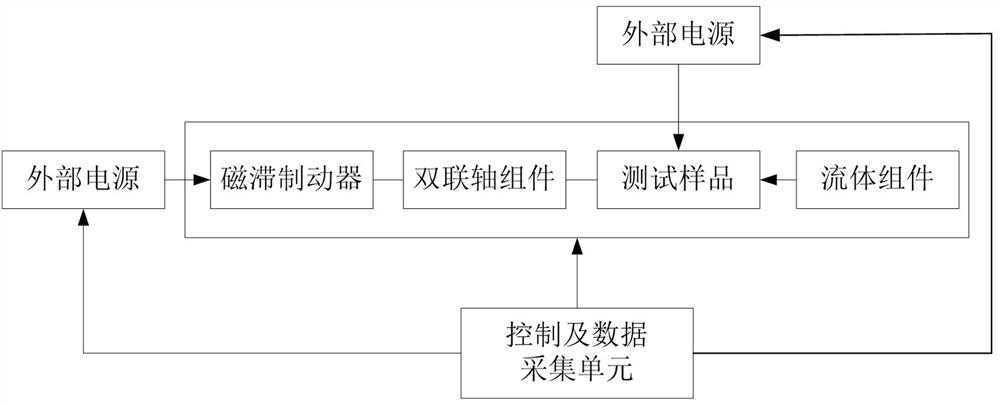

[0047] Considering the use environment of the medical planer and its structural particularity, refer to Figure 4 , in order to truly simulate the load situation of the medical planer and perform an accurate performance test on it, the present embodiment provides a medical planer test system, which includes a performance test unit for supporting the support of the performance test unit components, and control and data acquisition units. Preferably, the performance testing unit may include: a hysteresis brake 10 for providing a simulated load to the test sample 1 , a double coupling structure 20 , and a fluid assembly for temperature rise testing and cooling the test sample 1 . In addition, since the fluid assembly used for temperature rise test and cooling test sample 1 is provided, in order to prevent the fluid from the fluid assembly from splashing to undesired places and causing damage to the equipment, preferably, the testing system of this embodiment may also include a co...

Embodiment 2

[0063] This embodiment provides another preferred medical planer test system, such as Figure 6 Shown as an example. In this embodiment, the same structures as those in Embodiment 1 will not be described again, and the same structures will be represented by the same reference numerals.

[0064] The medical planer testing system provided in this embodiment may also include a performance testing unit, a support assembly, a protective cover 50, a testing rod 60, and a control and data acquisition unit. Preferably, the performance testing unit may include: a hysteresis brake 10 for providing a simulated load to the test sample 1 , a double coupling structure 20 , and a fluid assembly for temperature rise testing and cooling the test sample 1 .

[0065] The difference from Embodiment 1 is that in this embodiment, the second support member 42 which fixedly supports the test sample 1 will be arranged above the bottom plate 43 through a precision fine-tuning platform 45 . The precis...

Embodiment 3

[0068] see Figure 7 , The medical planer testing system provided in this embodiment has substantially the same structure as that of Embodiment 1 and Embodiment 2. Wherein, the support for the test sample 1 is the V-shaped seat 47 and the jaw 48 that cooperate with each other. The cooperation of the V-shaped seat 47 and the clamping jaw 48 can realize fast pick-and-place and fixation of other shaft test samples. Specifically, the V-shaped seat 47 can be widely used for shaft test samples of different sizes and diameters, and the clamping jaws 48 are used to cooperate with the V-shaped seat 47 to quickly clamp, position and fix the test samples. In this way, shaft test samples of different sizes do not need to replace the base according to the size of the test sample, and can be fixed by adjusting the adjustable screw on the jaw 48, which saves cost.

[0069] Those skilled in the art can also understand that the dual-coupling structure 20 used to realize the coaxial connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com