A transplanter test bench based on machine vision

A machine vision and transplanting machine technology, applied in the field of agricultural machinery, can solve problems such as low work efficiency, large influence of external factors, and high labor intensity, and achieve the effects of high work efficiency, low cost, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

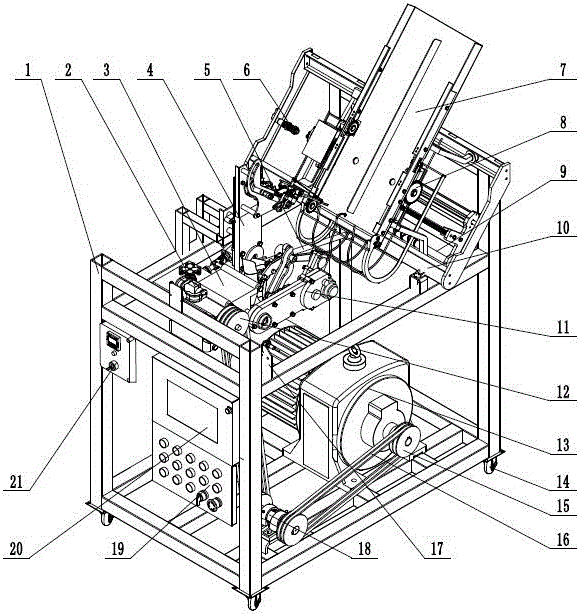

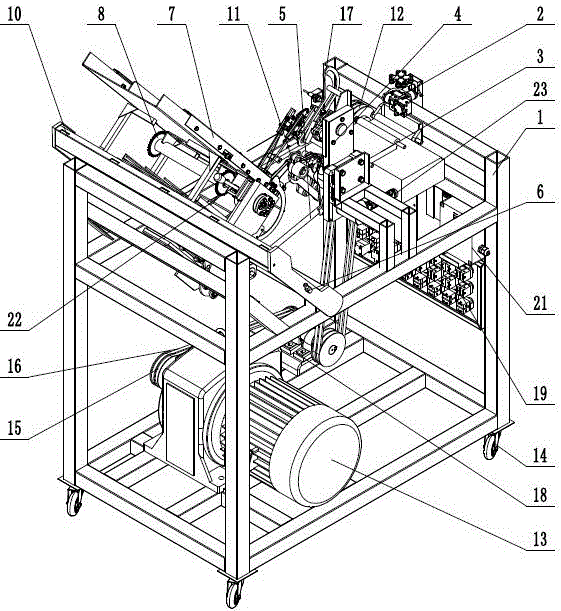

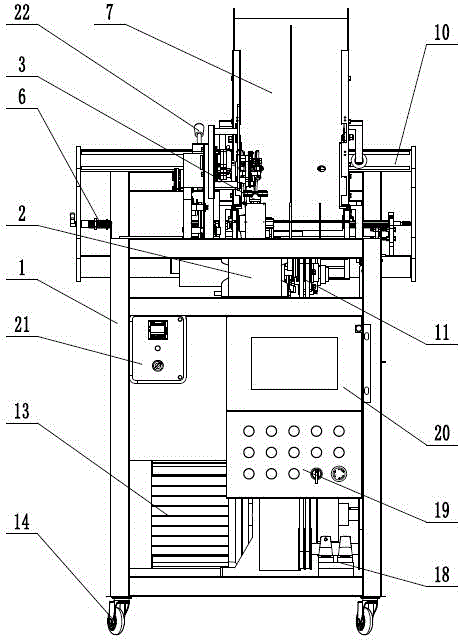

[0015]Embodiment 1: with reference to accompanying drawing, a kind of transplanting machine test bench based on machine vision comprises frame, transmission mechanism, detection device, seedling-taking mechanism 4, seedling delivery mechanism and planting mechanism 11, is characterized in that transmission mechanism is located at At the bottom of the frame, the detection device is located at the front of the frame and on both sides of the frame, the seedling-taking mechanism 4 is located at the middle position of the frame top, the seedling delivery mechanism is located at the rear side of the frame, and the planting mechanism 11 is located at the middle position of the frame top. In the middle part of frame; Described frame comprises transplanting machine test bench frame 1 and universal traveling wheel 14, and above-mentioned universal traveling wheel 14 is installed on the bottom of transplanting machine test bench frame 1, convenient to move The movement of the machine test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com