Evaporator and condenser performance joint test device

A combined test and condenser technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of inconvenient testing process, affecting product development progress, long waiting time for testing, etc., to improve testing safety, The test process is fast and the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Various modifications, replacements and changes made by technical knowledge and conventional means are included in the scope of the present invention.

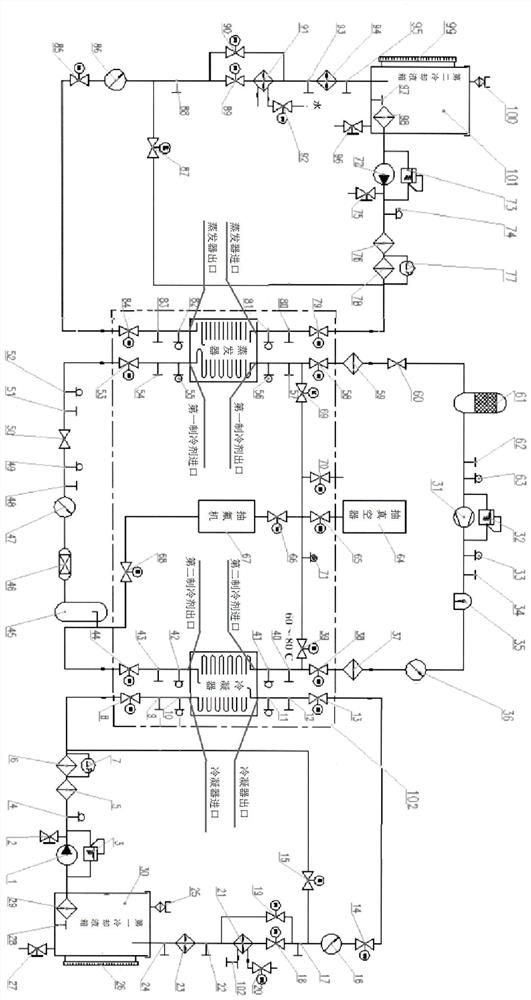

[0048] Such as figure 1 Shown is the combined test device for the performance of the evaporator and condenser in this embodiment, including the environmental chamber, evaporation system, condensation system, and refrigerant system. When the device is in normal operation, the working process of each system can be referred to figure 1 and the following test procedure. Five bypass pipelines are arranged in the performance combined testing device of the present invention, and the effect of each bypass pipeline is respectively:

[0049] The function of the first bypass line:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com