Automobile tensioner assembly performance testing mechanism and working method thereof

A technology of testing mechanism and tensioner, which is applied in vehicle testing, machine/structural component testing, mechanical component testing, etc. It can solve problems such as high labor intensity, low work efficiency, and potential safety hazards, and achieve a high degree of automation , easy to operate, and a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0016] Example.

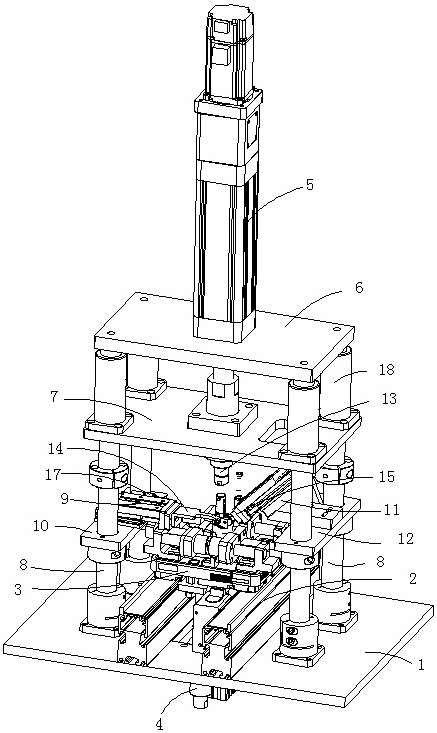

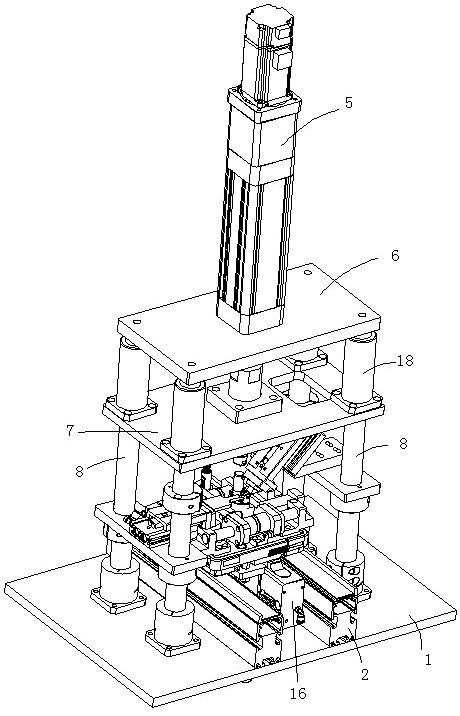

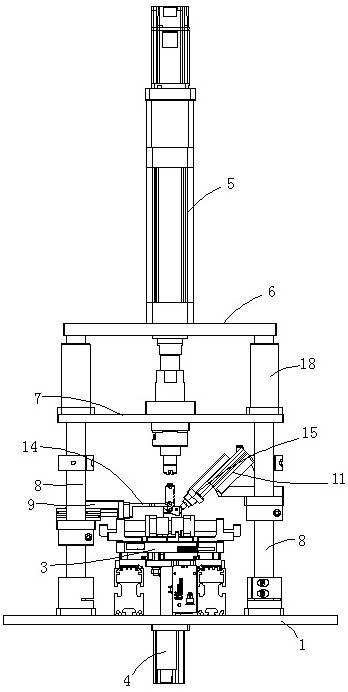

[0017] see Figure 1 to Figure 3 In this embodiment, the automobile tensioner overall stroke performance testing mechanism includes a base plate 1, an output line 2, a tray mechanism 3, a jacking mechanism 4, a servo electric cylinder 5, an electric cylinder fixing plate 6, a pressure head fixing plate 7, and a guide post 8 , cylinder one 9, cylinder mounting plate one 10, cylinder two 11 and cylinder mounting plate two 12, force measuring pressure head piece 13, hanging member 14 and top ratchet mechanism 15; output line 2 is installed on the bottom plate 1, tray mechanism 3 The activity is set on the output line 2, the jacking mechanism 4 is connected with the tray mechanism 3, the servo electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com