A method for measuring anchorage performance

An anchoring performance and bolt technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of not being able to obtain the displacement curve and the indentation amount, etc., to improve scientific rationality, simple measurement, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

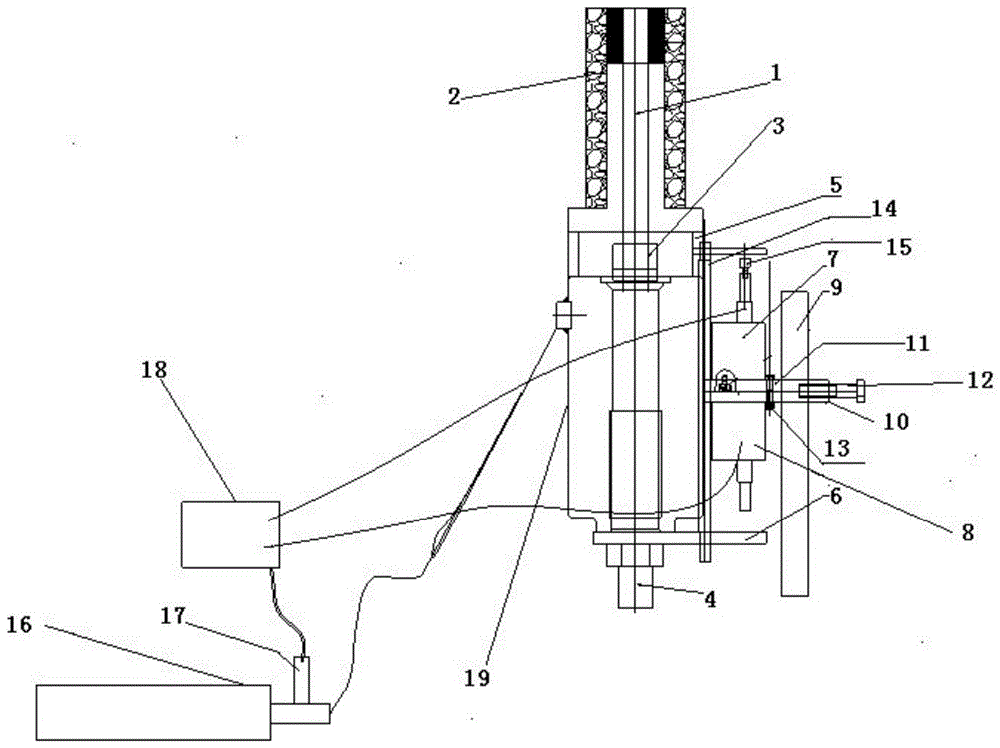

[0024] Such as figure 1 Shown, the present invention provides a kind of method for measuring anchor performance, comprises the following steps:

[0025] Step 1, a bolt is anchored on the surrounding rock of the coal and rock mass roadway, and the force applying device in the anchorage performance testing device is affixed to the bolt for applying a pulling force to the bolt;

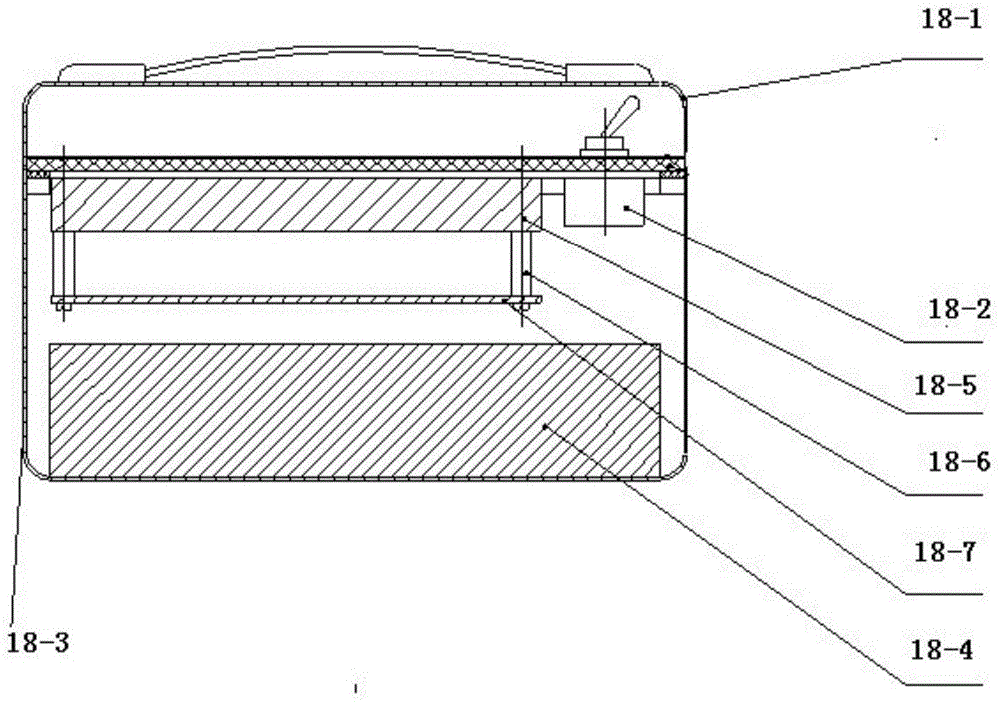

[0026] Step 2: Set the detection device in the anchoring performance testing device on one side of the force applying device, the detection device includes a supporting first rod body, measures the displacement and is fixed on the first rod body The first displacement sensor and the second displacement sensor, the first rod body is arranged in such a way that its longitudinal axis is parallel to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com