Process for manufacturing outer conductor in coaxial cable production process and special lubricating oil device thereof

A production process and production process technology, applied in the direction of cable/conductor manufacturing, coaxial cable, circuit, etc., can solve the problems of echo performance degradation, deterioration, and inability to provide high-quality signal transmission, etc., to achieve friction elimination and improve pressure. Improvement effect of marks and surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

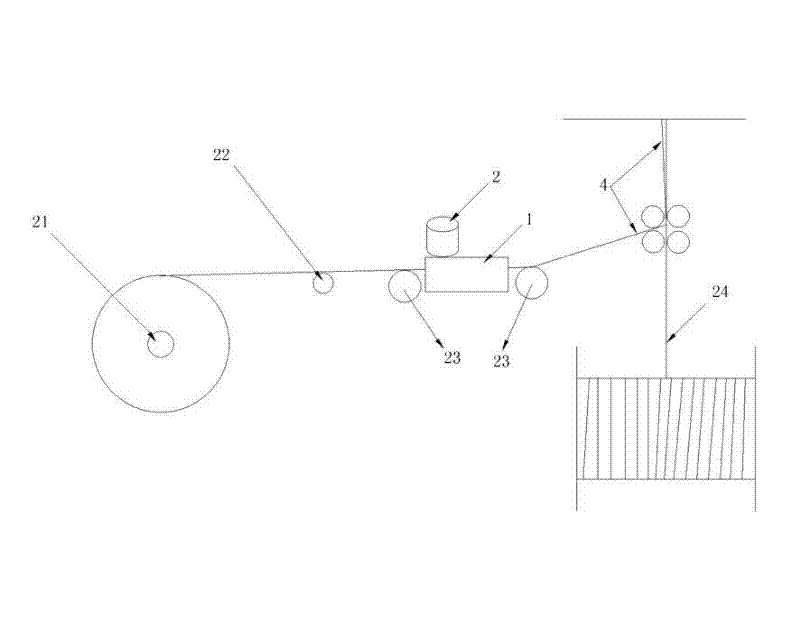

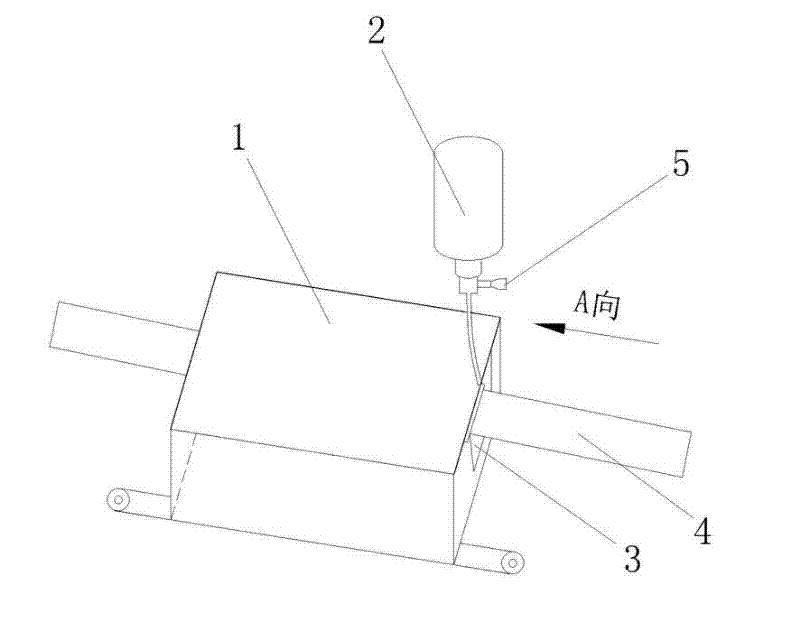

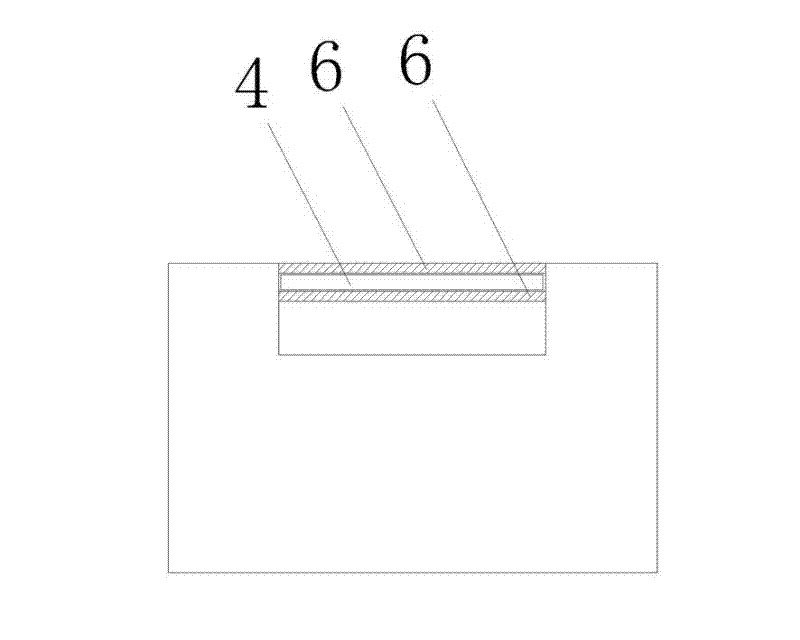

[0019] Embodiment 1: a kind of outer conductor manufacturing process in the production process of coaxial cable, described outer conductor is made up of aluminum foil shielding layer and braiding layer, and described outer conductor manufacturing process comprises the following steps in sequence: (1), aluminum foil longitudinal wrapping , Refueling: After the aluminum foil 4 in the aluminum foil pay-off reel 21 is released horizontally, it passes through the aluminum foil broken belt alarm 22 and enters the lubricating oil device for refueling. oil, the grade is ISO VG 100, the amount of lubricating oil added is 5 grams per kilometer, and the aluminum foil coated with the above lubricating oil comes out of the lubricating oil device and is drawn out by the guide wheel 23, and is gradually wrapped longitudinally into the prepared core On the line 24; (2), alloy wire weaving: after the aluminum foil longitudinal wrapping is finalized, after the exit of the weaving mold, the alloy...

Embodiment 2

[0020] Embodiment 2: the add-on of lubricating oil is 8 grams / every kilometer, other is with embodiment 1;

Embodiment 3

[0021] Embodiment 3: the add-on of lubricating oil is 10 grams / every kilometer, other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com