Patents

Literature

31results about How to "Easy to creasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

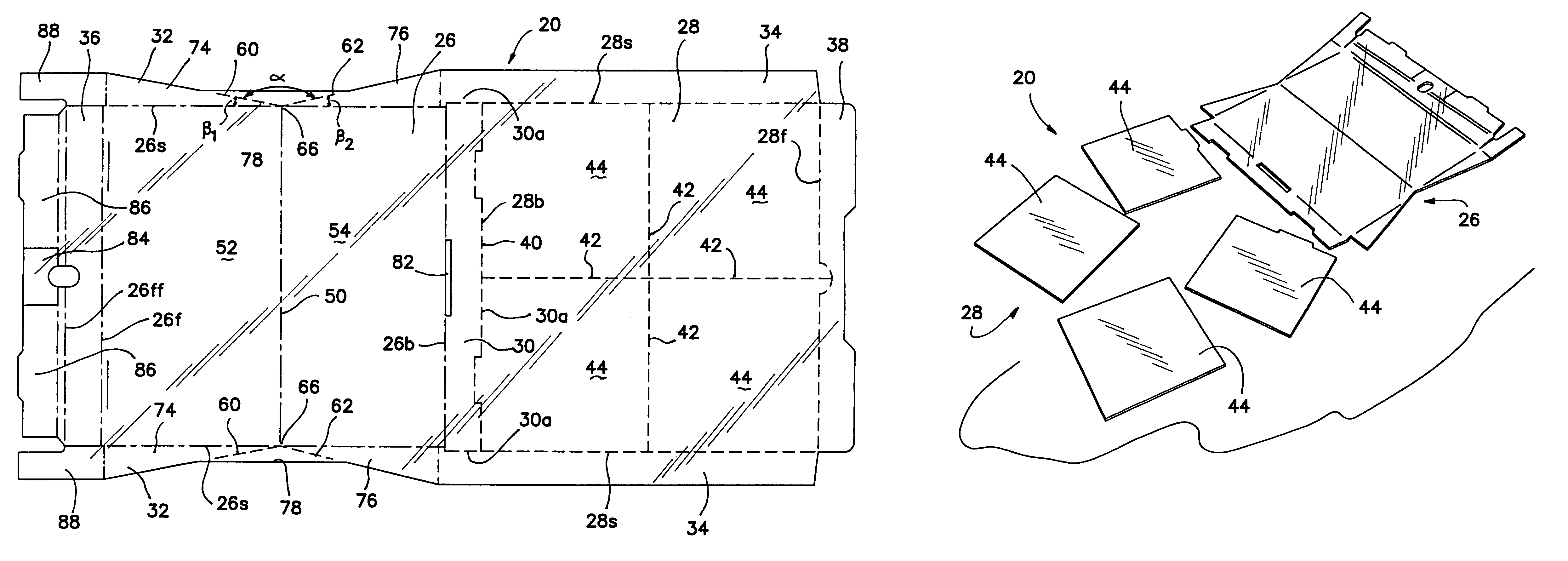

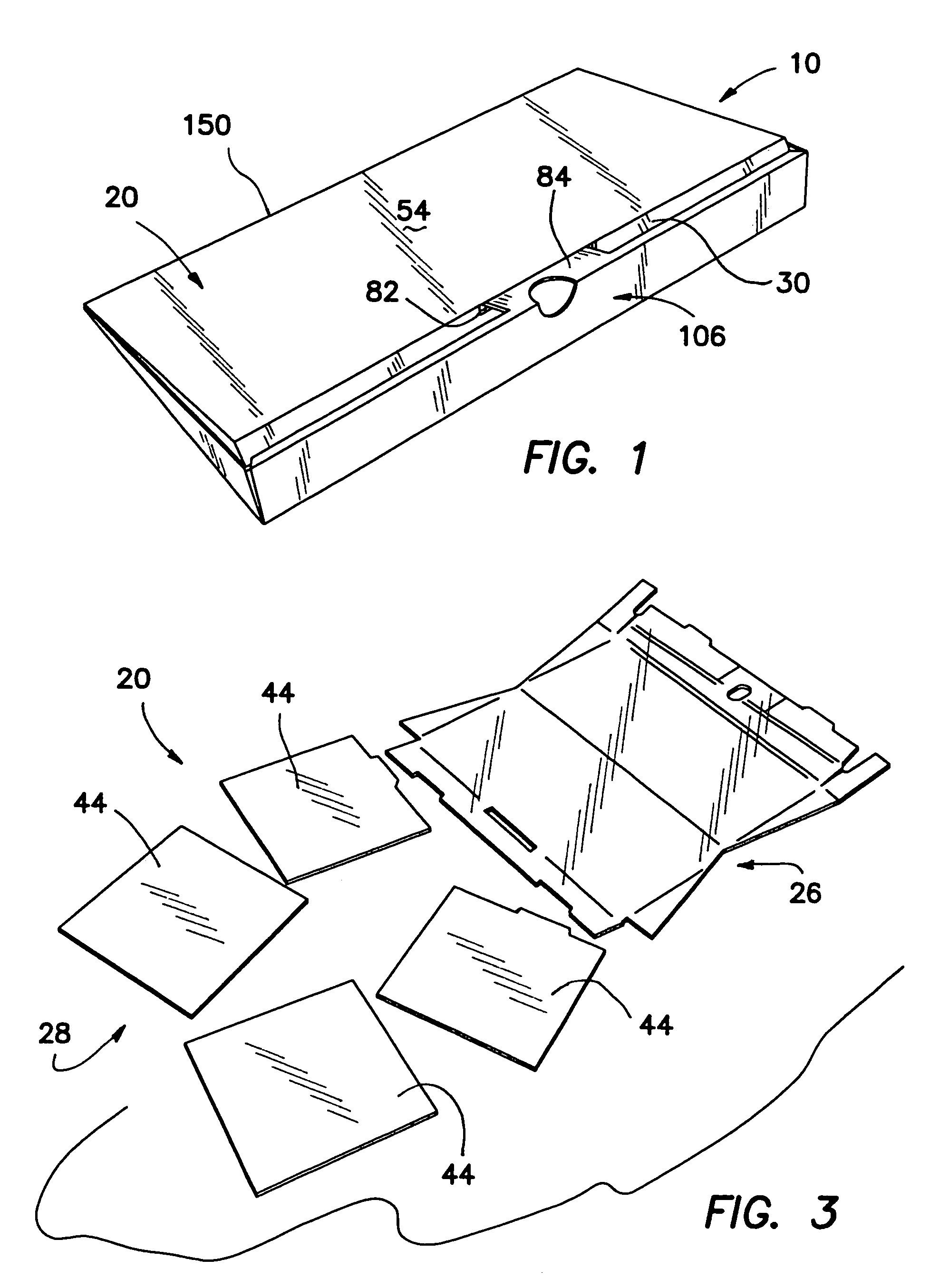

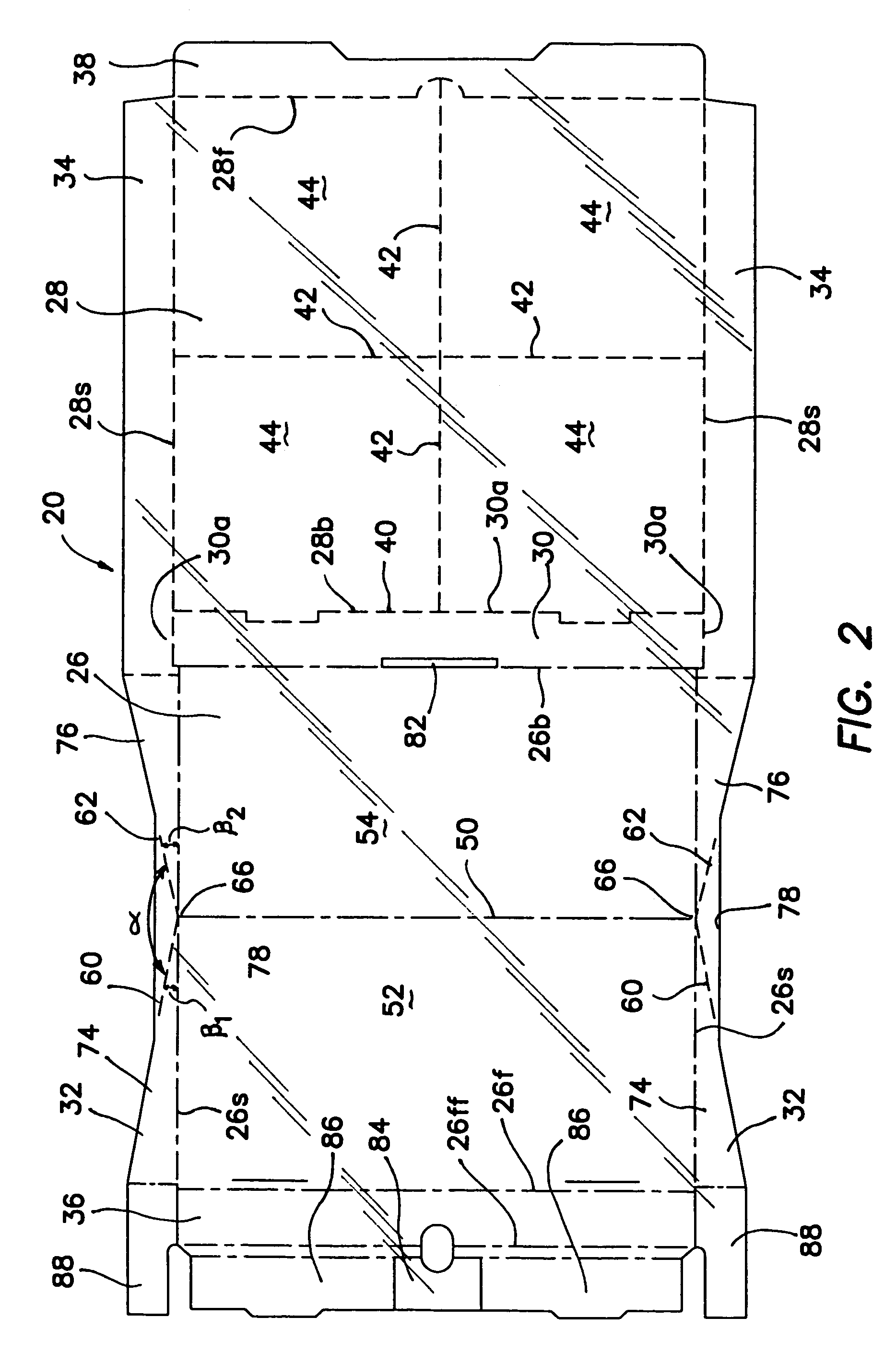

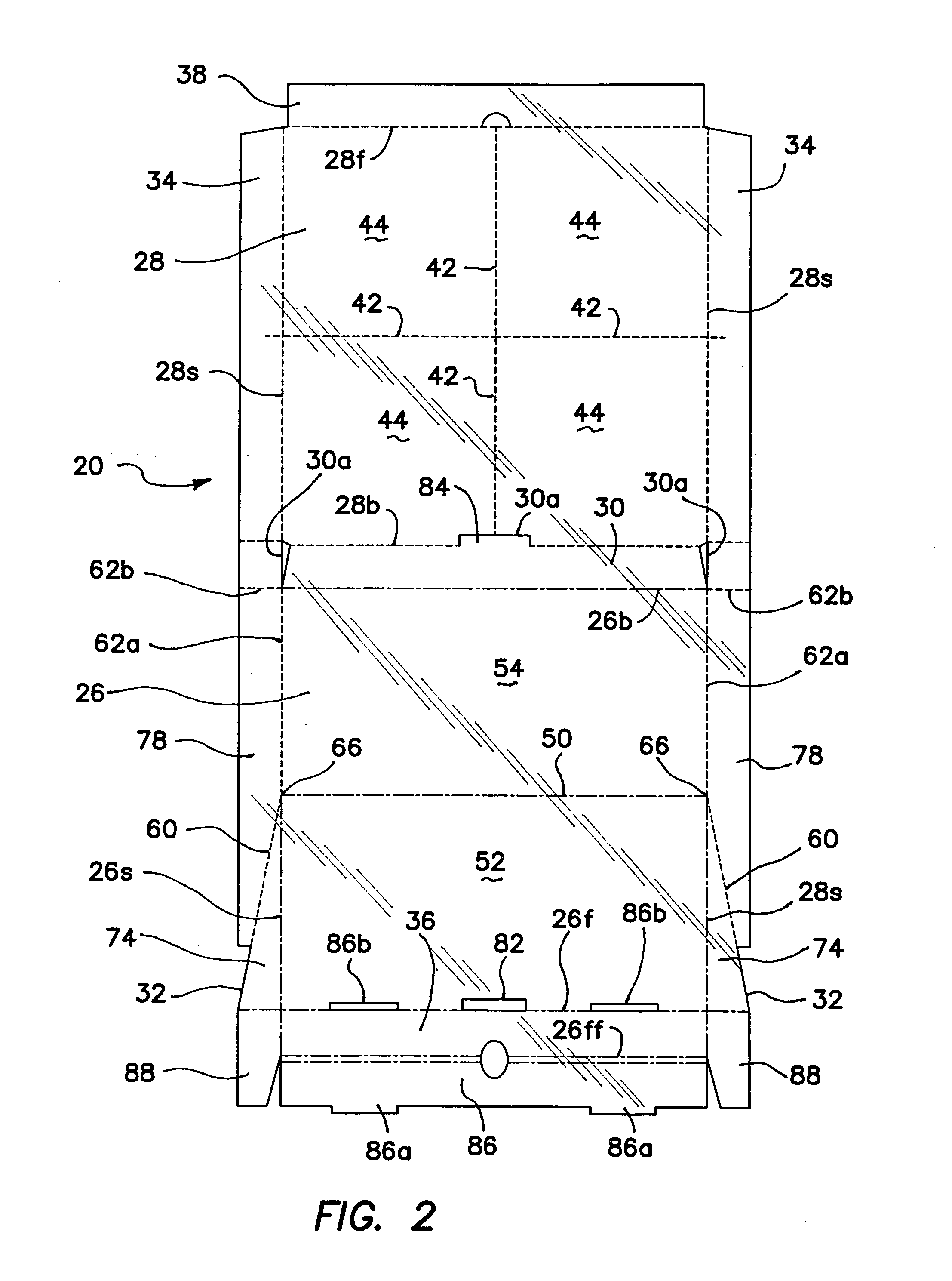

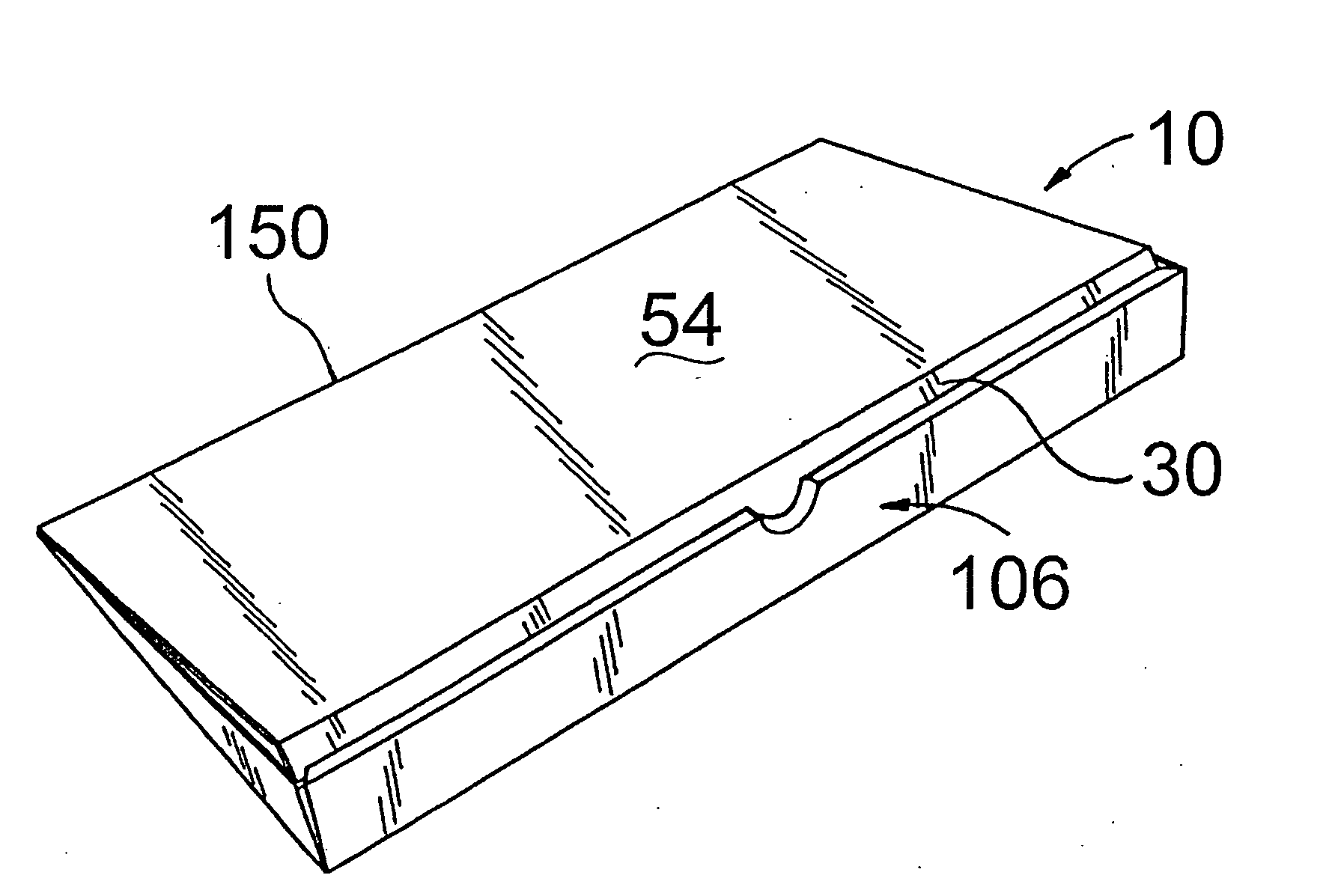

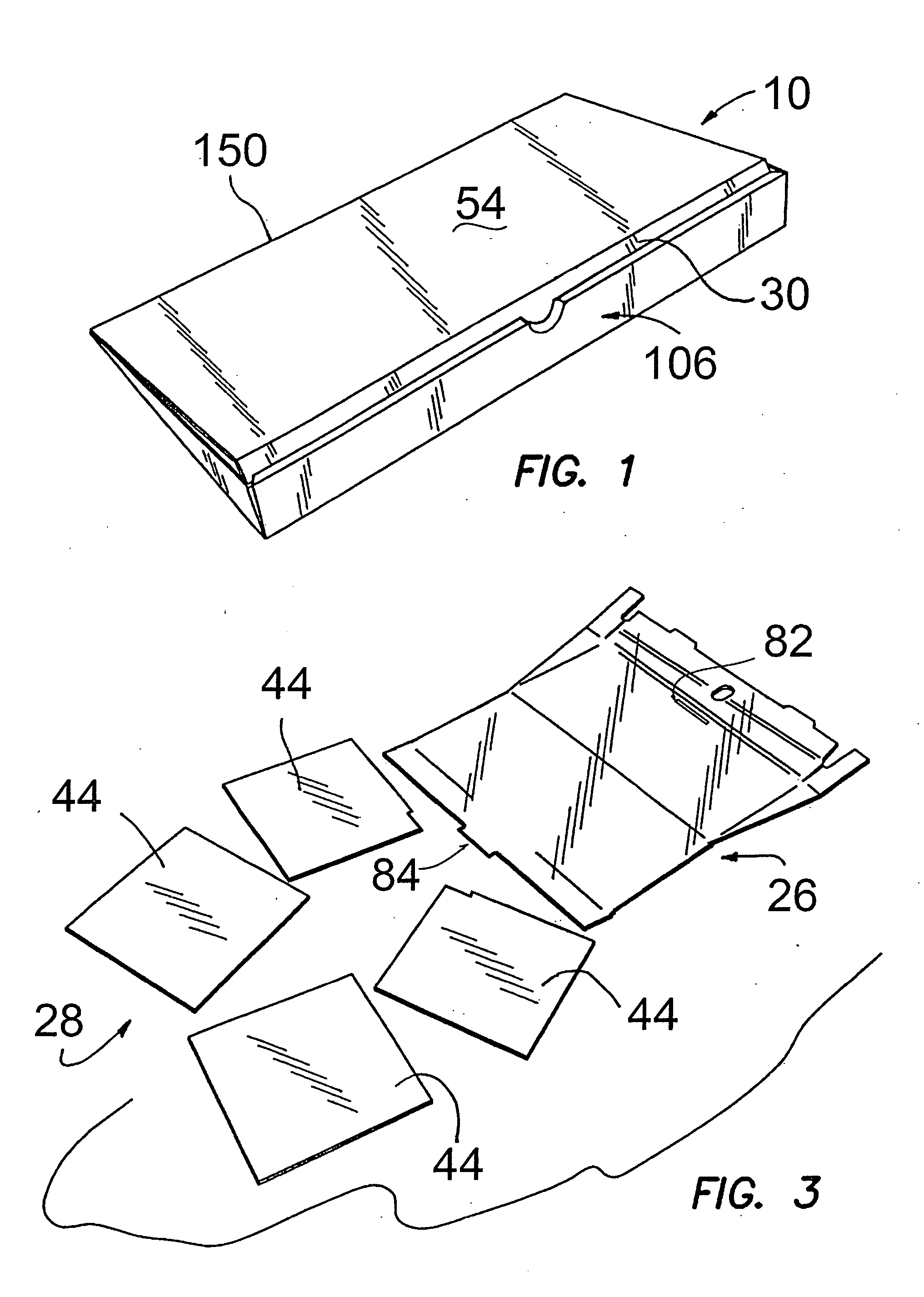

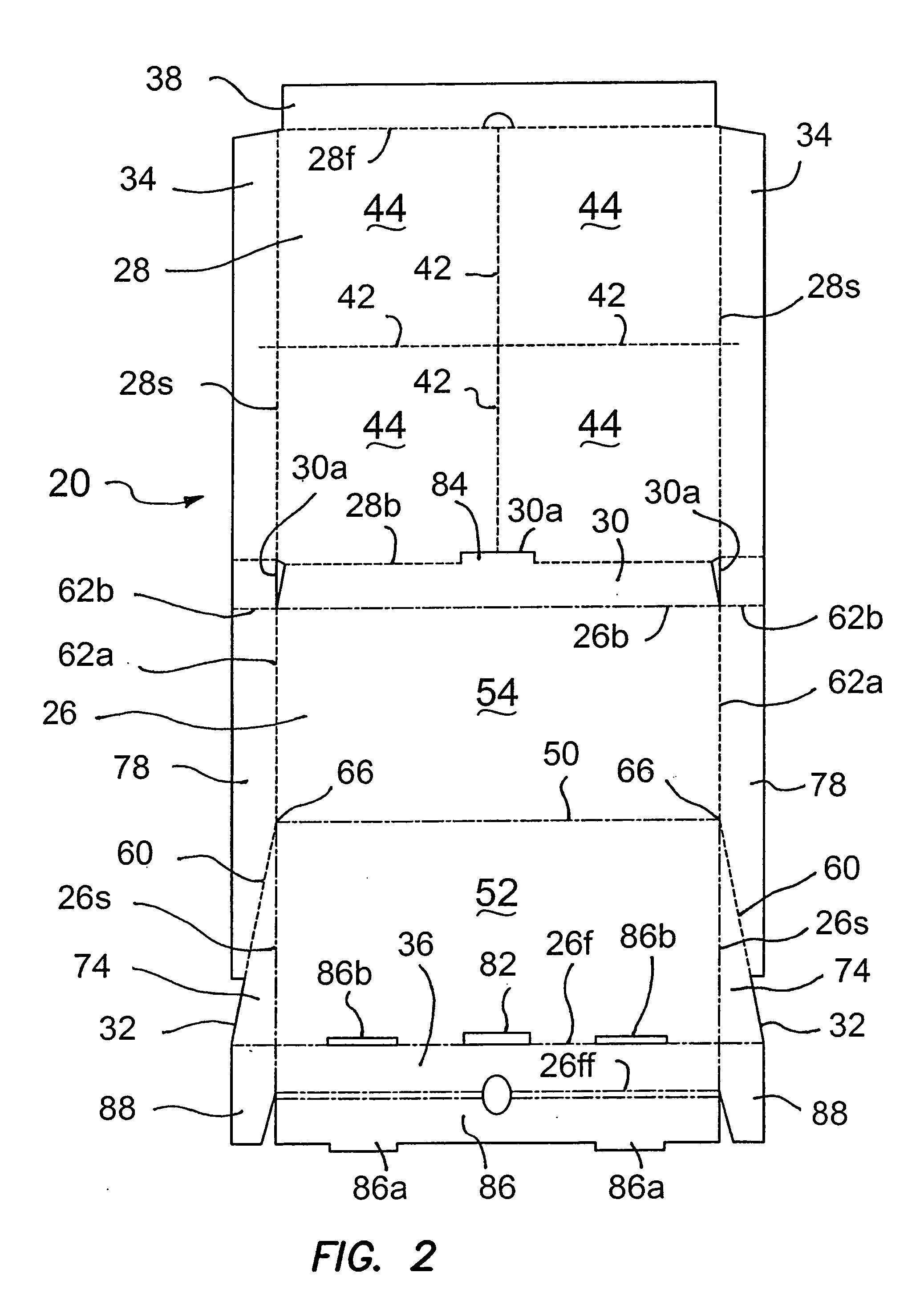

Convertible pizza box

ActiveUS7051919B1Facilitates reformingEasy to carryRigid containersInternal fittingsPaperboardEngineering

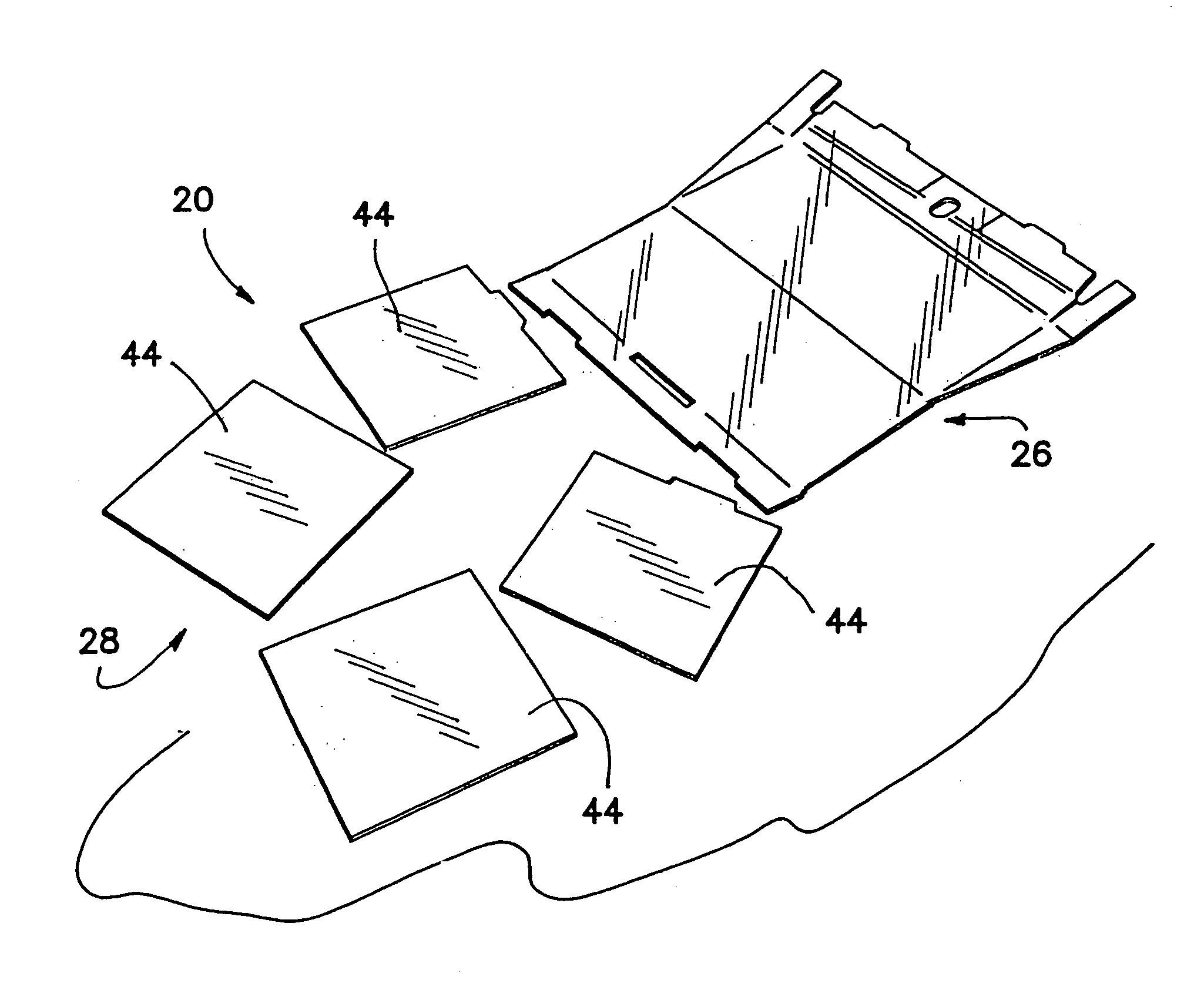

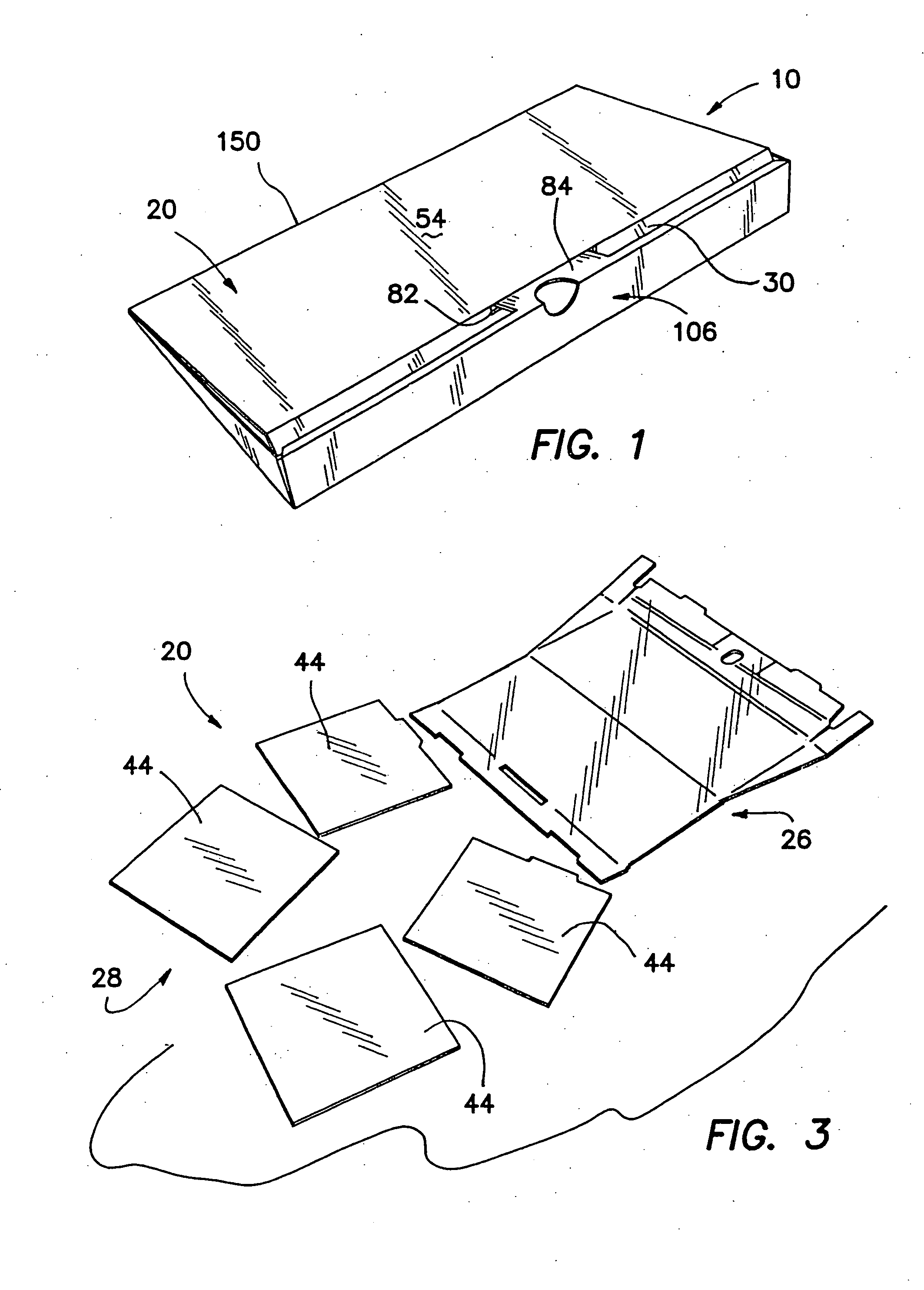

A space saving box and a box useful for pizza and other relatively flat food products is provided. The box generally includes a one piece cardboard or paperboard blank having a first portion hingedly connected to a second portion. The blank is structured to include various score lines such that first and second portions are formable into a full sized pizza box. In addition, the blank is structured such that, when separated from the second portion, the first portion is formable into a reduced sized, space saving box having a tapering depth, for facilitating storage of leftover pizza slices, for example.

Owner:PRATT CORRUGATED HLDG

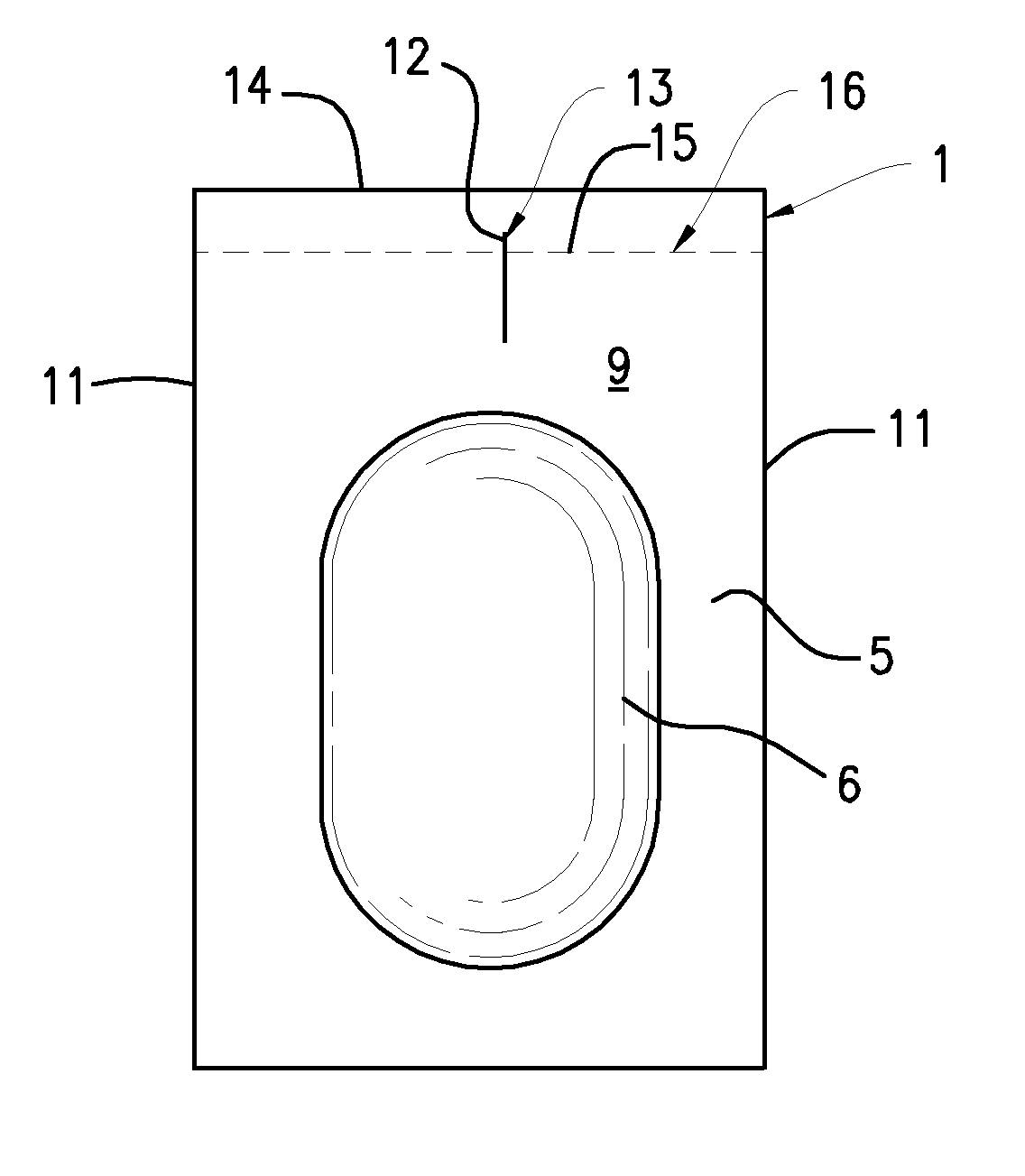

Film container

ActiveUS7866474B2Easy to creasingEasy to carrySmall article dispensingFlexible coversThin membraneStructural engineering

Owner:BOEHRINGER INGELHEIM INT GMBH

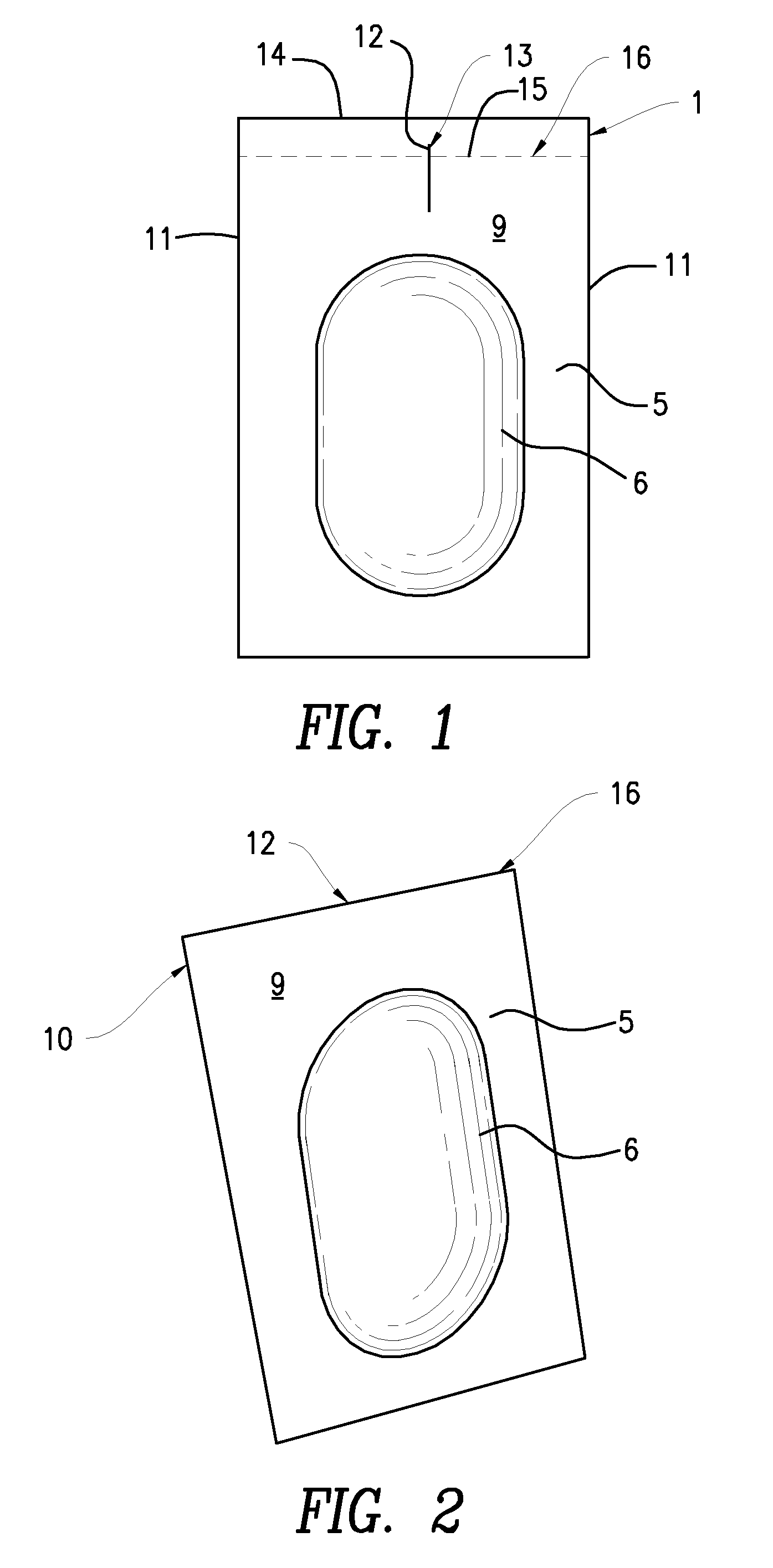

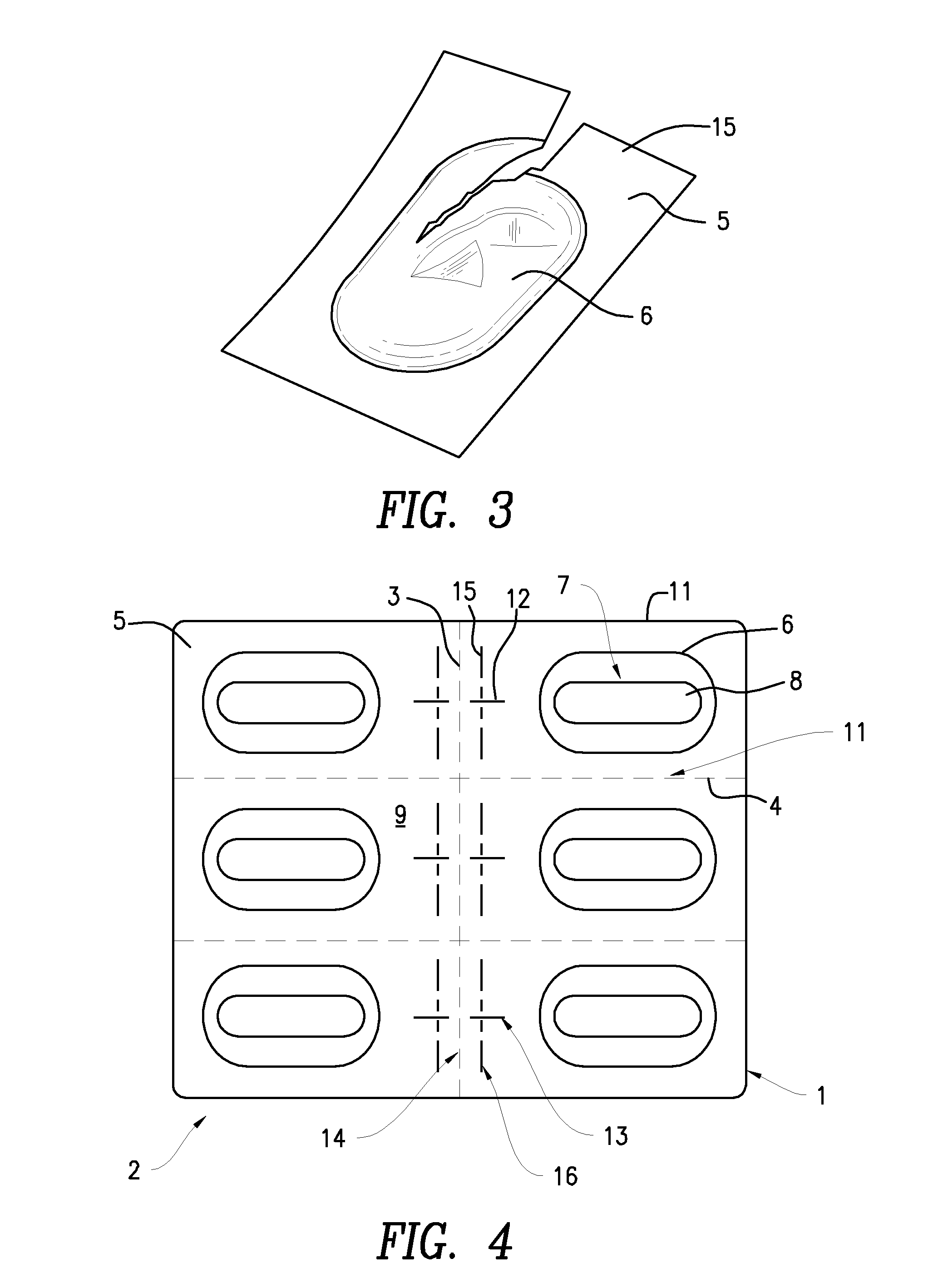

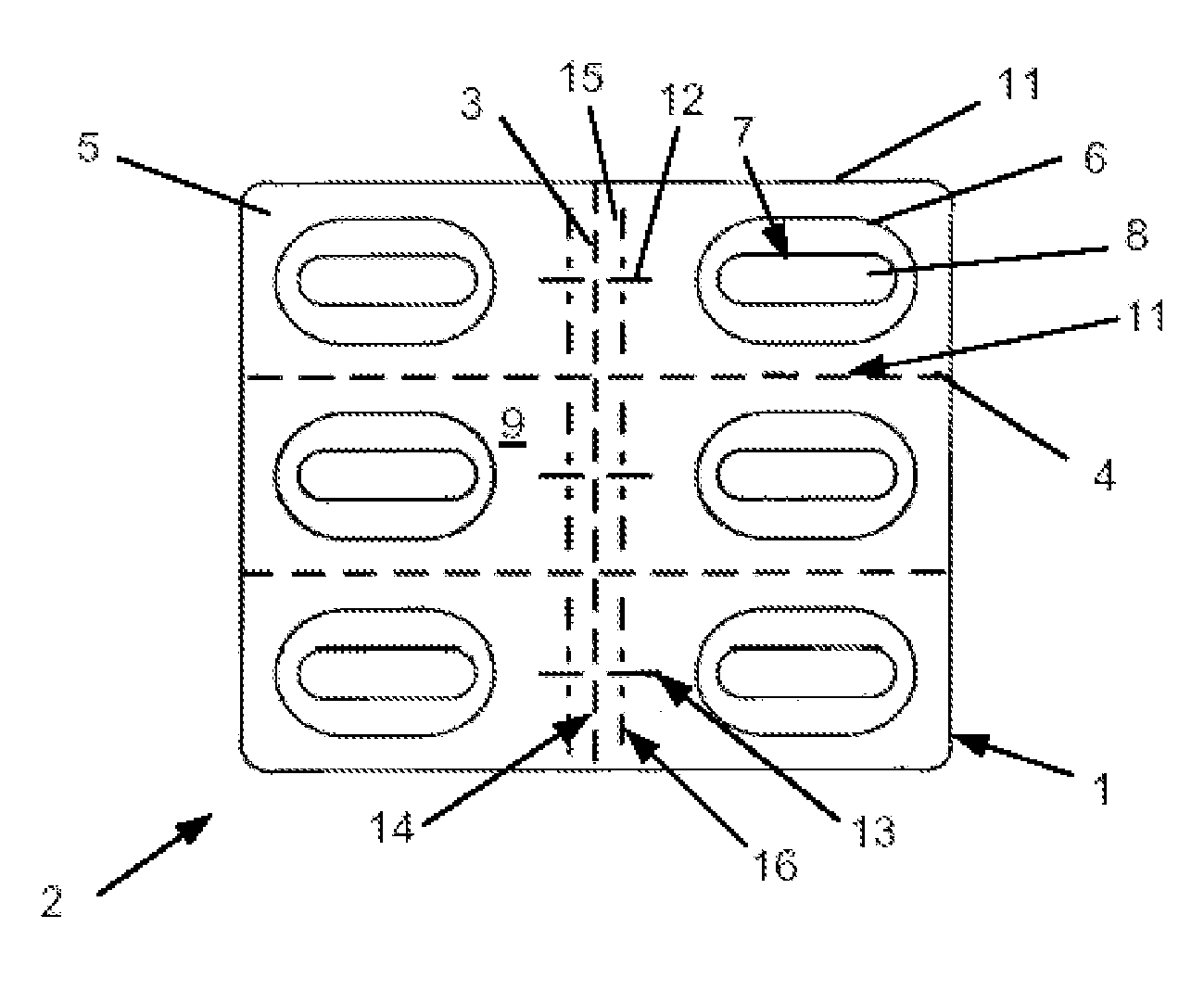

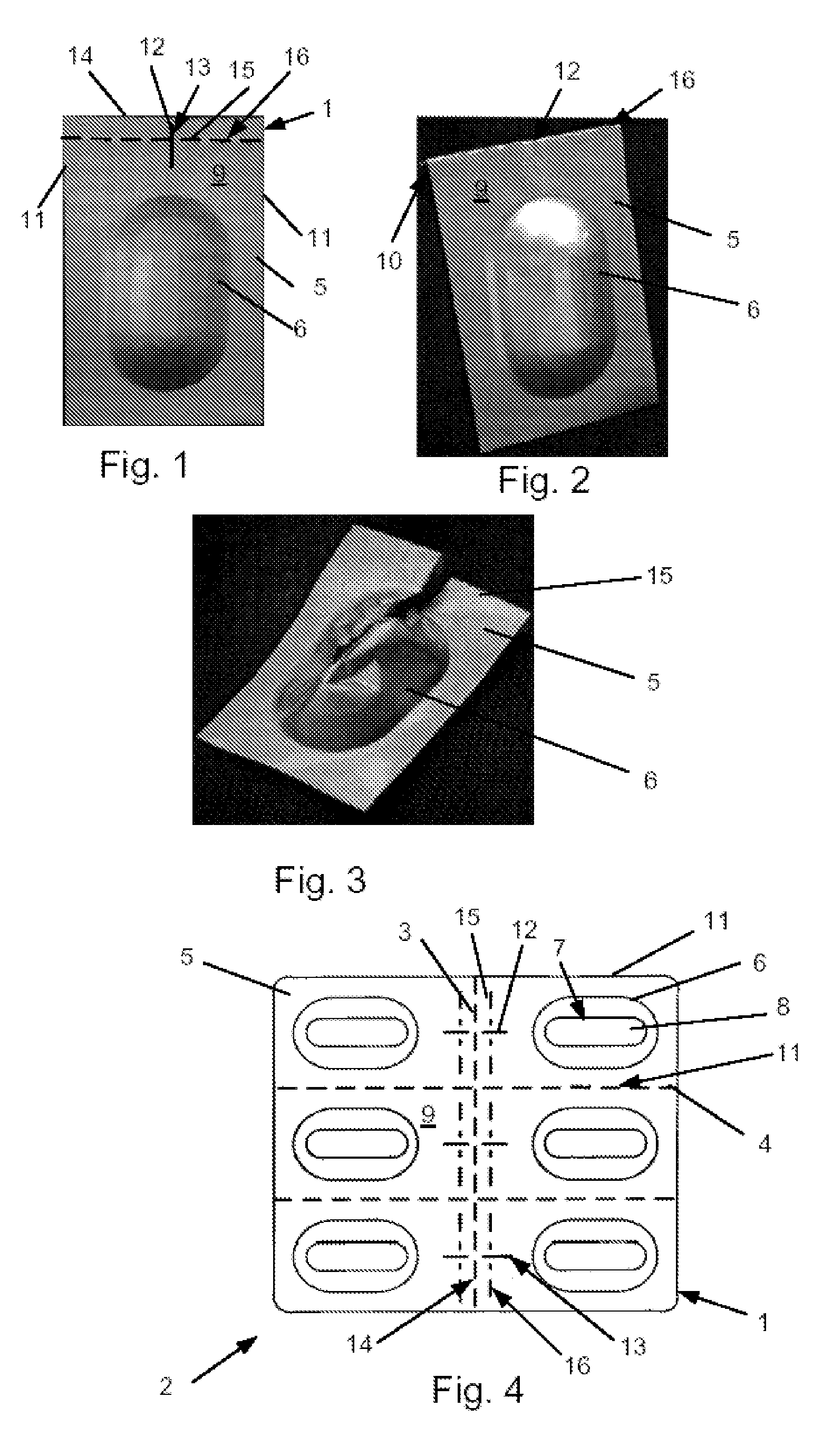

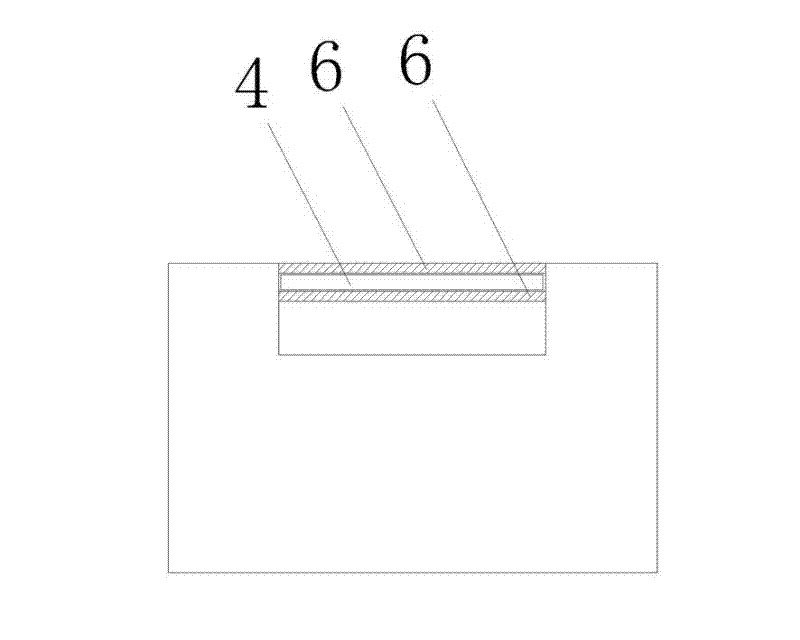

Film container

ActiveUS20060131204A1Low production costEasy and inexpensive to produceSmall article dispensingFlexible coversThin membraneStructural engineering

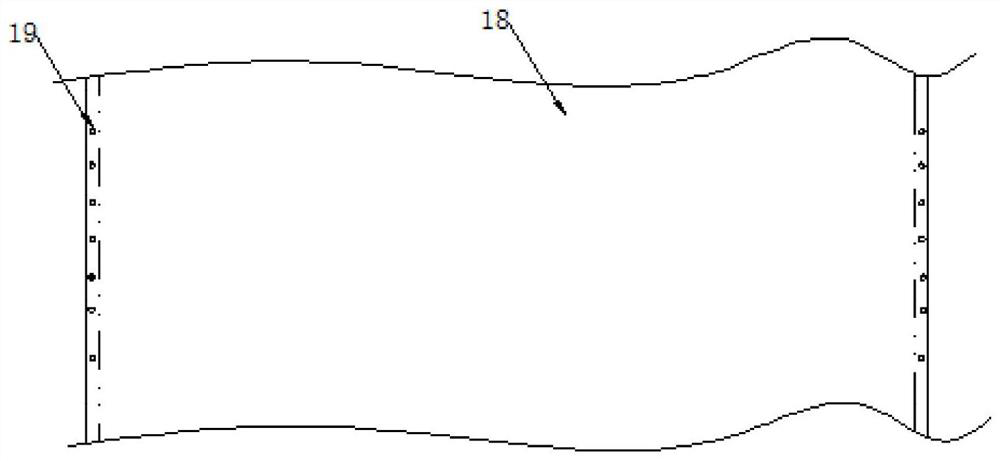

A film container (FIG. 4) comprises two rectangular films (5) joined together at their periphery to form a receiving chamber (6) for a filling (7), particularly a pharmaceutical formulation of an active substance, at least one of said films (5) being provided, for the purpose of tearing it open, with a marking (13) formed within the connecting region, which is exposed after the films (5) have been bent. The marking (13) extends centrally between two opposing outer edges (11) of the film container (1).

Owner:BOEHRINGER INGELHEIM INT GMBH

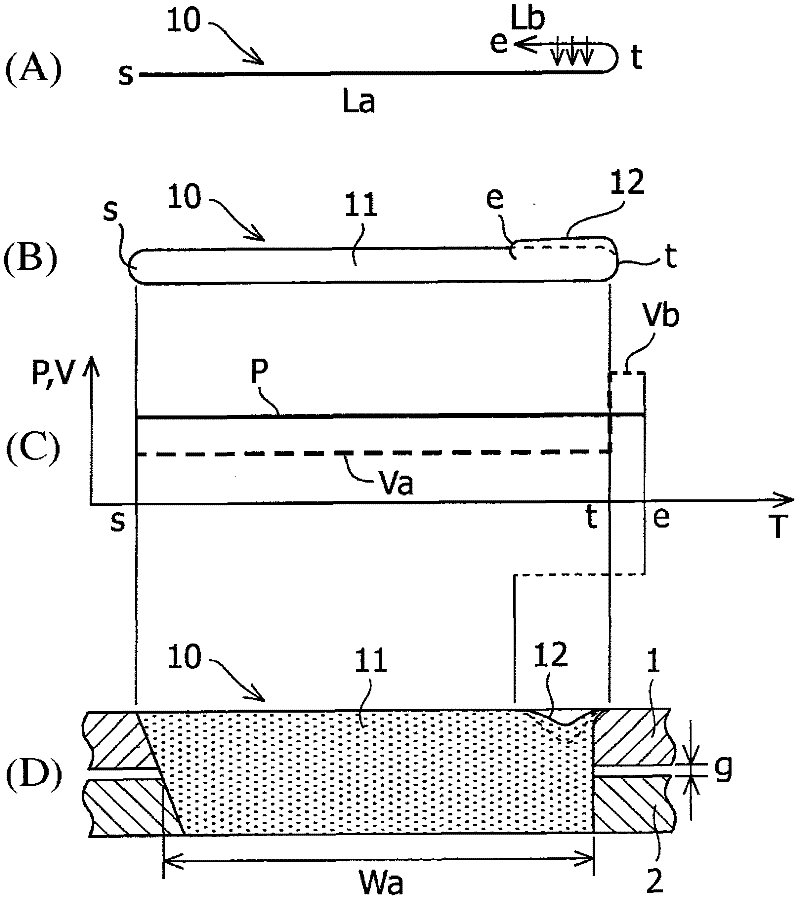

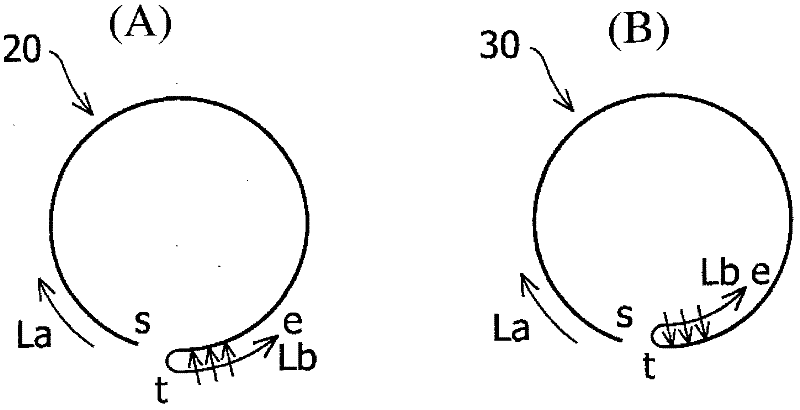

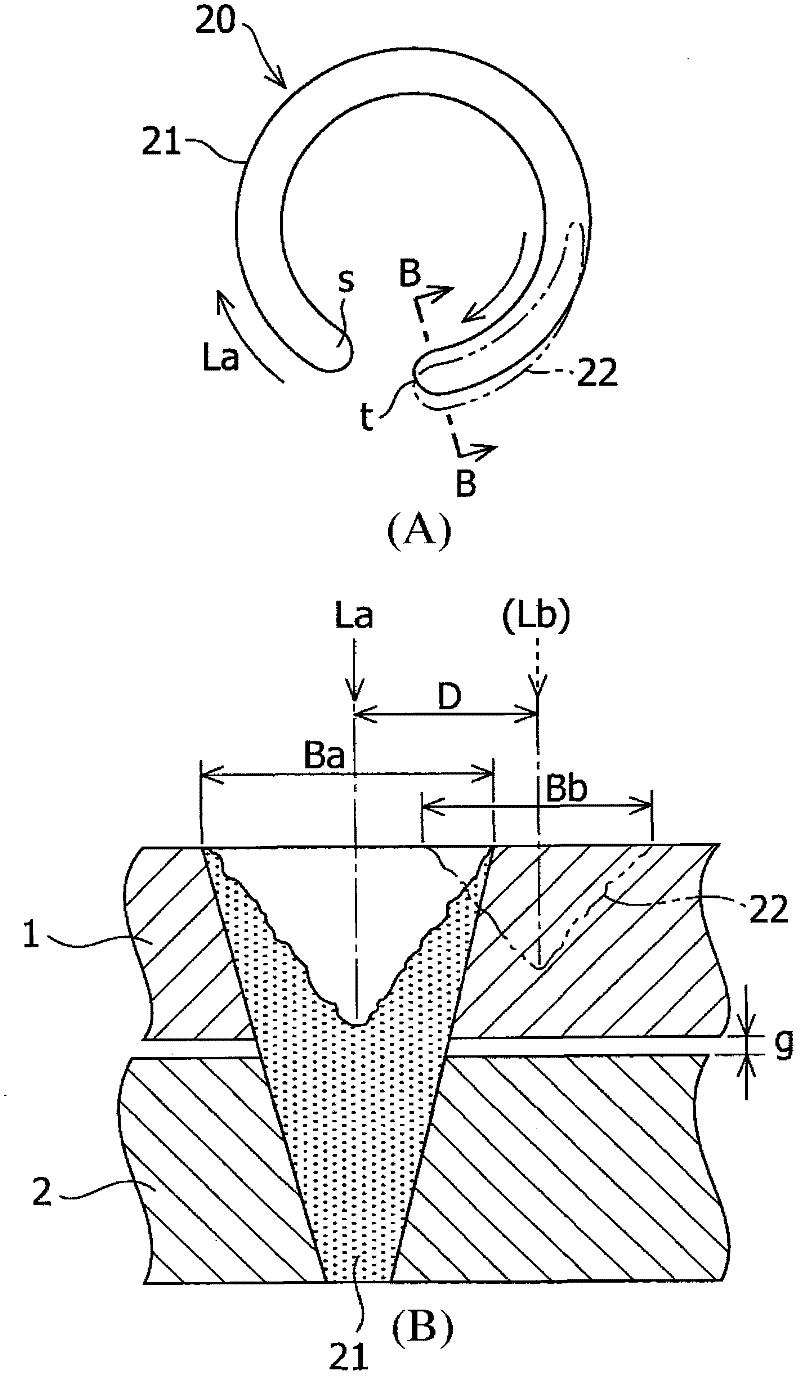

Laser lap welding method

InactiveCN102528284AQuality improvementEasy piercingVehicle componentsWelding/soldering/cutting articlesLaser scanningIrradiation laser

A laser lap welding method by irradiating of a laser beam from one side of a plurality of overlapped workpieces (1, 2), the method includes the steps of: scanning (La) the laser beam in the forward direction along a predetermined section of the workpieces; reversing the scanning direction of the laser beam at a terminating end (t) of the predetermined section; scanning (Lb) the laser beam in the backward direction and terminating of the irradiating of the laser beam onto the predetermined section, wherein the scanning of the laser beam in the backward direction is offset from the scanning of the laser beam in the forward direction such that a part of weld bead (12) formed by the laser scanning in the backward direction overlaps the weld bead (11) formed by the laser scan in the forward direction.

Owner:SUZUKI MOTOR CORP

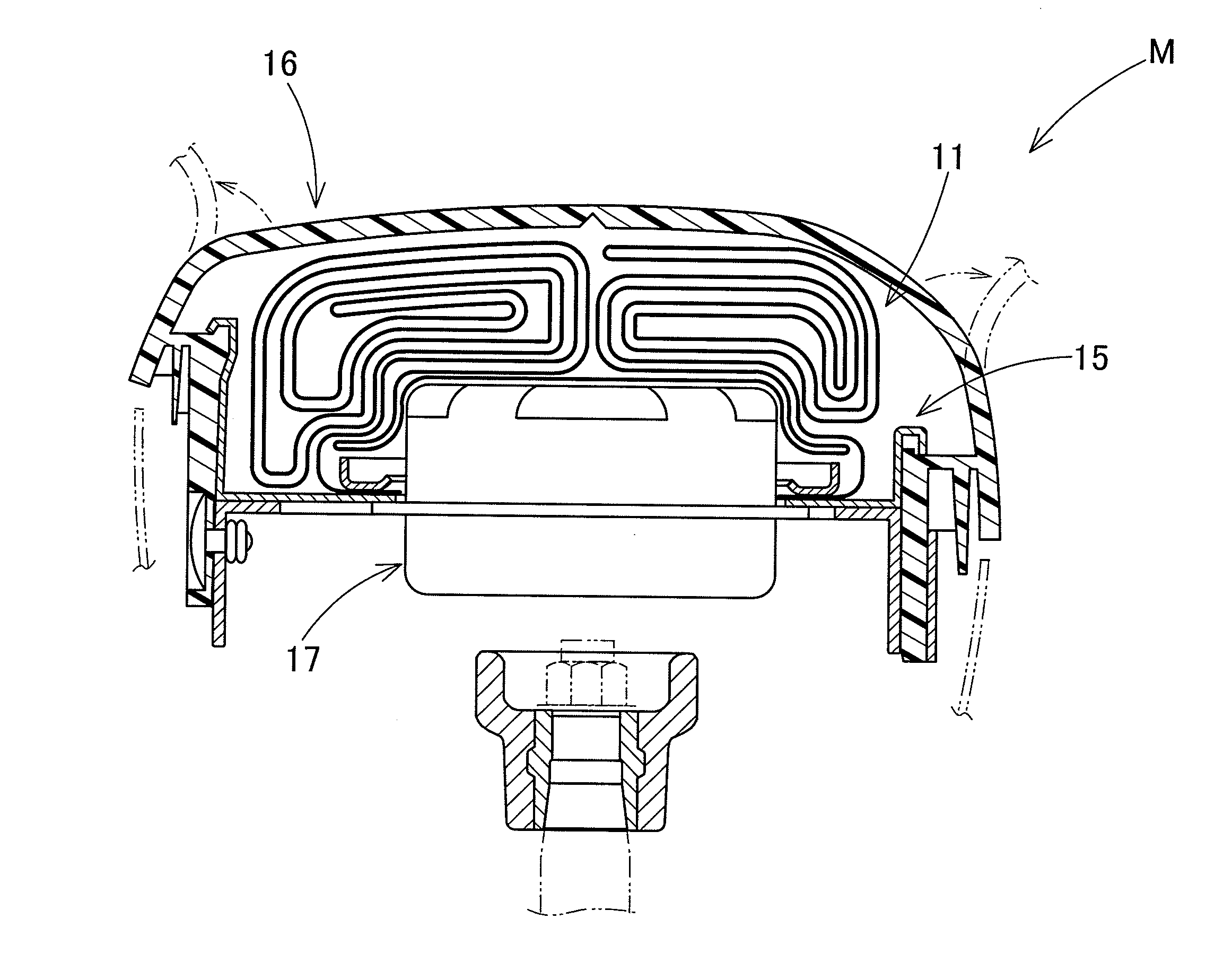

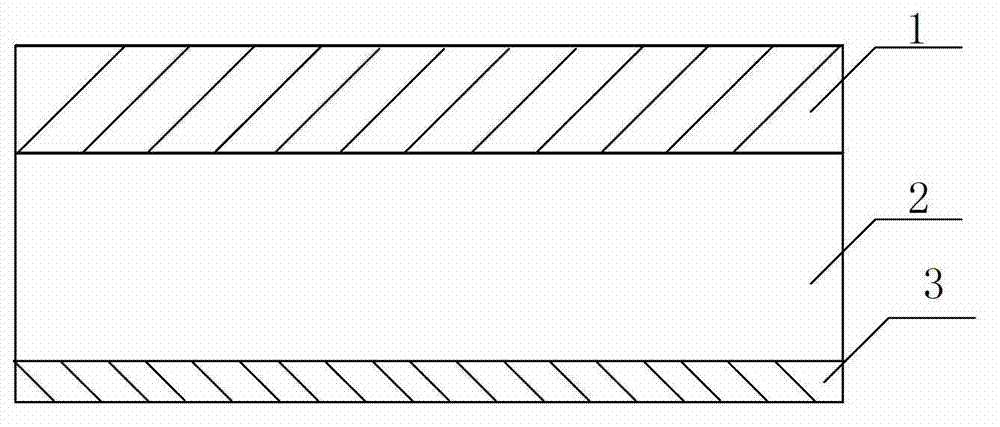

Coating material for airbag base fabric, and airbag base fabric

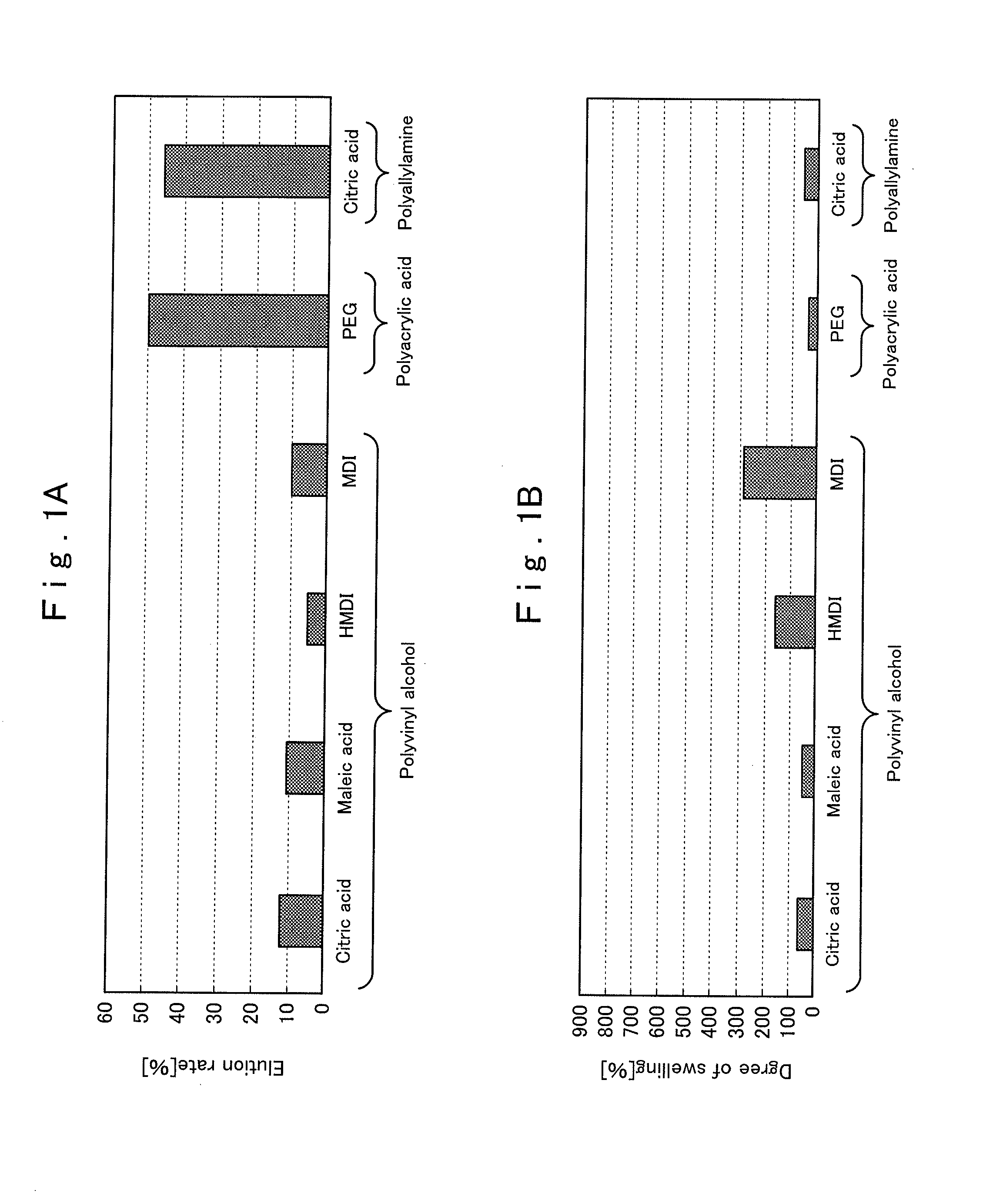

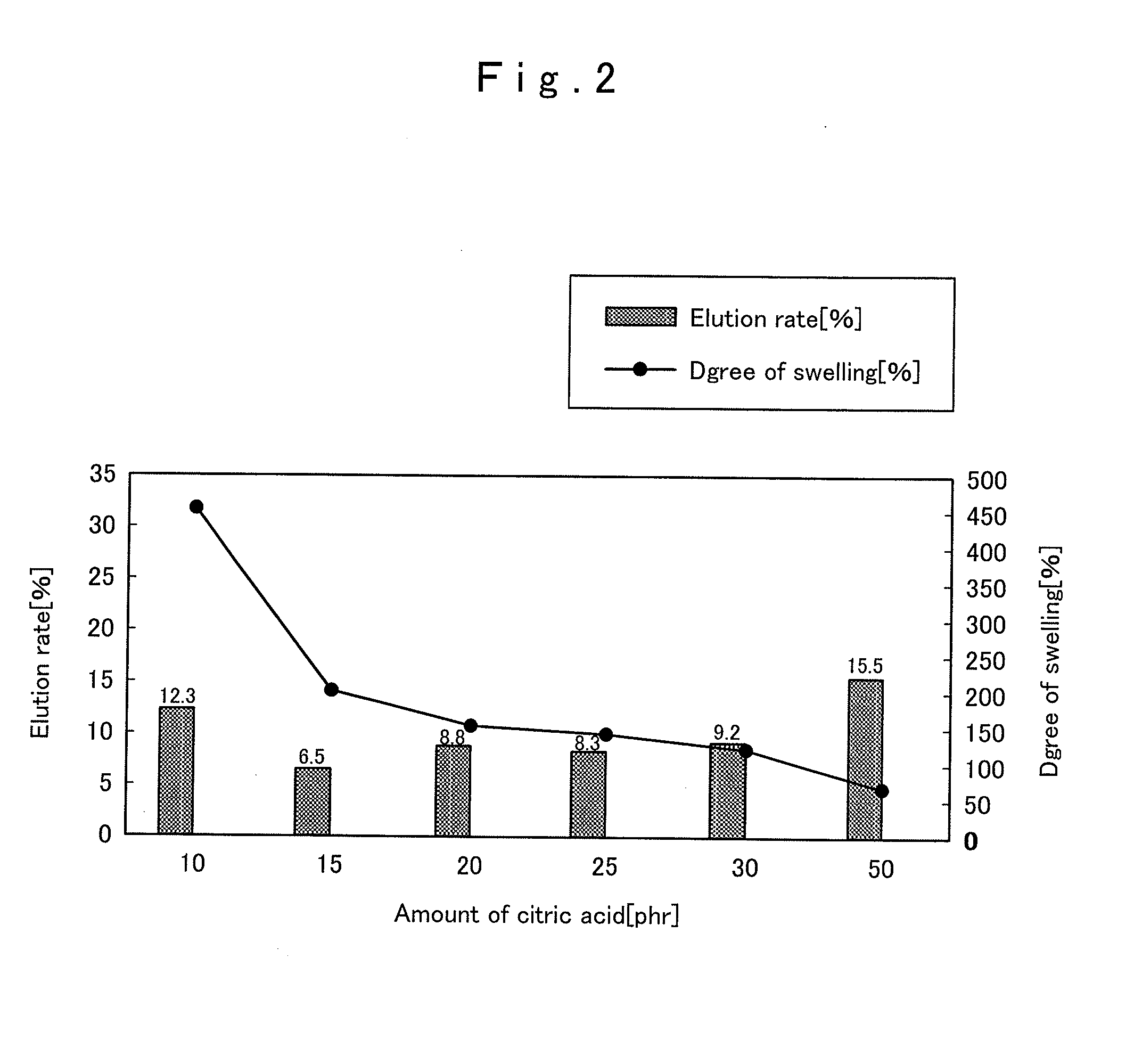

InactiveUS20140113516A1Increase flexibilityImprove the heating effectPedestrian/occupant safety arrangementFibre treatmentCross-linkPolyvinyl alcohol

The present invention relates to an aqueous coating material based on a water-soluble resin having the OH group for airbag base fabric. The water-soluble resin is a polyvinyl alcohol (PVAL). An aliphatic carboxylic acid or polyisocyanate which can cross-link with the OH group of the PVAL by heat treatment, and polyol as a plasticizer such as a liquid polyethylene glycol which does not volatilize in heat treatment are added. A water-insoluble coating film having excellent heat and moisture resistance (hot water resistance) and flexibility can be formed on one surface or both surfaces of the cloth.

Owner:TOYODA GOSEI CO LTD

Convertible pizza box

A container for pizza formable into a smaller, space saving box useful as, for example, refrigerator containers for pizza slices. Also disclosed are easily environmentally friendly disposable pizza boxes.

Owner:ECOVENTION

Convertible Pizza Box

InactiveUS20110138750A1Easy to creasingEasy to foldLiquid materialIndividual articlesRefrigerator carEngineering

A container for pizza formable into a smaller, space saving box useful as, for example, refrigerator containers for pizza slices. Also disclosed are easily environmentally friendly disposable pizza boxes.

Owner:WALSH WILLIAM R

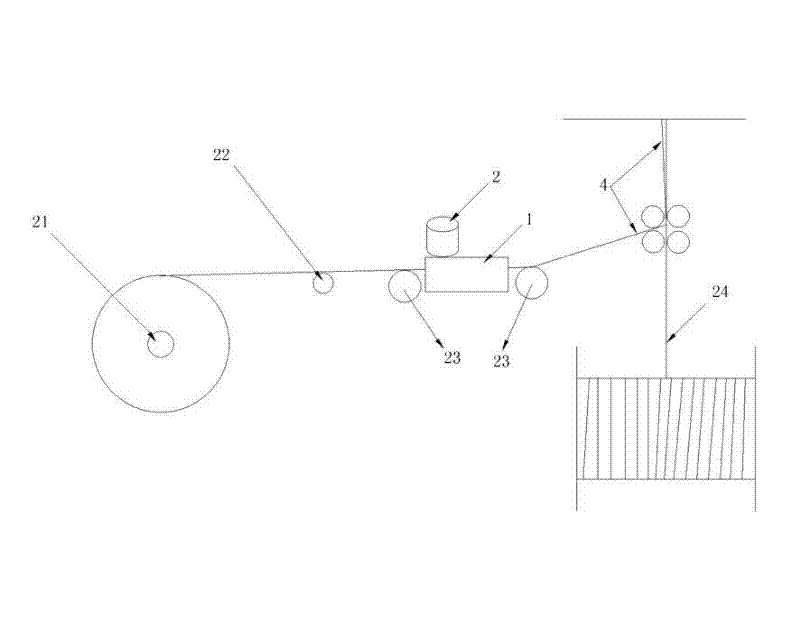

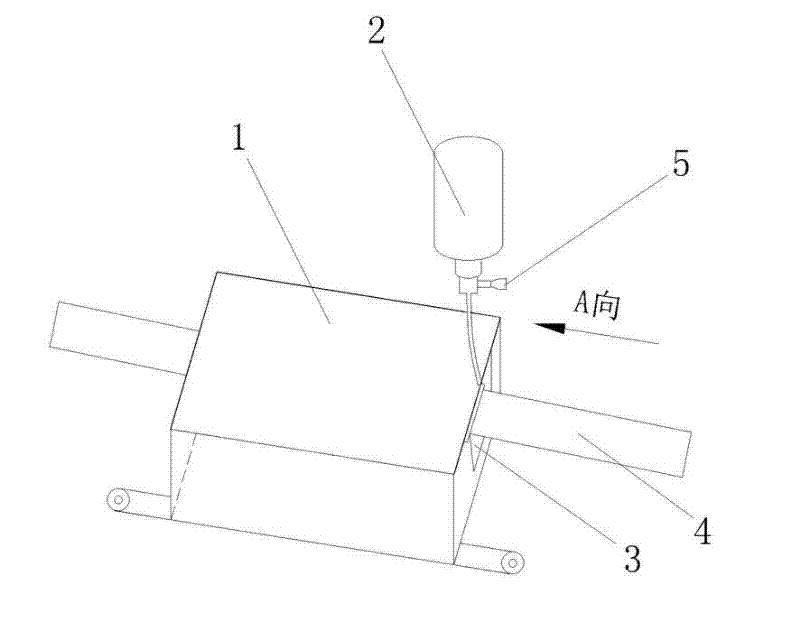

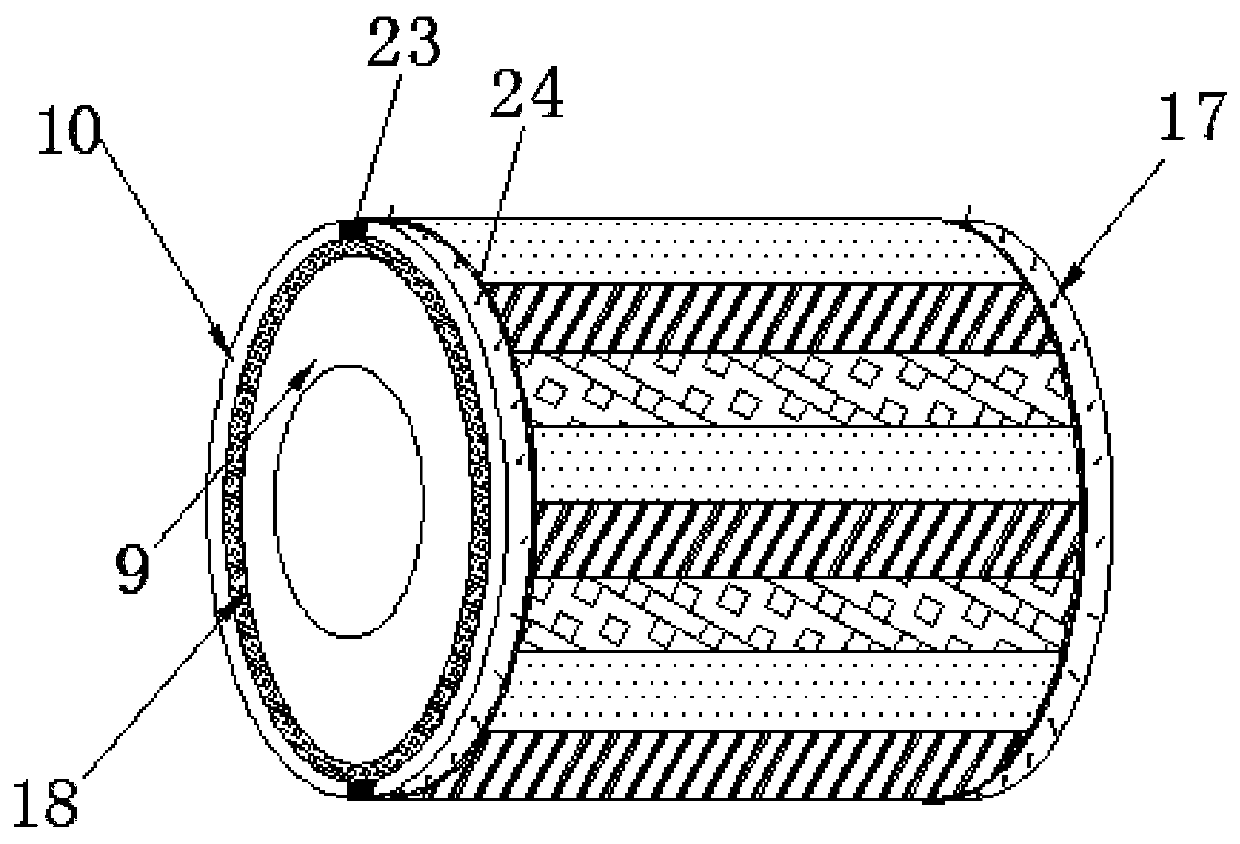

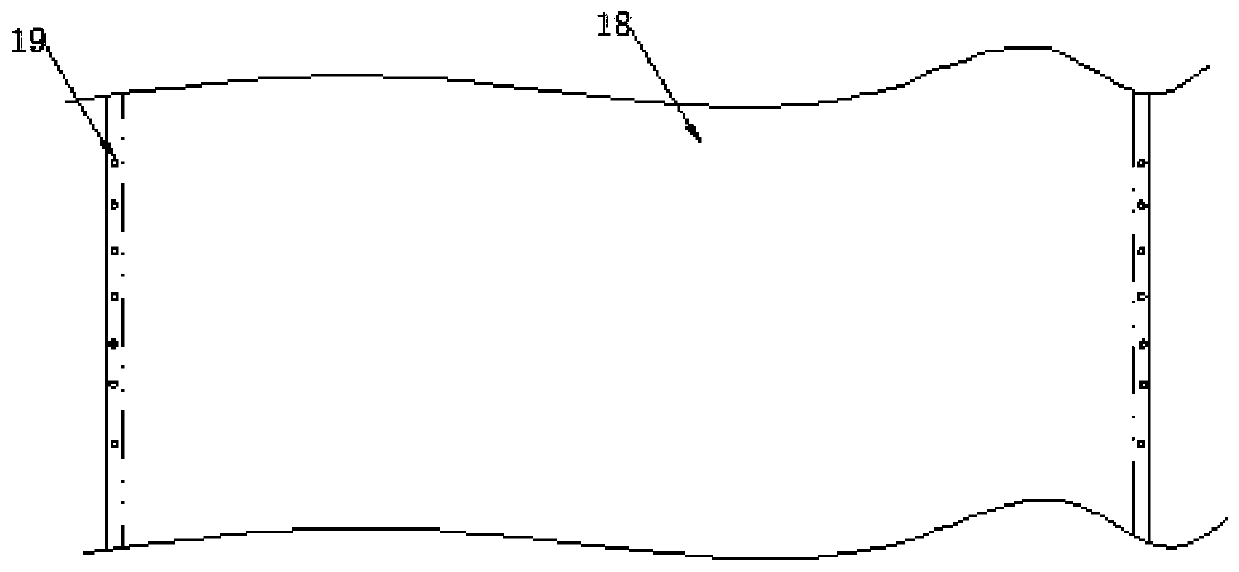

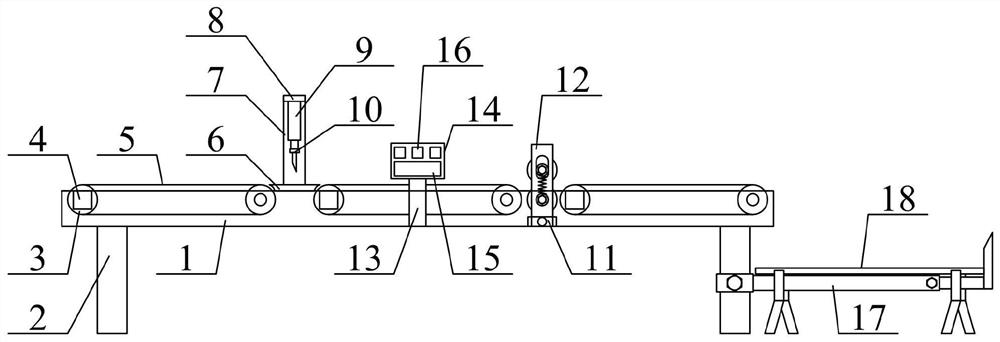

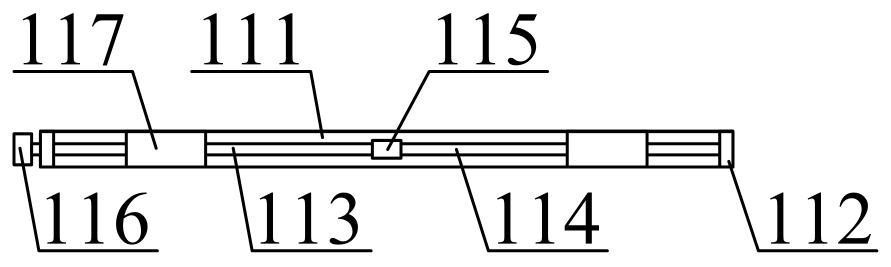

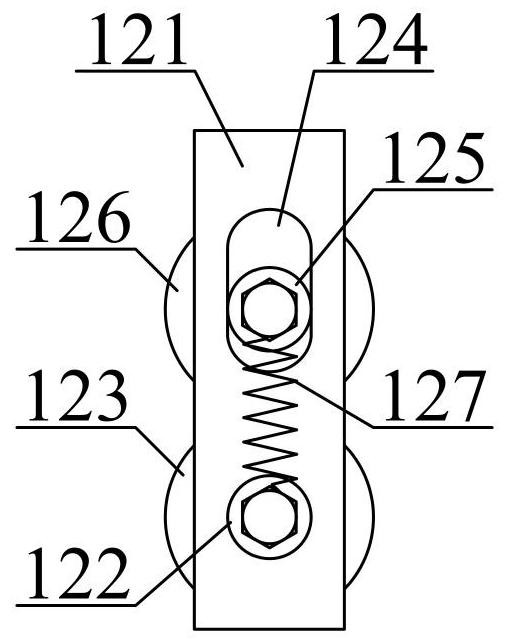

Process for manufacturing outer conductor in coaxial cable production process and special lubricating oil device thereof

InactiveCN102254636AEliminate frictionReduce wearManufacturing co-axial cablesEngineeringWire breakage

The invention discloses a process for manufacturing an outer conductor in a coaxial cable production process. The outer conductor consists of an aluminum foil shielding layer and a woven layer. The process for manufacturing the outer conductor comprises the following steps of: (1) longitudinally wrapping and oiling an aluminum foil: feeding the aluminum foil to a lubricating oil device through an aluminum foil breakage alarm after the aluminum foil in an aluminum foil payoff reel is horizontally released, oiling the aluminum foil, discharging the aluminum foil coated with the lubricating oil from the lubricating oil device, leading out the aluminum foil through a guide wheel, and gradually longitudinally wrapping the aluminum foil on a prepared core wire; and (2) weaving an alloy wire. The friction between the aluminum foil coated with the lubricating oil and the alloy wire is weakened and eliminated, abrasion of the aluminum foil and the alloy wire is reduced, and stability of product performance is ensured. Meanwhile, the probabilities of aluminum foil breakage and alloy wire breakage are reduced, shutdown in the production is reduced, and the production efficiency is greatly increased.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

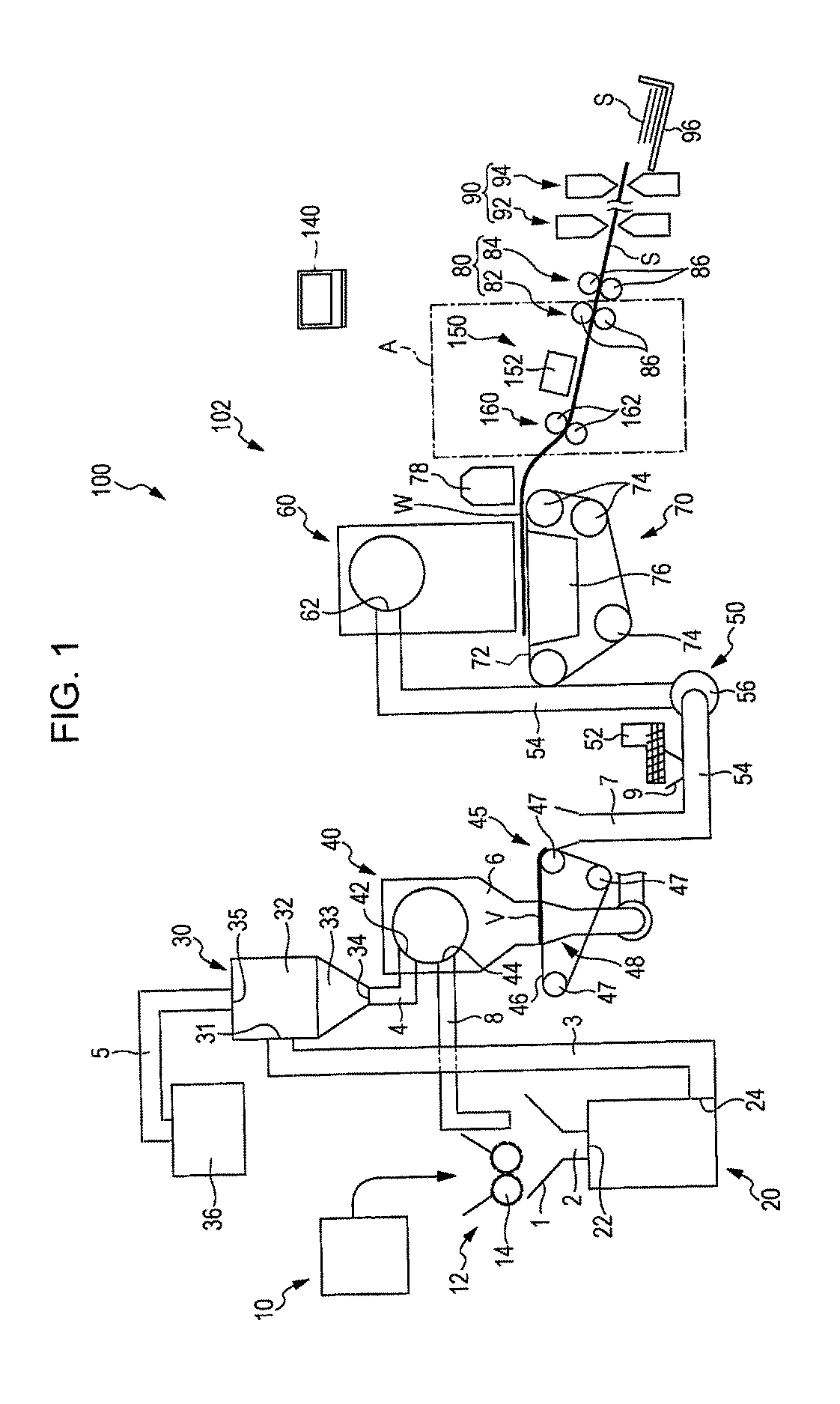

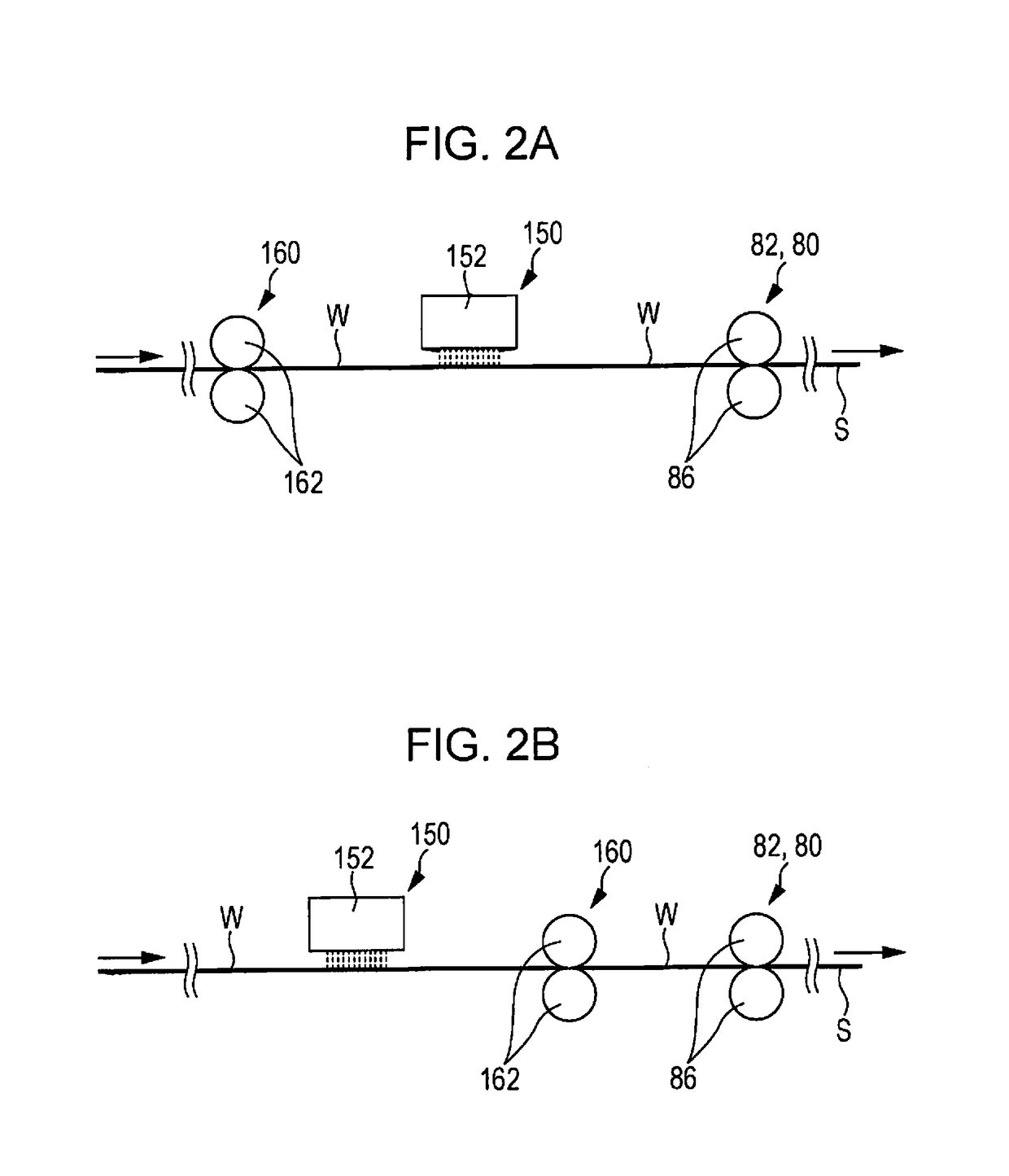

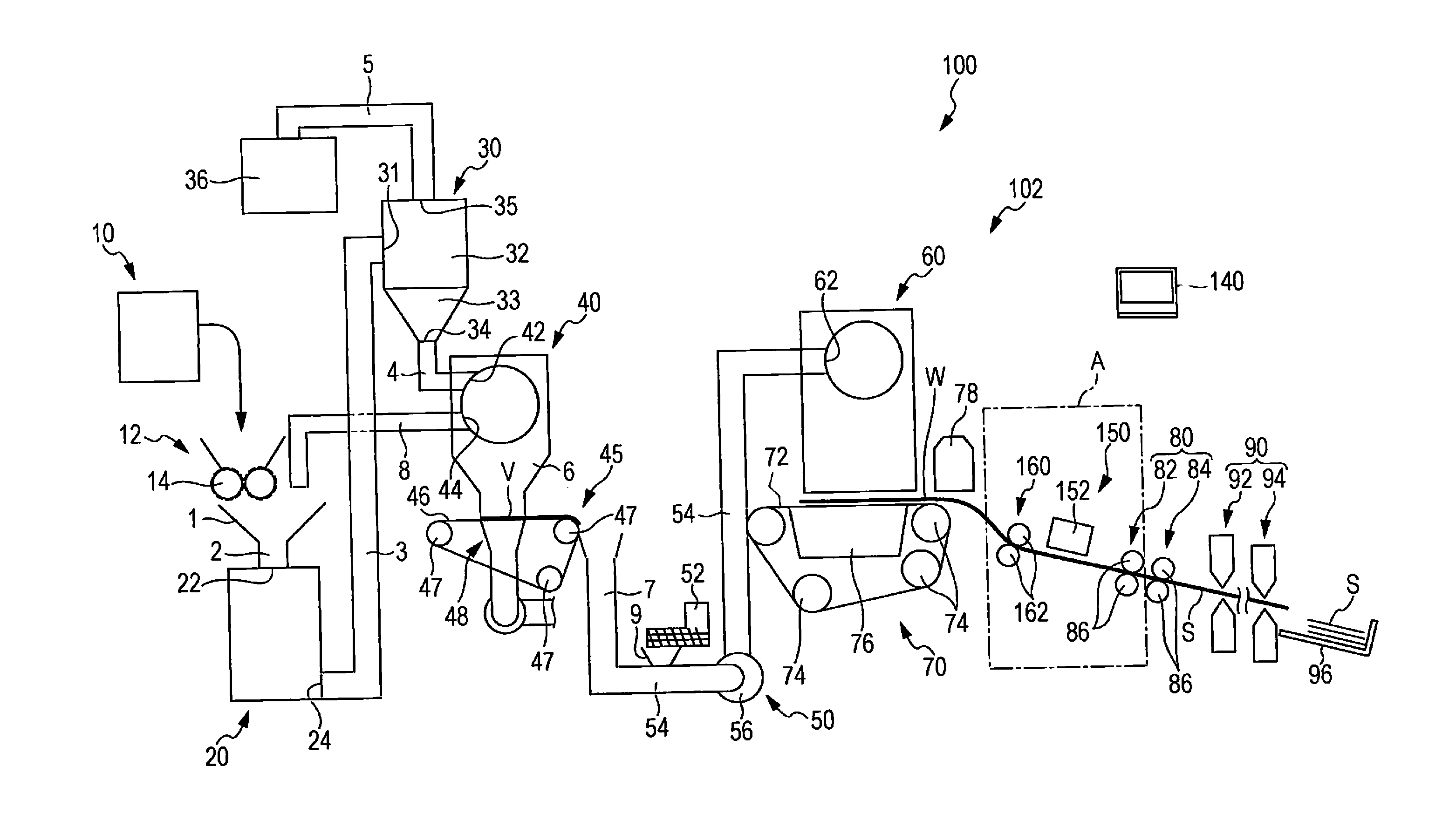

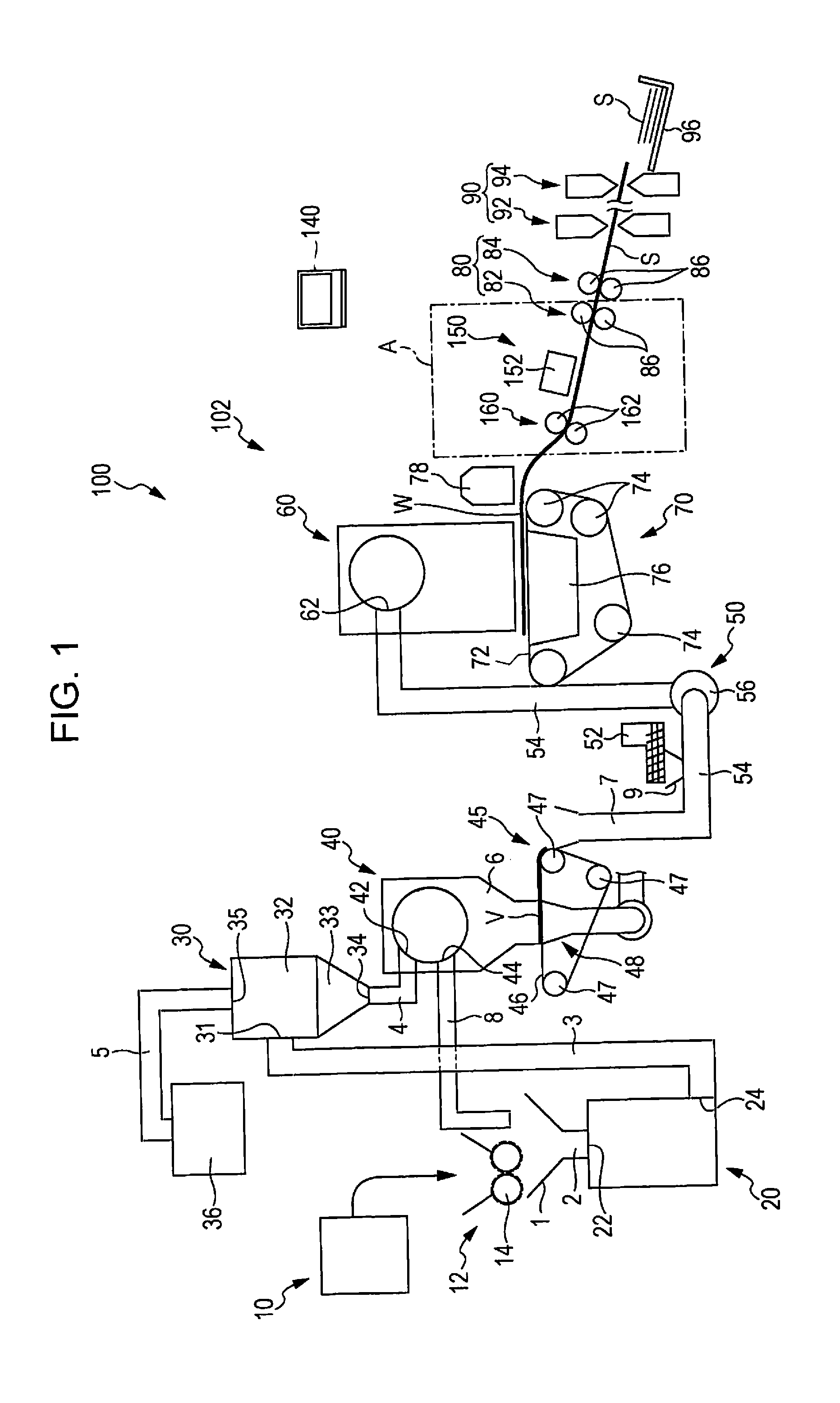

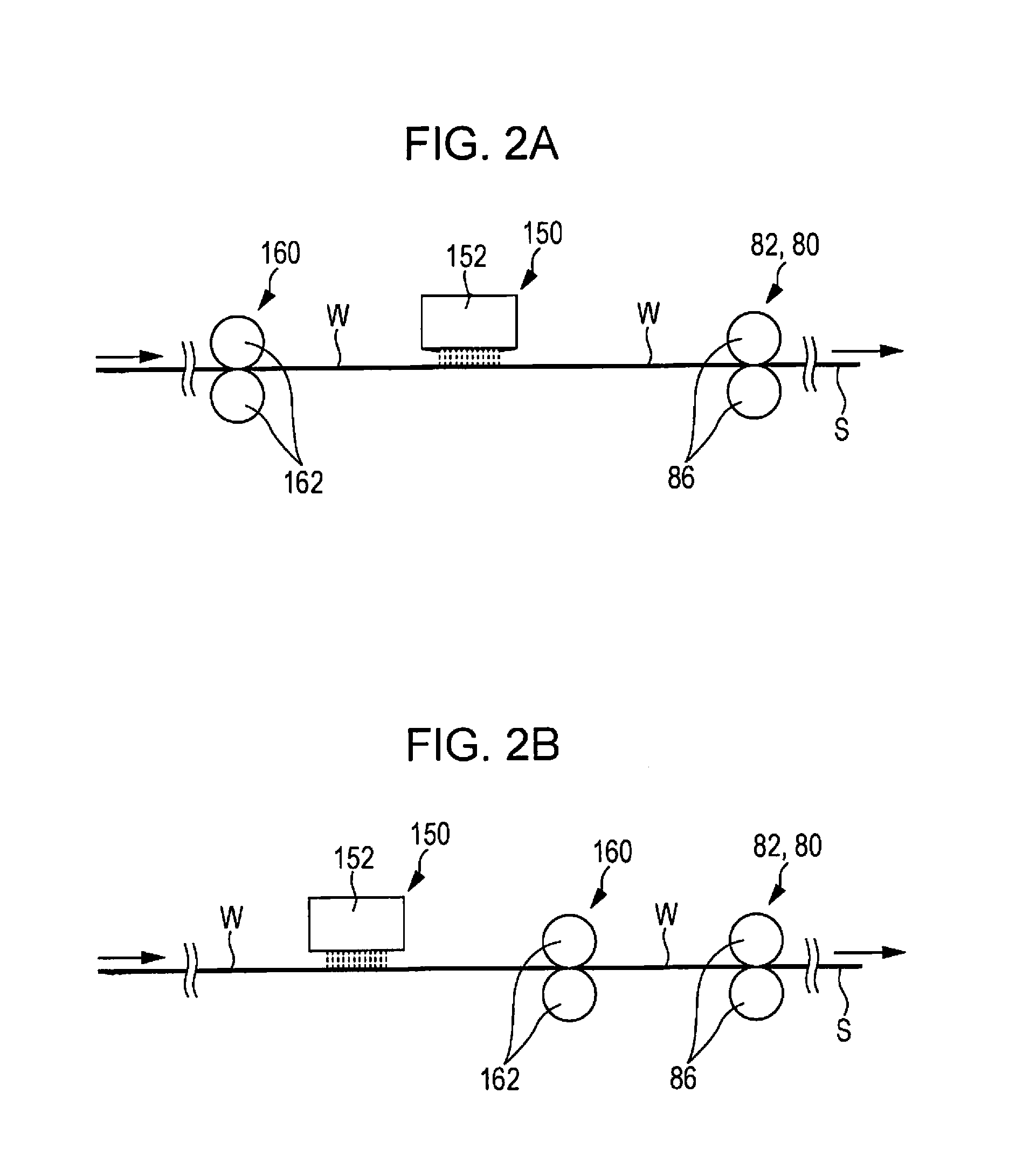

Sheet manufacturing apparatus, sheet manufacturing method, and sheet

ActiveUS9776365B2Easy to tearEasy to creasingMachine wet endPress sectionFiberManufactured apparatus

Owner:SEIKO EPSON CORP

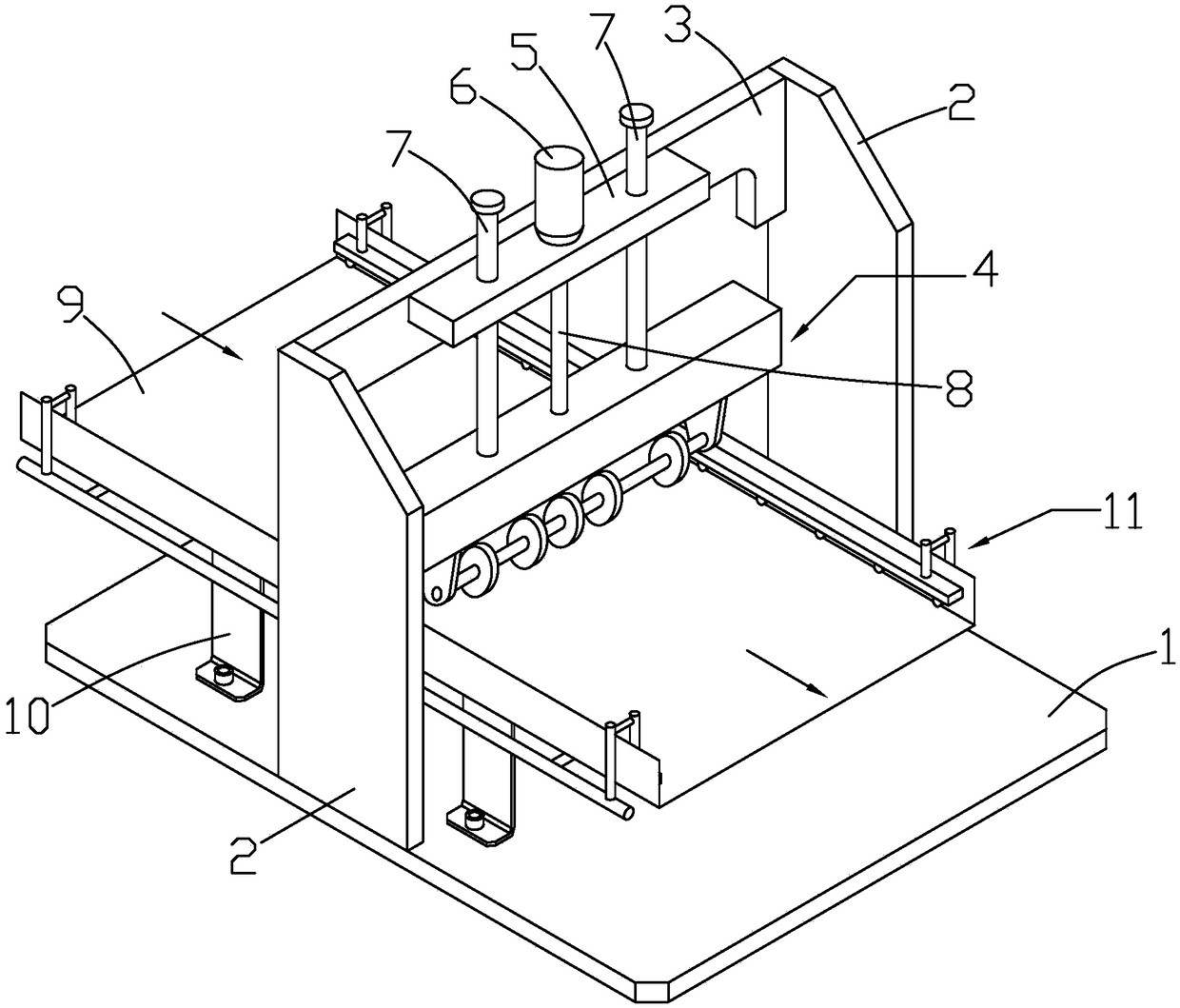

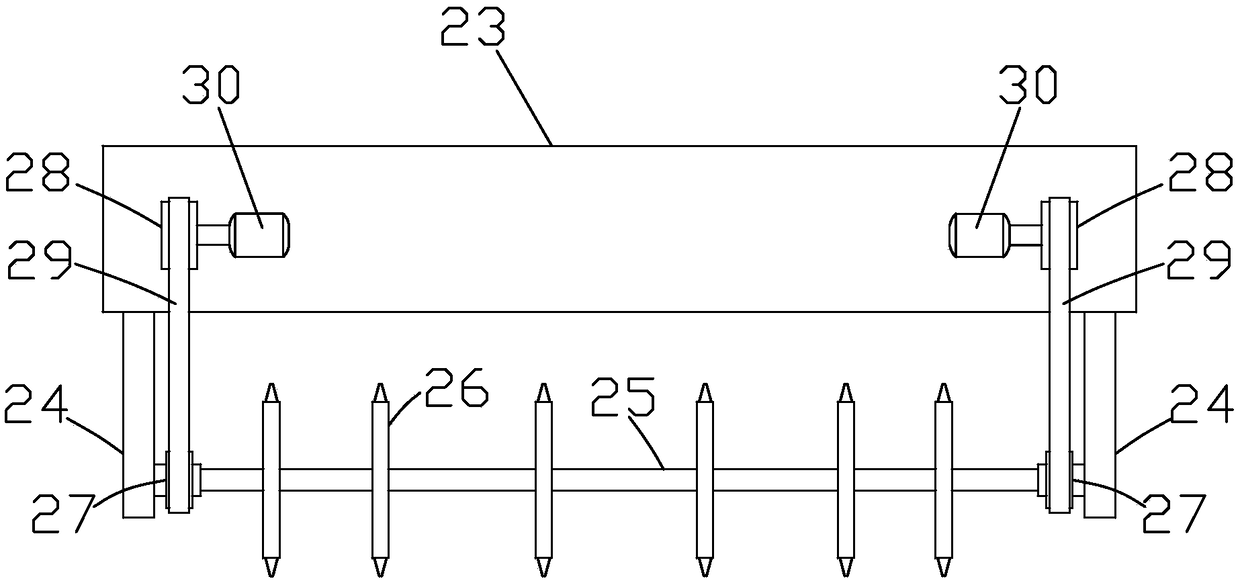

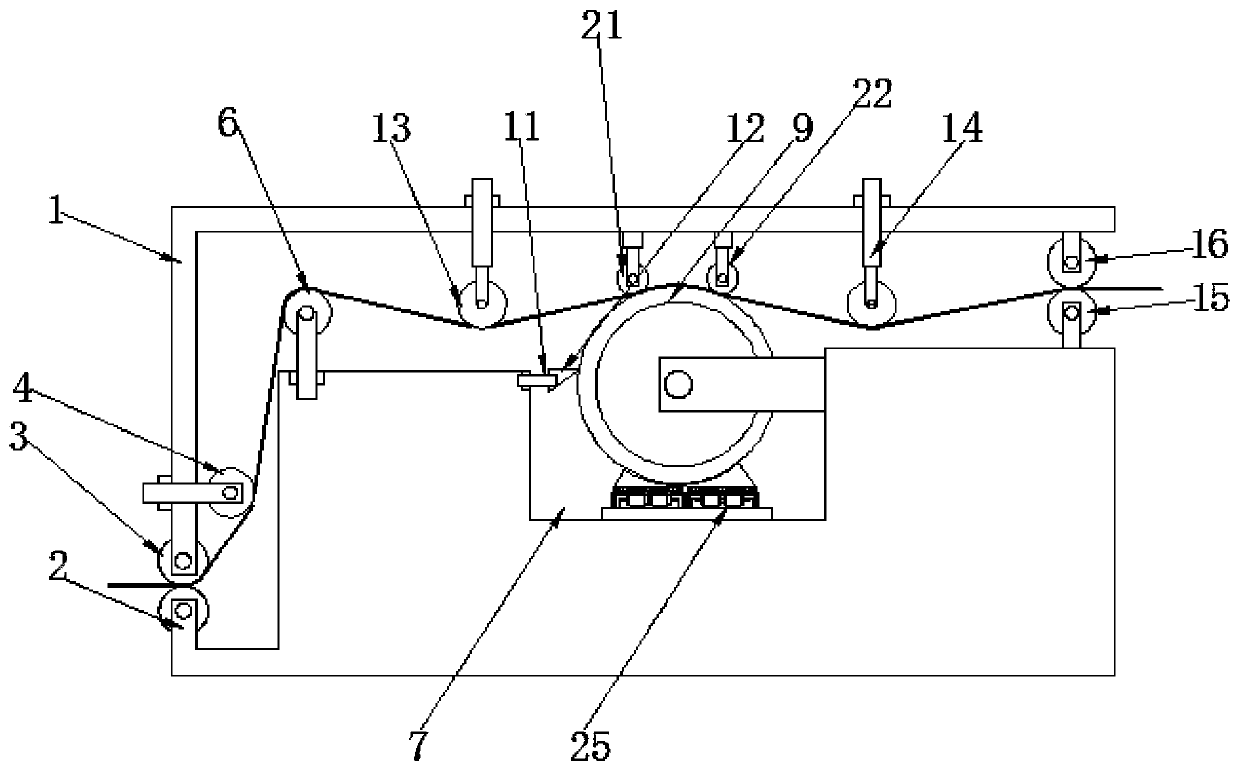

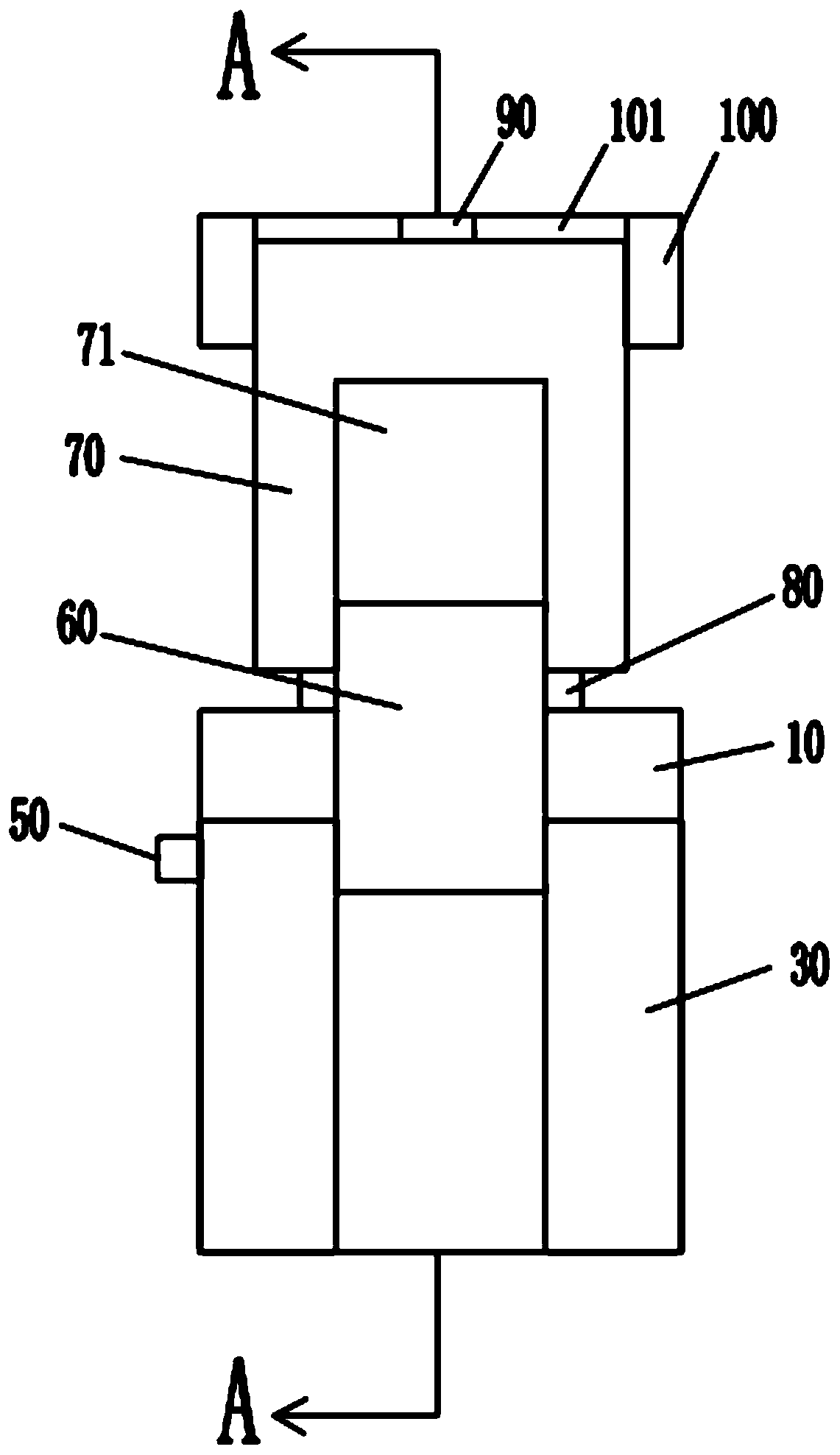

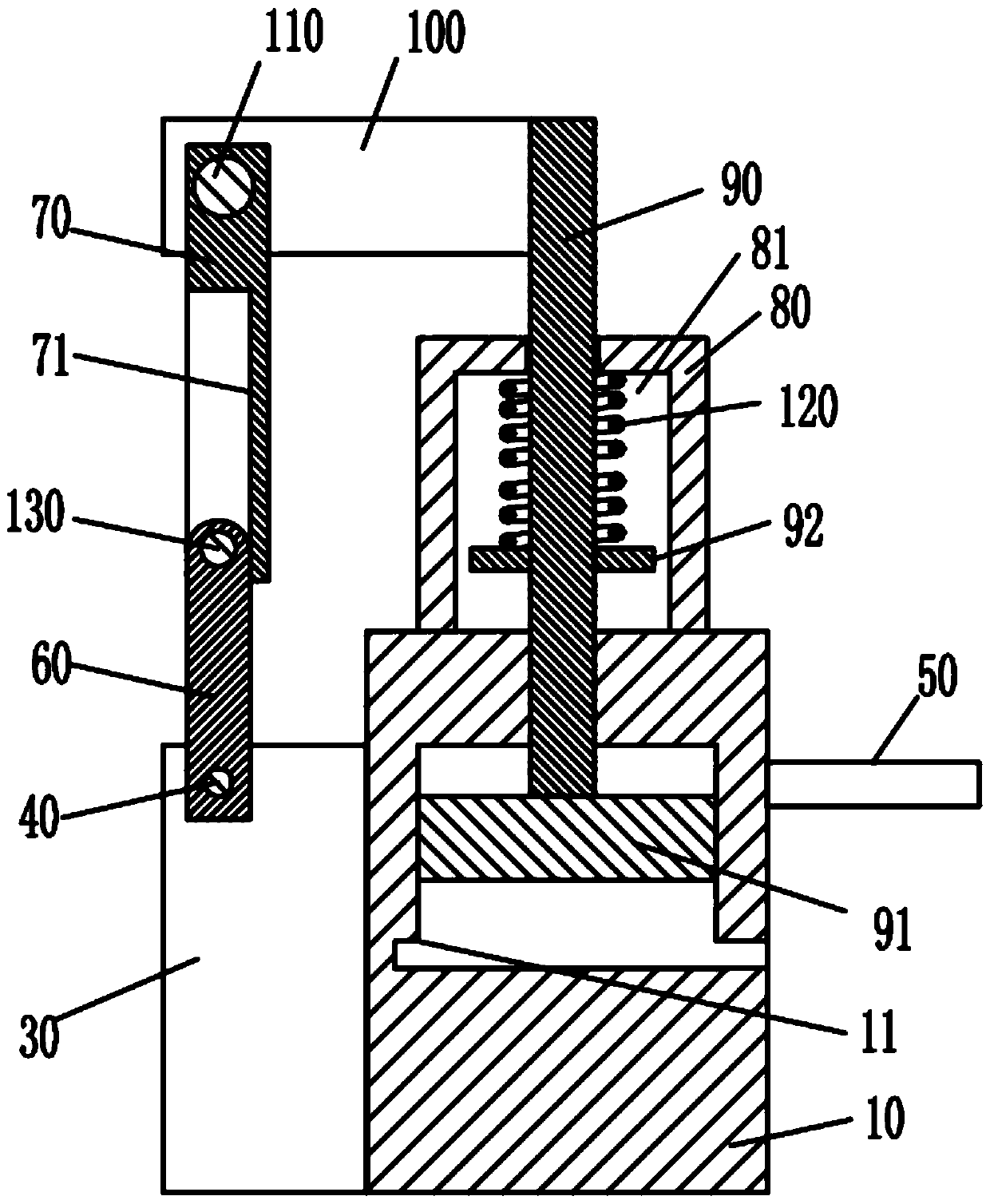

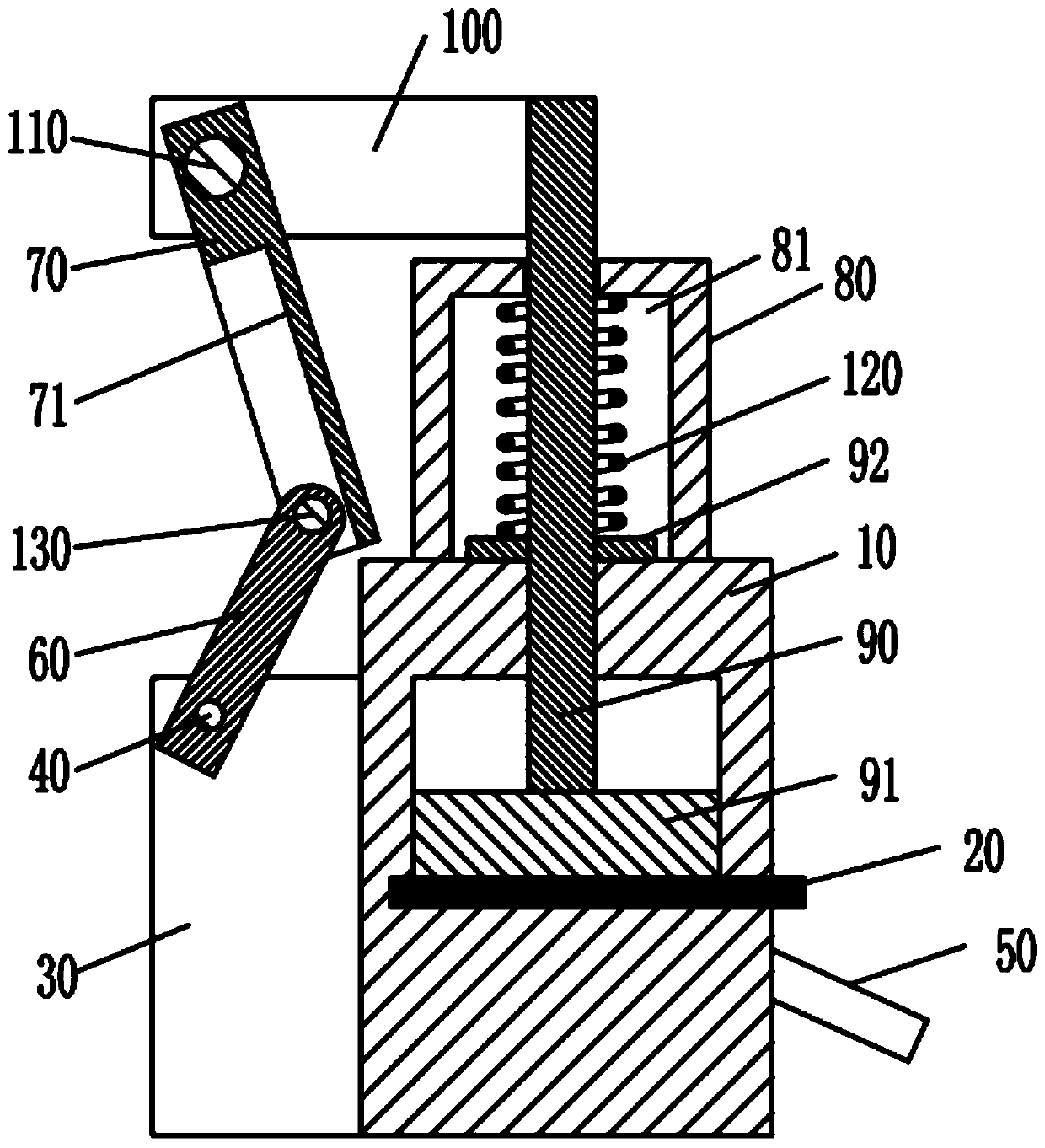

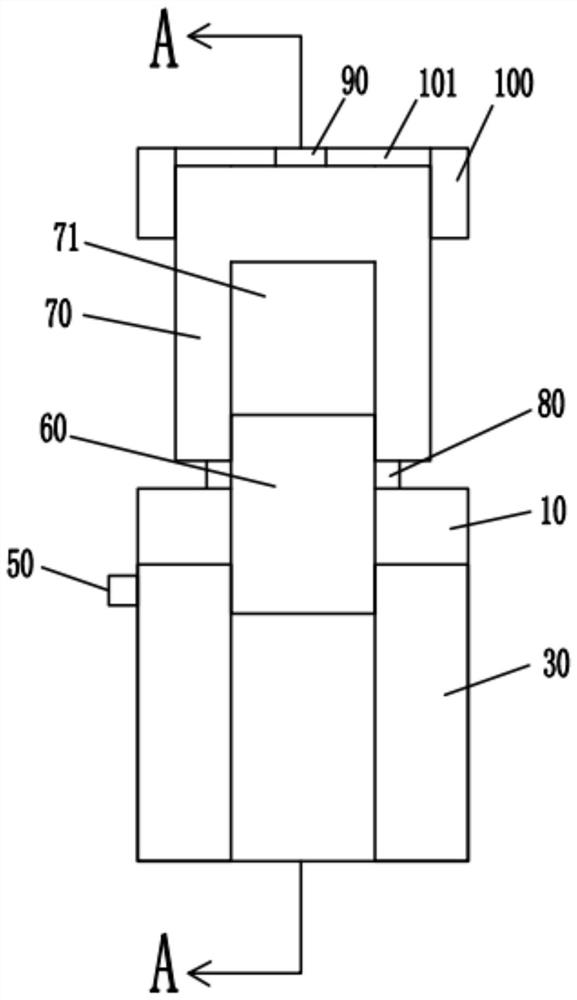

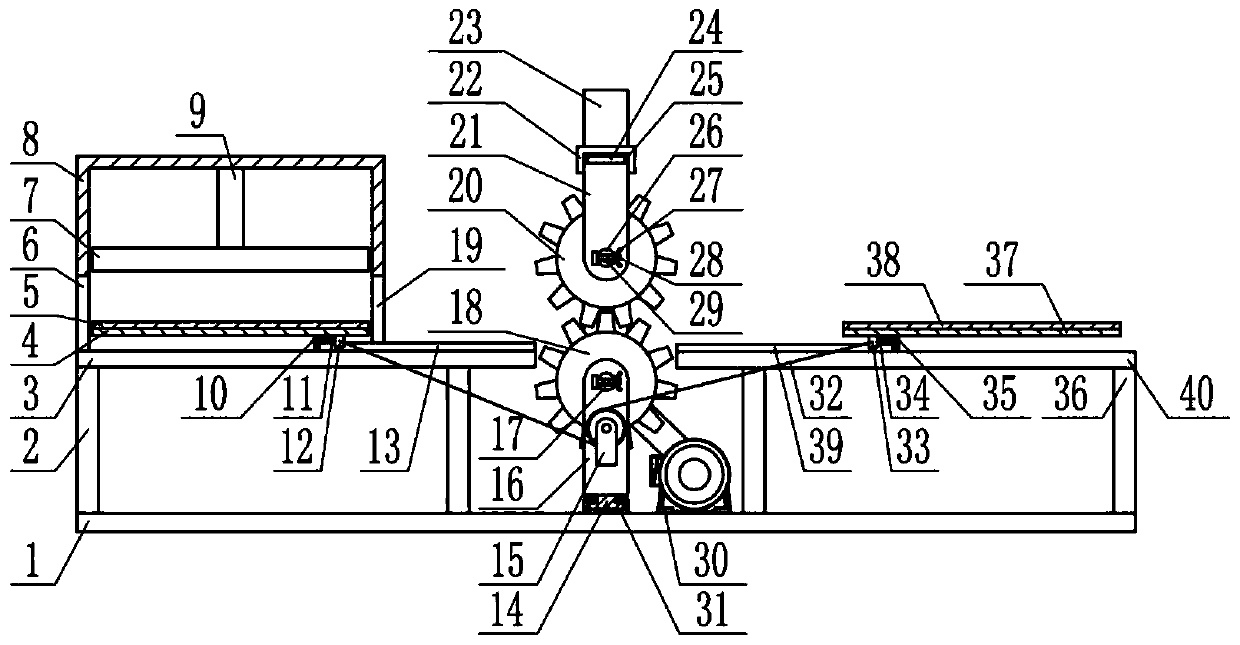

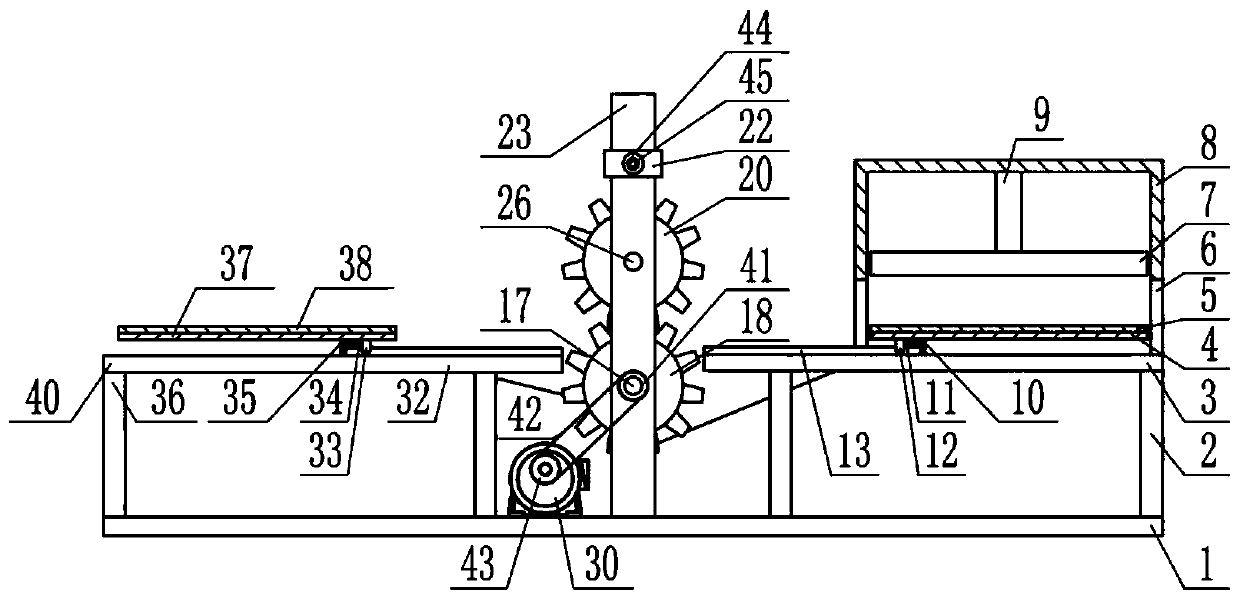

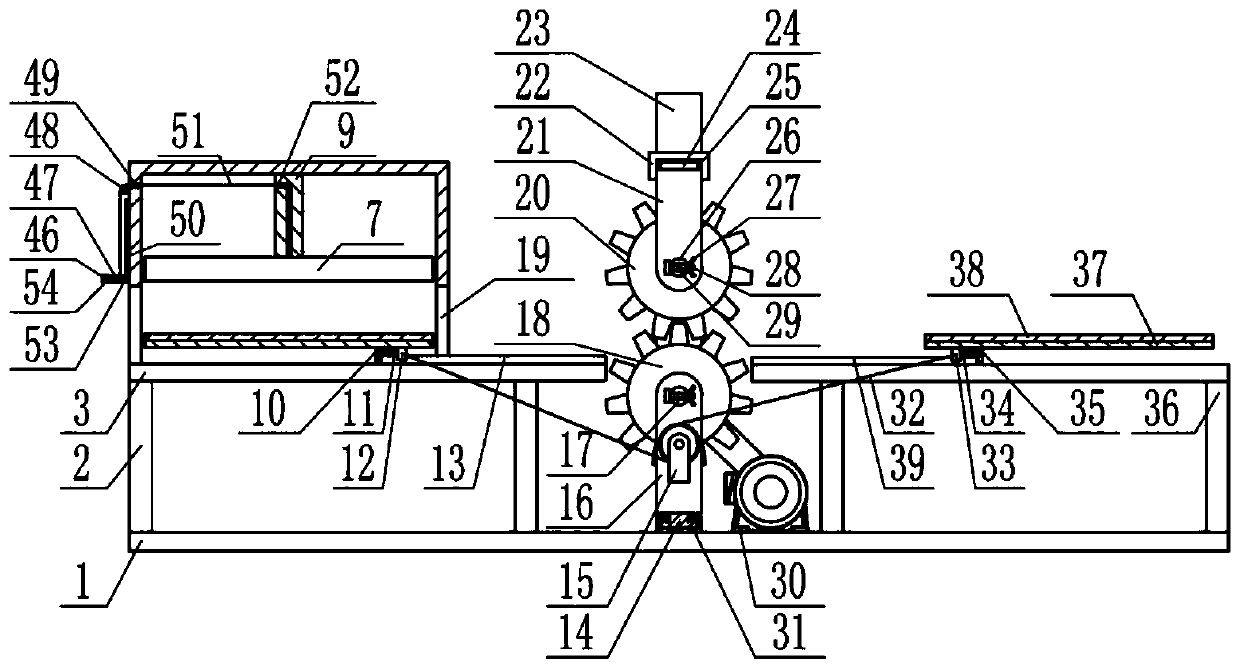

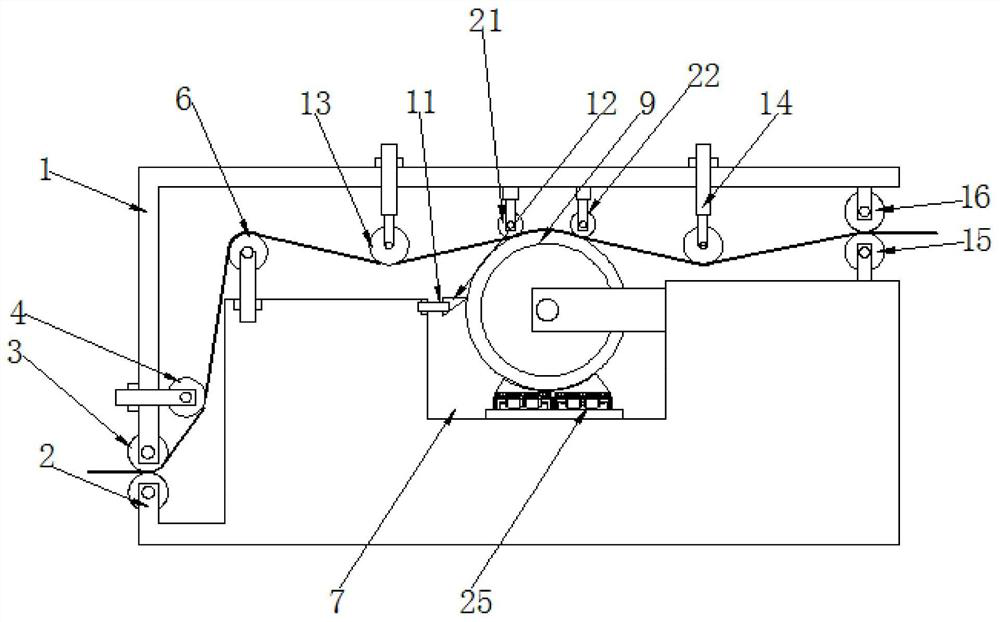

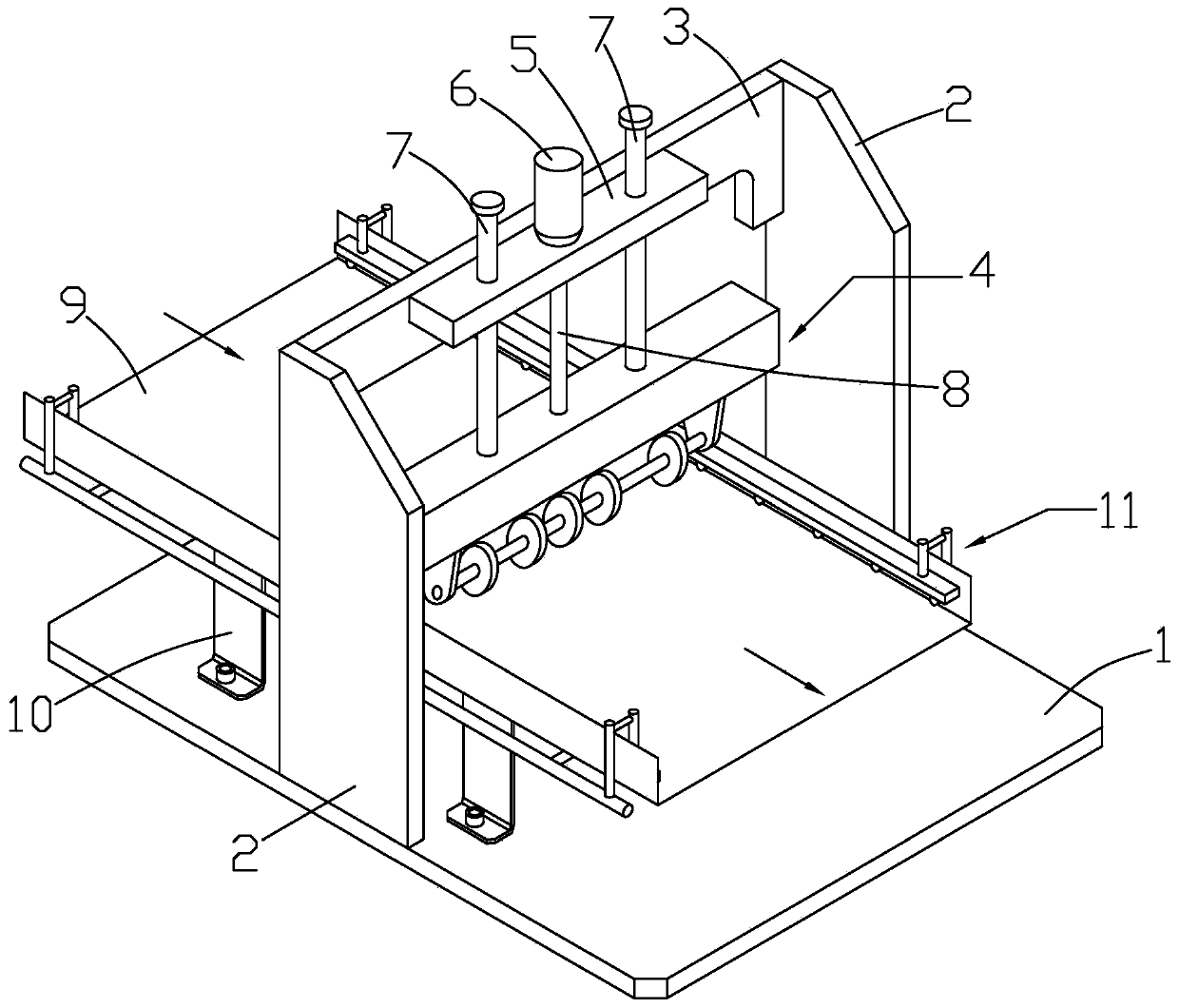

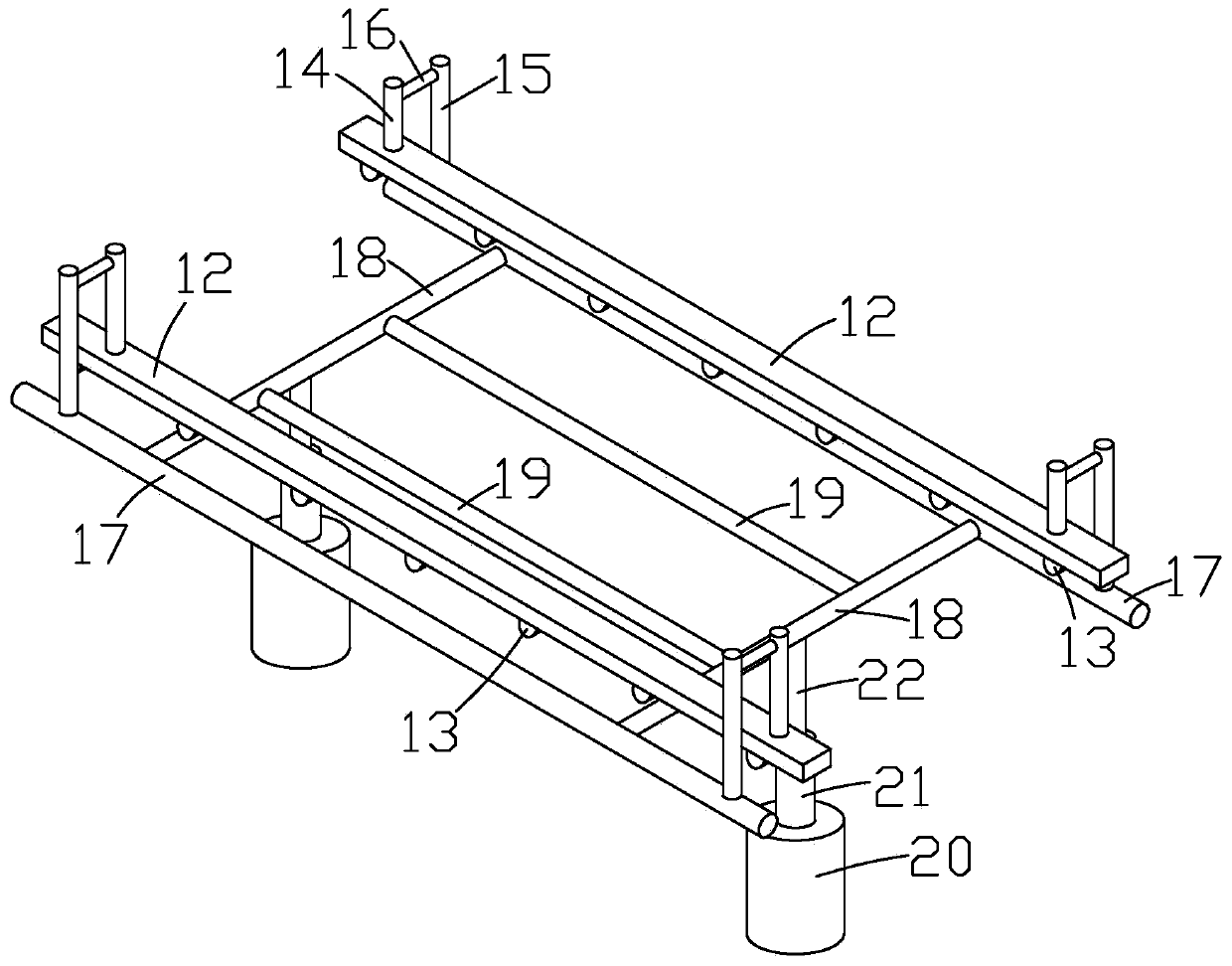

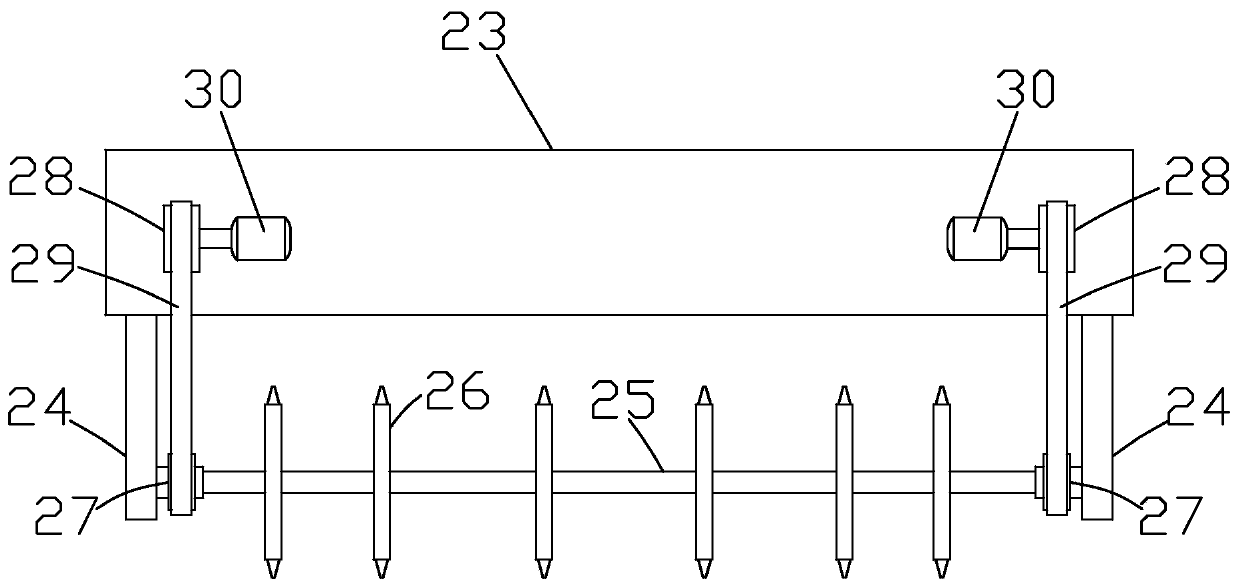

Paperboard indenting device for color printing packaging

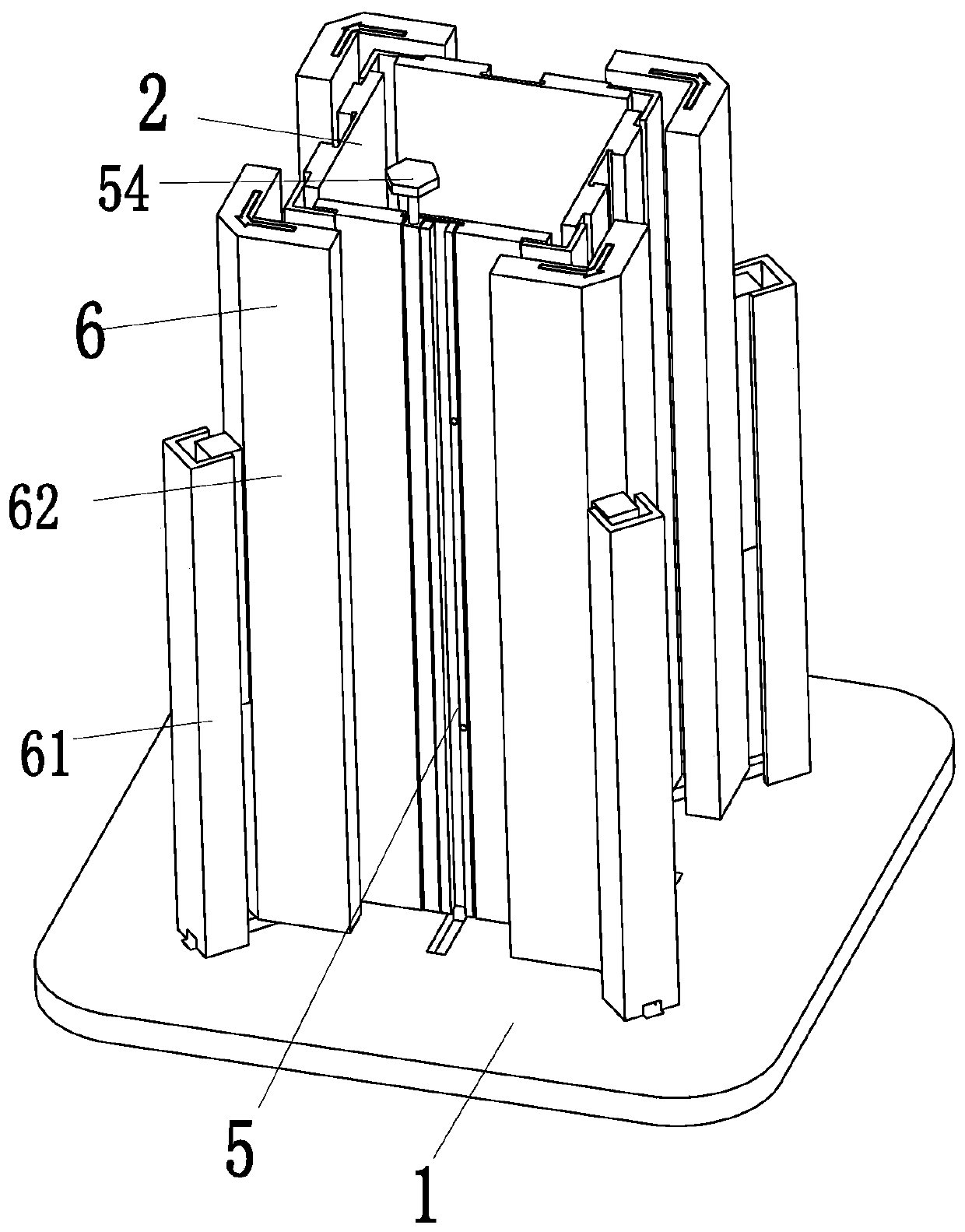

ActiveCN109334095AEasy to creasingMeet production needsPaper-makingBox making operationsCardboardColor printing

The invention discloses a paperboard indenting device for color printing packaging. The device comprises a bottom plate, a paperboard processing table, a paperboard indenting mechanism and a guiding and pressing mechanism; the paperboard processing table is fixedly connected on the bottom plate through second supporting plate; the paperboard indenting mechanism is located above the paperboard processing table and is connected to a cross beam through a lifting mechanism; two ends of the cross beam are fixedly connected to the bottom plate through first supporting plates; and the guiding and pressing mechanism is connected to the bottom plate through the paperboard processing table. The device is simple in structure, high in practicability, capable of realizing indenting processing of paperboards in different structure sizes and capable of guaranteeing that the depths of all dents are consistent, and meanwhile, the device can press the paperboards tightly to avoid the influence of deviation or tilting of the paperboards on the denting processing quality during denting processing.

Owner:恩施市硒珍源茶业股份有限公司

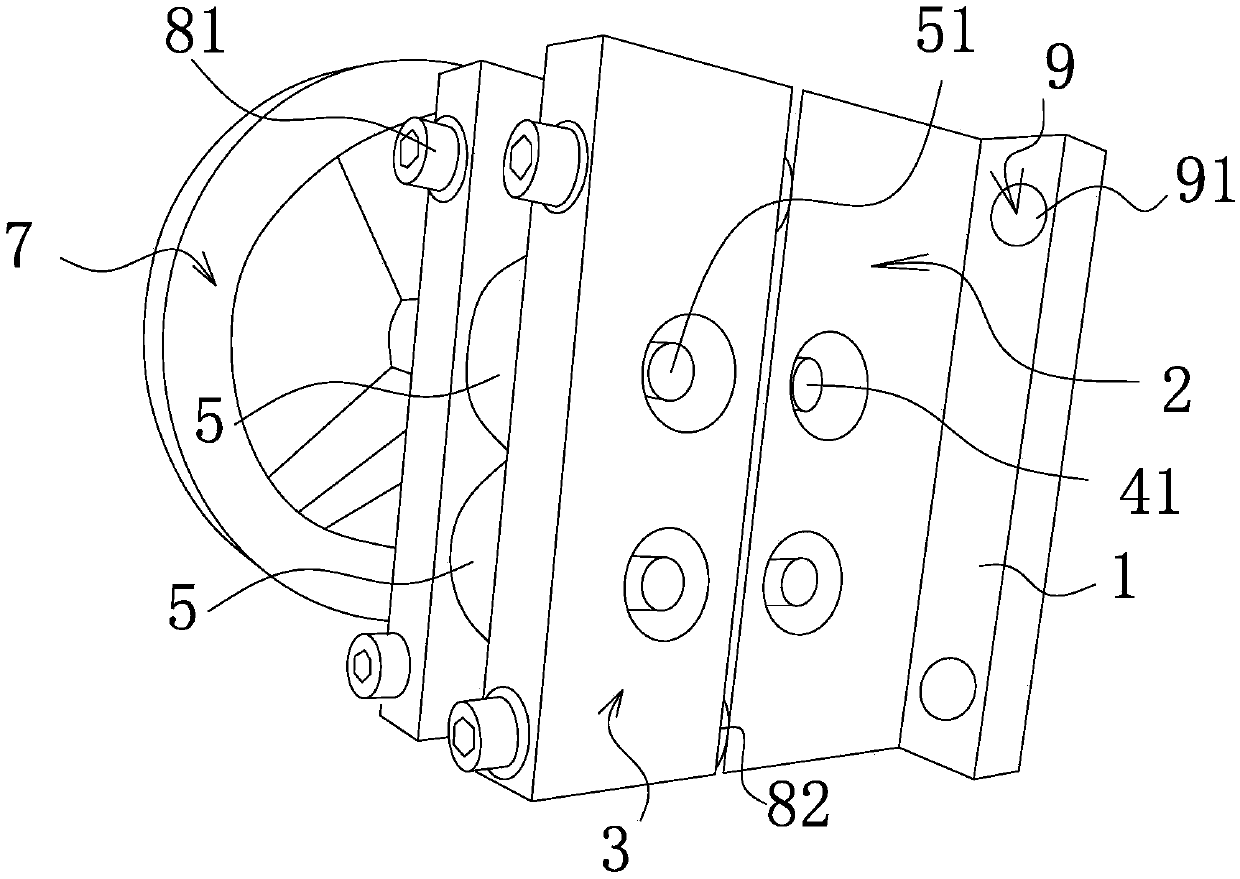

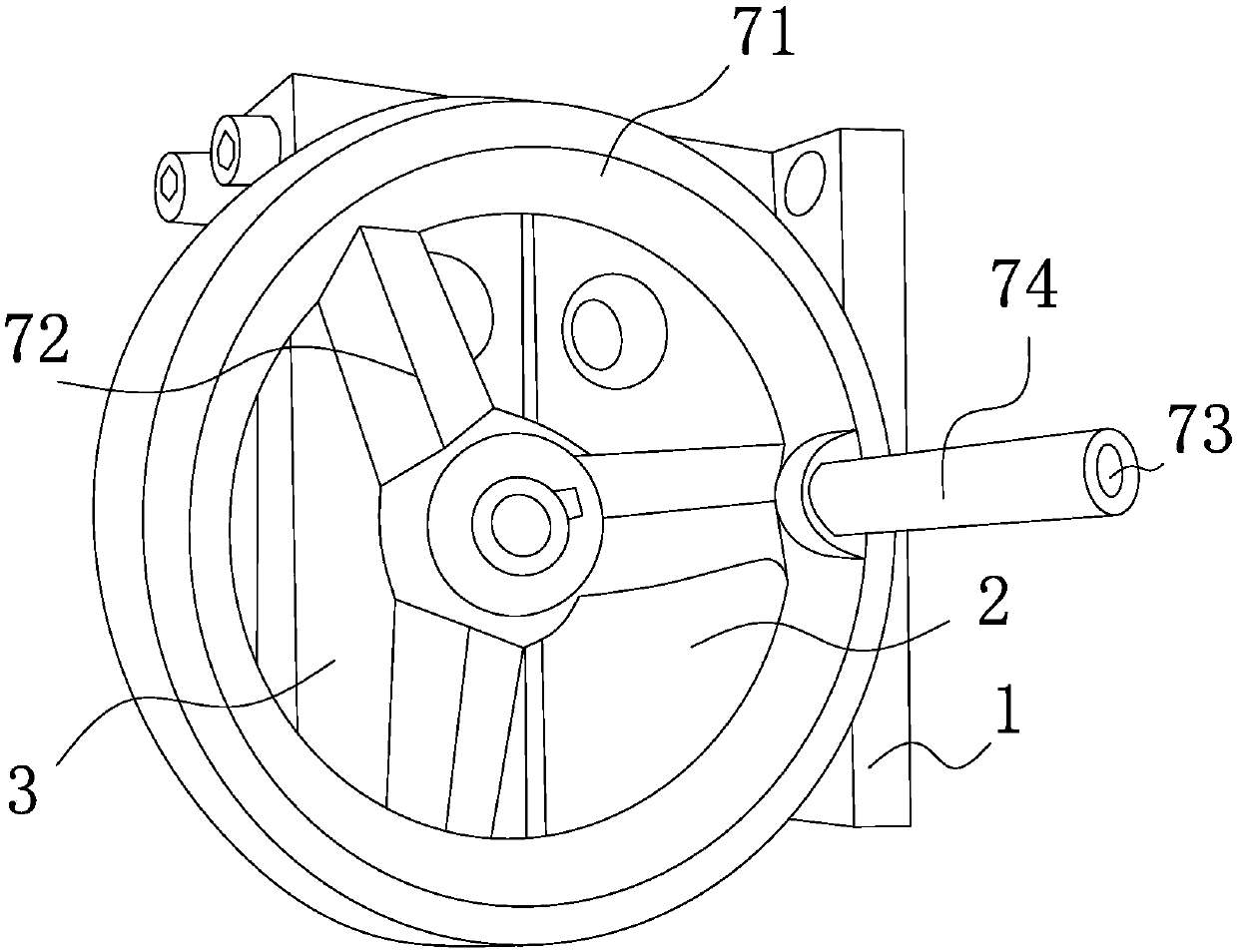

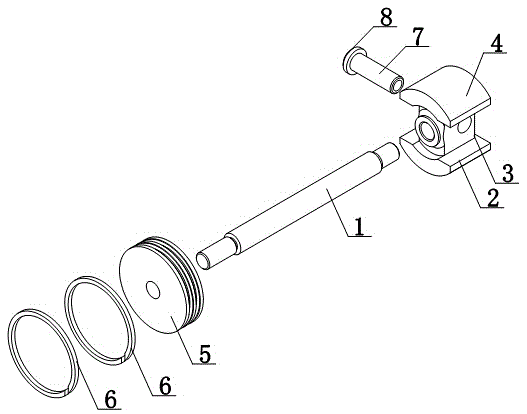

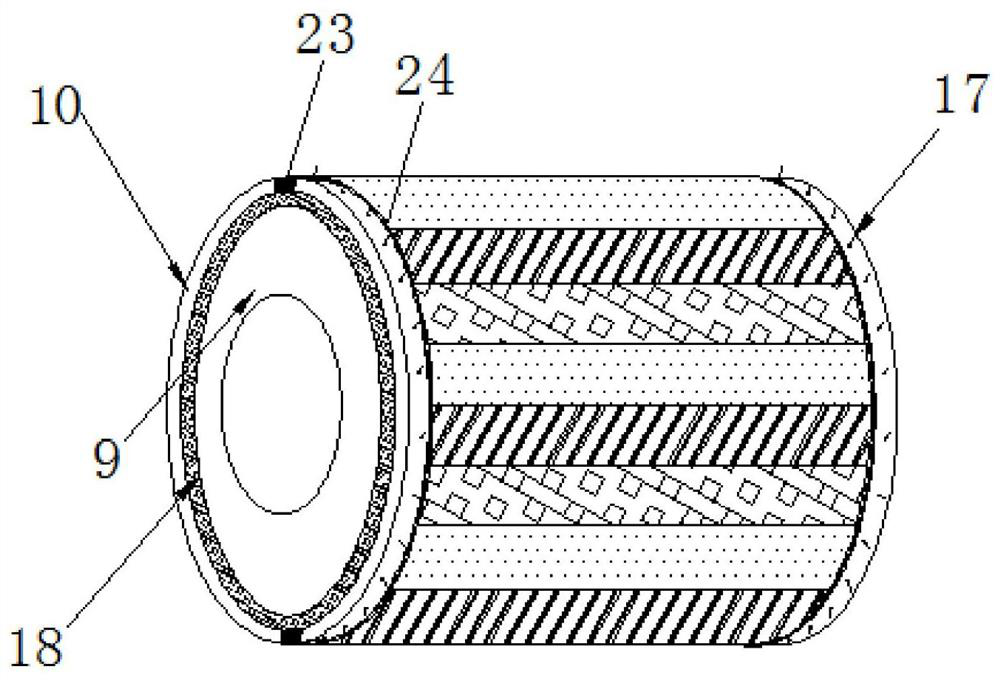

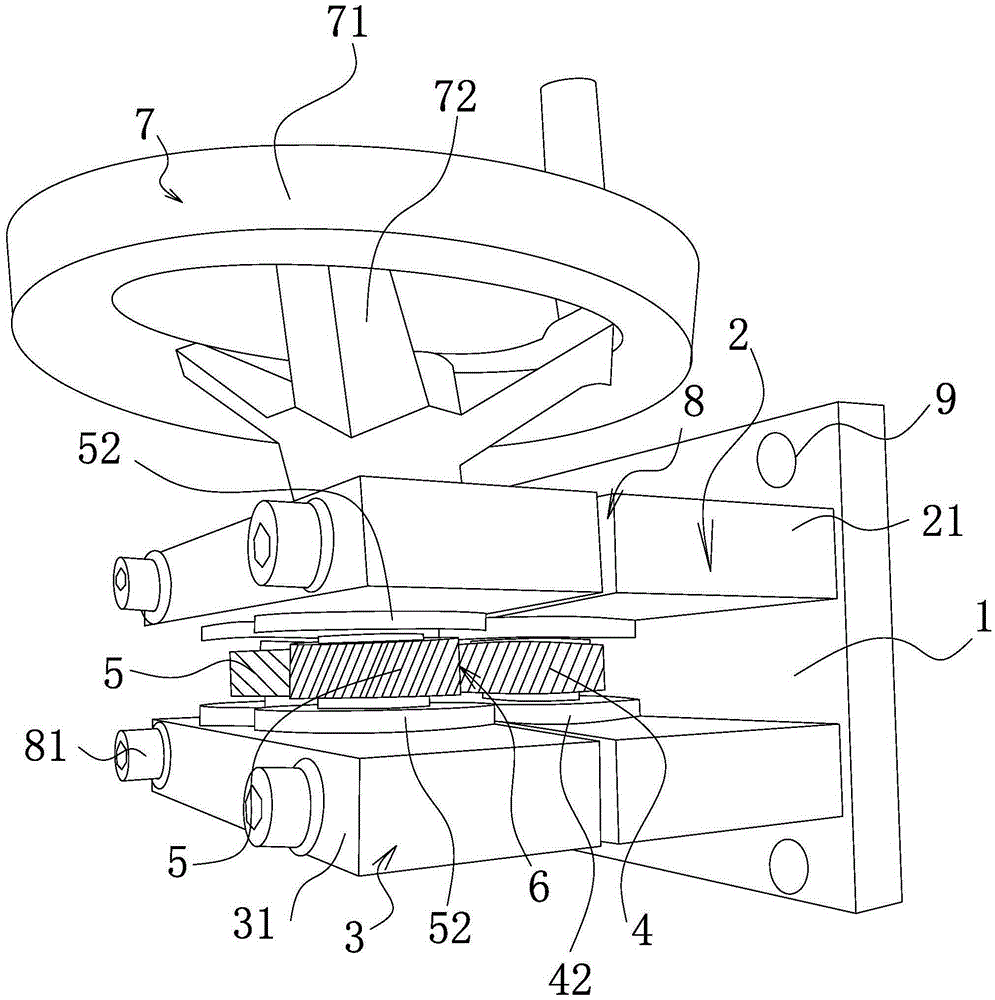

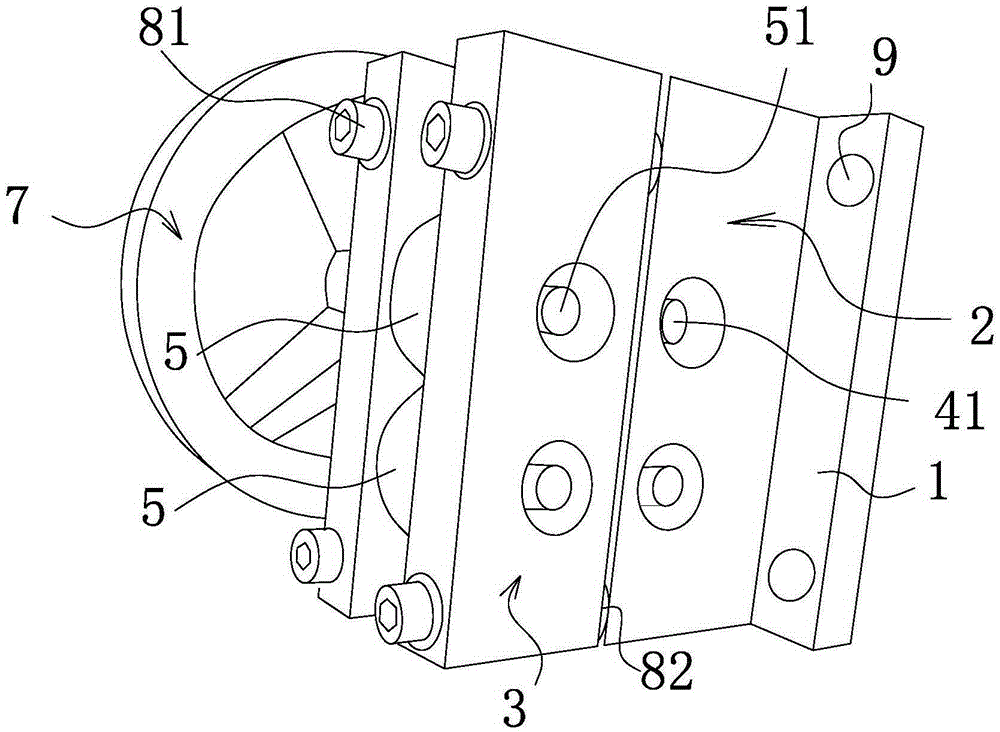

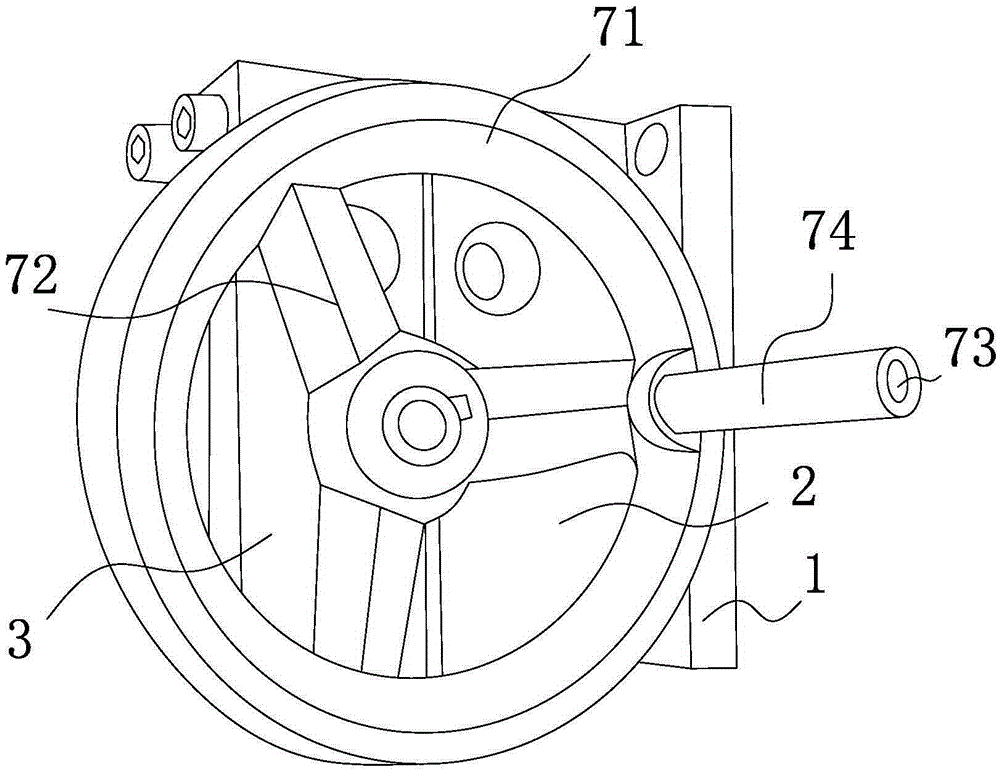

Creasing machine

The invention belongs to the technical field of machining devices and particularly relates to an indenting machine. The indenting machine comprises a base. A lower frame is arranged on the base. An upper frame is arranged above the lower frame. At least one downward-pressing wheel is arranged on the lower frame. At least one upward-pressing wheel capable of being matched with the downward-pressing wheels is arranged on the upper frame. An embossing channel is formed between the downward-pressing wheels and the upward-pressing wheels. Any one of the upward-pressing wheels or the downward-pressing wheels is connected with a drive device capable of driving the corresponding wheel to rotate. A height adjusting mechanism capable of adjusting the size of the embossing channel is arranged between the upper frame and the lower frame. Compared with the prior art, the indenting machine has the beneficial effects that design is reasonable, a pipeline can be indented conveniently, and the indenting machine is convenient to carry and install; the structure is firm, the service life is long, and cost is saved; installation is reliable and convenient, and the machine can be conveniently located after being moved; the machine is convenient and easy to use and can be conveniently operated by a worker; and the indenting machine is of an anti-seismic and anti-skidding structure and is prevented from being moved.

Owner:ZHEJIANG DEQING CONCEPTFE PLASTIC PROD

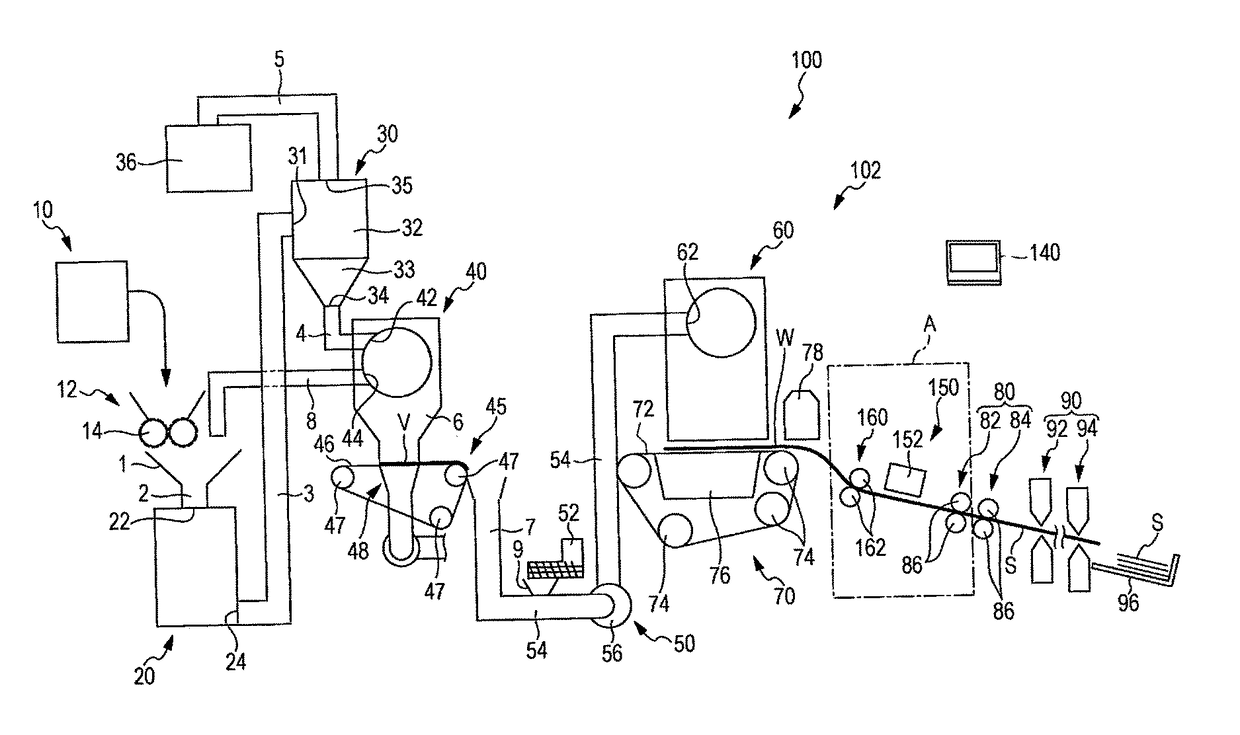

Sheet manufacturing apparatus, sheet manufacturing method, and sheet

ActiveUS20160288435A1Easy to tearEasy to creasingMachine wet endPress sectionFiberManufactured apparatus

A sheet manufacturing apparatus includes a defibrating unit configured to defibrate in an atmosphere a raw material that contains a fiber, a mixing unit configured to mix in the atmosphere a defibrated material that the defibrating unit has defibrated and a resin, an accumulating unit configured to accumulate a mixture of the defibrated material and the resin that the mixing unit has mixed, a liquid application unit configured to apply a liquid to a portion of an accumulation of the mixture that the accumulating unit has accumulated, and a heating unit configured to form a sheet by heating the accumulation to which the liquid application unit has applied the liquid.

Owner:SEIKO EPSON CORP

Wallpaper printing device based on foaming ink

ActiveCN110561900AQuality assuranceGuaranteed clarityRotary pressesPrinting press partsMechanical engineering

The invention relates to the technical field of printing equipment, and discloses a wallpaper printing device based on foaming ink. The device is characterized in that a front pressing roller and a rear pressing roller are arranged on two sides above a printing roller, wherein and the front pressing roller and the rear pressing roller enable wallpaper at a printing part between the front pressingroller and the rear pressing roller to be tightly attached to the printing roller, so that reliable contact at the printing part is realized, and the printing quality and definition are ensured; an anti-slip assembly is capable of preventing from the sliding between wallpaper at the printing part and the printing surface of the printing roller during the printing operation, thus effectively improving the printing reliability, preventing from the problem of unqualified printing quality caused by the sliding, and preventing from the damage of the whole piece of wallpaper. The anti-slip assemblyis also capable of embossing the edge part of the wallpaper at the printing part, so that the edge part of the printed wallpaper can be torn along the embossed marks, and the requirement on later useis met, and the artistic performance is achieved; the operation is simple and convenient; later edge cutting process is saved; equipment is simplified; processes are decreased; and the efficiency is improved.

Owner:北京中国科学院老专家技术中心

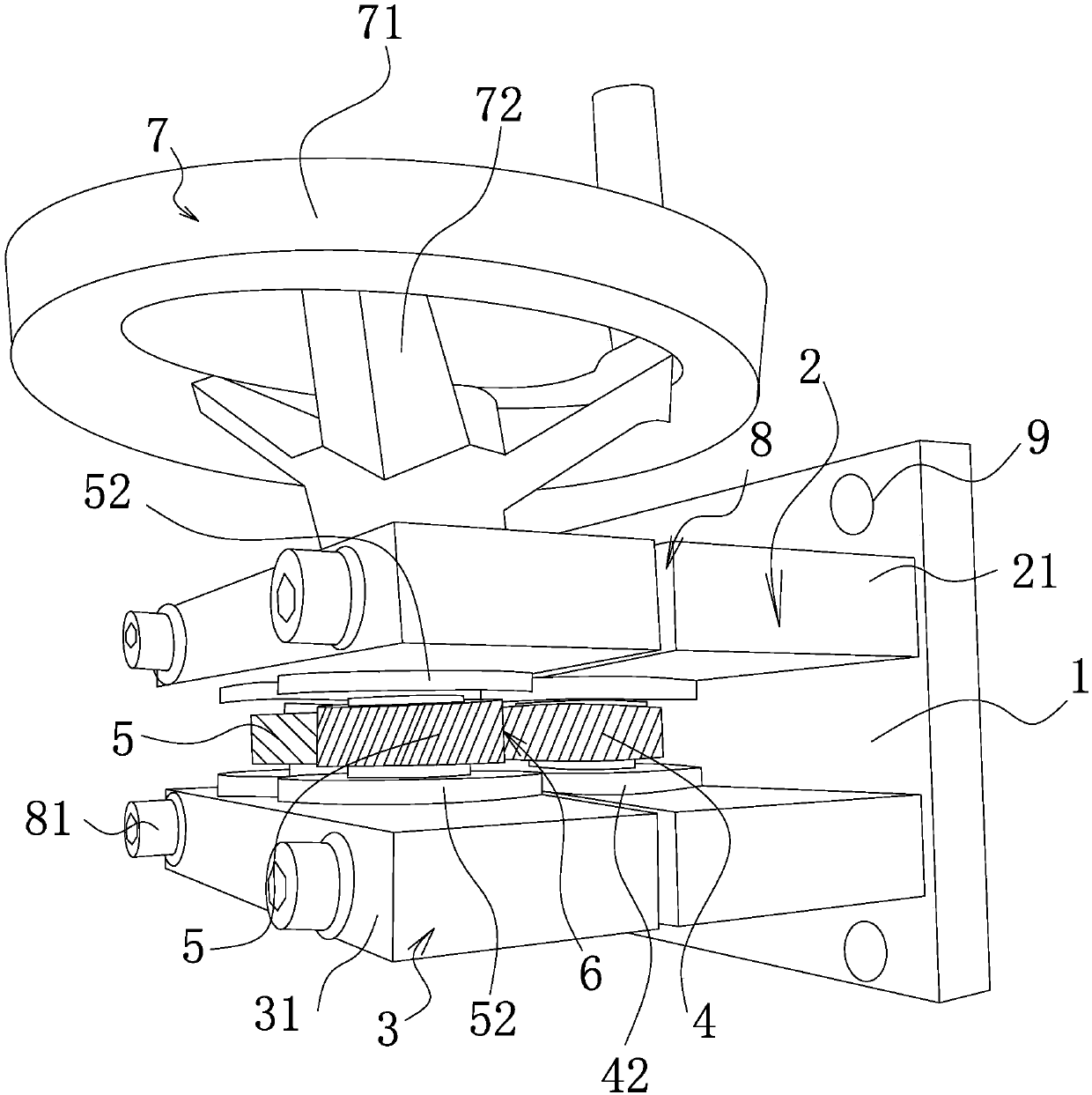

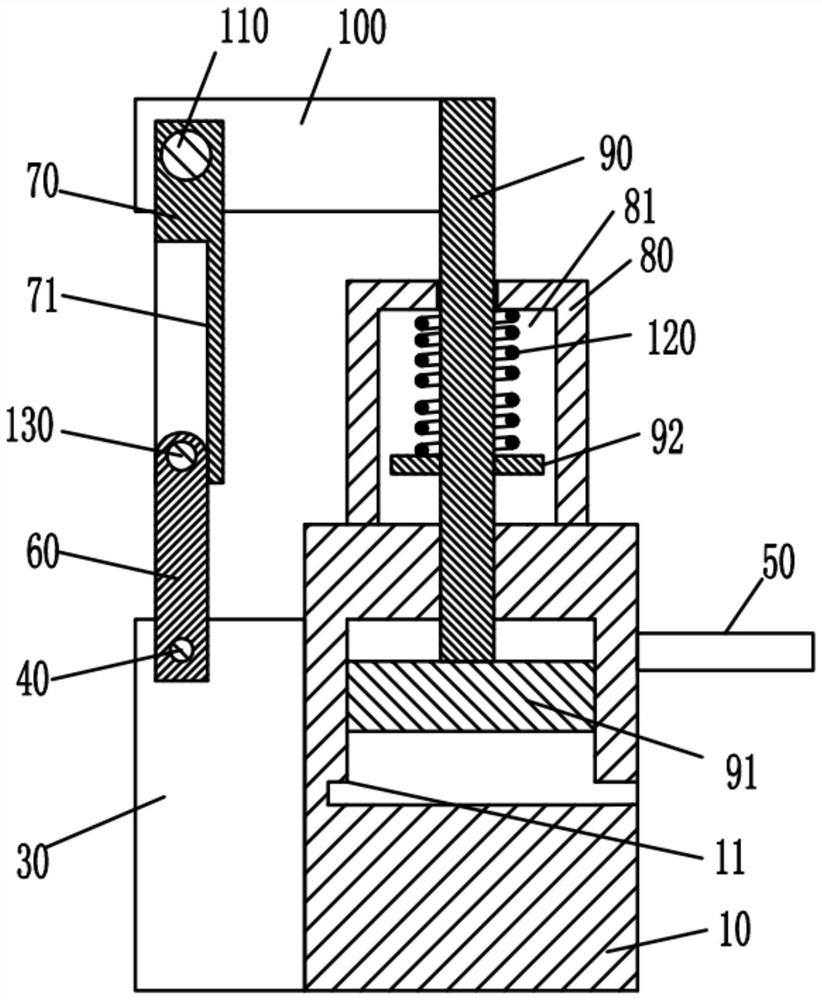

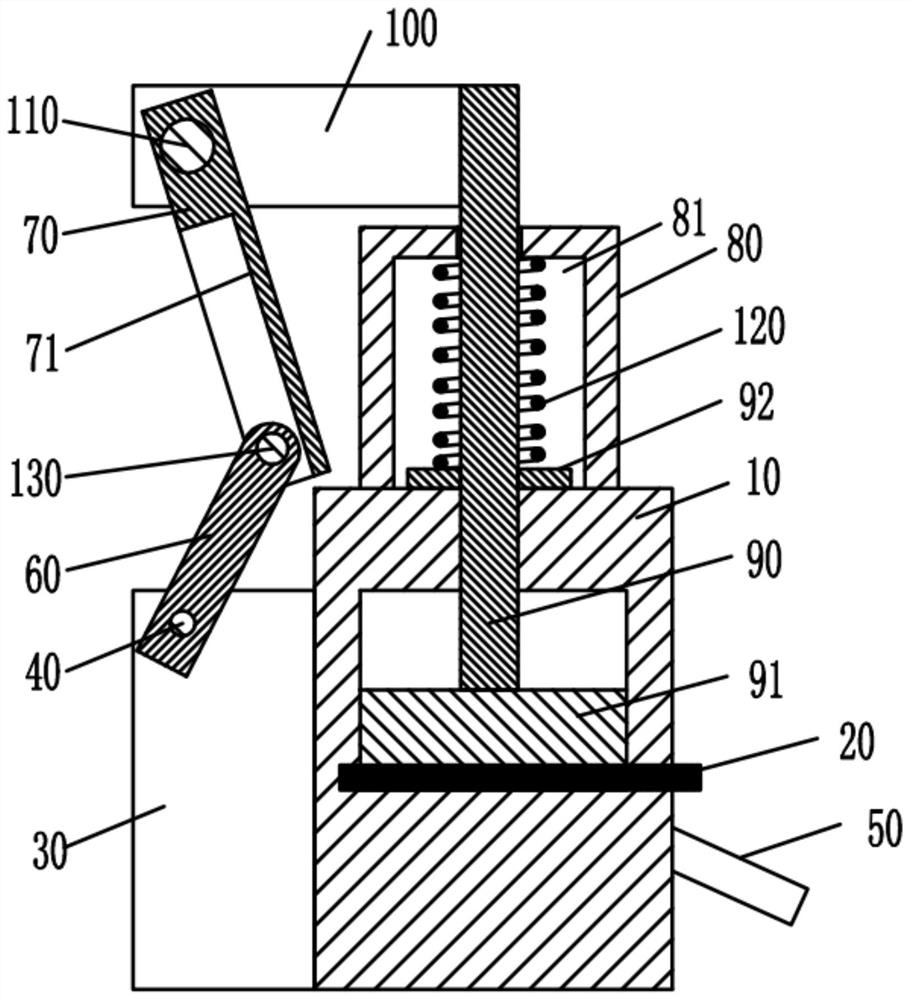

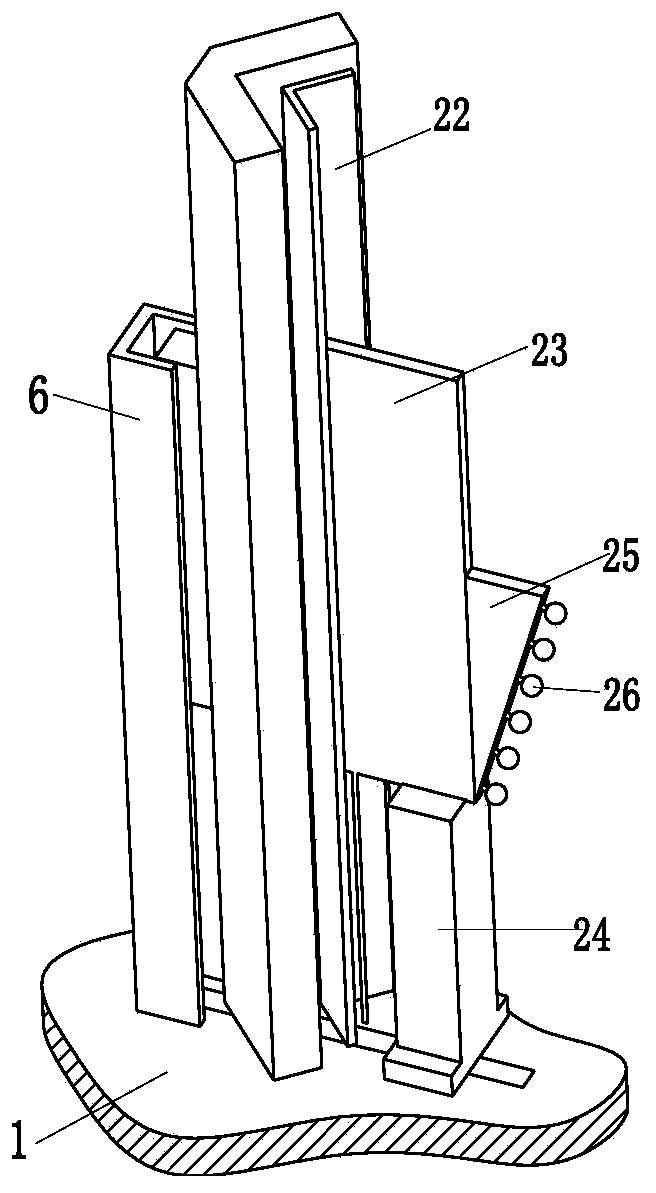

Ceramic substrate manual indentation device and indentation method thereof

ActiveCN110126097AEasy to creasingEasy accessWorking accessoriesStone-like material working toolsCeramic substrateMaterials science

The invention discloses a ceramic substrate manual indentation device and an indentation method thereof. The device comprises a frame, a first support plate, a first rotating shaft, a poking rod, a lower folding plate, an upper folding plate, a guide cylinder, a pressing rod and a second support plate; an indentation cavity is formed in the inner side of the frame for placing ceramic substrates; one end of the first rotating shaft penetrates through the first support plate in a transverse rotating mode; one end of the poking rod is fixedly connected with the first rotating shaft, and the otherend extends to the outer side of the first support plate; the lower section of the lower folding plate tightly sleeves the section, penetrating through the first support plate, of the first rotatingshaft; the inner side of the lower section of the upper folding plate is rotationally connected with the upper section of the lower folding plate through a second rotating shaft, and a shielding plateis fixedly arranged on the inner side wall; the guide cylinder is fixedly arranged on the upper surface of the frame, and a cylinder cavity communicates with the indentation cavity; the lower end ofthe pressing rod movably penetrates through the guide cylinder, and is inserted in the indentation cavity on the inner side of the frame, and an indentation block is fixedly arranged at the bottom; the second support plate is fixed on the side wall of the pressing rod; and the upper section of the upper folding plate is rotationally connected to the inner side of the second support plate through athird rotating shaft.

Owner:金洁华

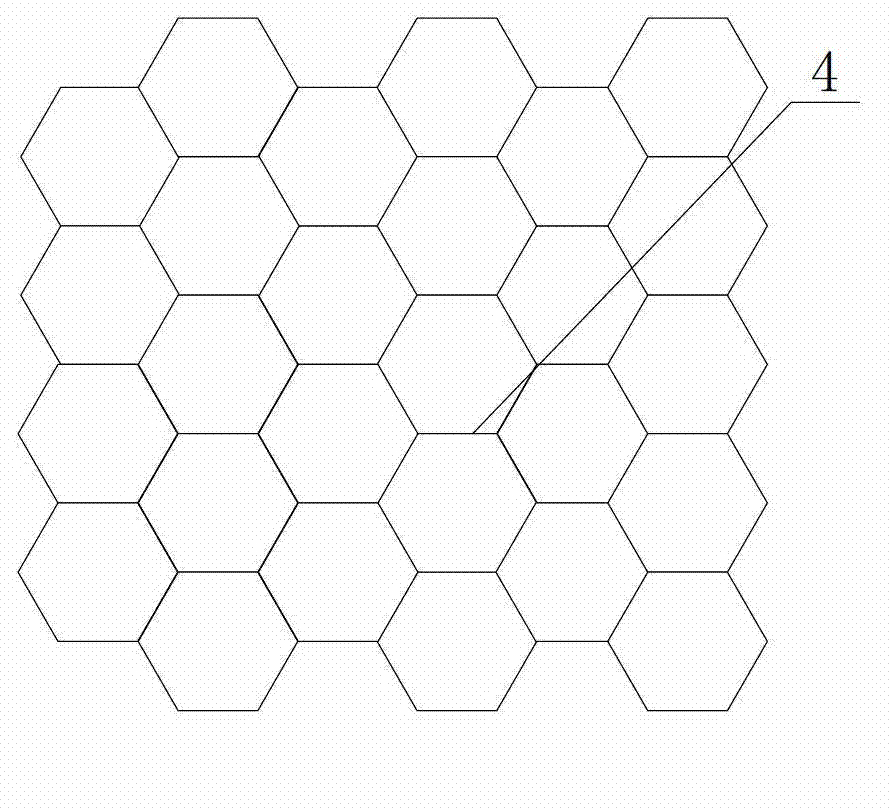

Manufacture method of anti-theft labels for supermarket bulk goods

InactiveCN103117025AAvoid completenessPrevent secondary useStampsLaminationBarcodePulp and paper industry

The invention provides a manufacture method of anti-theft labels for supermarket bulk goods. The manufacture method of the anti-theft labels for the supermarket bulk goods comprises the following steps: firstly utilizing fragile paper in the anti-counterfeiting printing industry to be special paper for manufacturing anti-theft labels; spreading coating on one face of the special paper to form a spreading coating layer; then utilizing orthohexagonal indentations on the back face of the special paper spreading coating layer, and manufacturing an adhesive sticker layer on the back face of the special paper spreading coating layer; and finally printing bar codes on the spreading coating layer to form the anti-theft labels. According to the manufacture method of the anti-theft labels for the supermarket bulk goods, the orthohexagonal indentations are adopted on the anti-theft labels, so that the labels can bear deformation from each angle, indentation processing is convenient, and rupturing is easy, and therefore intact peeling and reutilization after the labels are pasted can be prevented. The manufacture method of the anti-theft labels for the supermarket bulk goods is applicable to anti-theft labels of plastic package bulk goods.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

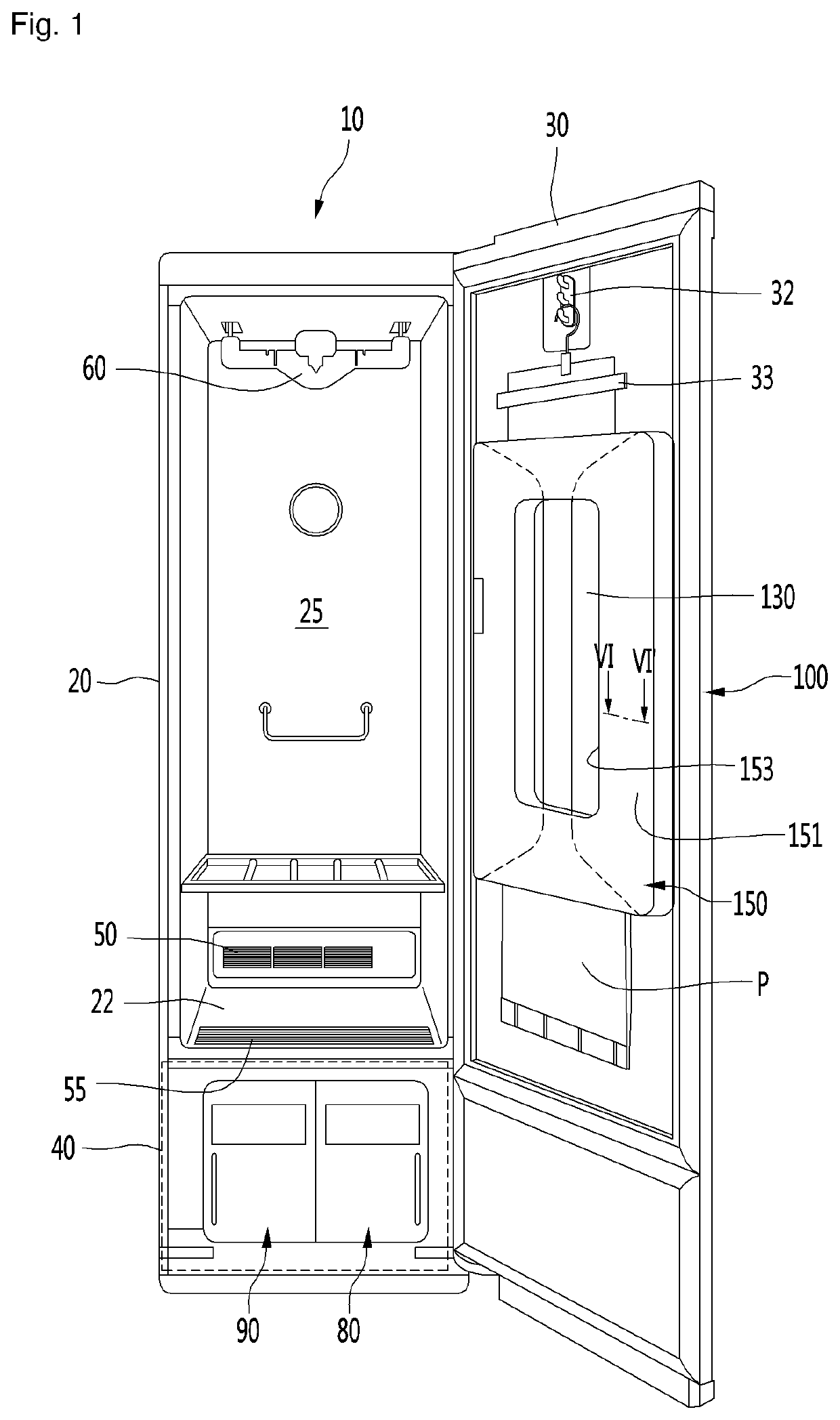

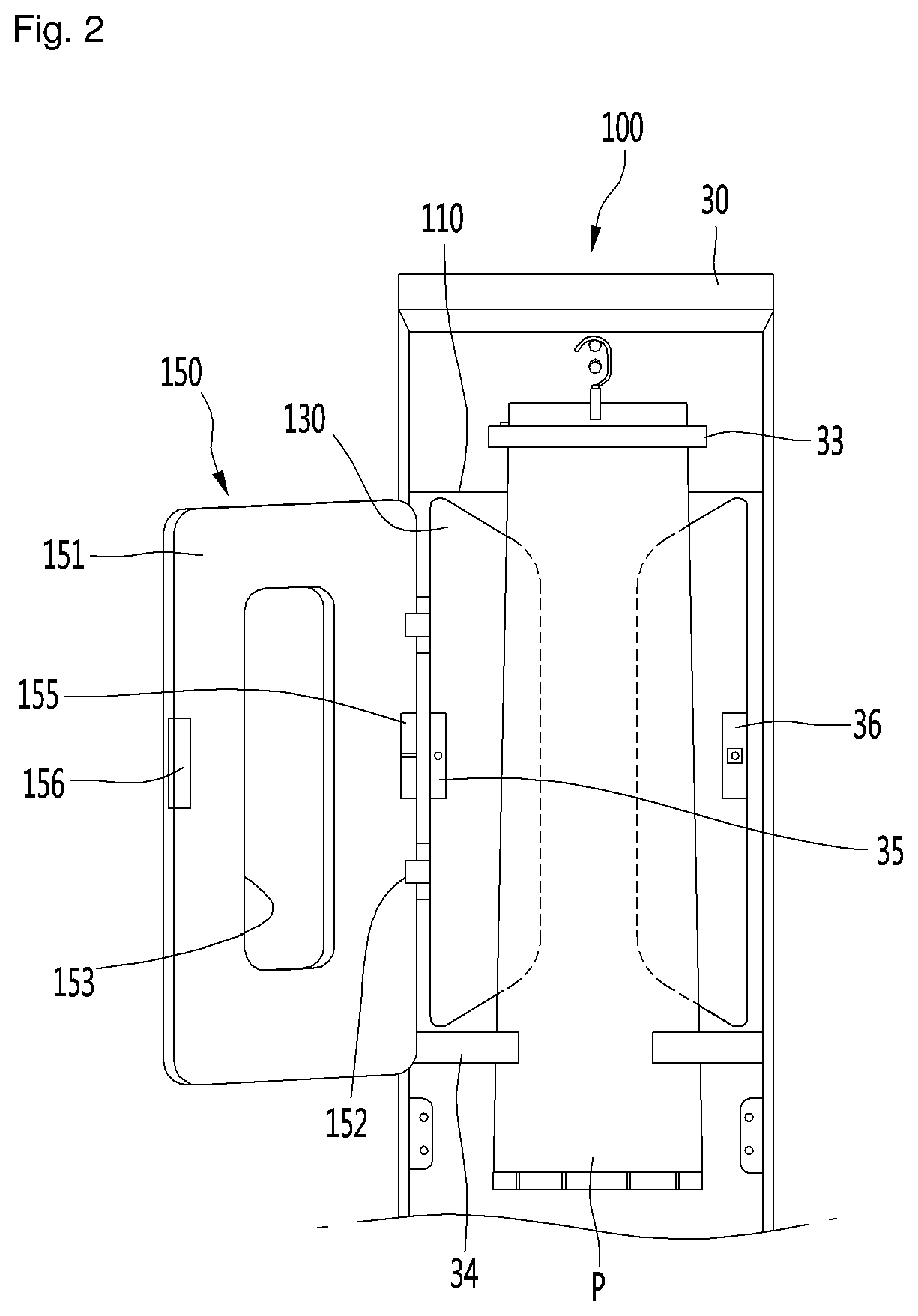

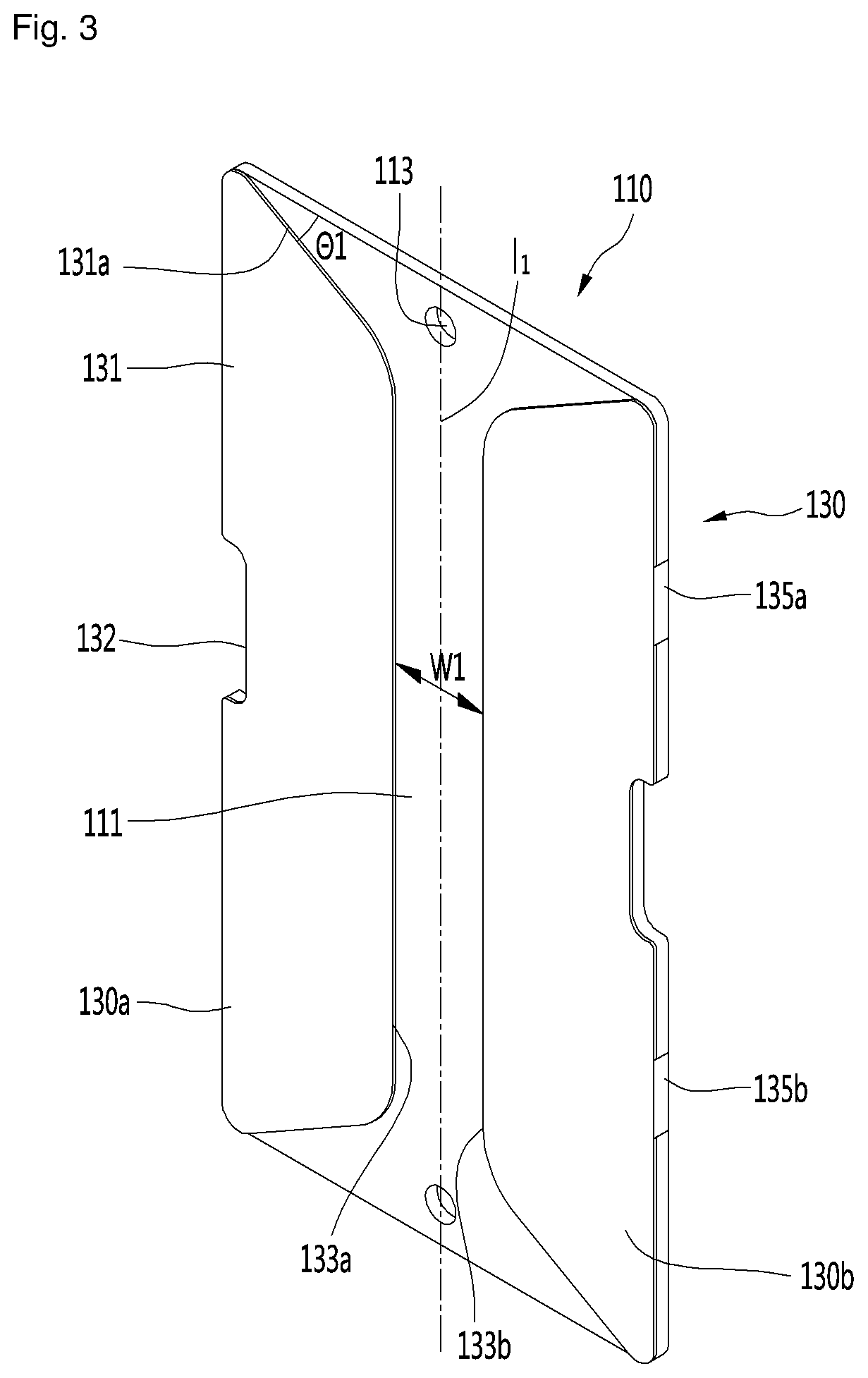

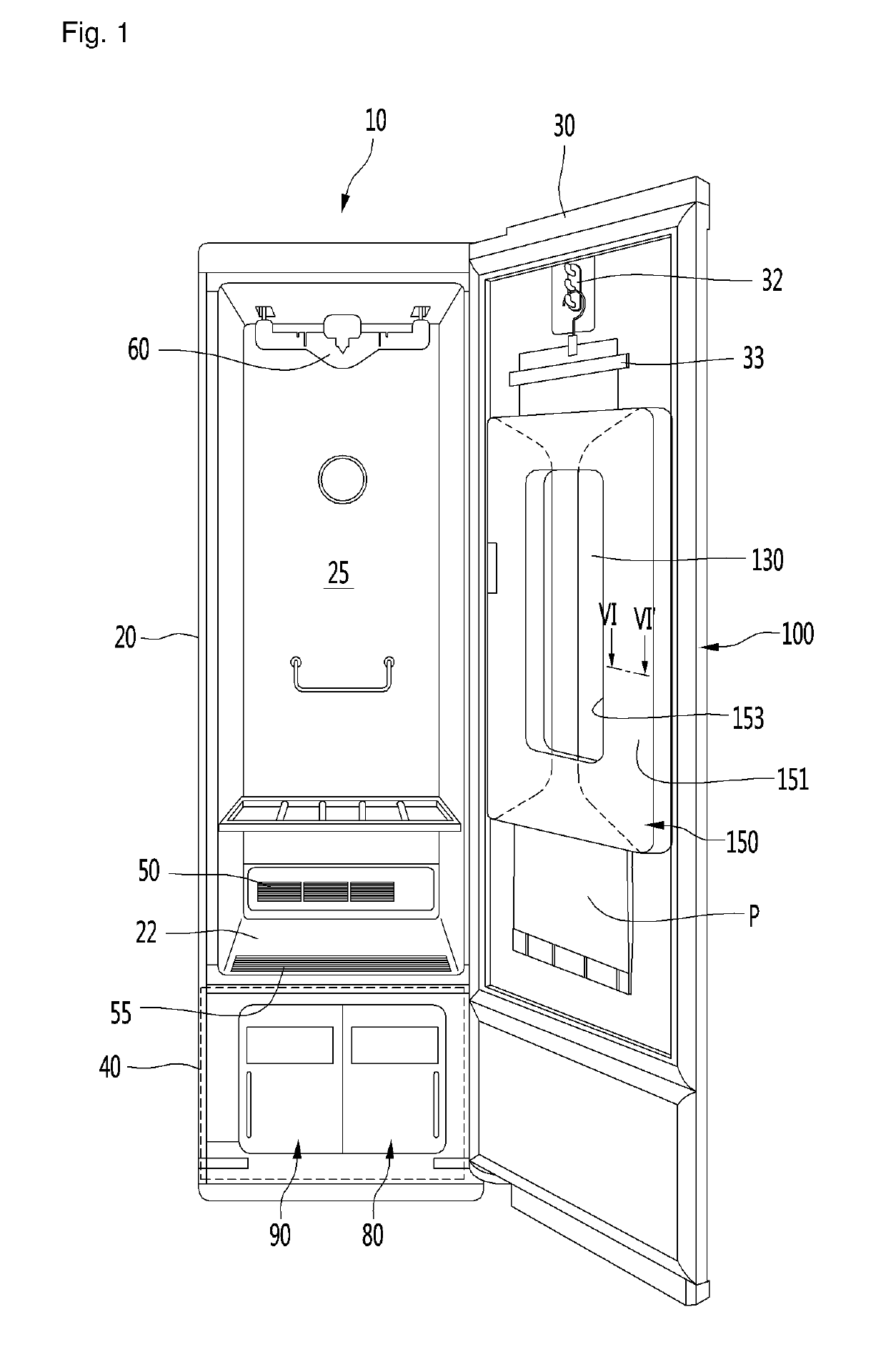

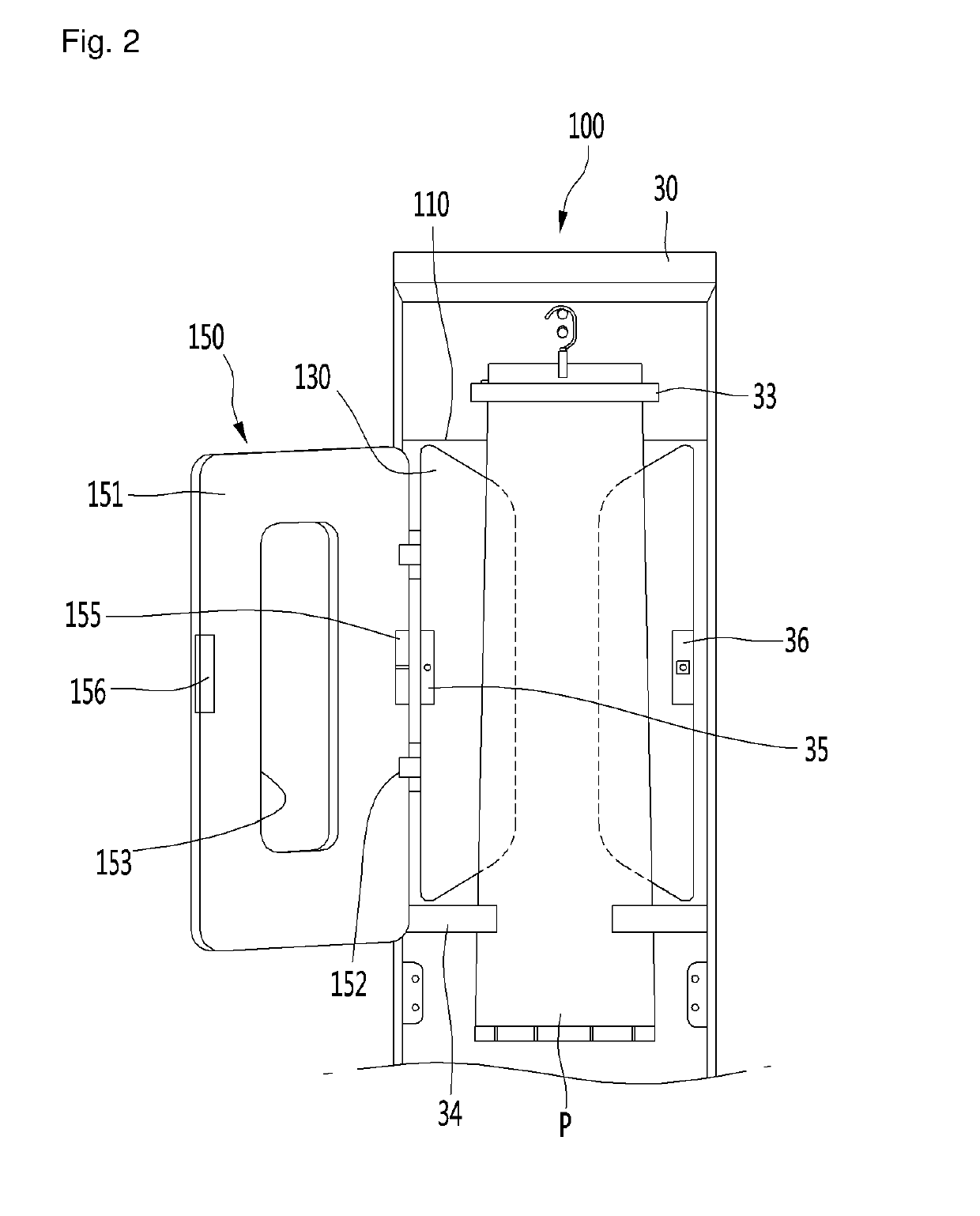

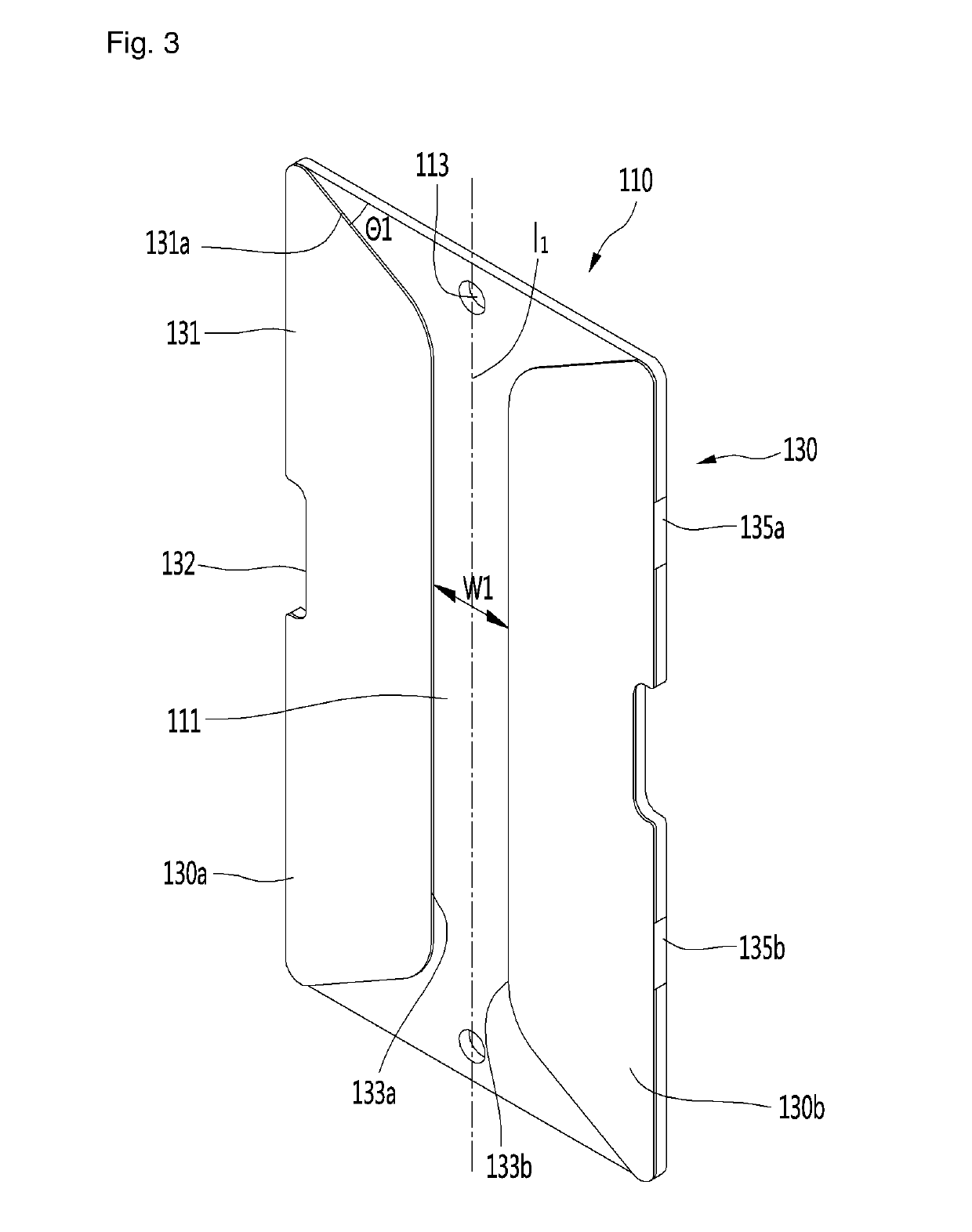

Clothes treatment apparatus

ActiveUS11060237B2Promote repairEasy to transformIroning machinesIroning apparatusMechanical engineeringIndustrial engineering

Owner:LG ELECTRONICS INC

Clothes treatment apparatus

ActiveUS20190257025A1Easy to placeSmall thicknessIroning machinesIroning apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

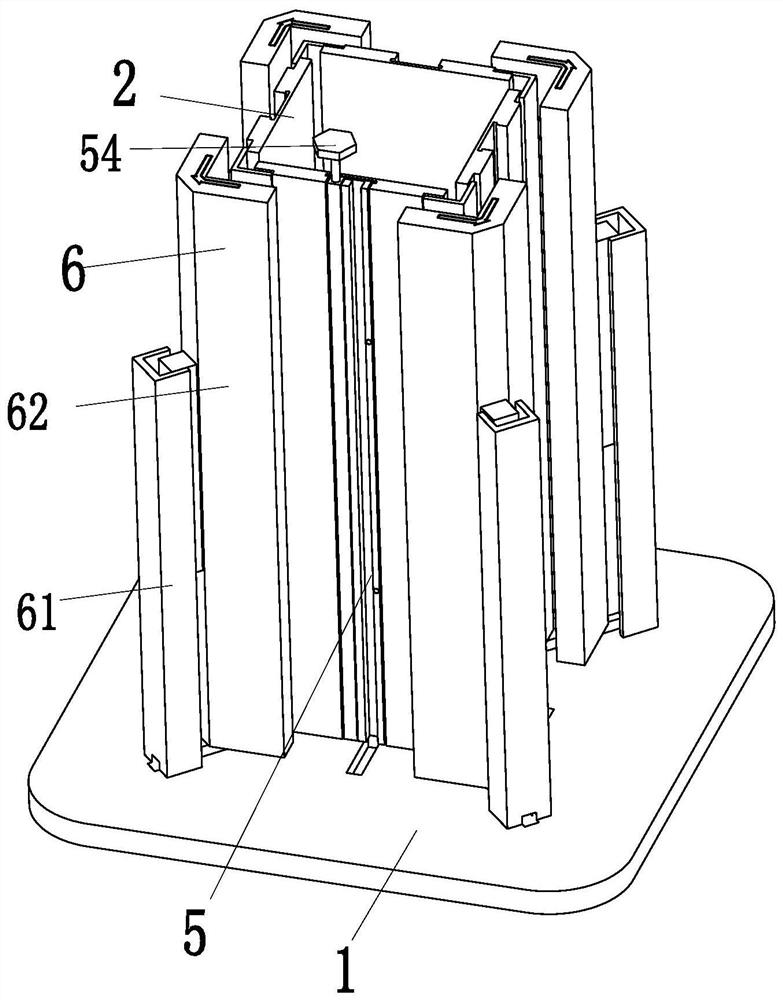

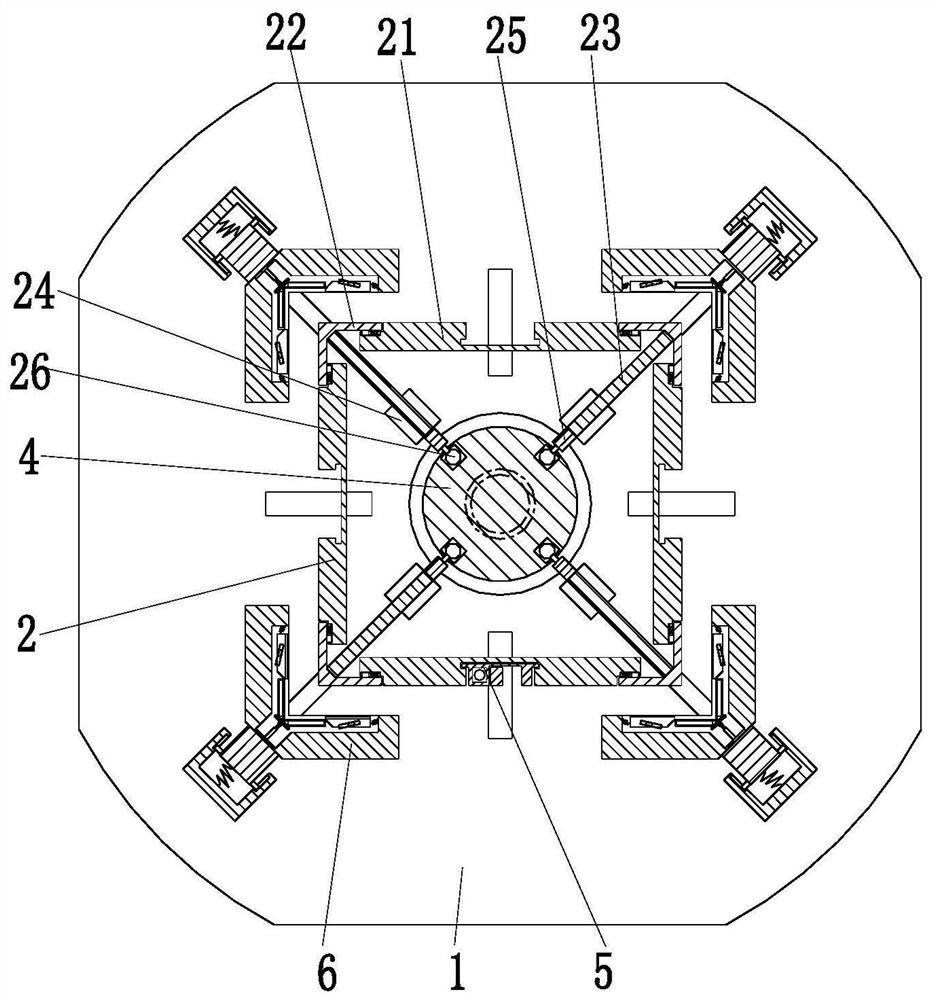

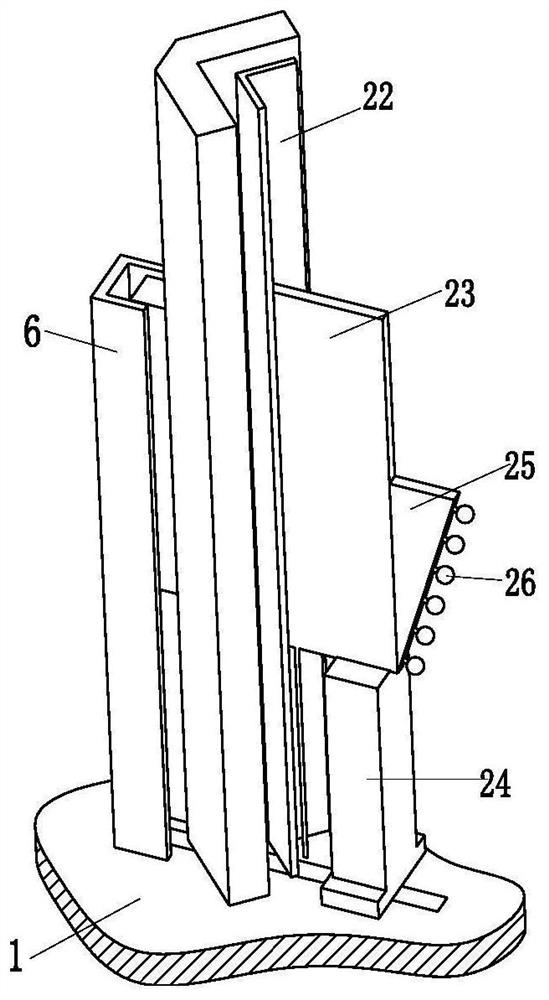

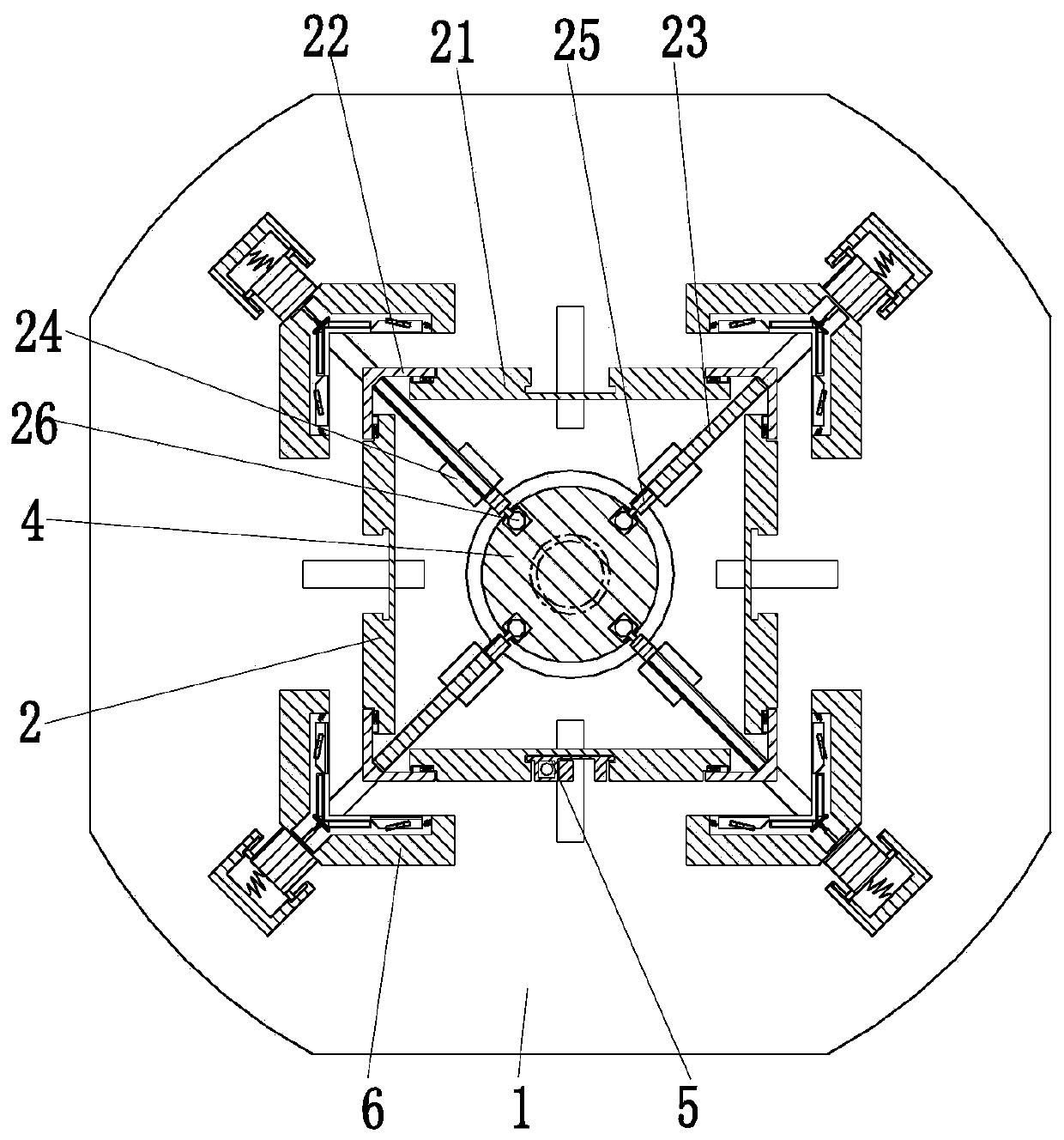

A forming and folding device for non-woven packaging bags and a forming and folding process

ActiveCN111070790BPrevent deviationImprove flatnessBag making operationsPaper-makingStructural engineeringNonwoven fabric

The invention relates to a non-woven packaging bag forming and folding device and a forming and folding process, including a bottom plate, an inner support device, a main cylinder, an extrusion column, a clamping device and four folding devices. The bottom plate An internal support device is installed on the top, and an extrusion column is arranged inside the internal support device. A main cylinder is connected between the lower end of the extrusion column and the bottom plate. Four folding devices are evenly installed on the bottom plate, and the internal support device is located on four Between the hemming devices. The invention can solve the problem that usually only one place of non-woven fabric can be indented in a single artificial indentation, the efficiency is low, and the non-woven fabric is soft in texture, and creases may appear after artificial indentation in an untightened state. In the case of uneven crease lines, and it is difficult to form obvious crease lines when indenting non-woven fabrics manually, personnel need multiple indentations to obtain more obvious indentations. However, the positions of multiple indentations are difficult to be completely consistent. As a result, the final indentation line may be skewed and other problems.

Owner:汕头市雄业实业有限公司

A manual indentation device and indentation method for a ceramic substrate

ActiveCN110126097BEasy to creasingEasy accessWorking accessoriesStone-like material working toolsBar pressingMechanical engineering

The invention discloses a ceramic substrate manual indentation device and an indentation method thereof, comprising: a frame, a first support plate, a first rotating shaft, a driving lever, a lower folding plate, an upper folding plate, a guide cylinder, a pressing rod, a second There is an indentation cavity on the inside of the frame for placing the ceramic substrate. One end of the first rotating shaft can be rotated through the first supporting plate horizontally. One end of the driving rod is fixedly connected with the first rotating shaft, and the other end extends to the first supporting plate. On the outside, the lower section of the lower flap is fastened and sleeved on the section where the first rotating shaft passes through the first support plate, and the inner side of the lower section of the upper flap is rotatably connected to the upper section of the lower flap through the second rotating shaft, and the inner side wall is also fixed with a The shroud and the guide cylinder are fixed on the upper surface of the frame, and the cylinder cavity is connected with the indentation chamber. The lower end of the pressure rod can move through the guide cylinder and be inserted into the indentation chamber inside the frame. For the indentation block, the second support plate is fixed on the side wall of the pressure rod, and the upper section of the upper flap is rotatably connected to the inner side of the second support plate through the third rotating shaft.

Owner:金洁华

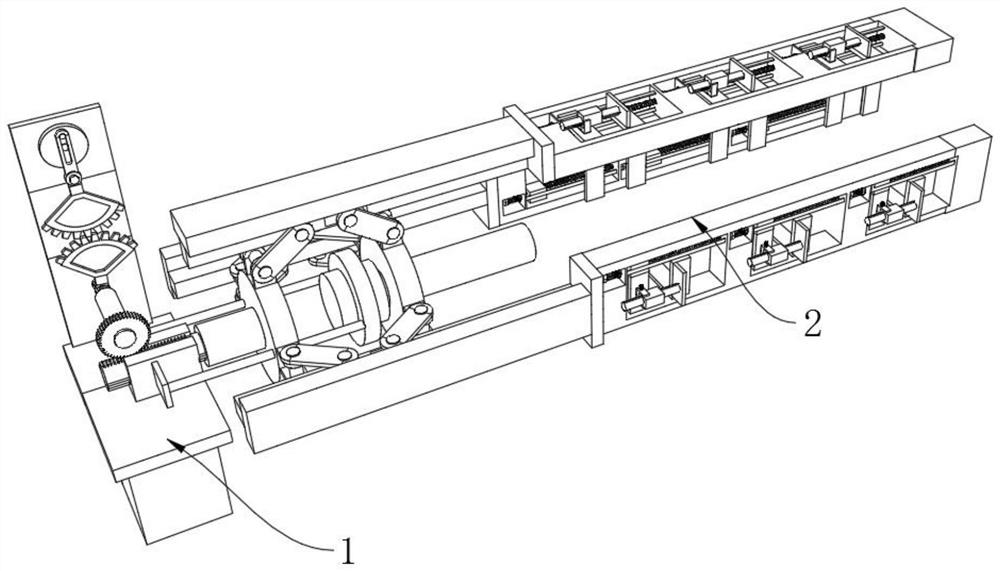

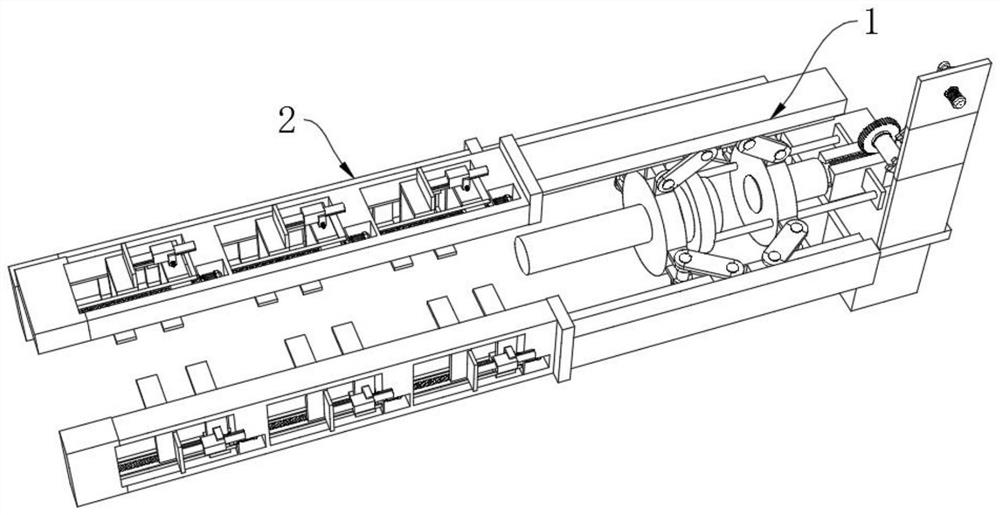

Energy-saving and environment-friendly intelligent corrugated paper production line

InactiveCN112009031AEasy to slideEasy to adjust spacingMechanical working/deformationPaper productionElectric machinery

The invention provides an energy-saving and environment-friendly intelligent corrugated paper production line. The production line comprises a U-shaped outer frame, supporting legs, conveying rollers,a conveying motor, a conveying belt, a transverse base plate, a rear side supporting plate, a top fixed plate, an extensible air cylinder, an indentation plate, an adjustable fixing frame structure,a mechanical indentation frame structure, an installation supporting plate, a control frame, a controller, a control button, an adjustable storage frame structure and a corrugated paper fixing frame structure; the supporting leg are installed at the four corners of the lower part of the U-shaped outer frame through bolts; and the conveying rollers are sequentially connected with the inner side ofthe U-shaped outer frame from left to right through shafts. Rectangular sliding blocks are in threaded connection with the outer side of a left-handed screw and the outer side of a right-handed screwcorrespondingly and are inserted into the left side and the right side of the interior of a rectangular sliding frame, the rectangular sliding blocks on the left side and the right side can be conveniently driven to slide in the rectangular sliding frame when the left-handed screw and the right-handed screw are rotated, and therefore the distance between longitudinal frames can be conveniently adjusted.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

An adjustable creasing machine for corrugated paper production

ActiveCN108973246BEasy to driveSmooth rotationMechanical working/deformationPhysical paper treatmentPaper productionPulp and paper industry

The invention belongs to the field of corrugated paper production, and particularly relates to an adjustable indenting machine for corrugated paper production. The adjustable indenting machine is convenient and quick in adjusting of indenting distance, convenient for replacement and capable of drying to-be-processed paper. The adjustable indenting machine comprises a first mounting plate, a firstsupporting rod, a second mounting plate, a first placement plate, a second placement plate, a drying device, a mounting frame, a mounting rod, a first fixing plate, a first elastic member, a first slider, a first sliding rail, a second slider and an electric reel, a second sliding rail is fixedly connected at the top of the first mounting plate, and the second slider is slidably connected with thesecond sliding rail. By the adjustable indenting machine, a wet paper raw material can be dried to a certain degree, and a distance between a first indenting barrel and a second indenting barrel canbe adjusted conveniently and quickly, so that effect of accelerating indenting speed is realized.

Owner:开平市世昌新材料科技有限公司

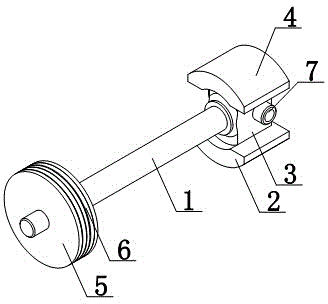

Swing type coated paper surface indentation device

InactiveCN104875428AEasy to creasingEasy to implementMechanical working/deformationPulp and paper industryEngineering

The invention discloses a swing type coated paper surface indentation device. The device comprises a swing rod, wherein a connection column is arranged at one end of the swing rod and is arranged on a swing base, the bottom of the swing base is in a shape of a cambered surface, a buckle plate is arranged at the upper part of the connection column and is in a shape of a cambered surface, a pressing wheel is arranged at the other end of the swing rod, and a pressing ring is arranged on the outer surface of the pressing wheel. To-be-processed coated paper is put at the bottom of the pressing wheel of the indentation device, indentation can be realized on the coated paper by the pressing wheel through the pressing ring, and the swing base can swing to control the pressing wheel to swing back and forth through the swing rod, so that indentation on the coated paper is conveniently realized.

Owner:赵士立

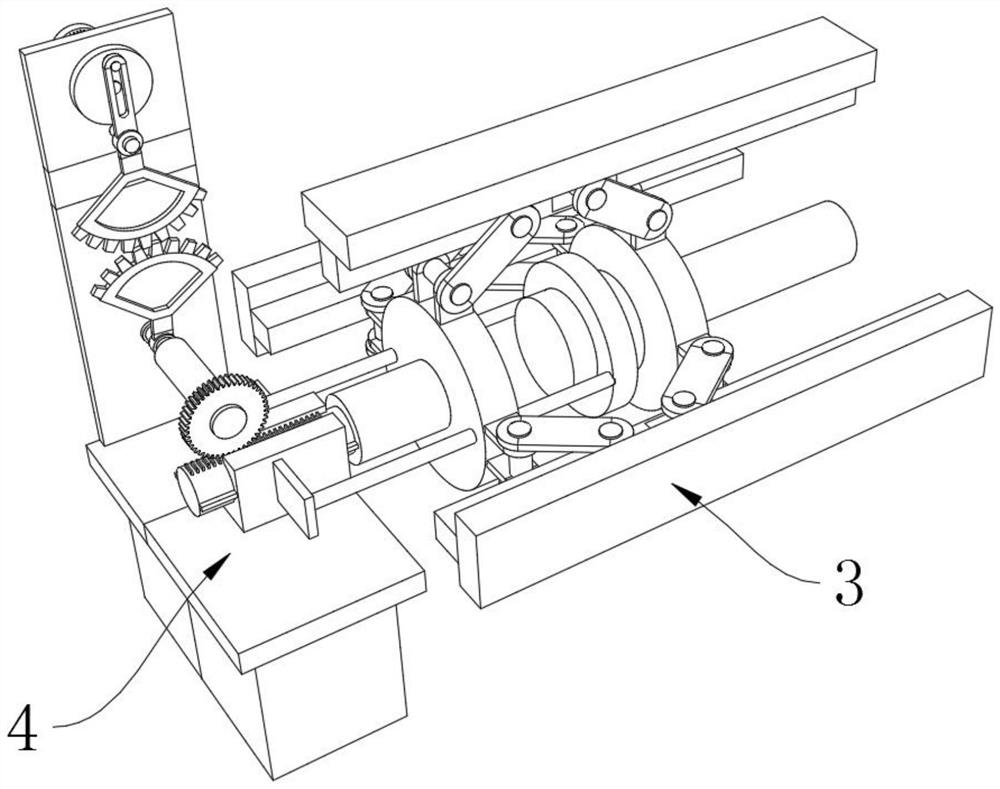

Novel carton indenting equipment

PendingCN113895082AFacilitate reciprocating automatic multi-directional indentationImprove efficiencyBox making operationsPaper-makingControl engineeringCarton

The invention discloses novel carton indenting equipment, and relates to the technical field of novel carton making devices. The novel carton indenting equipment comprises a reciprocating multi-directional indenting output structure and matched movable adjustable indenting plate structures, the multiple matched movable adjustable indenting plate structures are arranged at one end of the reciprocating multi-directional indenting output structure, the reciprocating multi-directional indenting output structure is used for providing continuous reciprocating power output, and the matched movable adjustable indenting plate structures are used for adjusting the tooth pitch according to requirements and then identing cartons by using the power of the reciprocating multi-direction identing output structure to complete. Due to the design of the reciprocating multi-direction identing output structure, the device can conveniently complete synchronous indenting output on cartons in three directions, so that reciprocating automatic multi-direction indenting on multiple cartons can be conveniently completed, the indenting production efficiency and convenience are greatly improved, and due to the design of the matched movable adjustable indenting plate structures, the distance between the teeth in the indenting process can be conveniently adjusted through the device, so that indenting can be conveniently carried out according to different requirements.

Owner:安徽佰特包装制品股份有限公司

A wallpaper printing device based on foaming ink

ActiveCN110561900BQuality assuranceGuaranteed clarityRotary pressesPrinting press partsWallpaperMechanical engineering

Owner:北京中国科学院老专家技术中心

Non-woven packaging bag making forming and edge overturning device and making forming and edge overturning technology

ActiveCN111070790APrevent deviationAvoid the situationBag making operationsPaper-makingStructural engineeringNonwoven fabric

Owner:汕头市雄业实业有限公司

Indenting machine

The invention belongs to the technical field of machining devices and particularly relates to an indenting machine. The indenting machine comprises a base. A lower frame is arranged on the base. An upper frame is arranged above the lower frame. At least one downward-pressing wheel is arranged on the lower frame. At least one upward-pressing wheel capable of being matched with the downward-pressing wheels is arranged on the upper frame. An embossing channel is formed between the downward-pressing wheels and the upward-pressing wheels. Any one of the upward-pressing wheels or the downward-pressing wheels is connected with a drive device capable of driving the corresponding wheel to rotate. A height adjusting mechanism capable of adjusting the size of the embossing channel is arranged between the upper frame and the lower frame. Compared with the prior art, the indenting machine has the beneficial effects that design is reasonable, a pipeline can be indented conveniently, and the indenting machine is convenient to carry and install; the structure is firm, the service life is long, and cost is saved; installation is reliable and convenient, and the machine can be conveniently located after being moved; the machine is convenient and easy to use and can be conveniently operated by a worker; and the indenting machine is of an anti-seismic and anti-skidding structure and is prevented from being moved.

Owner:ZHEJIANG DEQING CONCEPTFE PLASTIC PROD

A cardboard creasing device for color printing packaging

ActiveCN109334095BEasy to creasingMeet production needsBox making operationsPaper-makingColor printingPaperboard

The invention discloses a paperboard indenting device for color printing packaging. The device comprises a bottom plate, a paperboard processing table, a paperboard indenting mechanism and a guiding and pressing mechanism; the paperboard processing table is fixedly connected on the bottom plate through second supporting plate; the paperboard indenting mechanism is located above the paperboard processing table and is connected to a cross beam through a lifting mechanism; two ends of the cross beam are fixedly connected to the bottom plate through first supporting plates; and the guiding and pressing mechanism is connected to the bottom plate through the paperboard processing table. The device is simple in structure, high in practicability, capable of realizing indenting processing of paperboards in different structure sizes and capable of guaranteeing that the depths of all dents are consistent, and meanwhile, the device can press the paperboards tightly to avoid the influence of deviation or tilting of the paperboards on the denting processing quality during denting processing.

Owner:恩施市硒珍源茶业股份有限公司

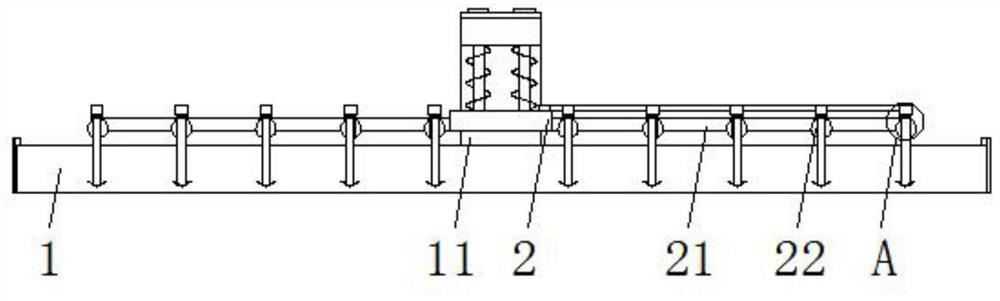

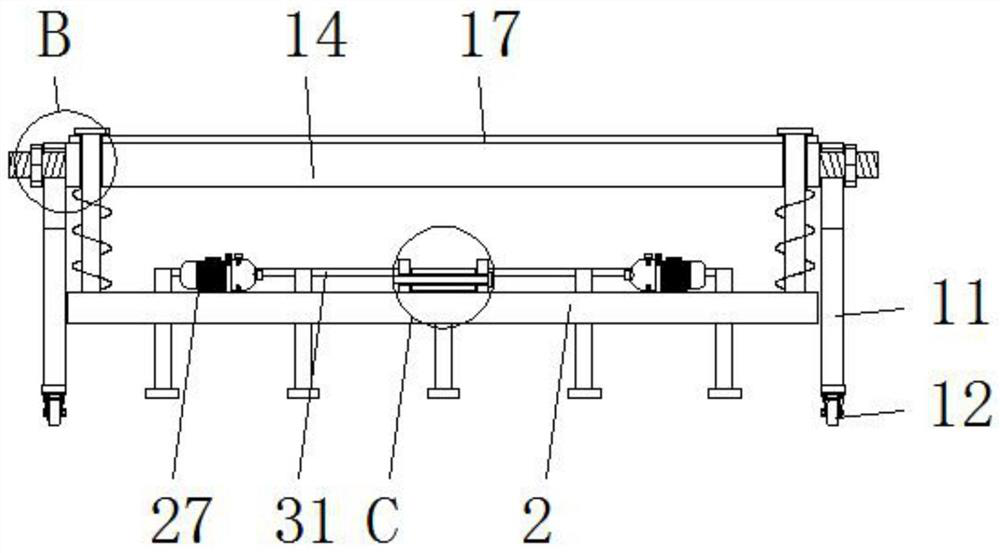

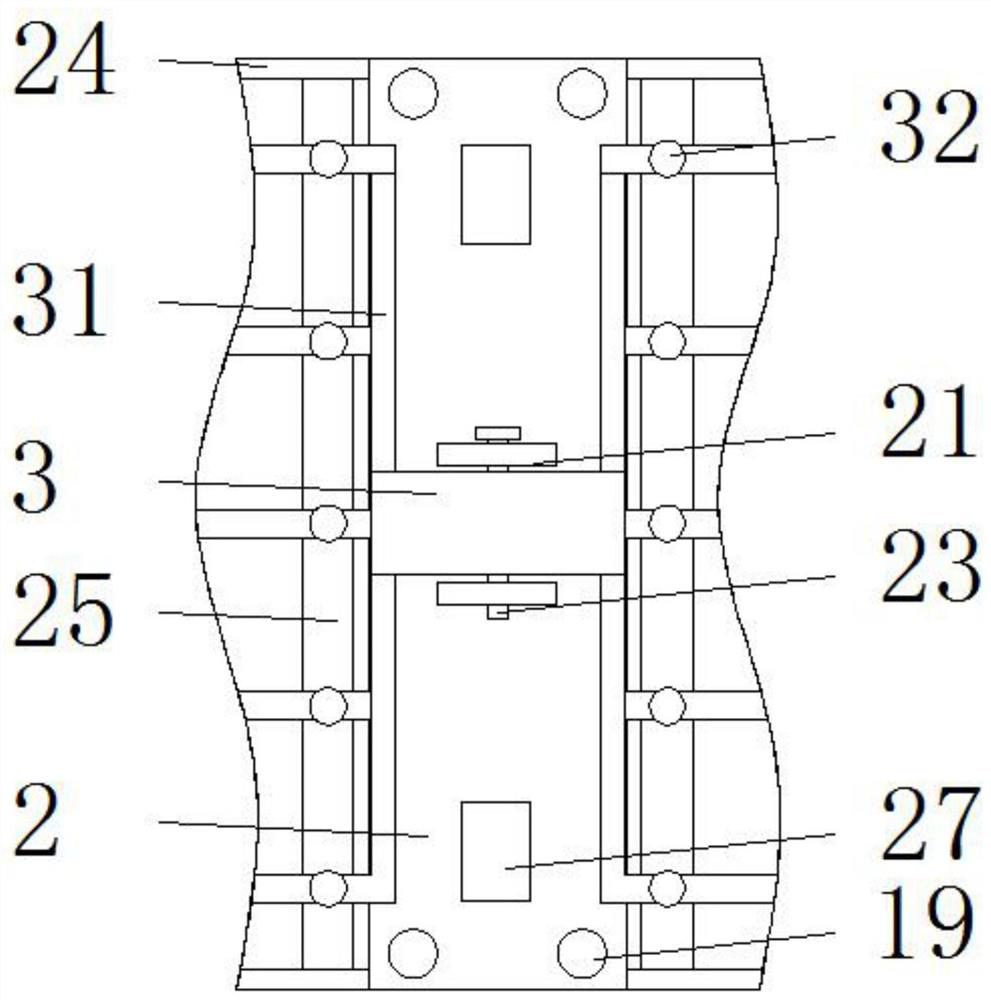

Auxiliary indentation equipment for concrete construction pouring and rapid indentation method thereof

ActiveCN113355982ACombined denseGuaranteed positional stabilitySolid waste managementRoads maintainenceArchitectural engineeringElectric machinery

The invention provides auxiliary indentation equipment for concrete construction pouring. The equipment comprises a mold body, a connecting plate, a clamping block and a fixing plate, supporting plates are arranged on the outer walls of the two sides of the mold body, the fixing plate is arranged on the outer walls of the opposite sides of the two supporting plates, a connecting plate is arranged on one side of the outer wall of the lower end of the fixing plate, connecting frames are symmetrically installed on the outer walls of the two sides of the connecting plate, indentation rods which are distributed in parallel at equal intervals are installed between the connecting frames, through holes which are distributed in parallel at equal intervals are formed in the indentation rods, vibration motors are symmetrically installed on one side of the outer wall of the upper end of the connecting plate, clamping sleeves are symmetrically mounted on the outer wall of the side, away from the vibration motors, of the connecting plate, and clamping blocks are arranged in the clamping sleeves. By arranging the indentation rods, the fixing plate and the connecting plate, the effect of conveniently indenting concrete is achieved, the workload of workers is reduced, the construction period is prevented from being affected, and the indentation making efficiency is improved.

Owner:广东辰集建设工程有限公司

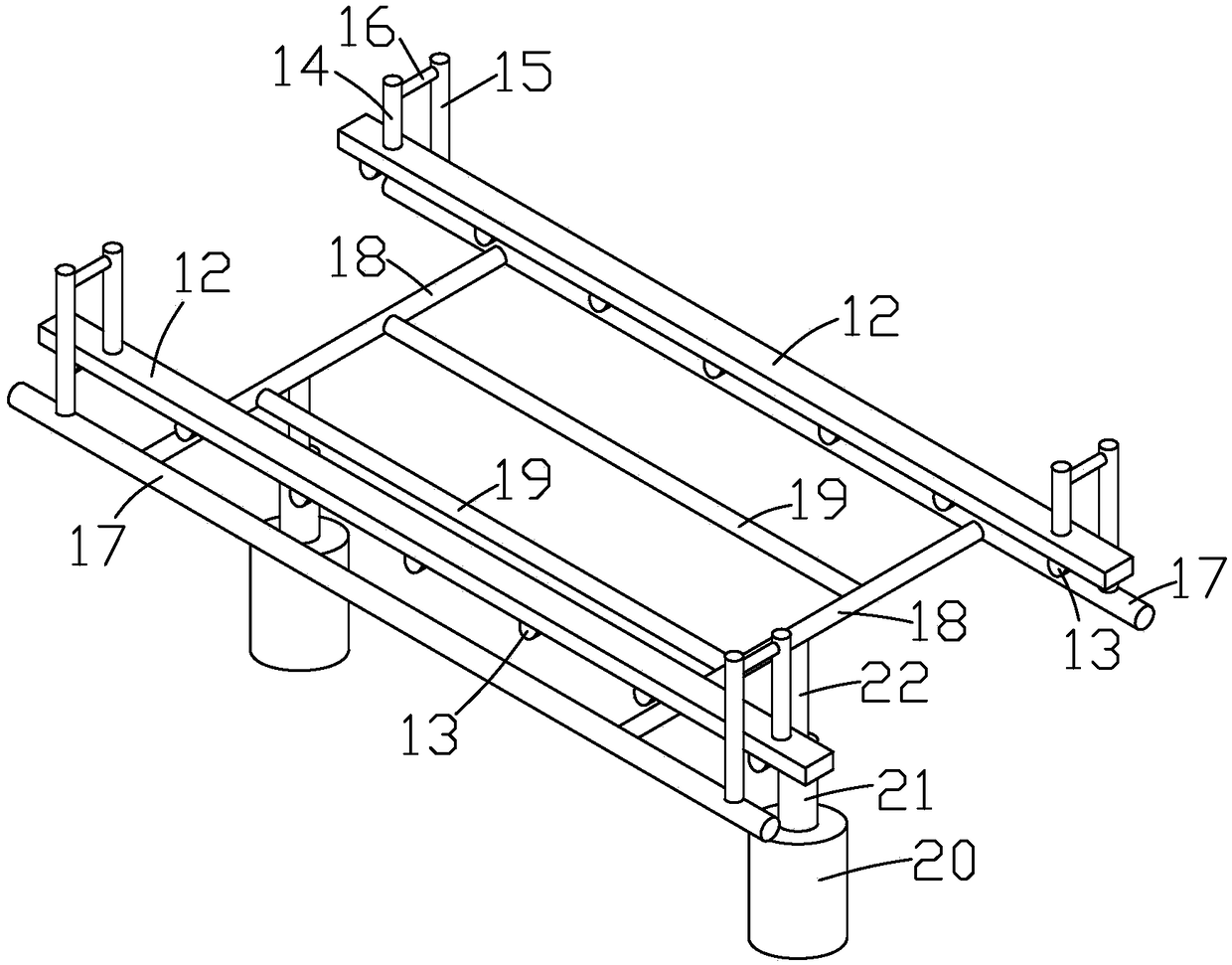

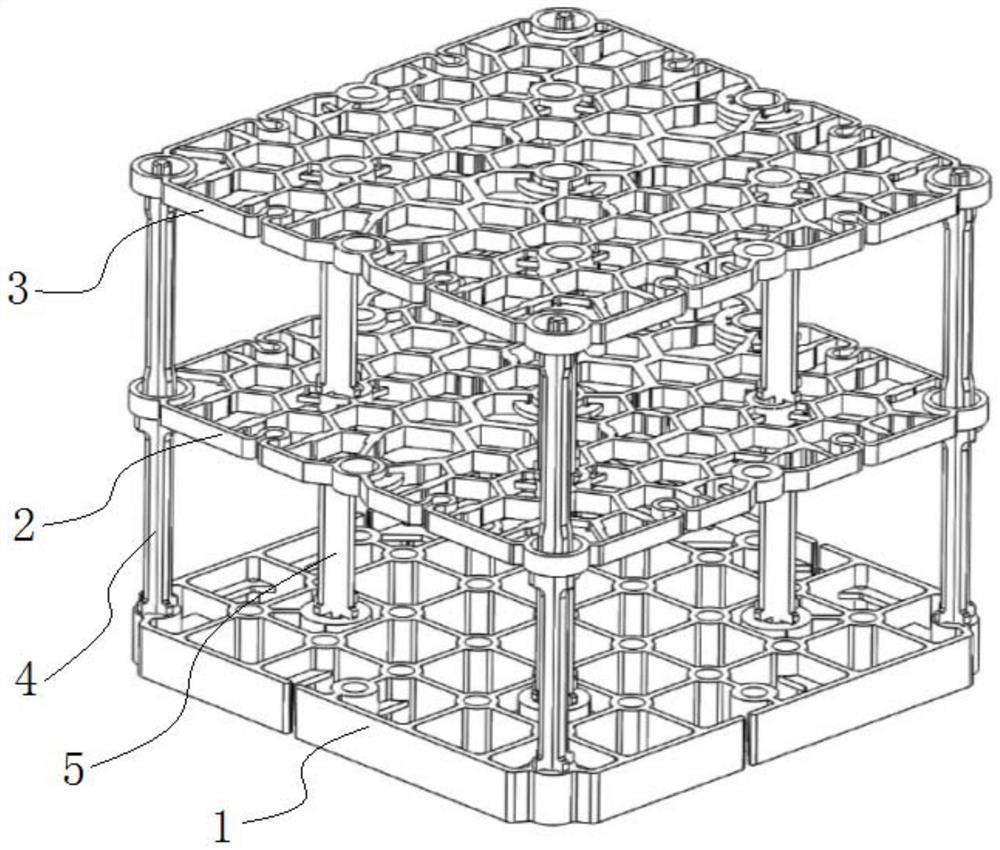

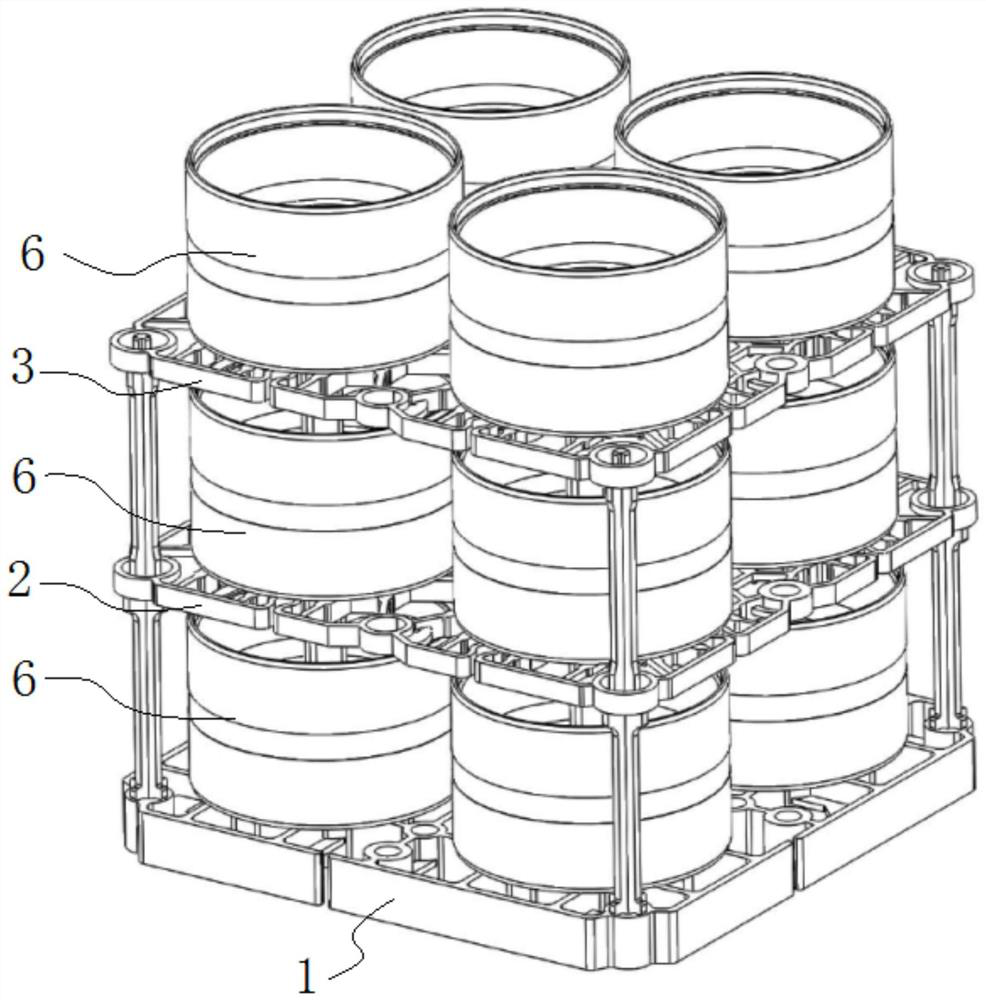

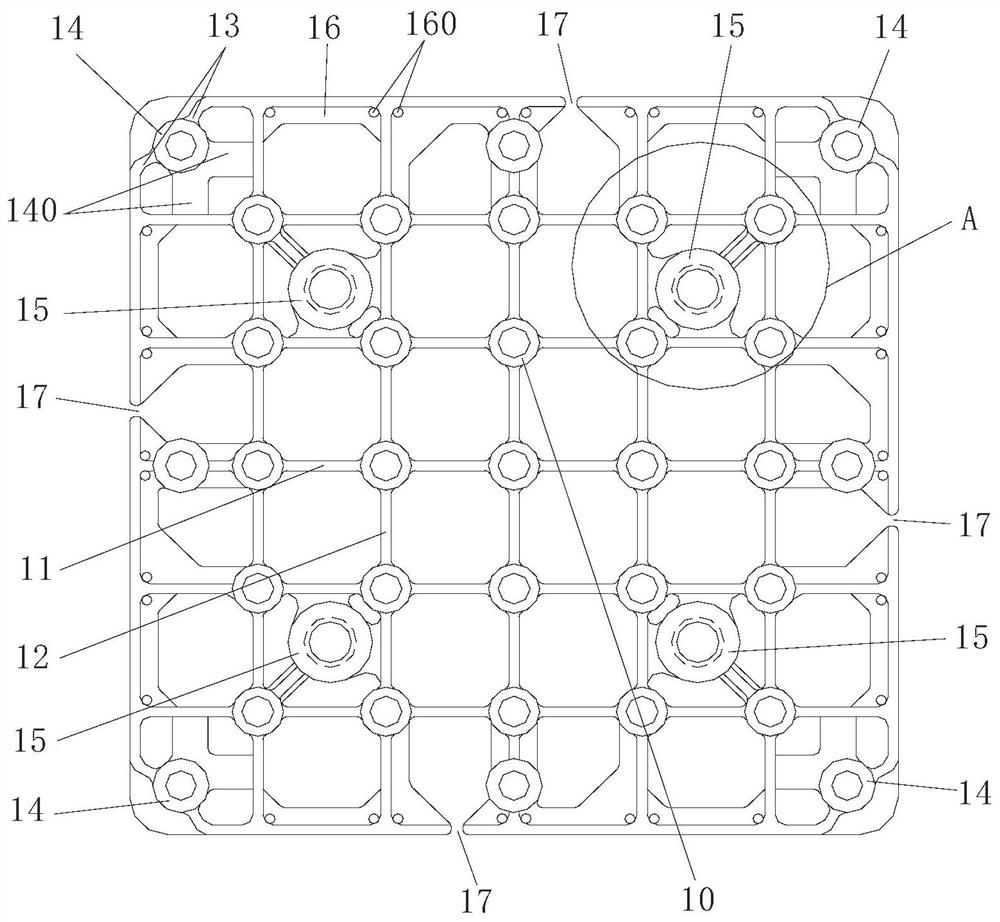

Carburizing charging tray for bearing rings

PendingCN111926283AReduce distortionReduce crackingCharge supportsSolid state diffusion coatingStructural engineeringMechanical engineering

The invention discloses a carburizing charging tray for bearing rings. The carburizing charging tray comprises a bottom layer charging tray, a middle layer charging tray and an upper layer charging tray, wherein the bottom layer charging tray, the middle layer charging tray and the upper layer charging tray are respectively and uniformly loaded with the four bearing rings; four lower bearing column bases are arranged on the bottom layer charging tray, each lower bearing column base is provided with a reinforcing structure, and the reinforcing structure comprises two inner rib plates, a lower bearing rod and two lower reinforcing rib plates; the inner side surface of a transverse connecting plate and the inner side surface of a longitudinal connecting plate located on the peripheral edge ofthe bottom layer charging tray are provided with horizontal edge rib plates at half height; four upper bearing column bases are uniformly distributed on the middle layer charging tray and the upper layer charging tray, each upper bearing column base is provided with an upper reinforcing structure, and the upper reinforcing structure comprises three pairs of upper reinforcing rib plates; and partitions, in contact with the four bearing rings, of the middle layer charging tray and the upper layer charging tray are locally widened to 2.5-4.5 times the width of the bottom wall thickness of the bearing rings. According to the carburizing charging tray for the bearing rings, the deformation of the bearing rings can be reduced, and the deformation and cracking of the bearing column bases are reduced.

Owner:SHANGHAI UNITED BEARING

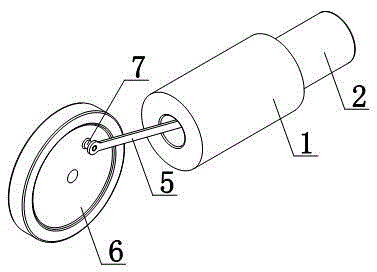

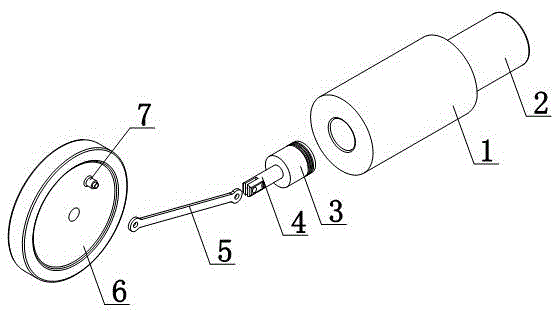

Electric heating wheel creasing mechanism

InactiveCN105537383AEasy indentation handlingEasy to creasingShaping toolsMetallic materialsEngineering

The invention discloses an electric heating wheel creasing mechanism which comprises a barrel. A fixing pipe is arranged at the end of the barrel, a connecting pipe is arranged in the barrel, a connecting rod is connected to the connecting pipe, a connecting strip is connected to the connecting rod, an electric heating wheel made of metal materials is arranged at the end of the connecting strip, and electric heating wires are arranged in the electric heating wheel. The electric heating wheel creasing mechanism can be installed on a rack, creasing can be conveniently conducted on an aluminum sheet through the electric heating wheel, the electric heating wheel is connected with an external power source, therefore, heat is generated after energizing is conducted, and creasing processing is conveniently conducted on the aluminum sheet.

Owner:孟书芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com