Energy-saving and environment-friendly intelligent corrugated paper production line

An energy-saving and environmentally friendly corrugated paper technology, applied in the field of corrugated paper processing, can solve the problems of not having the distance between creasing wheel frames, not having the function of pressing wheel locking, and inconvenient fixing of corrugated paper, so as to improve energy saving effect, facilitate collection, and increase energy consumption. Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

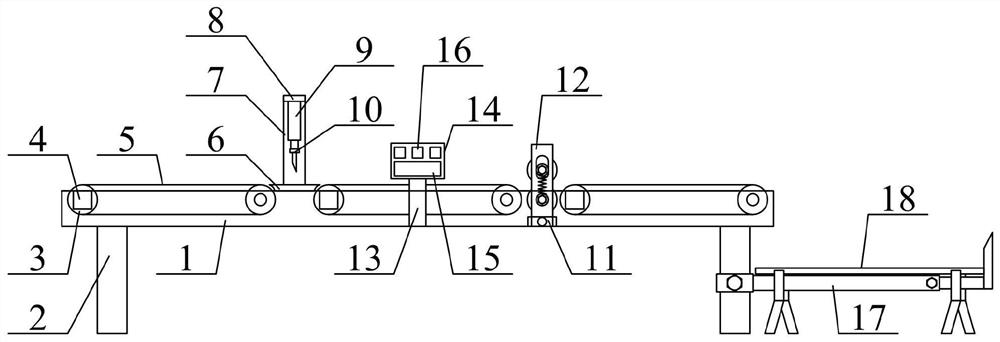

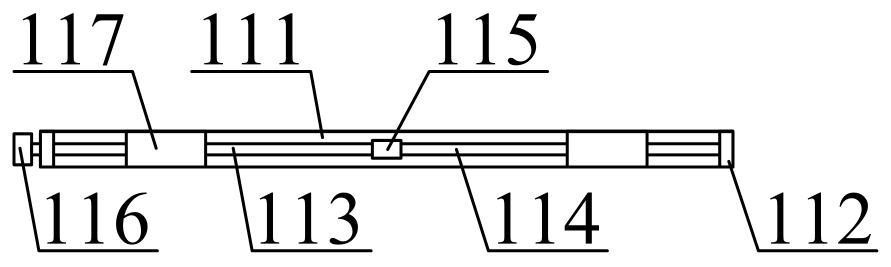

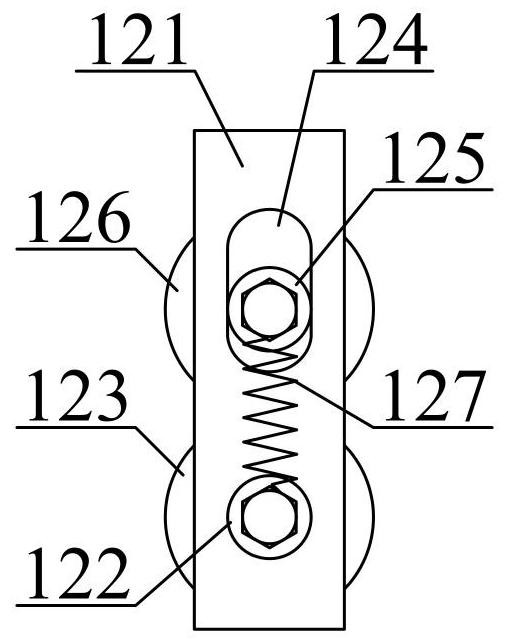

[0042] as attached figure 1 And attached figure 2 shown

[0043] The present invention provides an energy-saving and environment-friendly intelligent corrugated paper production line, which includes a U-shaped outer frame 1, supporting legs 2, conveying rollers 3, conveying motor 4, conveying belt 5, horizontal backing plate 6, rear support plate 7, top fixing plate 8, Telescopic cylinder 9, indentation plate 10, adjustable fixed frame structure 11, mechanical indentation frame structure 12, mounting support plate 13, control frame 14, controller 15, control button 16, adjustable storage frame structure 17 and corrugated paper fixed frame Structure 18, the bolts of the supporting legs 2 are installed at the lower four corners of the U-shaped frame 1; the conveying rollers 3 are axially connected to the inner side of the U-shaped frame 1 from left to right; the conveying motor 4 The bolts are installed on the front side of the U-shaped outer frame 1, and are connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com