Creasing machine

A technology of creasing machine and pressing wheel, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of inconvenient portability, high use cost, unsuitable for pipe indentation, etc., and achieves long service life, easy operation and installation. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

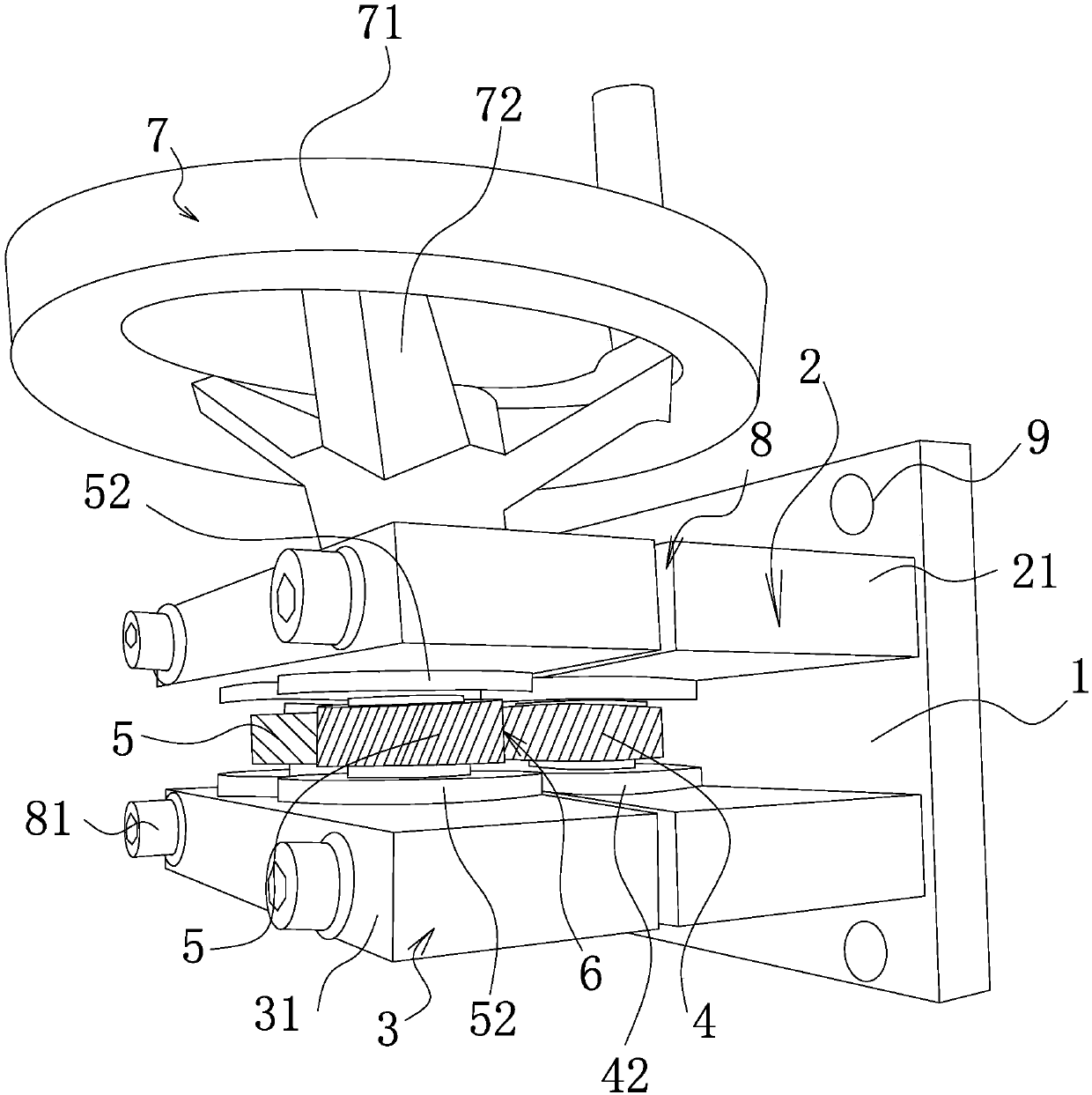

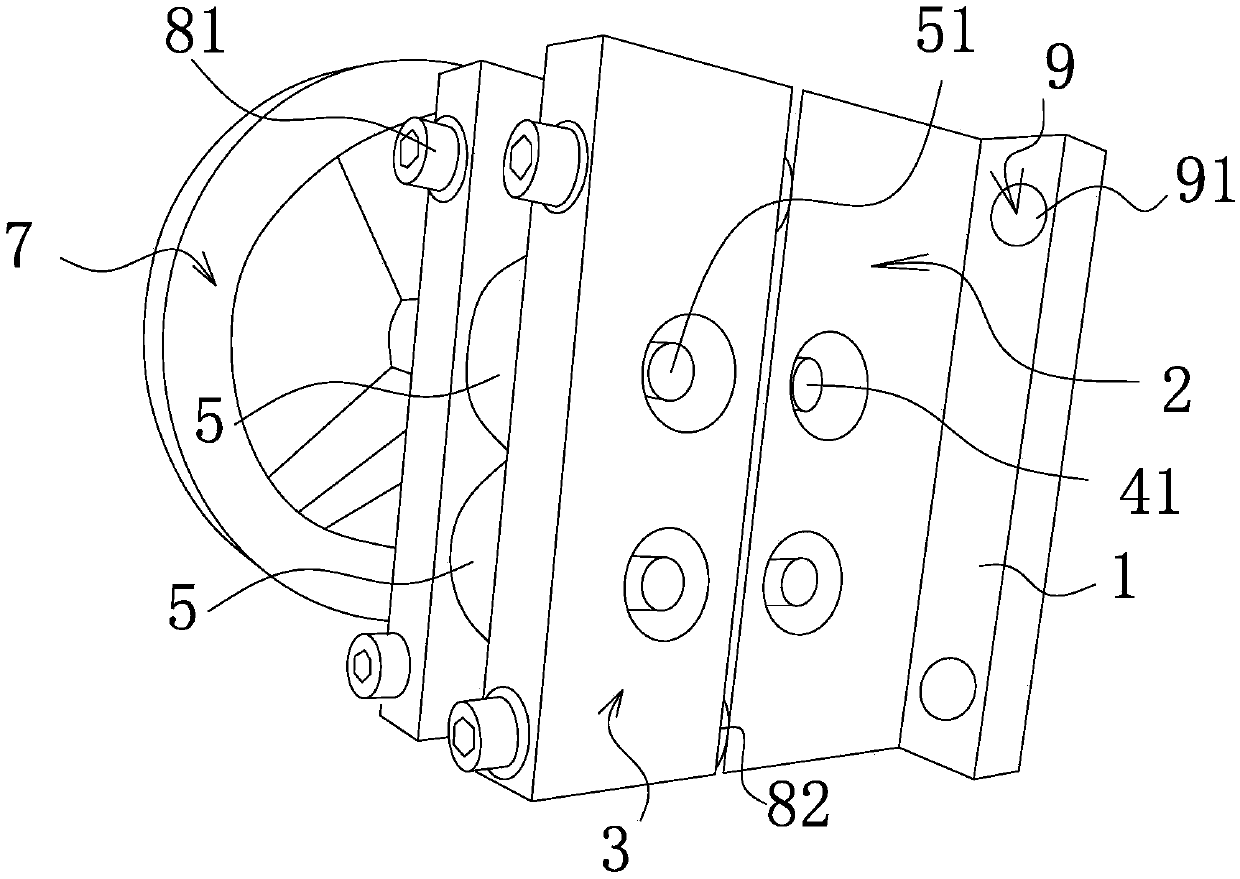

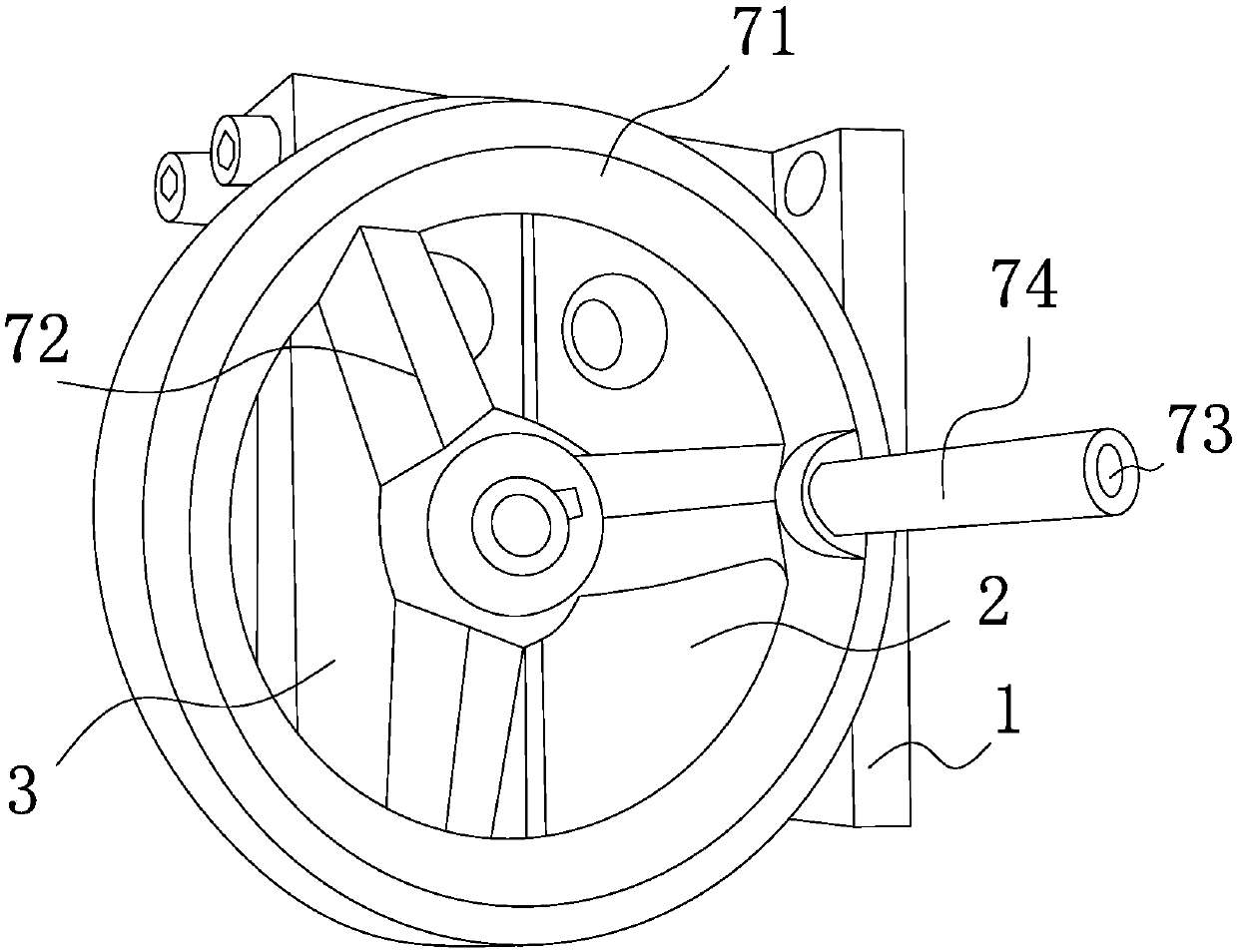

[0023] Such as Figure 1-5 As shown, the creasing machine includes a base 1, a lower frame body 2 is arranged on the base 1, an upper frame body 3 is arranged above the lower frame body 2, at least one lower pressing wheel 4 is arranged on the lower frame body 2, and the upper frame body 3 There is at least one upper pressing roller 5 capable of cooperating with the lower pressing roller 4, an embossing channel 6 is formed between the lower pressing roller 4 and the upper pressing roller 5, and any one of the upper pressing roller 5 or the lower pressing roller 4 is connected with The driving device 7 capable of driving its rotation is connected, and a height adjustment mechanism 8 capable of adjusting the size of the embossing passage 6 is provided between the upper frame body 3 and the lower frame body 2 .

[0024] The upper frame body 3 includes two opposing upper side plates 31, the upper pressure roller 5 is mounted on the upper rotating shaft 51, and the two ends of the ...

Embodiment 2

[0028] Such as Figure 6-7 As shown, in this embodiment, a detachable fixing part 11 is provided at the bottom of the base 1. The fixing part 11 includes strip-shaped rubber pads 111 arranged on both sides of the bottom of the base 1. The bottom of the strip-shaped rubber pad 111 has an arc-shaped part 112 , the outer surface of the arc portion 112 is provided with a number of uniformly distributed rubber protrusions 113, and each strip-shaped rubber pad 111 is also pierced with a number of horizontally distributed and vertically arranged metal support columns 114, and the upper end of the metal support column 114 and the base 1 fixed connection, a number of trapezoidal metal protrusions 114a are provided at the lower end of the metal support column 114, the vertical length of the metal support column 114 is smaller than the vertical thickness of the strip-shaped rubber pad 111, and there is also a bottom of the strip-shaped rubber pad 111 The bottom metal clamping block 115, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com