Carburizing charging tray for bearing rings

A technology of bearing rings and trays, which is applied in metal material coating technology, lighting and heating equipment, furnace components, etc., can solve problems such as deformation and cracking of core stress-bearing parts, and achieve reduction of deformation and cracking, strengthening of strength, and The effect of protecting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

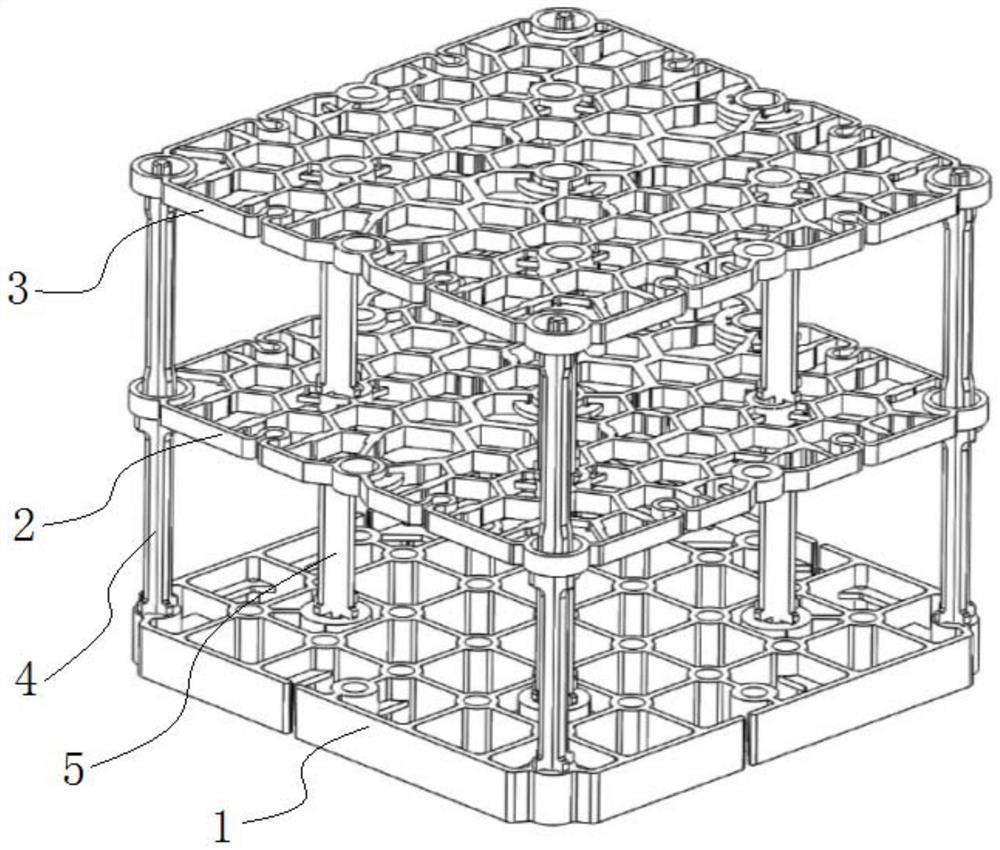

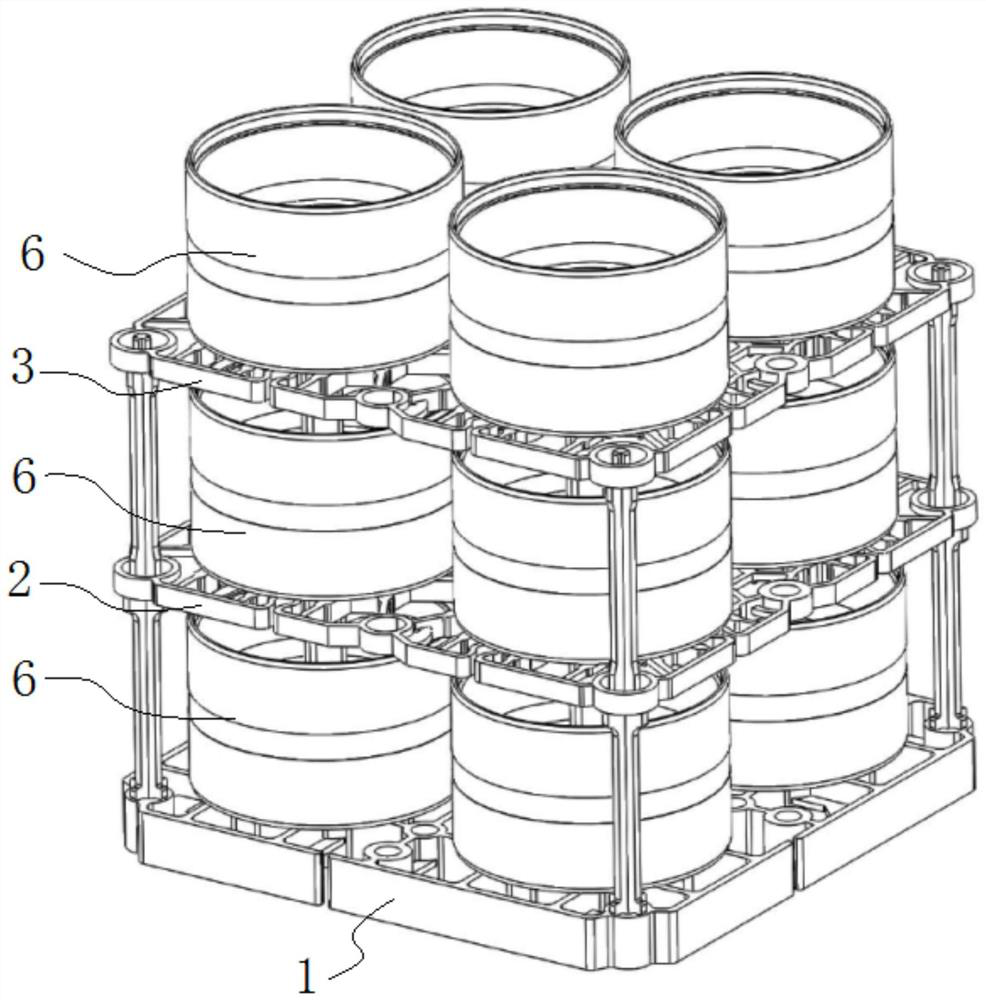

[0029] see Figure 1 to Figure 4b , the carburizing tray of the bearing ring of the present invention comprises a bottom tray 1, a middle tray 2 and an upper tray 3 connected by four positioning columns 4 and four load-bearing columns 5; the bottom tray 1, the middle tray The shape and size of the disc 2 and the upper tray 3 are the same and each is loaded with four bearing rings 6 evenly distributed. The thickness of the middle layer material tray 2 and the upper layer material tray 3 is the same and less than the thickness of the bottom layer material tray 1 .

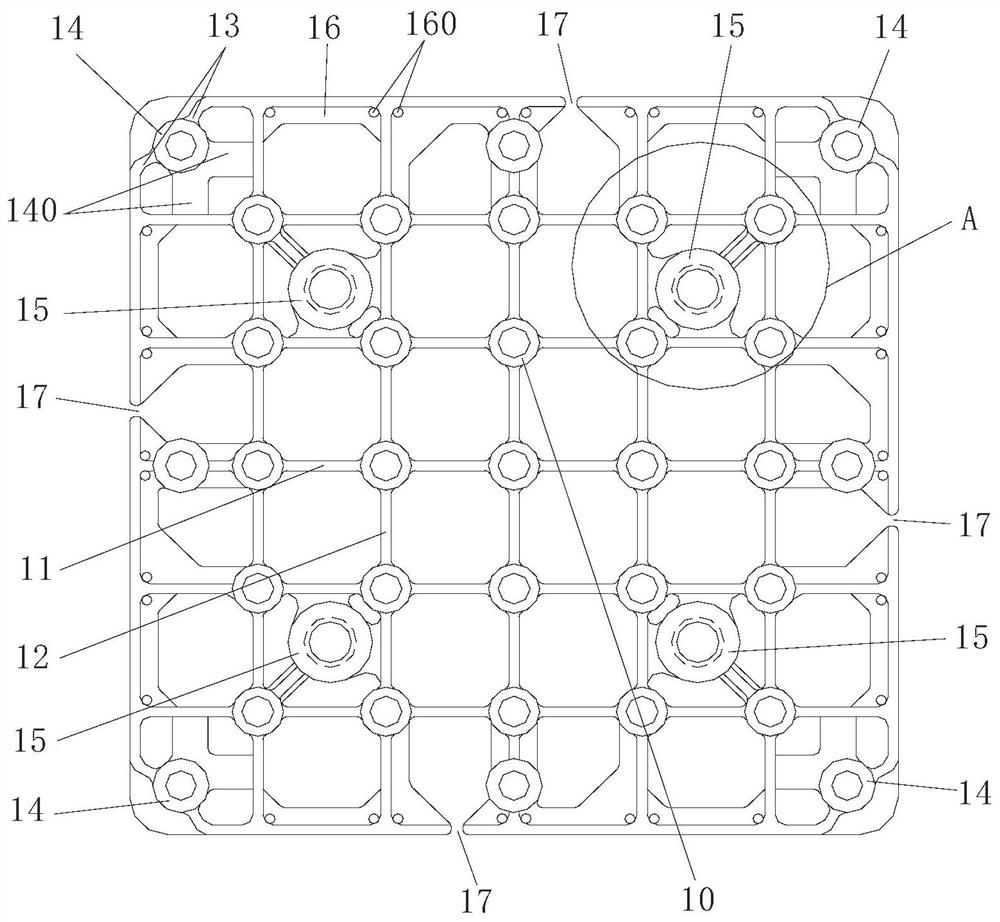

[0030] The bottom material tray 1 is composed of several horizontal connecting plates and several longitudinal connecting plates to form a mesh plate with a square mesh. The intersection of the horizontal connecting plates 11 and the longitudinal connecting plates 12 is also provided with a hole seat 10; Each co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com