An adjustable creasing machine for corrugated paper production

An adjustable, corrugated paper technology, applied in the direction of physical treatment of paper, mechanical processing/deformation, etc., can solve the problems of drying of paper that cannot be processed, inconvenient to replace, inability to adjust the distance of indentation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

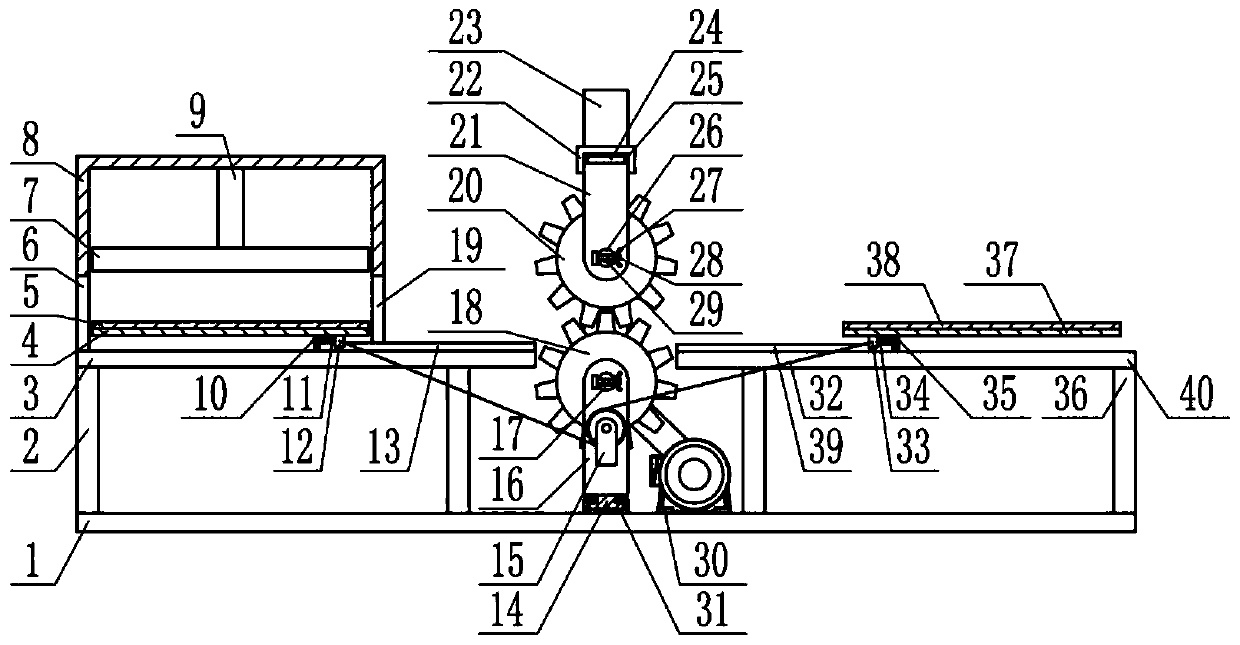

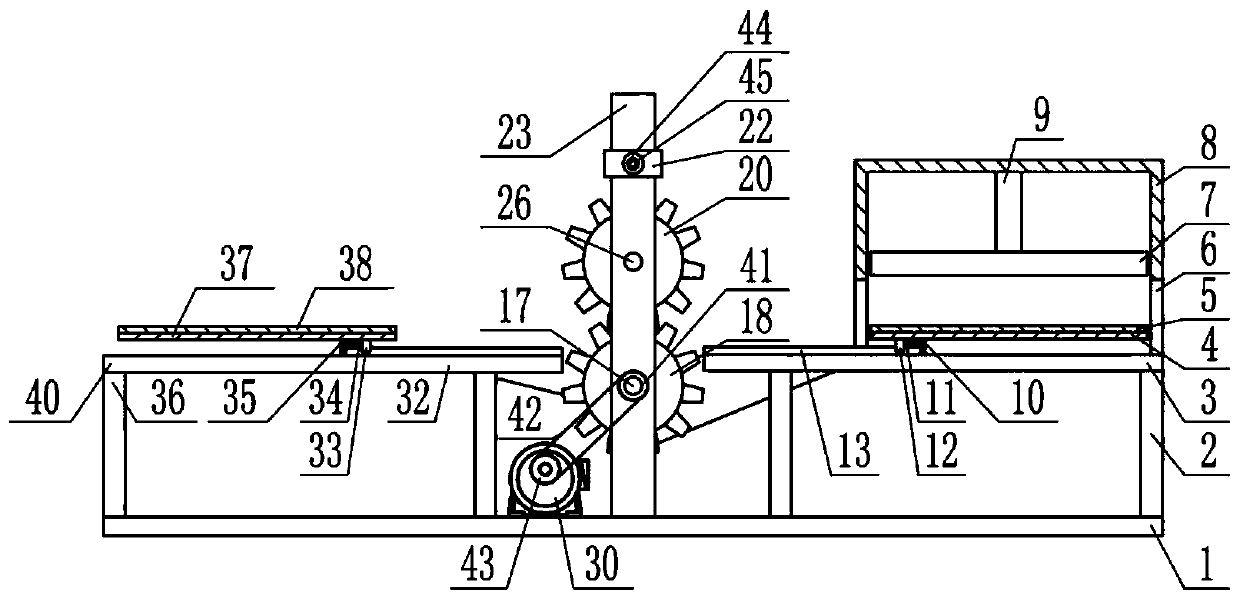

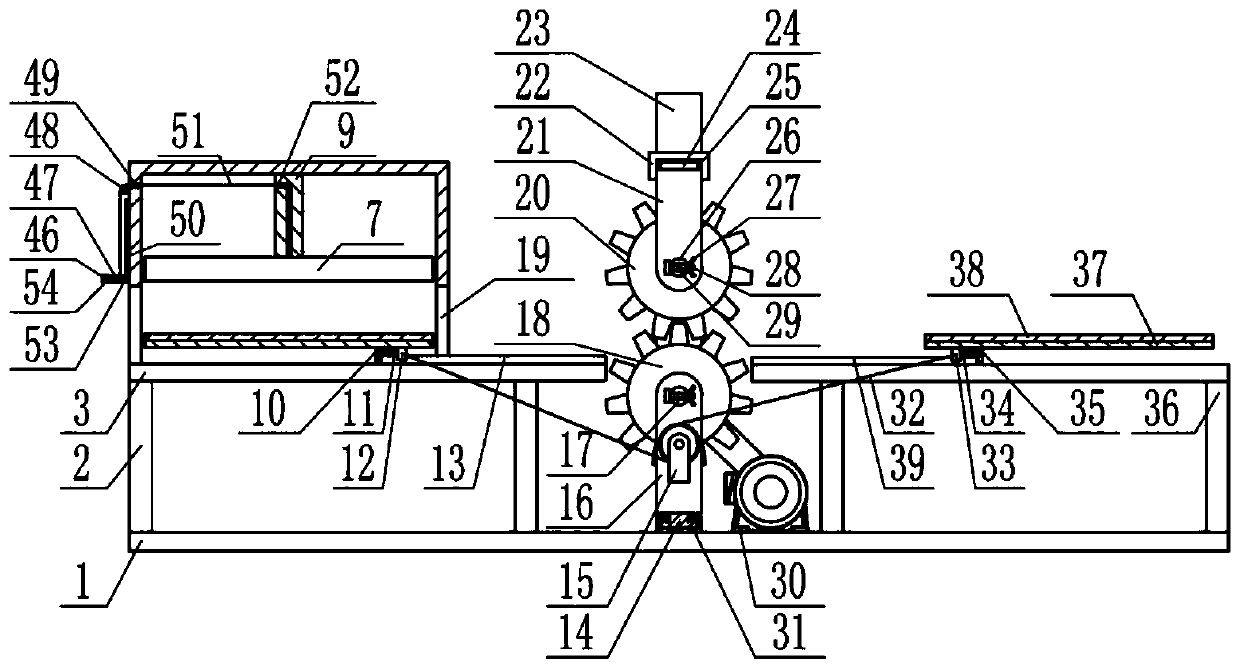

[0025]An adjustable creasing machine for corrugated paper production, such as Figure 1-8 As shown, it includes a first installation board 1, a first support rod 2, a second installation board 3, a first placement board 4, a second placement board 5, a drying device 7, an installation frame 8, an installation rod 9, a first Fixed plate 10, first elastic member 11, first slider 12, first slide rail 13, second slider 14, electric reel 15, third mounting plate 16, first rotating shaft 17, first creasing cylinder 18. Second creasing cylinder 20, first L-shaped plate 21, sliding sleeve 22, sliding rod 23, second fixing plate 24, chute 25, second rotating shaft 26, wing nut 27, flange bolt 28, servo Motor 30, second slide rail 31, first pull wire 32, third slider 33, second elastic member 34, third fixing plate 35, second support rod 36, third placing plate 37, fourth placing plate 38, The third slide rail 39, the fourth mounting plate 40, the first pulley 41, the first flat belt 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com