Auxiliary indentation equipment for concrete construction pouring and rapid indentation method thereof

A concrete and indentation technology, applied in the field of concrete pouring, can solve the problems of inconvenient tamping and indentation of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

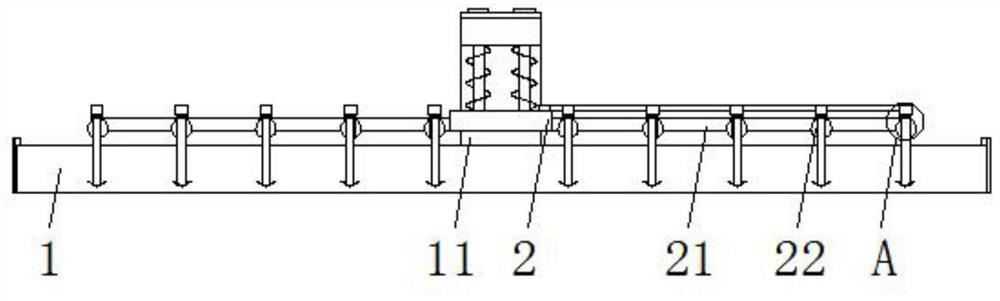

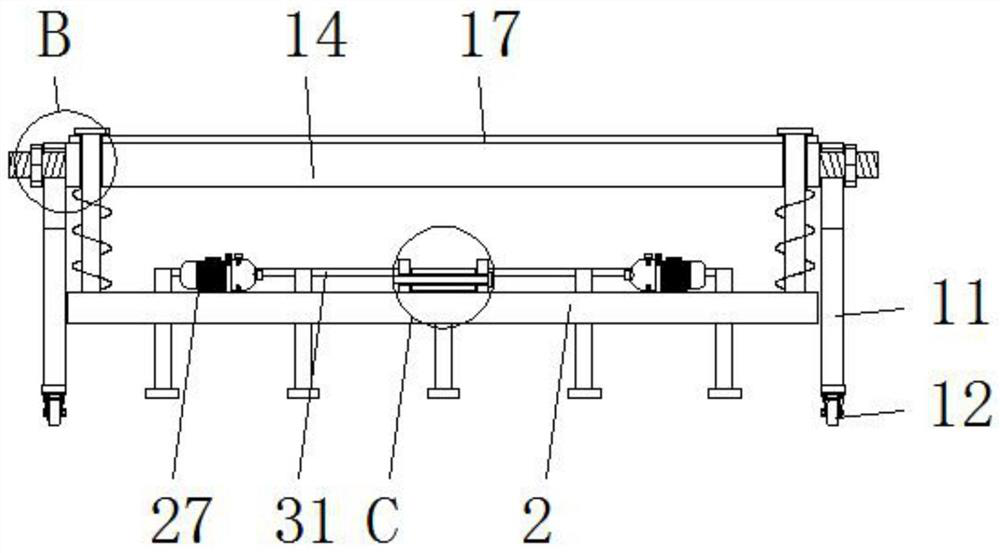

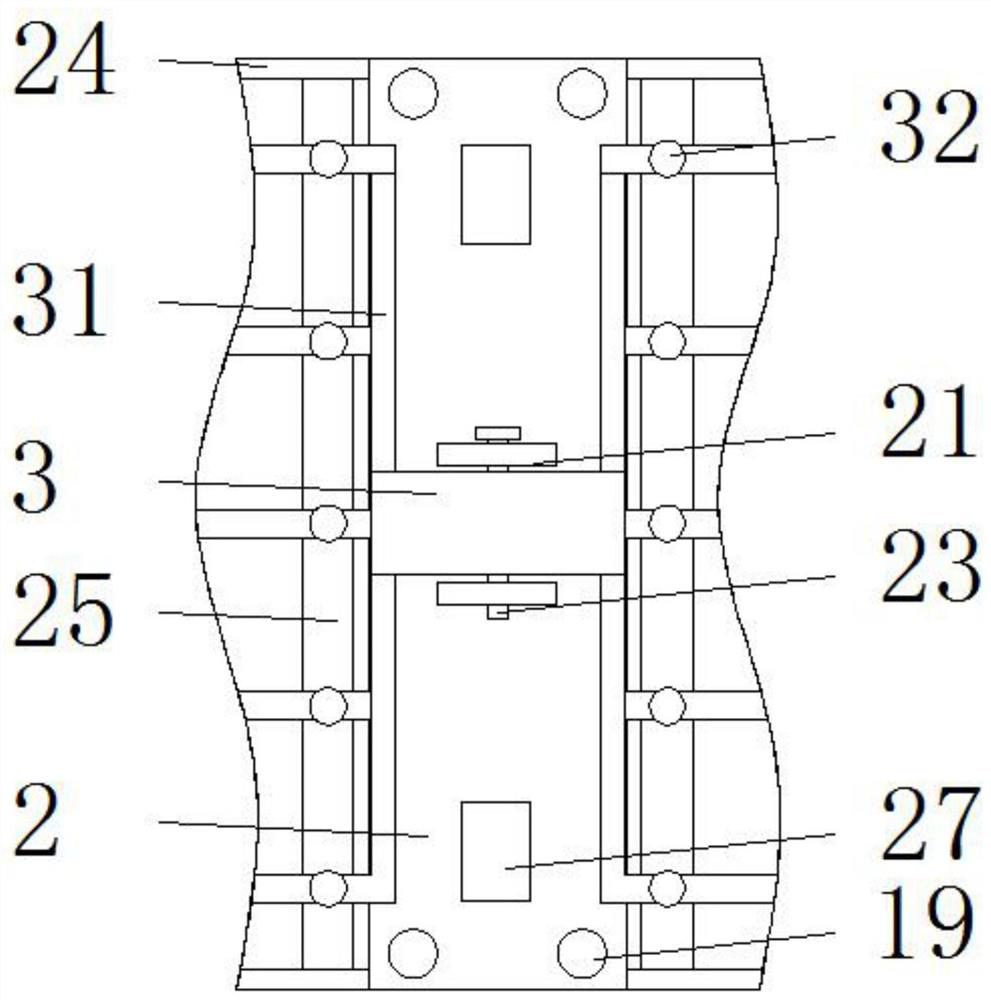

[0033]Embodiment 1: An auxiliary indentation equipment for concrete pouring and its rapid indentation method, including a mold body 1, a connecting plate 2, a block 3 and a fixing plate 14, and the outer walls of both sides of the mold body 1 are provided with support plates 11 , two support plates 11 are provided with a fixed plate 14 on the opposite side of the outer wall, a connecting plate 2 is arranged on one side of the outer wall of the lower end of the fixed plate 14, and connecting frames 24 are symmetrically installed on the outer walls of both sides of the connecting plate 2, and a connecting frame 24 is installed between the connecting frames 24. The indentation rods 25 distributed equidistantly in parallel, the indentation rods 25 are provided with through holes 26 equidistantly distributed in parallel, and a vibrating motor 27 is symmetrically installed on one side of the outer wall of the upper end of the connecting plate 2, as is well known to those skilled in th...

Embodiment 2

[0036] Embodiment 2: An auxiliary indentation equipment for concrete pouring and its rapid indentation method, including a mold body 1, a connecting plate 2, a block 3 and a fixing plate 14, and the outer walls of both sides of the mold body 1 are provided with support plates 11 , two support plates 11 are provided with a fixed plate 14 on the opposite side of the outer wall, a connecting plate 2 is arranged on one side of the outer wall of the lower end of the fixed plate 14, and connecting frames 24 are symmetrically installed on the outer walls of both sides of the connecting plate 2, and a connecting frame 24 is installed between the connecting frames 24. Indentation rods 25 distributed equidistantly and in parallel, inside the indentation rod 25 are provided with through holes 26 equidistantly distributed in parallel, a vibrating motor 27 is symmetrically installed on one side of the outer wall of the upper end of the connecting plate 2, and the outer wall of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com