Material deformation measurement method and device based on laser marking automatic tracking

A technology of laser marking and automatic tracking, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reduced measurement accuracy and deformation of sample marking lines, and achieve the effects of high measurement accuracy, simple structure, and easy practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

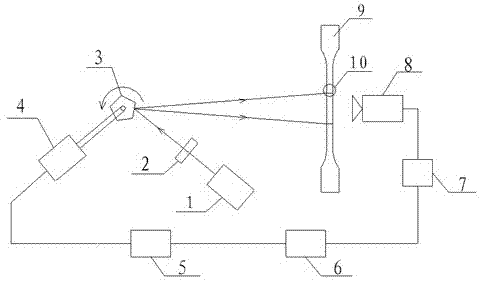

[0018] The laser beam of the laser device 1 of the present invention passes through the laser mark formed after the reticle 2, and is reflected on the sample mark line 10 of the sample 9 through the pentagonal prism 3, so that the laser mark coincides with the sample mark line 10; the motor controller One end of 5 controls the servo motor 4 to drive the pentagonal prism 3 to rotate, and the other end of the motor controller 5 is connected to the CCD8 through the computer 6 and the image acquisition card 7, and the CCD8 collects the images of the laser marking and the sample marking line 10 in real time, and through image acquisition The card 7 is input into the computer 6 to obtain the deformation amount of the sample.

[0019] Material deformation measurement method and device based on laser marking automatic tracking, such as figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com