Method and device for detecting configuration error of rated capacity of battery

A technology of rated capacity and detection method, which is applied in the direction of measuring devices, secondary batteries, and measuring electrical variables, etc., can solve problems such as safety problems, error-prone, and affecting battery charge and discharge control, and achieve the effect of life prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

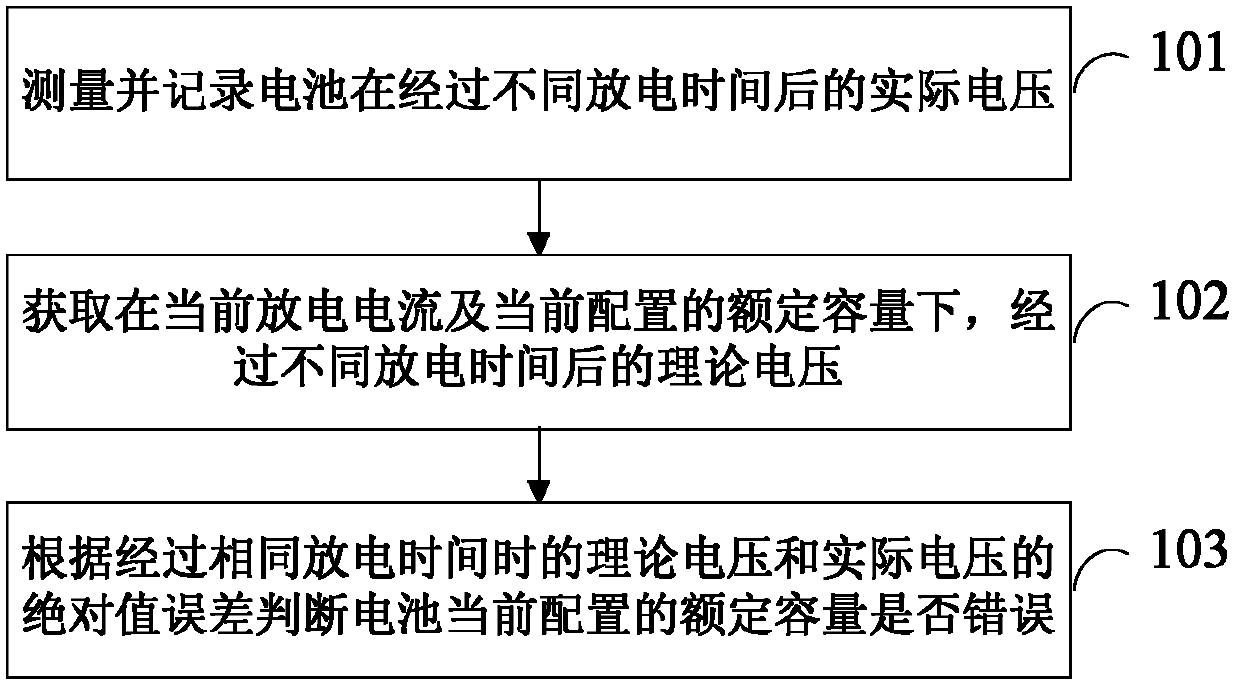

[0025] Embodiment 1 of the present invention provides a detection method for battery capacity configuration errors, the flow of which is as follows figure 1 As shown, the method includes:

[0026] Step 101, measuring and recording the actual voltage of the battery after different discharge times;

[0027] Step 102, obtaining the theoretical voltage after different discharge times under the current discharge current and the currently configured rated capacity;

[0028] Step 103 , judging whether the currently configured rated capacity of the battery is wrong according to the absolute value error between the theoretical voltage and the actual voltage when the same discharge time elapses.

[0029] The embodiment of the present invention measures and records the actual voltage of the battery at different discharge times during the discharge operation of the battery, and compares it with the theoretical voltage at different discharge times under the current discharge current and t...

Embodiment 2

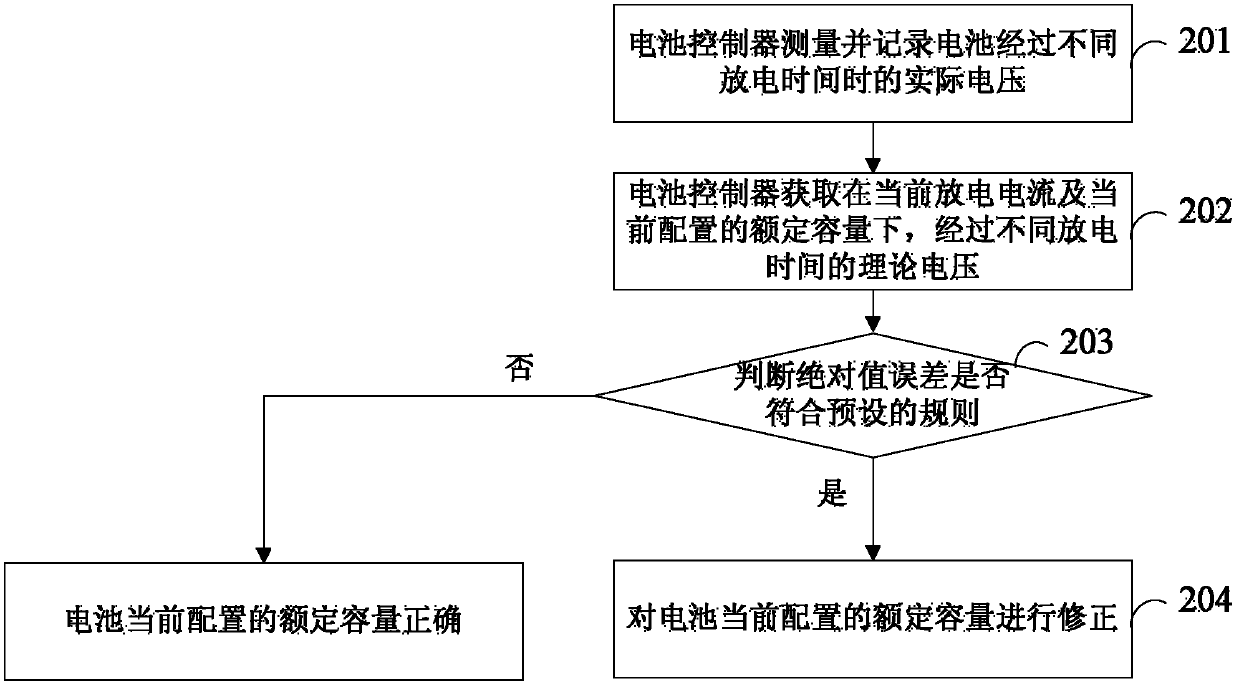

[0031] Embodiment 2 of the present invention provides a detection method for the wrong configuration of the rated capacity of the battery, which is an improvement on the basis of Embodiment 1, and can automatically detect the human-made wrong configuration of the rated capacity of the battery. In the embodiment, a battery with an actual rated capacity of 100AH is used as an example for illustration, and the process is as follows figure 2 shown, including:

[0032] Step 201. When the battery is being discharged, the battery controller measures and records the actual voltage of the battery after different discharge times;

[0033] When the battery is discharging, generally, the battery controller sets the discharge current of the battery as (discharge coefficient × rated capacity of the battery), wherein the battery controller itself cannot obtain the rated capacity of the battery, and the battery stored in the battery controller The rated capacity of the battery is artifici...

Embodiment 3

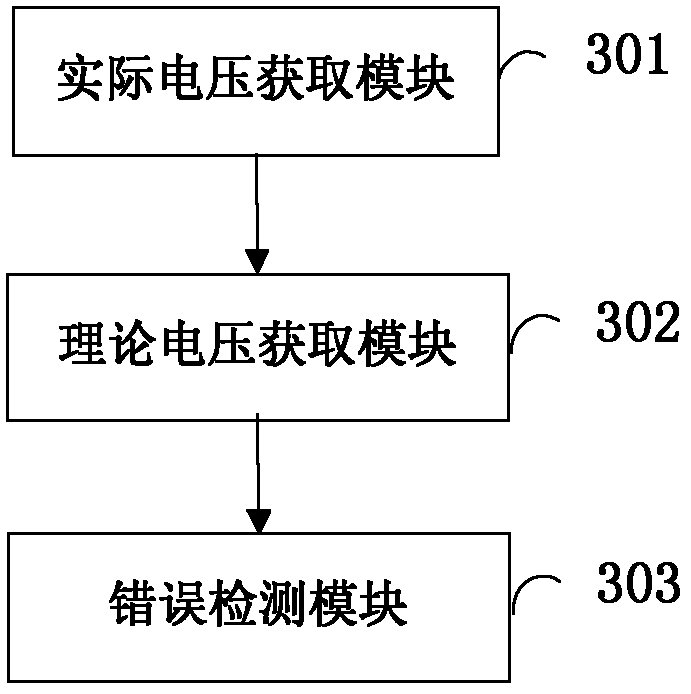

[0059] This embodiment provides a detection device for a battery rated capacity configuration error, such as image 3 As shown, the device includes:

[0060] The actual voltage acquisition module 301 is used to measure and record the actual voltage of the battery when different discharge times have elapsed;

[0061] A theoretical voltage acquisition module 302, configured to acquire the theoretical voltage after different discharge times under the current discharge current and the currently configured rated capacity;

[0062] The error detection module 303 is configured to judge whether the currently configured rated capacity of the battery is wrong according to the absolute value error between the theoretical voltage and the actual voltage when the same discharge time elapses.

[0063] Further, as Figure 4 As shown, the above-mentioned device also includes:

[0064] The mapping acquisition module 304 is used to acquire the mapping of the corresponding relationship between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com