Aluminum alloy frame and its splicing method

A splicing method, aluminum alloy technology, applied in the direction of slender components, building components, etc., can solve the problems of insufficient utilization of resources, single structure, high cost, etc., and achieve the effect of flexible splicing mode, unique structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

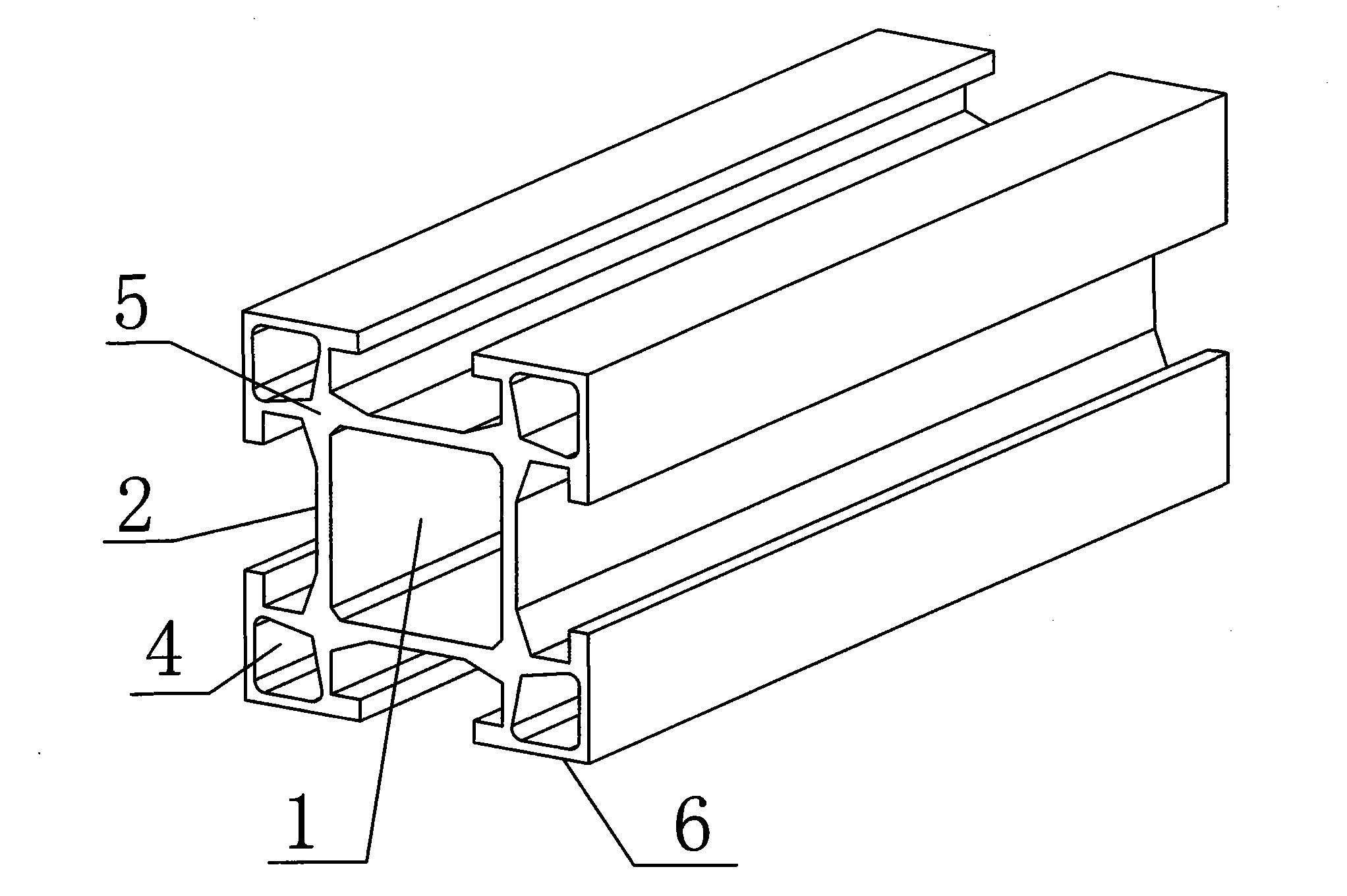

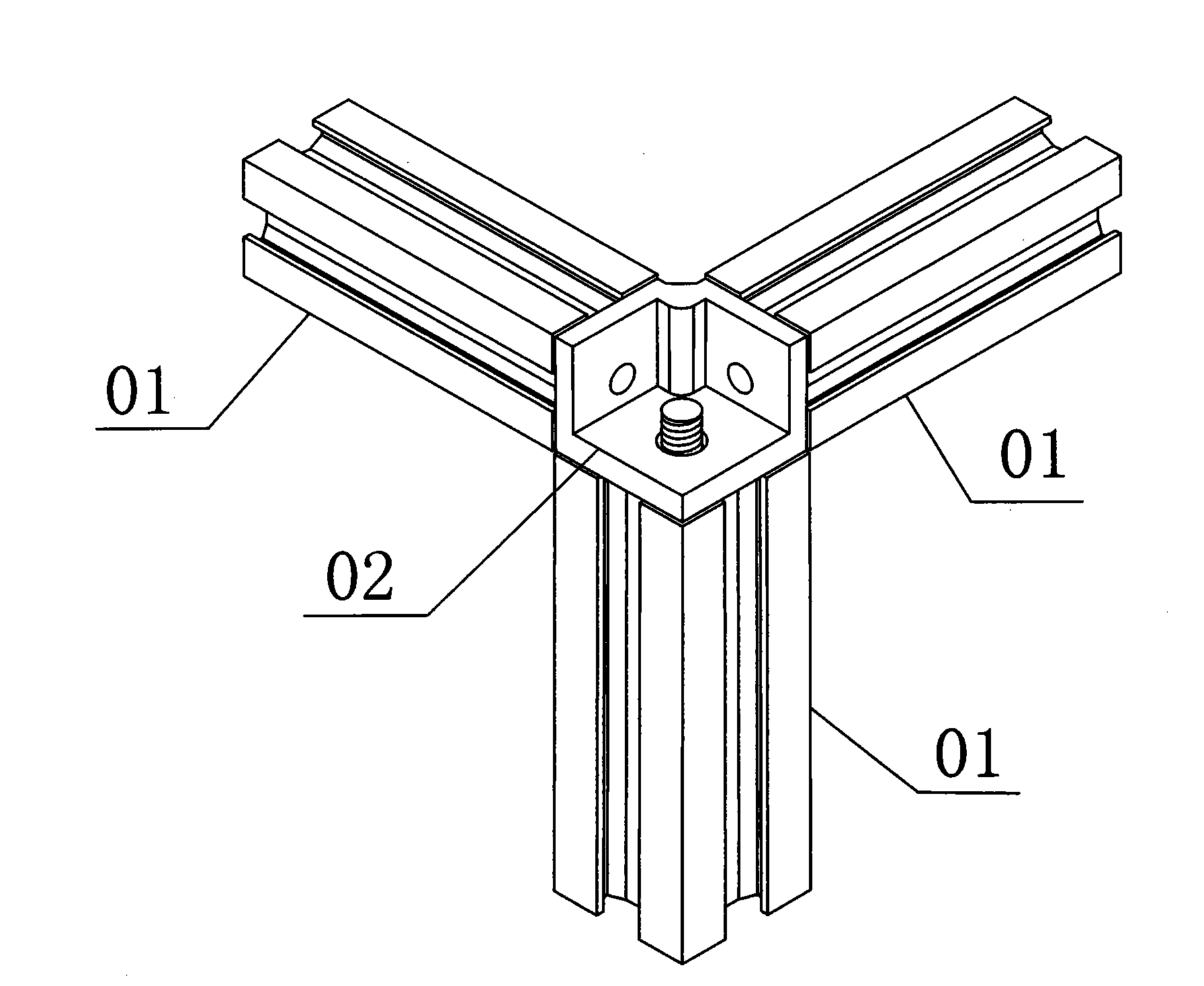

[0038] The aluminum alloy frame includes a plane frame or a three-dimensional frame composed of a plurality of aluminum alloy profiles and splicing pieces. The plane frame is rectangular, and each aluminum alloy profile is connected through the splicing pieces; the plane frame is rectangular, The three-dimensional frame includes a cube, a cuboid and the like.

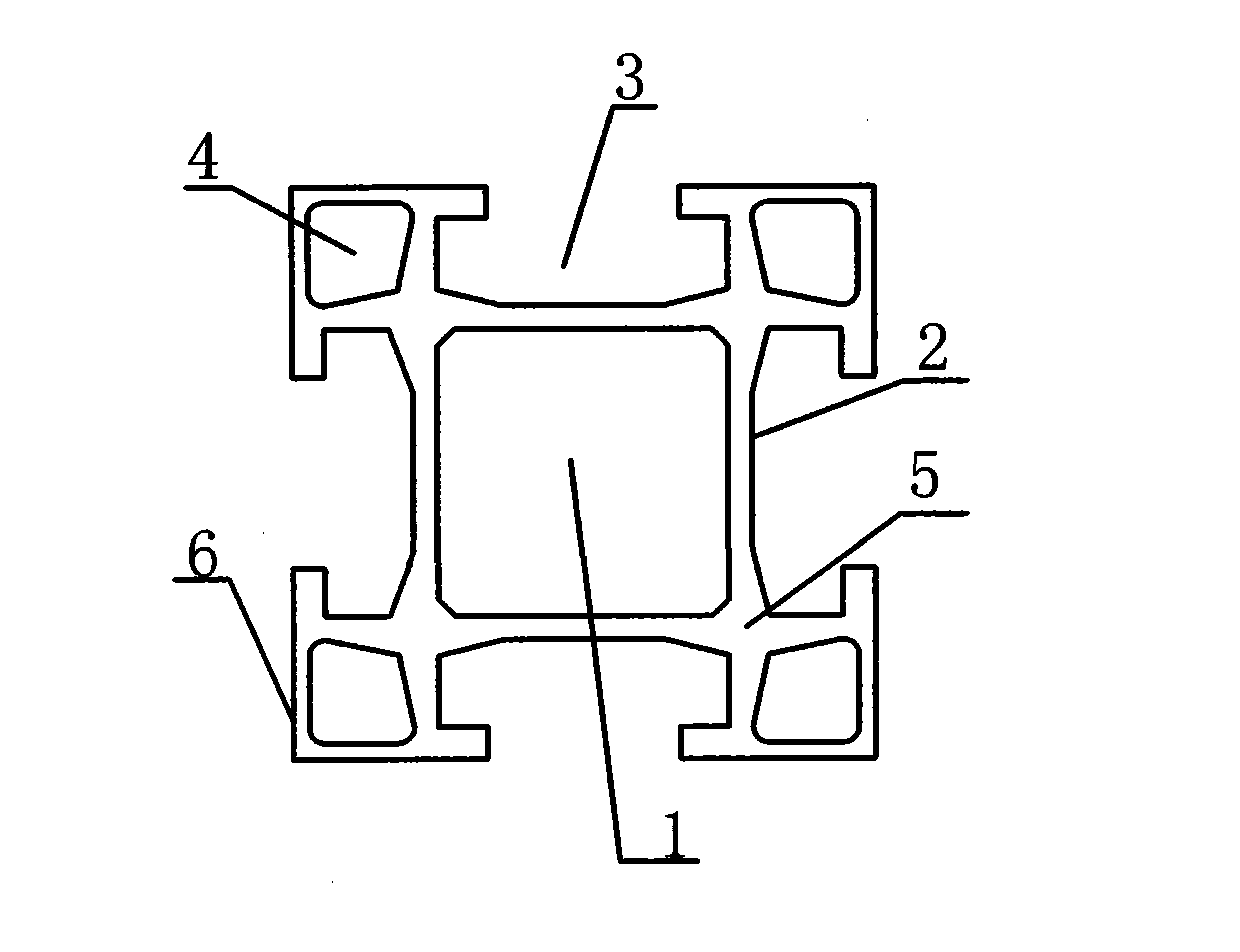

[0039] see figure 1 and figure 2 , the aluminum alloy profile is composed of the main hollow tube 1, the auxiliary hollow tubes 4 distributed at the four corners of the main hollow tube 1, the "well" shaped ribs 2 formed between the main hollow tube 1 and the four auxiliary hollow tubes 4 , the embedded inner tank 3 distributed on four sides and the aluminum alloy edging 6 wrapped on the outside of the auxiliary hollow tube 4 are jointly formed.

[0040] The main body hollow tube 1 and the four auxiliary hollow tubes 4 are rectangular, which is conducive to splicing flanges and convenient extrusion; the central recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com