Motherboard for blueray optical disc and manufacturing method for motherboard

A technology of Blu-ray disc and manufacturing method, which is applied in the direction of optical recording carrier manufacturing, optical recording/reproduction, optical recording carrier, etc., and can solve the problems of photoresist receiving uneven light, increasing groove density, increasing laser intensity, etc. , to achieve the effect of improving photosensitive resolution, increasing groove slope, and increasing exposure width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

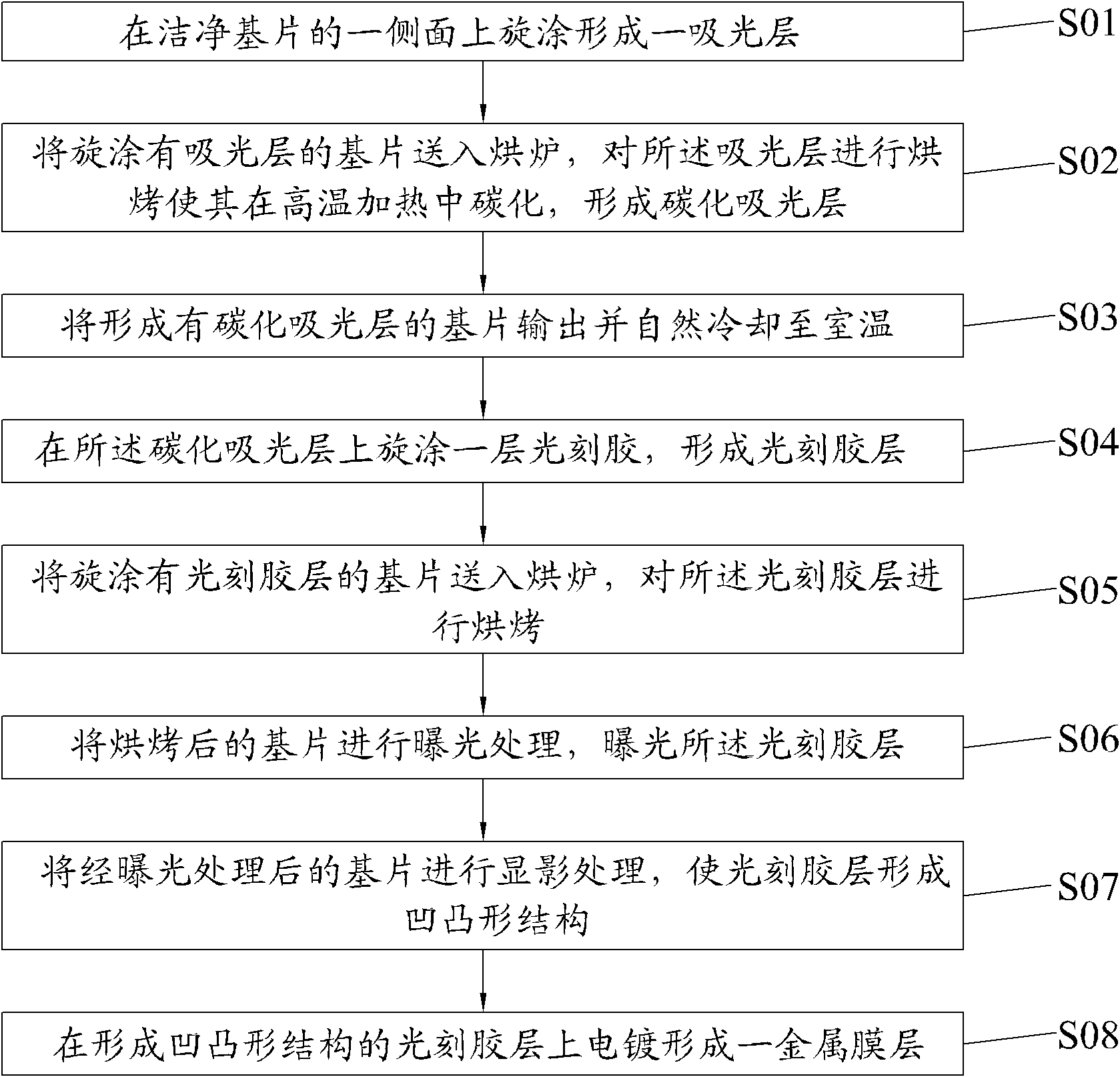

[0028] Such as figure 1 As shown, the manufacturing method of the master disc for the Blu-ray disc of the present invention comprises the following steps:

[0029] (S01) Spin coating on one side of the clean substrate to form a light-absorbing layer;

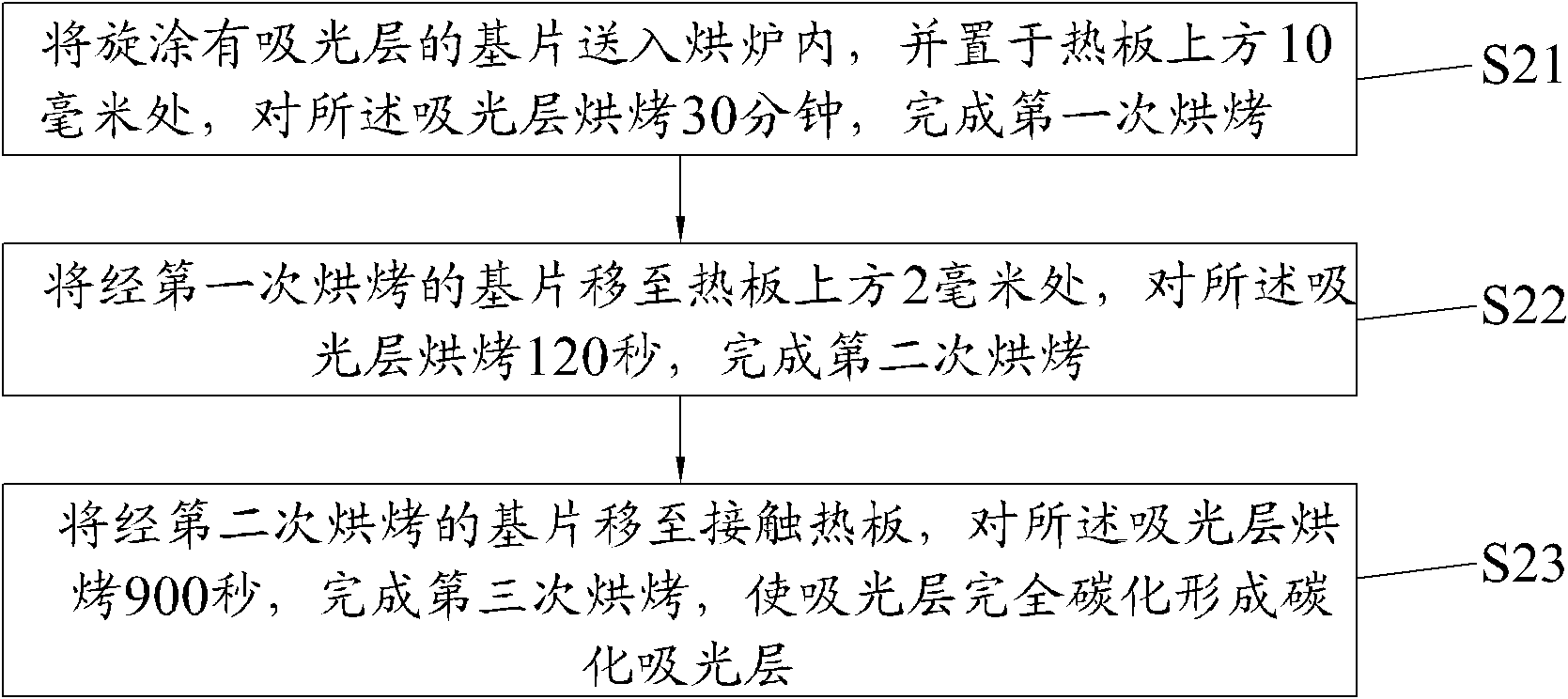

[0030] (S02) sending the substrate spin-coated with the light-absorbing layer into an oven, and baking the light-absorbing layer to carbonize it under high-temperature heating to form a carbonized light-absorbing layer;

[0031] (S03) Outputting the substrate formed with the carbonized light-absorbing layer and cooling it naturally to room temperature;

[0032] (S04) spin-coating a layer of photoresist on the carbonized light-absorbing layer to form a photoresist layer;

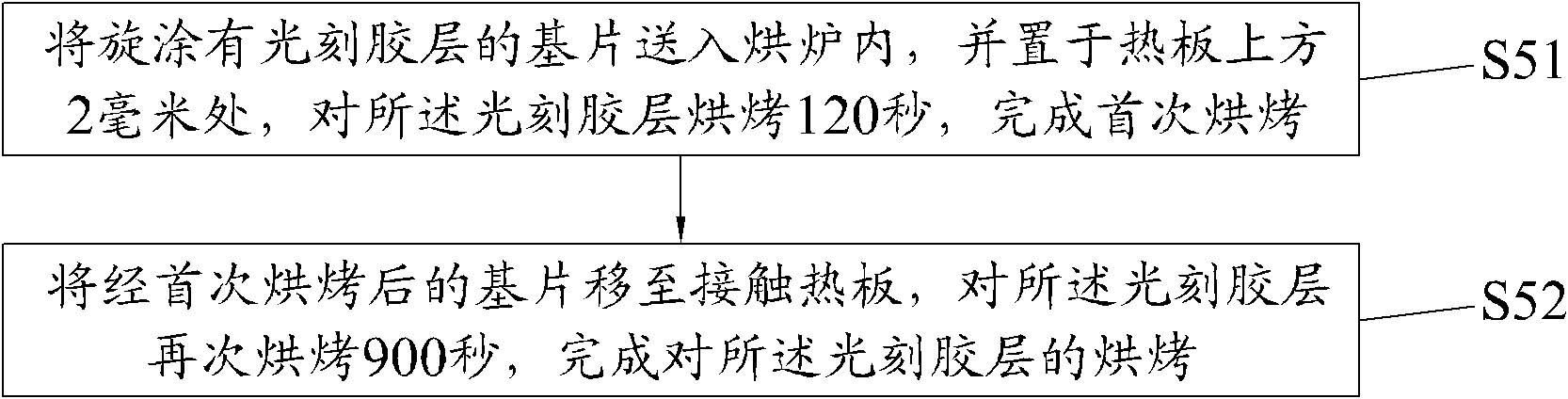

[0033] (S05) sending the substrate spin-coated with the photoresist layer into an oven, and baking t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com