mcralx-layers with different chromium and aluminum contents

A technology of chromium content and aluminum content, applied in the field of MCrAlX layer, can solve the problems of said layer failure, peeling and damage of thermal insulation coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

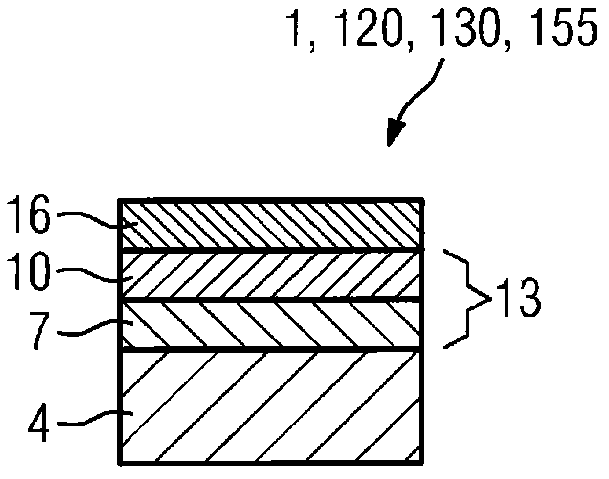

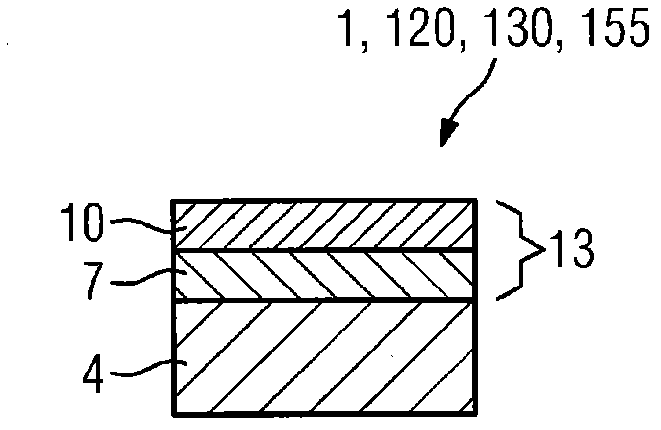

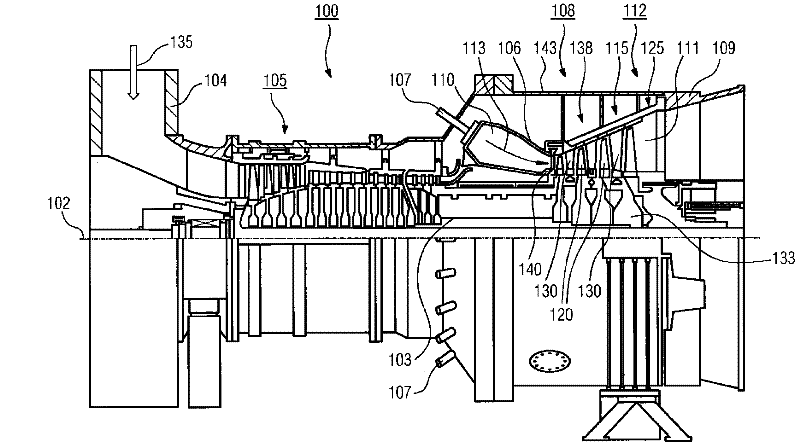

[0013] in the attached figure 1 The first embodiment is shown in . The component 1 , 120 , 130 , 155 has a substrate 4 . Especially for gas turbines 100 used at high temperatures ( image 3 ), said substrate 4 has in particular according to Figure 6 super alloy.

[0014] A metallic protective layer 13 is present on the substrate 4 .

[0015] According to the invention, the metallic protective layer 13 comprises two chemically different MCrAlX layers 7 , 10 , wherein the outer layer 10 preferably has a higher chromium content.

[0016] It is also preferred that the outer layer 10 has a higher aluminum content than the underlying layer 7 .

[0017] The difference (absolute value) in the chromium content of the two layers 7 , 10 is preferably at least 1% by weight (|Cr(7)−Cr(10)|≧1% by weight). The difference (absolute value) in the chromium content of the two layers 7, 10 is preferably at least 1% by weight (|Al(7)−Al(10)|≧1% by weight), more preferably at least 2% by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com