A hydraulic press device

A technology of hydraulic press and machine body, applied in the field of hydraulic press mechanism and hydraulic press device, which can solve the problems of inconvenient production and use, and achieve the effect of convenient production and use, and convenient and adjustable space position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

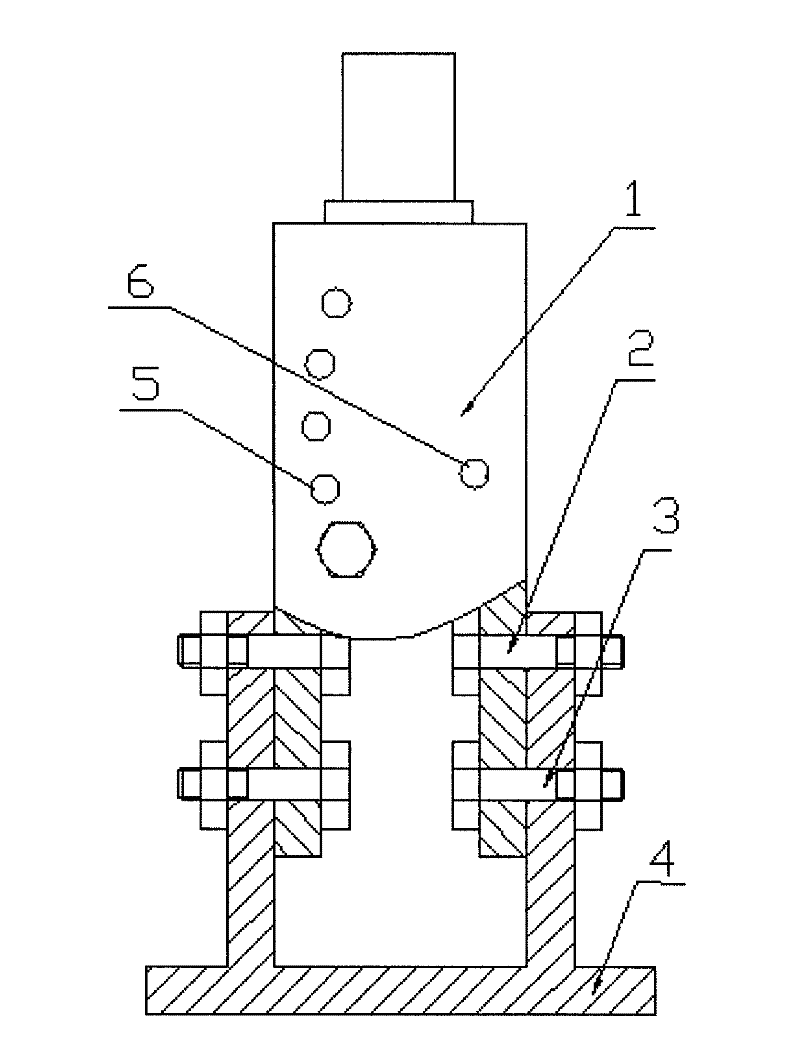

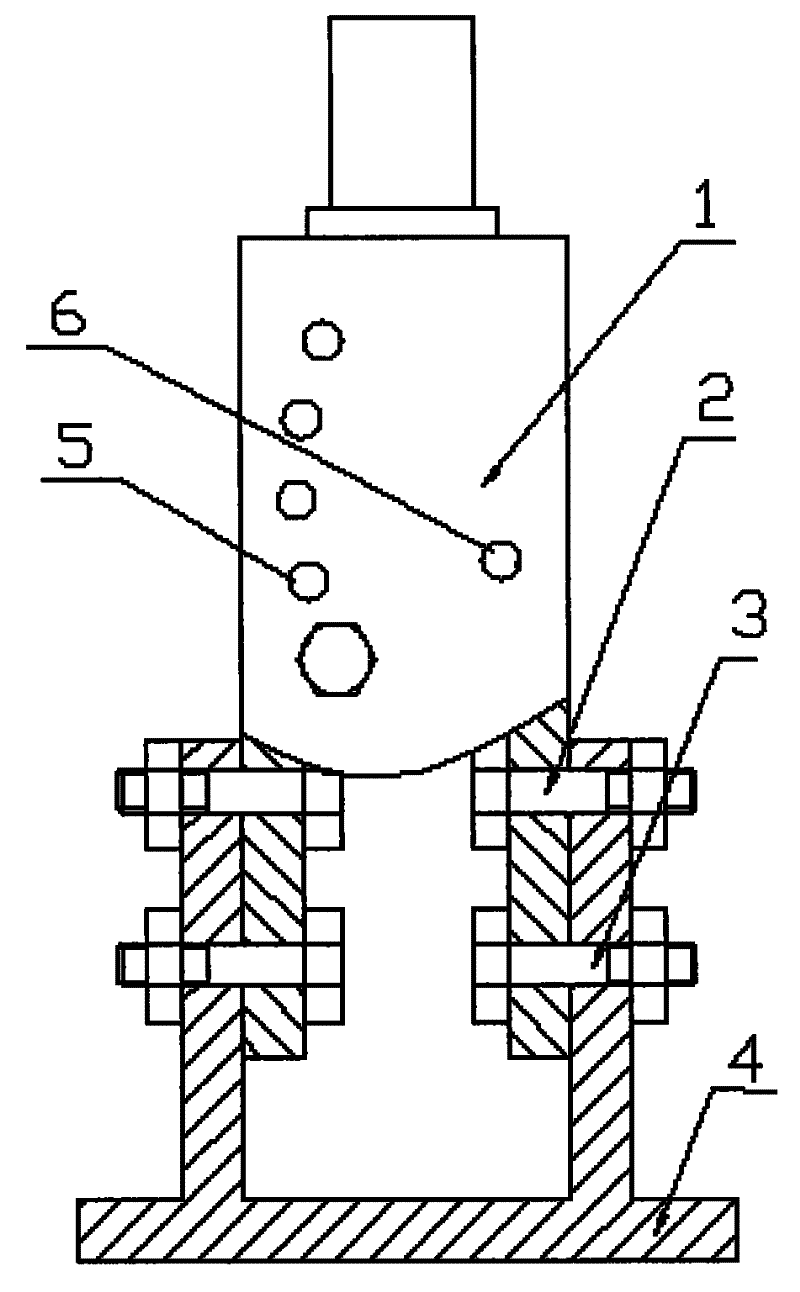

[0008] Install the fuselage (1) on the U-shaped bracket (4) through the corresponding through hole (6) and the adjustment hole (5) on the U-shaped bracket (4) with the positioning bolt (3) and the adjusting bolt (2) respectively. Above, when it is necessary to adjust the space inclination of the working surface of the fuselage, loosen the nut of the positioning bolt (2), remove the adjusting bolt (2) installed in the adjustment hole (5), and make the fuselage (1) rotate around the positioning After the bolt (3) is rotated to the desired position, place the adjusting bolt (2) in the adjusting hole (5) at the position, at this time, fasten the fuselage by adjusting the bolt (2) and the positioning bolt (3) after that.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap