Oil press capable of automatically damping

A hydraulic press, automatic technology, used in forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problems of workers' safety not being well guaranteed, the vibration of the pressing platform equipment, affecting the quality of stamping workpieces, etc. Achieve uniform force, reduce burden, and facilitate production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

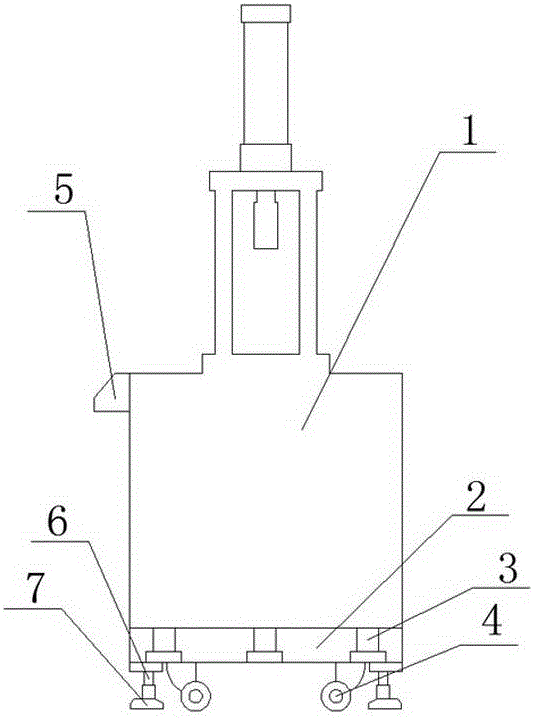

[0012] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

[0013] See figure 1 , The present invention provides a technical solution: an automatic shock-absorbing hydraulic press, comprising a main body 1, a base 2, a movable wheel 4 and a shock absorber 3. The base 2 is installed below the main body 1, and one end of the main body 1 is provided with a control The table 5, the base 2 is provided with a shock-absorbing buffer 3, a moving wheel 4 is provided under the base 2, and a telescopic rod 6 and a supporting foot 7 are also provided under the base 2.

[0014] The supporting feet 7 are installed at the bottom end of the telescopic rod 6, and the supporting feet 7 are connected and fixed to the base 2 through the telescopic rod 6. The telescopic rod 6 and the supporting feet 7 installed at the bottom end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap