A device to reduce buffer force

A cushioning force and cushioning layer technology, applied in transportation and packaging, railway car body parts, cargo support/fastening parts, etc., can solve problems such as uneven quality of grass products, lack of grass resources, and insufficient length of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

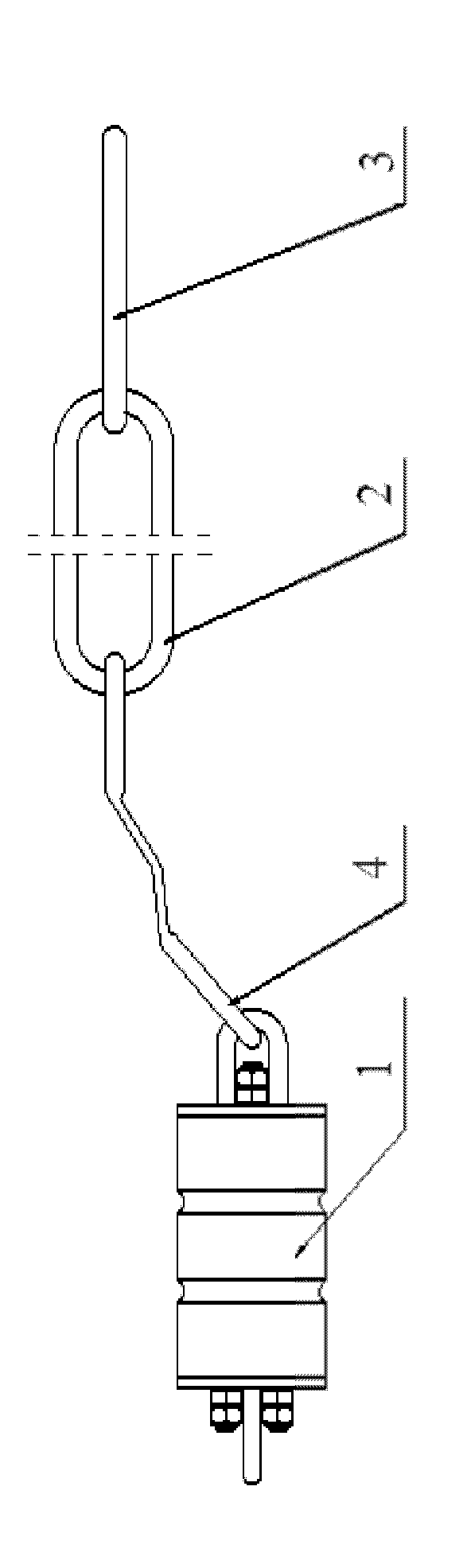

[0025] figure 1 It shows a schematic structural view of the device for reducing buffer force in this embodiment, which includes a buffer unit and a connecting unit, and the structural schematic view of the buffer unit is as follows Figure 4 shown. The buffer unit includes a buffer layer 7 and connecting rods passing through the buffer layer. There are at least two connecting rods, which respectively pass through the buffer layer 7 oppositely; this embodiment uses two connecting rods as an example to introduce the structure of the buffer unit.

[0026] Buffer layer 7 comprises at least one layer, and when buffer layer 7 is more than one layer, is separated by separator 8 between several buffer layers 7, and baffle plate 9 is set respectively at the two ends of buffer unit, buffer layer 7, The partition plate 8 and the baffle plate 9 are combined together to form a stacking mechanism, on which four through holes are provided in a cross shape in the axial direction, and the fir...

Embodiment 2

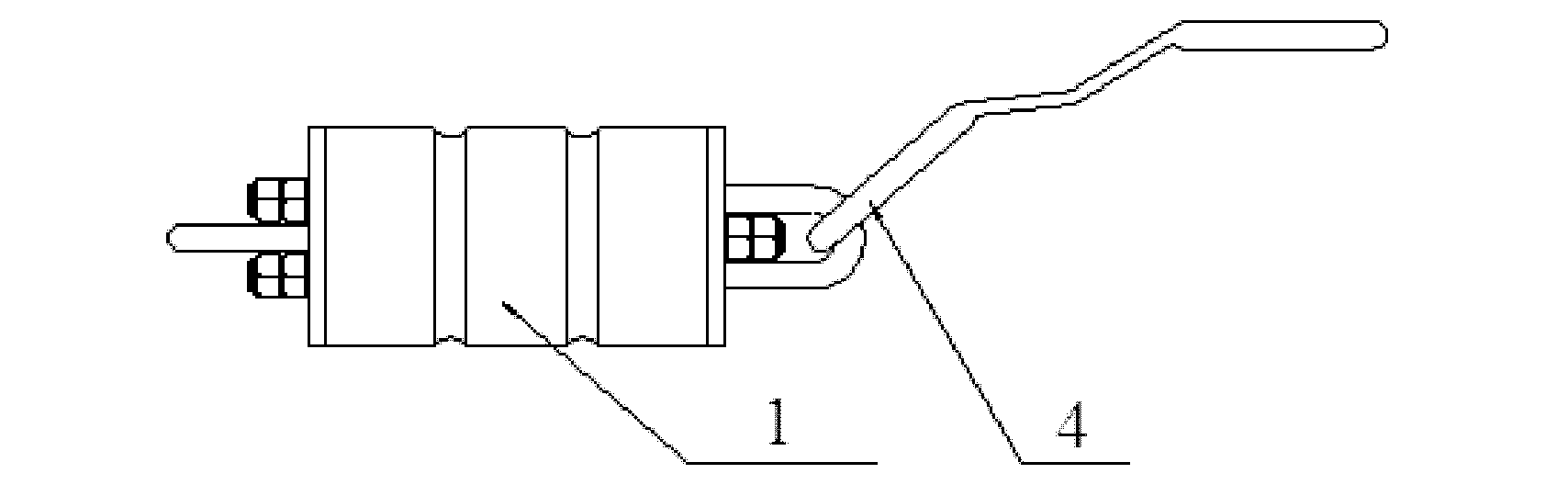

[0031] figure 2 A schematic structural view of the device for reducing buffer force of this embodiment is shown. The structure of the device for reducing buffer force in this embodiment is similar to that of the device for reducing buffer force in Embodiment 1, except that the structure of the connecting unit is different.

[0032] The connection unit of this embodiment includes a door ring 4, and the structure of the door ring 4 is: the lower part is a semi-circular ring, which is used to hang on the T-shaped iron of the gondola; Between the opening of the door; the upper part is an inwardly inclined semi-circular ring, which is exposed in the open car and can be used to bundle and reinforce the goods in the open car.

[0033] The device for reducing the buffer force of the present embodiment is suitable for gondola carriages.

Embodiment 3

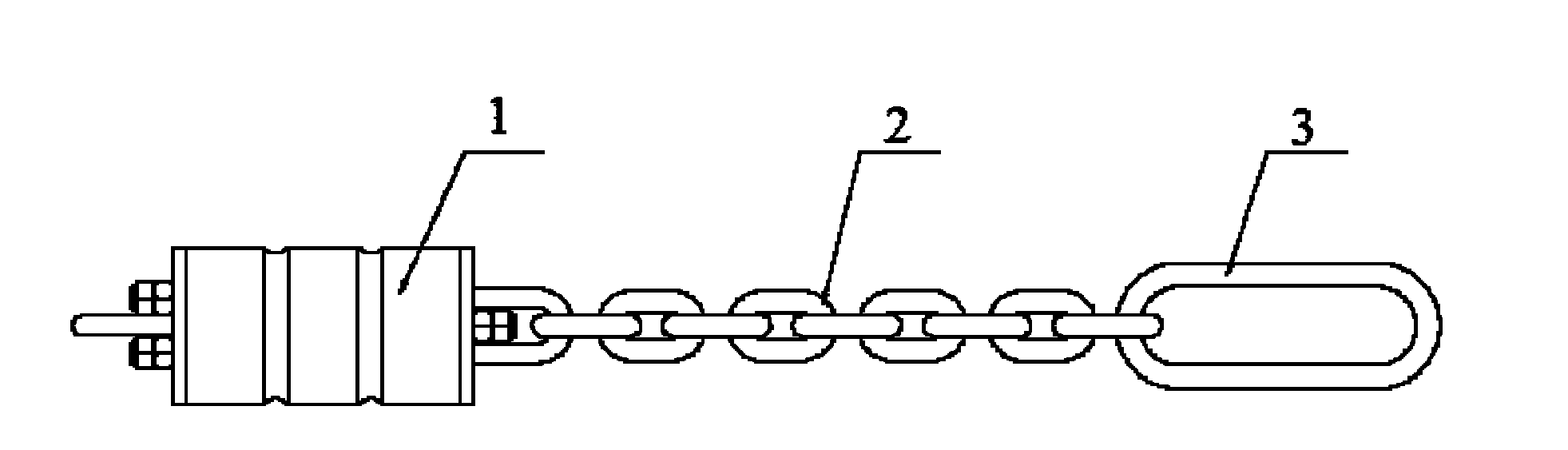

[0035] image 3 A schematic structural view of the device for reducing buffer force of this embodiment is shown. The device for reducing buffer force in this embodiment is similar in structure to the device for reducing buffer force in Embodiment 1, except that the structure of the connecting unit is different.

[0036] The connection unit in this embodiment includes a door ring 4 , a connecting chain 2 and a hanging ring 3 , the door ring 4 is connected to the buffer unit, and the connecting chain 2 is connected between the door ring 4 and the hanging ring 3 .

[0037] The structure of the door ring 4 of this embodiment is the same as that of the door ring in Embodiment 2. The length of the connecting chain 2 is determined according to the size of the means of transport and the arrangement height of the goods to be transported.

[0038] It can be seen from the above embodiments that the device for reducing the buffer force provided by the embodiments of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com