Screw drive

A technology of driving device and screw rod, which is applied in the direction of transmission device, hoisting device, portable lifting device, etc., can solve the problems of unstable movement of the screw rod, insufficient accuracy of the manufacturing accuracy of the worm gear and the position of the bearing at the threaded connection, etc. Simple, stable motion, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The screw driving device of the present invention will be further described in detail through specific embodiments below.

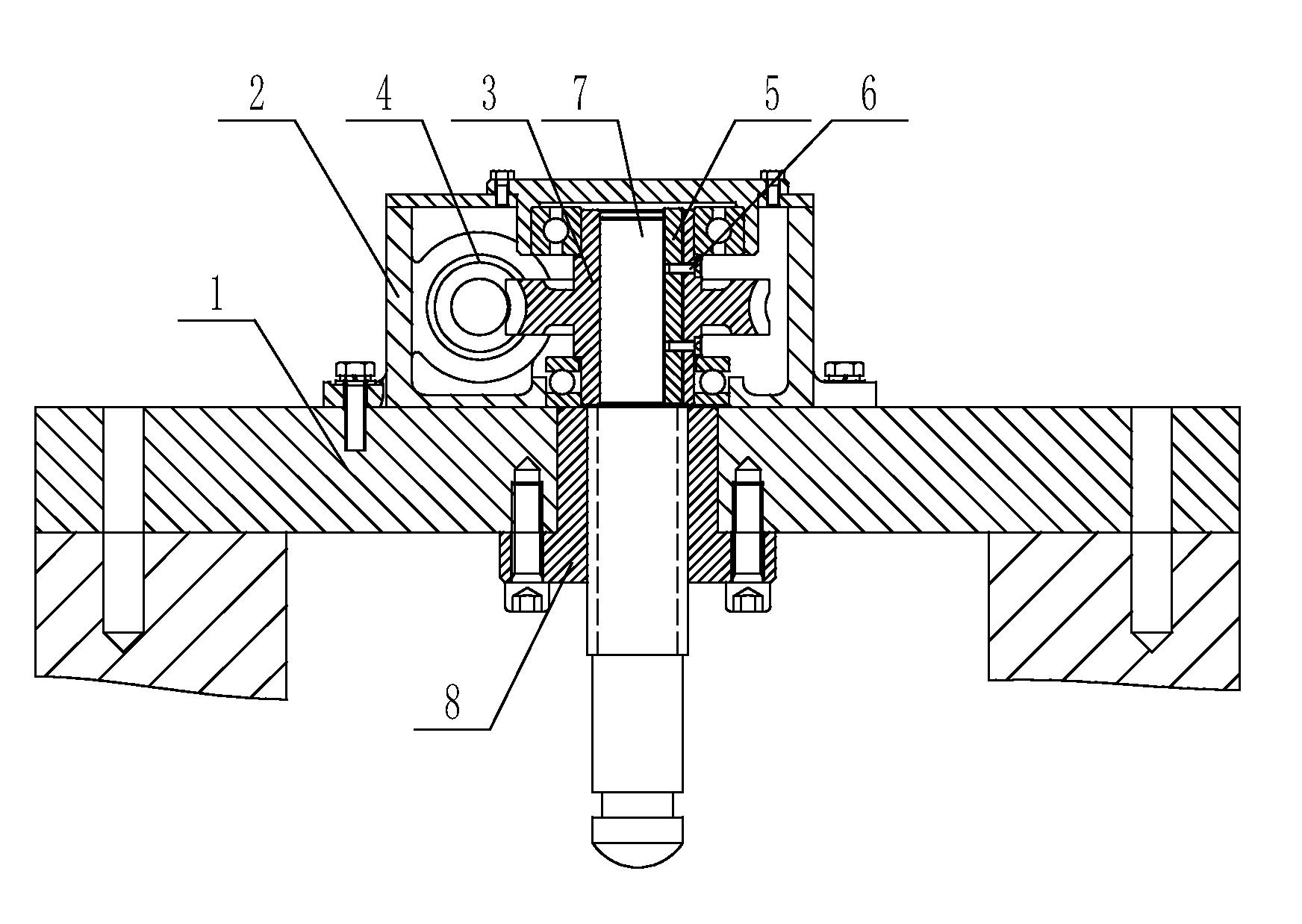

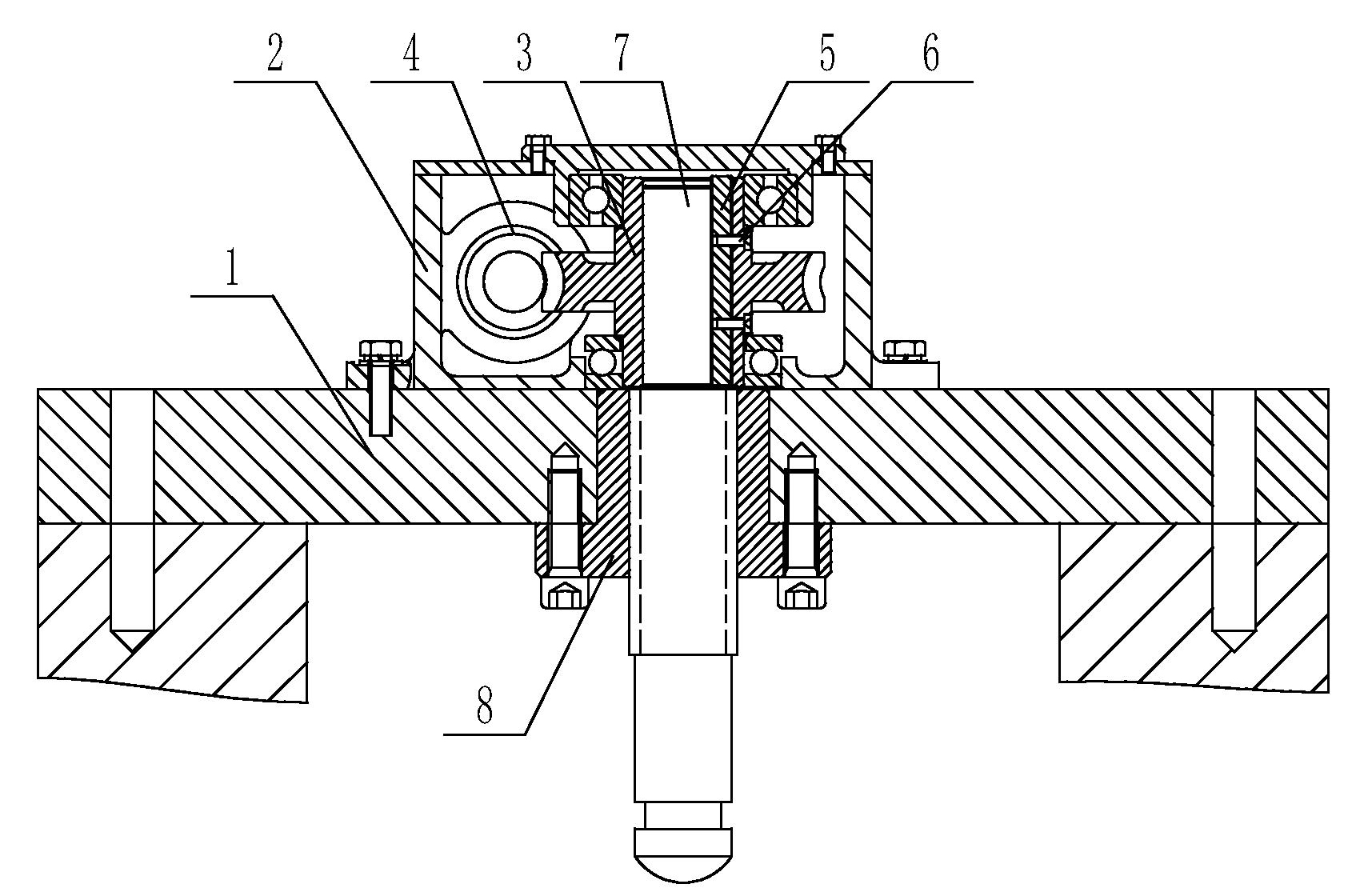

[0010] Such as figure 1 As shown, the screw driving device includes a frame 1, and a reduction box 2 is arranged on the frame 1, and a worm wheel 3 and a worm 4 that cooperate with each other are arranged inside the reduction box 2, and the inner wall of the worm wheel 3 is smooth and is provided with The key 5, the key 5 is fixed inside the worm wheel 3 through the bolt 6, the worm wheel 3 is connected with the screw rod 7, the upper part of the screw rod 7 is set in the worm wheel 3, the outer wall of the upper part of the screw rod 7 is smooth and is provided with a key hole, and the key hole runs through the screw rod 7, the key 5 is arranged in the keyhole, the outer wall of the lower part of the screw mandrel 7 is provided with threads, the lower part of the screw mandrel 7 is covered with a shaft sleeve 8, the shaft sleeve 8 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com