Density triangular driving mechanism for computer flat knitting machine

A technology of density triangle and drive mechanism, applied in the directions of knitting, weft knitting, textiles and papermaking, etc., can solve problems such as motion deviation, and achieve the effect of eliminating motion deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

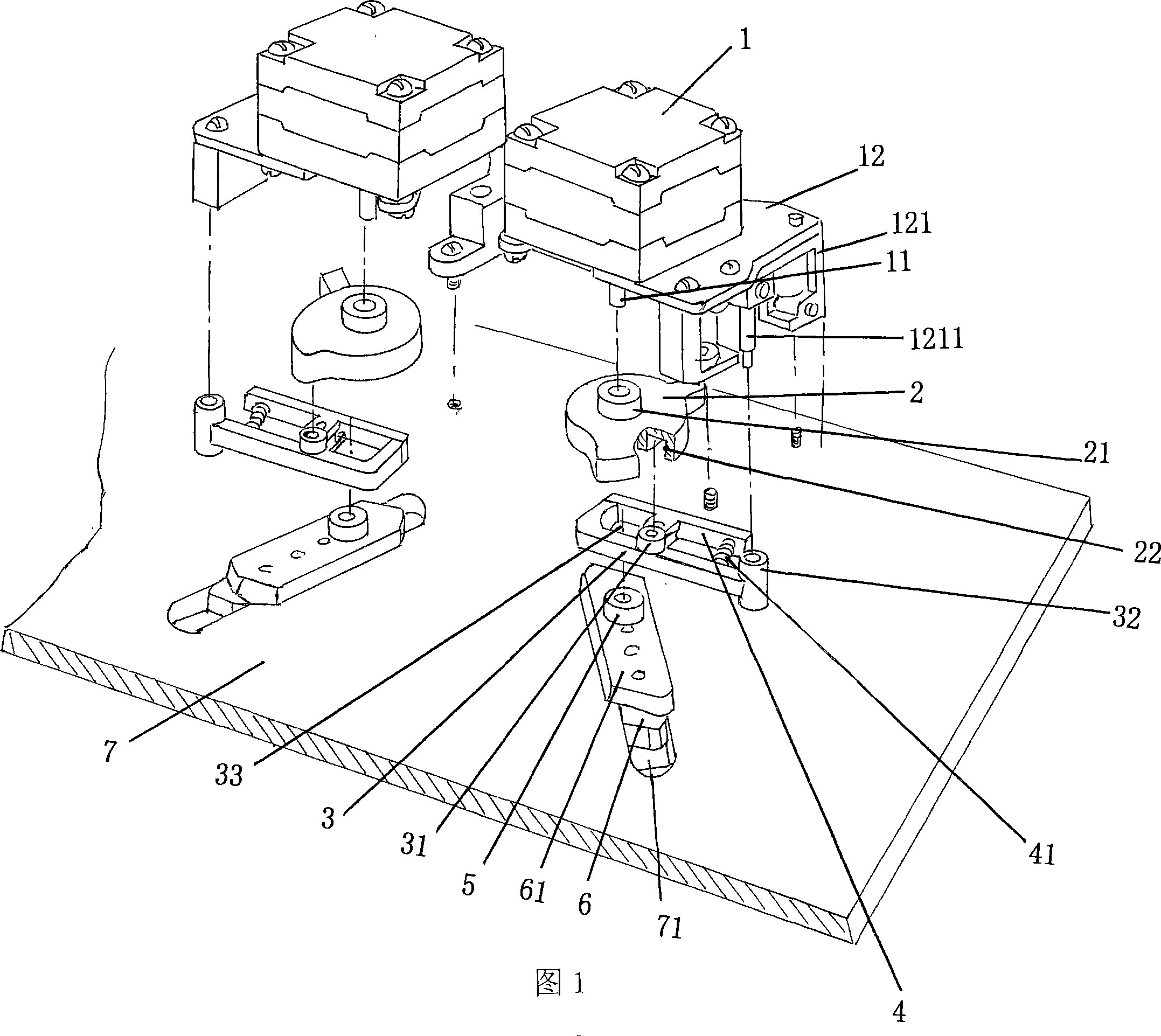

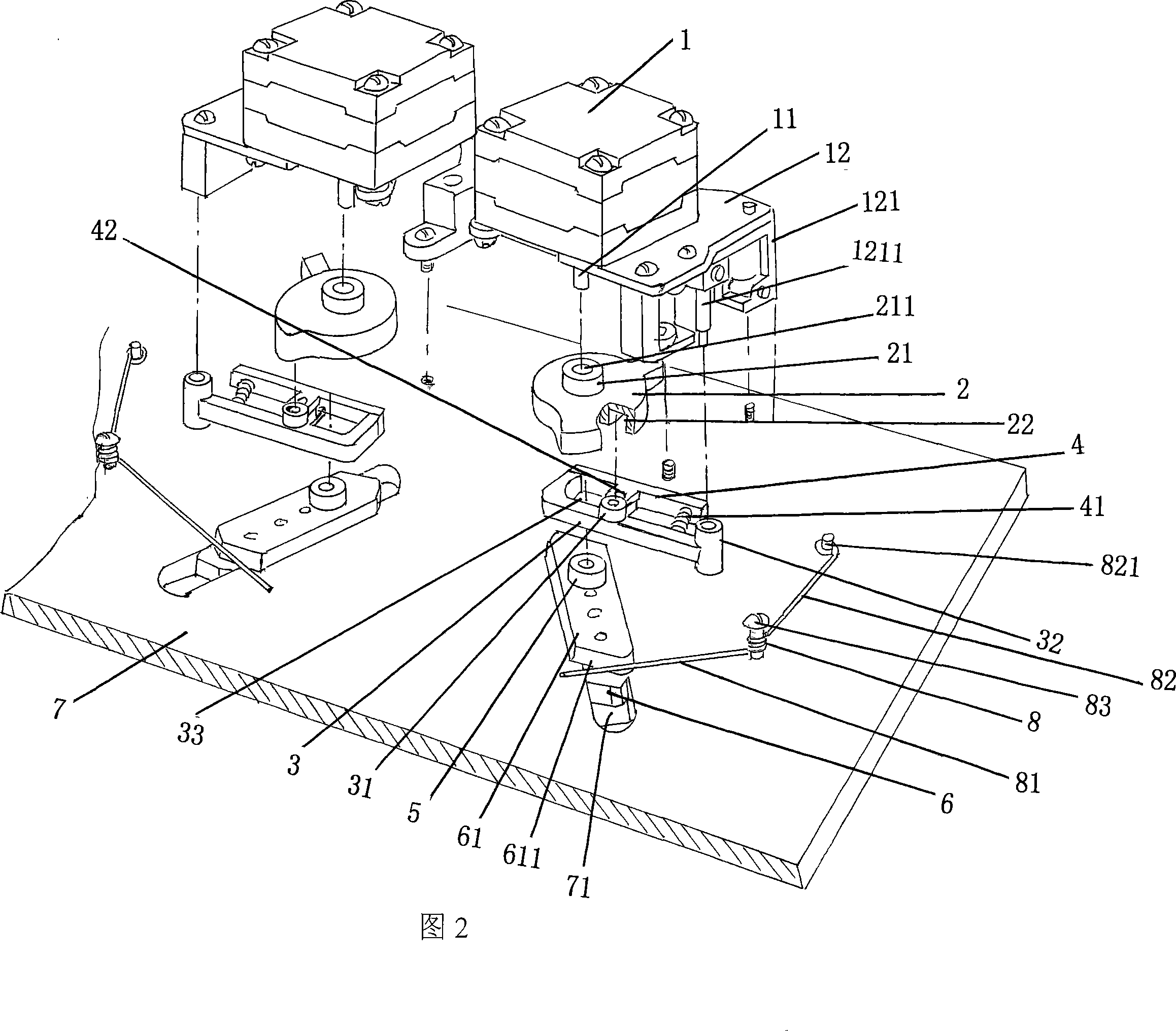

[0013] Please refer to Fig. 2, the applicant has mentioned earlier that the machine head of the weaving mechanism has a pair of triangular base plates 7, and a pair of density cams 6 are arranged on each triangular base plate 7, and each density cam 6 is equipped with a set of density triangular drive mechanisms , under the action of this mechanism, the density triangle 6 is moved up and down on the preset density triangle adjustment groove 71 on the triangle bottom plate 7 under the guidance of the density triangle guide block 61 . Based on an example by analogy, the following only describes the adjustment mechanism of one of the density triangles 6 .

[0014] The motor 1 of the density triangular drive mechanism of the computerized flat knitting machine recommended by the present invention is a motor with forward and reverse functions, which is placed on the motor base 12, and the motor base 12 is fixed to the triangular bottom plate 7 with screws through the bracket 121 A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com