High-performance slow-shut check valve

A check valve, high-performance technology, applied in the direction of functional valve type, valve details, control valve, etc., can solve the problems of high spring force selection requirements, affecting slow closing performance, large collision sound, etc., to achieve simple structure, slow down Stable closing performance and low closing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

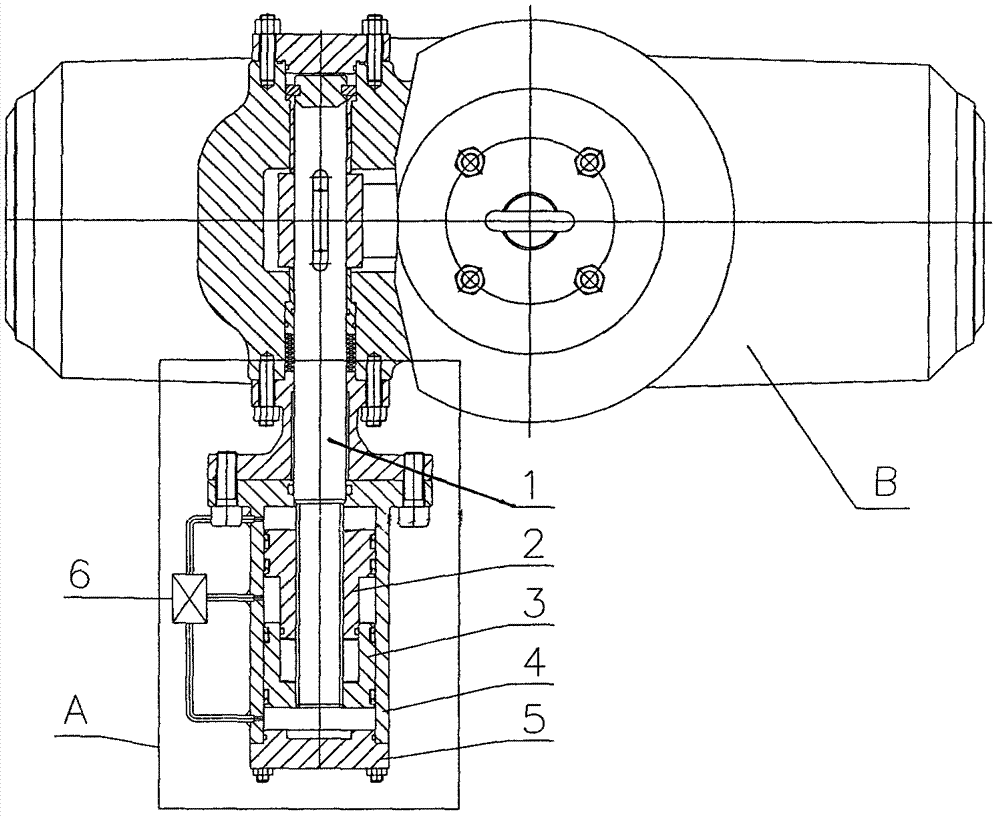

[0007] Such as figure 1 The high-performance slow-closing check valve shown includes a main valve B and a slow-closing mechanism A. The main valve B adopts a swing check valve, and the swing check valve includes a valve body, a valve seat, a disc, a rotating Axis 1, the disc is installed on the valve body by the rotating shaft 1. One end of the rotating shaft 1 protrudes out of the valve body and connects with the slow closing mechanism A, which is a piston structure, consisting of a cylinder body 4, a cylinder head 5, a piston rod, a piston convex plate 2, and a piston concave plate 3 , one end of the piston rod is fixedly connected with the rotating shaft 1, and the other end of the piston rod in the cylinder body 4 is provided with a T-shaped thread, and the piston convex plate 2 and the piston concave plate 3 are respectively provided with a forward T-shaped thread and a reverse T-shaped thread. Type screw thread is engaged with piston rod, and the projection of piston co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com