a pneumatic valve

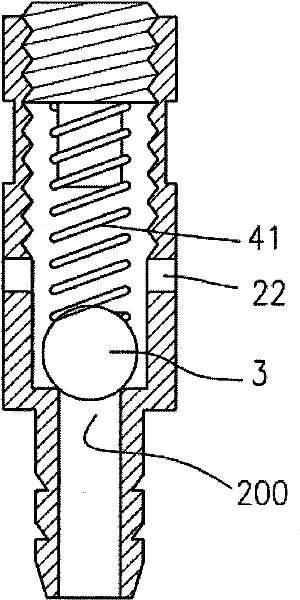

A technology of air pressure valve and tubular body, which is applied in the field of valve devices and air pressure valves, and can solve problems such as easy corrosion, loss of function of pressure relief valve, loss of spring 41, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

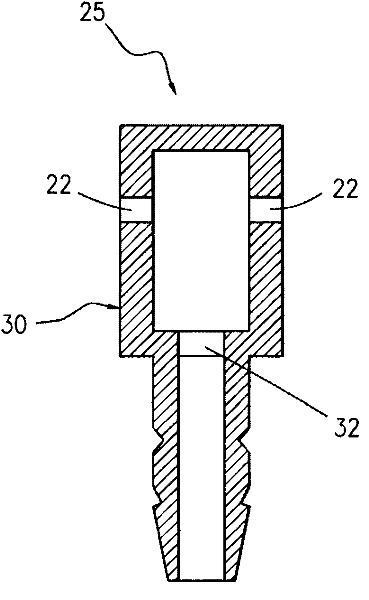

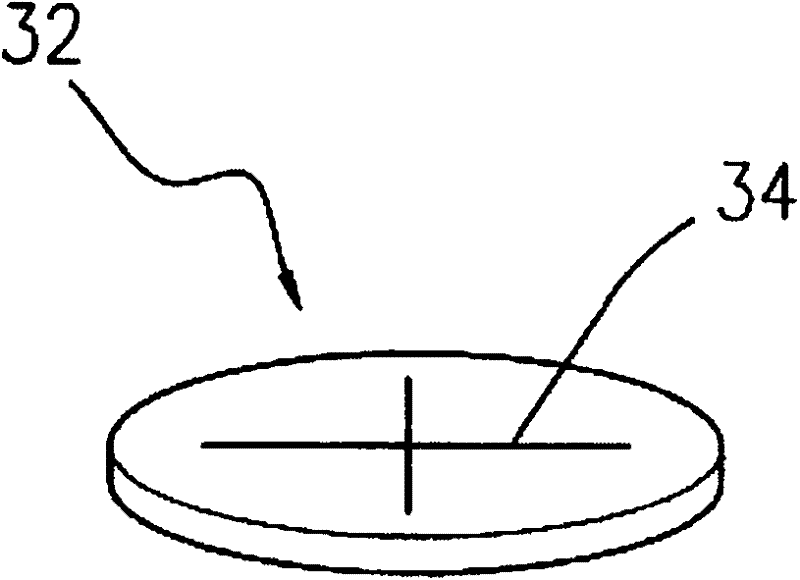

[0013] as attached figure 2 , 3 Shown is a pneumatic valve 25 of the present invention, which is mainly composed of a tubular body 30, an elastic plug body 32, and a pressure relief slit 34 pierced through the elastic plug body 32, and the shape is trident, cross, and rice. or other types of slits. The edge of the elastic plug body 32 is completely against the wall of the tubular body, and the selected material can be silica gel or latex material. Therefore, although the elastic plug body 32 has been penetrated, due to its own elasticity, the When no external force is applied or the active force is not large enough, the gas in the tubular body 30 still cannot flow to the gas release part 22 through the pressure relief slit of the elastic plug body 32 (as attached image 3 shown).

[0014] When the gas flows to the elastic plug body 32 through the tubular body 30, when the impact pressure brought by the gas is greater than the resistance of the slit 34 of the elastic plug b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com