Long-service-life piston ring sealing system

A sealing system and piston ring technology, applied in the field of compressors, can solve the problems of accelerating the wear of piston rings, reducing the wear resistance of piston rings, and existing bottlenecks, and achieving the effects of increasing service life, reducing friction, and reducing debris.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail by specific embodiments:

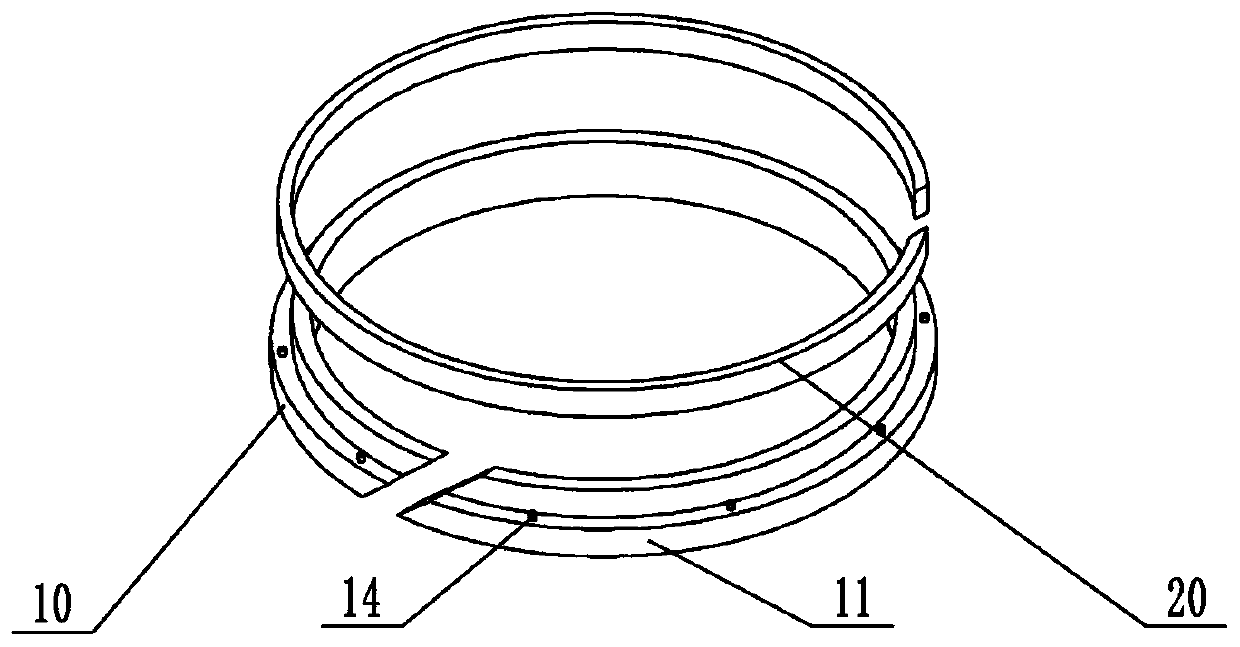

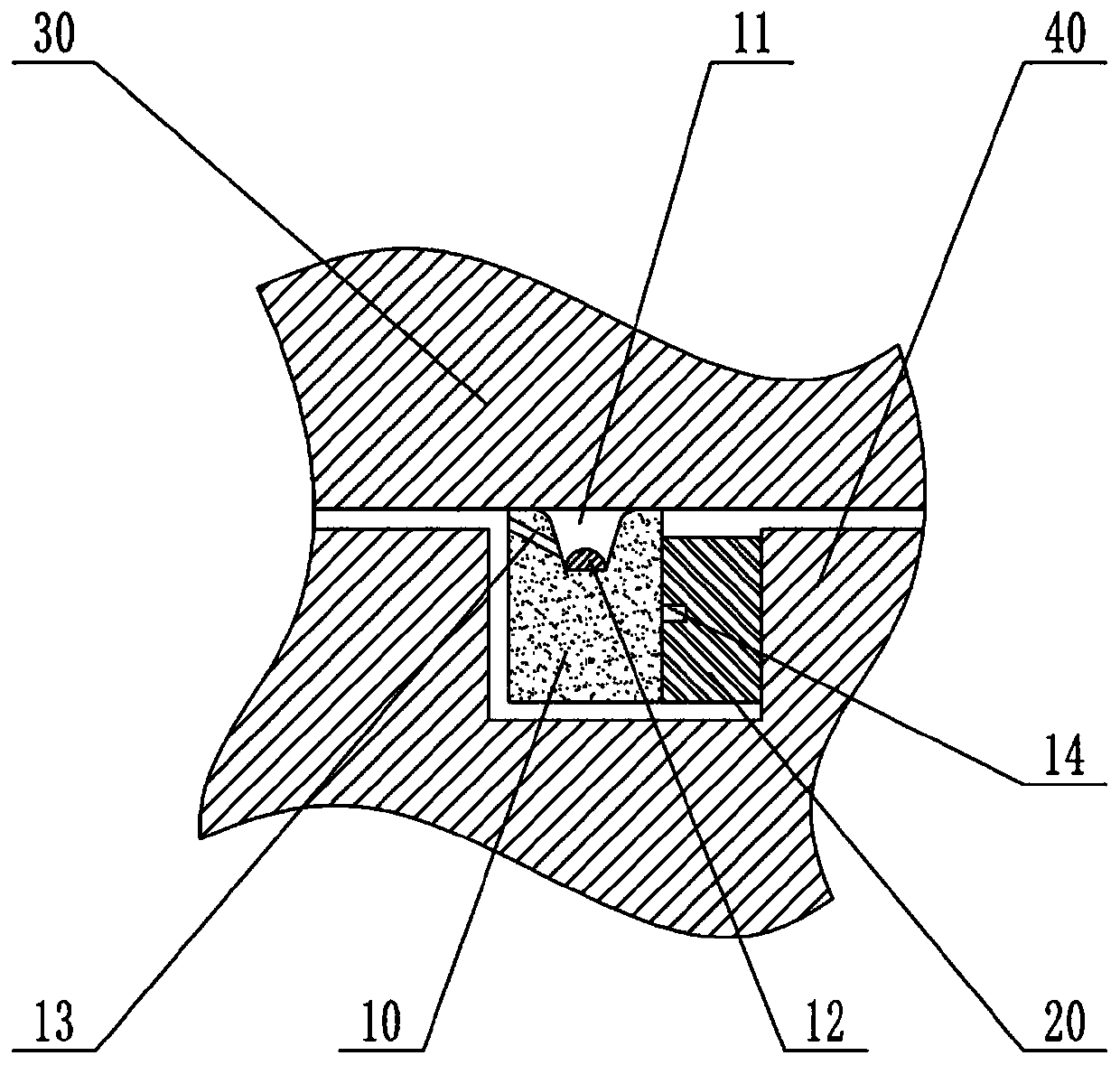

[0021] Reference numerals in the accompanying drawings include: piston ring 10 , circumferential groove 11 , magnet block 12 , balance hole 13 , positioning block 14 , support ring 20 , cylinder 30 , and piston 40 .

[0022] like figure 1 As shown, this figure is a simple exploded view of a long-life piston ring 10 sealing system of this embodiment. It mainly includes two parts, the piston ring 10 and the support ring 20 . A piston ring 10 and a support ring 20 form a sealing unit. The number of sealing units is multiple, and the structure of five sealing units is adopted in this solution. The piston ring 10 should pay attention to the selection of wear-resistant materials, while the support ring 20 is mainly made of materials with high thermal conductivity. choose.

[0023] The piston ring 10 is in the shape of a boss, and its surface is provided with a plurality of positioning blocks 14 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com