a caliper

A caliper, the first handle technology, applied in the field of caliper, can solve the problems of inconvenient use, inability to accurately measure wall thickness, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

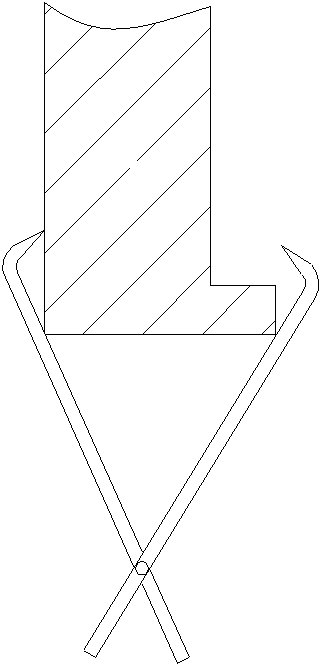

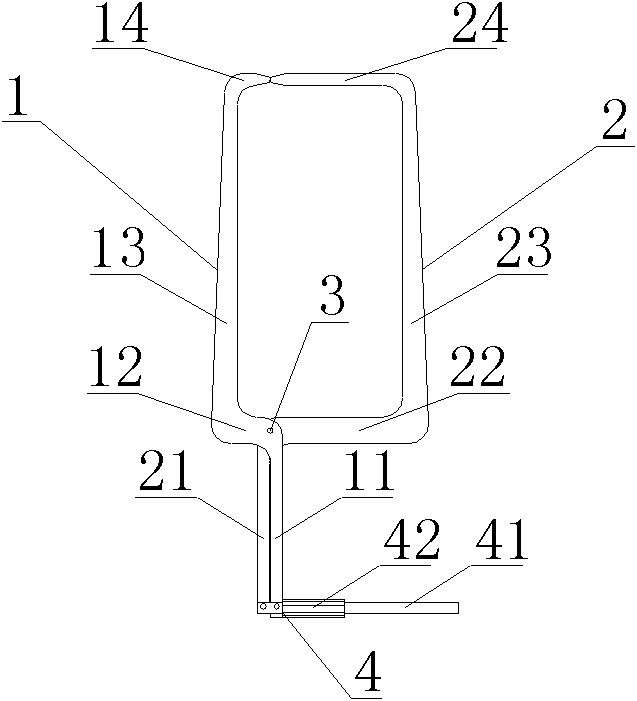

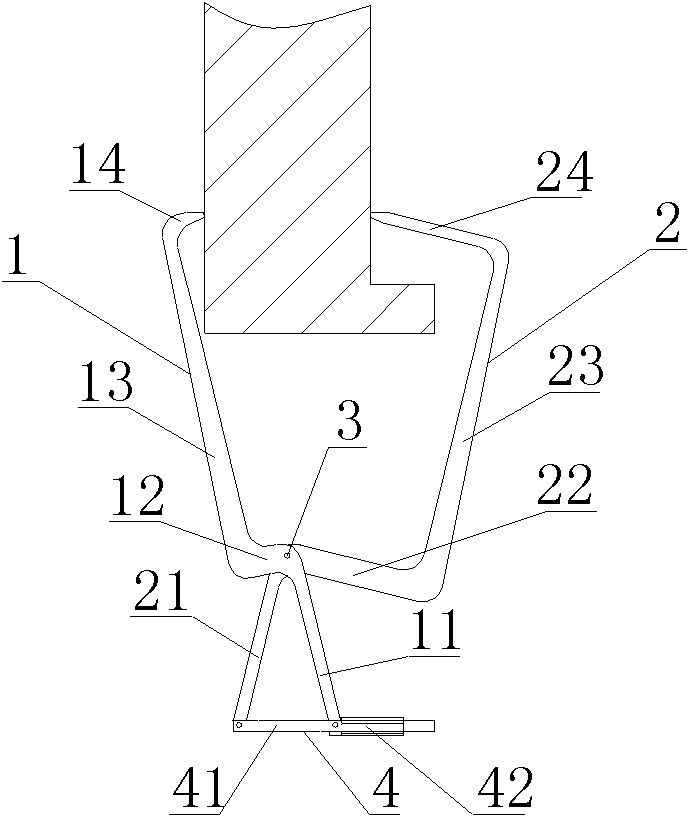

[0012] Such as figure 2 As shown, a caliper includes a first caliper rod 1 and a second caliper rod 2, and the first caliper rod 1 and the second caliper rod 2 are connected through a rotating shaft 3, and it is characterized in that: The first caliper bar 1 includes a first handle 11, a first cross bar 12 connected to the first handle 11, a first vertical bar 13 connected to the first cross bar 12, and a first clip hook 14 connected to the first vertical bar 13, The first cross bar 12 is parallel to the first clip hook 14, and the second caliper bar 2 includes a second handle 21, a second cross bar 22 connected with the second handle 21, and a first cross bar 22 connected with the second cross bar 22. Two vertical bars 23 and a second clamping hook 24 connected to the second vertical bar 23 , the second horizontal bar 22 is parallel to the second clamping hook 24 . The bottom of the first handle 11 is connected to the bottom of the second handle 21 through a vernier caliper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com