Method for forming thin film pattern and flat panel display having same

一种平板显示器、薄膜图案的技术,应用在形成薄膜图案以及具有该薄膜图案的平板显示器领域,能够解决难形成分辨率薄膜图案等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Reference will now be made in detail to specific embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

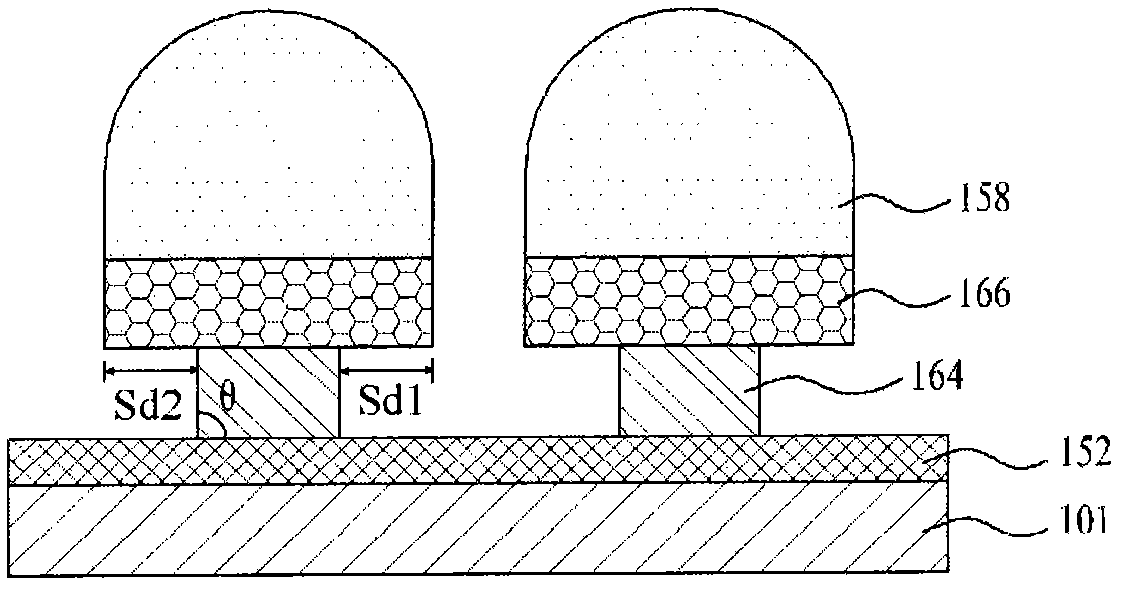

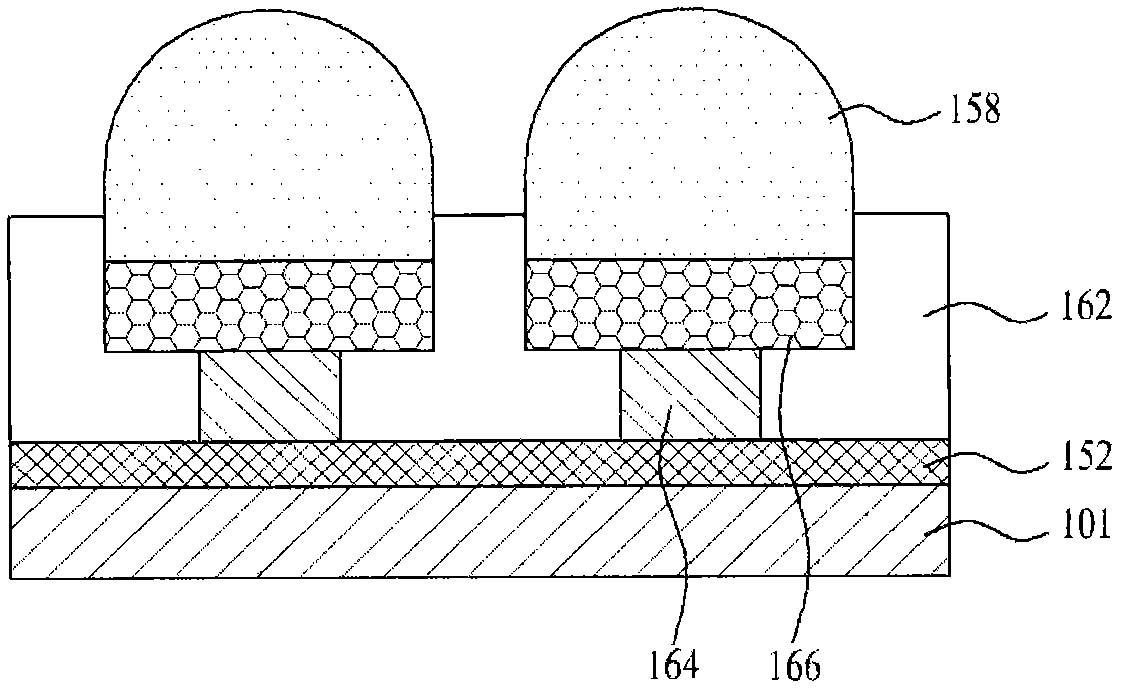

[0030] Figures 1A-1G There are shown cross-sectional views illustrating steps of a method of forming a thin film pattern according to a preferred embodiment of the present invention.

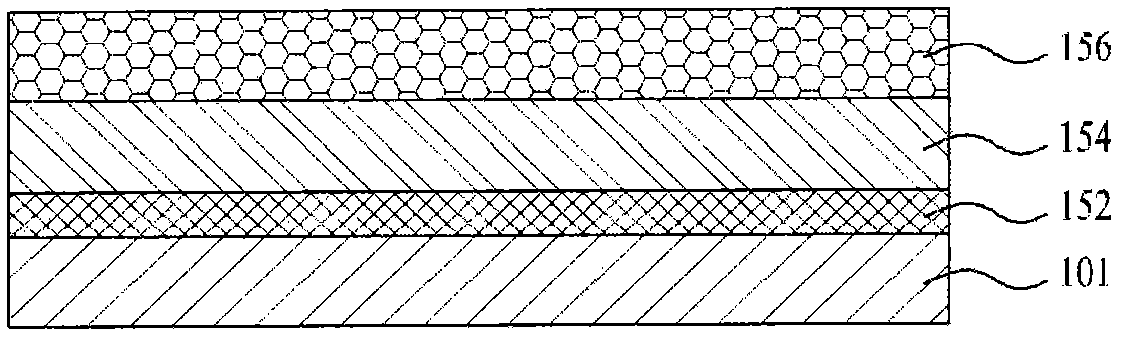

[0031] refer to Figure 1A , the first to third film layers 152 , 154 and 156 are sequentially stacked on the substrate 101 .

[0032] The first thin film layer 152 , which is a material layer of a thin film pattern to be formed on the substrate 101 , is formed of a metal, an insulating film, or a semiconductor layer.

[0033] The second thin film layer 154 is formed of a material that forms an obtuse or right angle θ after the etching process. In detail, the second thin film layer 154 is formed of an inorganic insulating fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com