Lithium battery cap, manufacturing method and lithium battery

A manufacturing method and technology for lithium batteries, which are applied to lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of small qualified tolerance range of aluminum casings, loose fit between steps and aluminum casings, and troublesome battery manufacturing. Achieve the effect of relaxing the qualified tolerance range, facilitating assembly and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

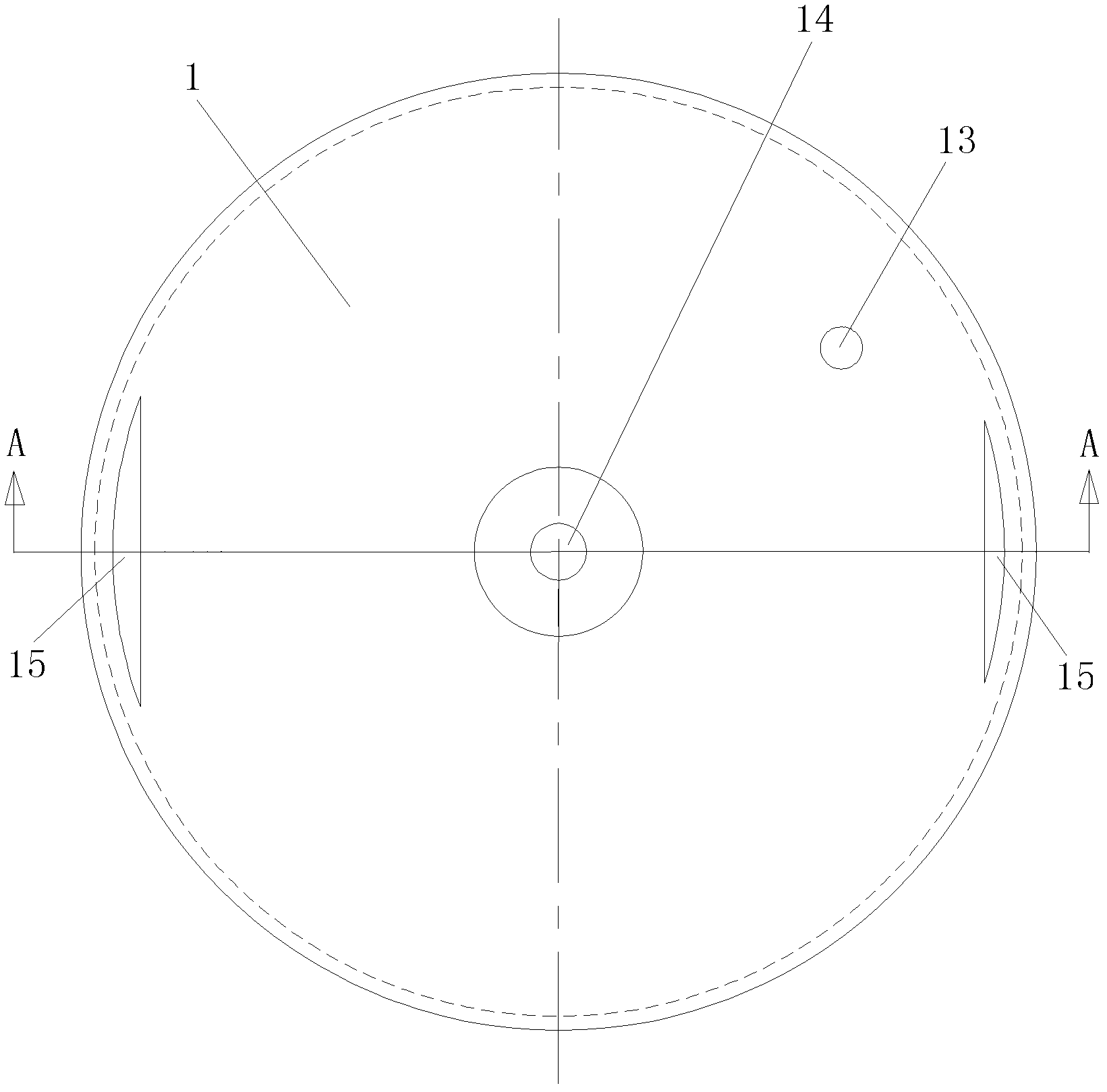

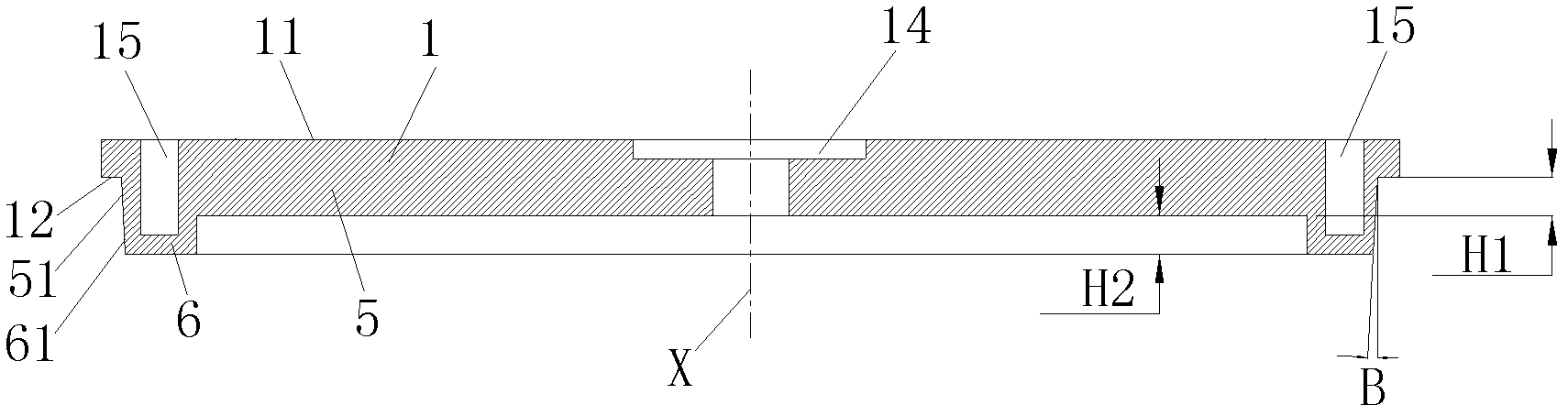

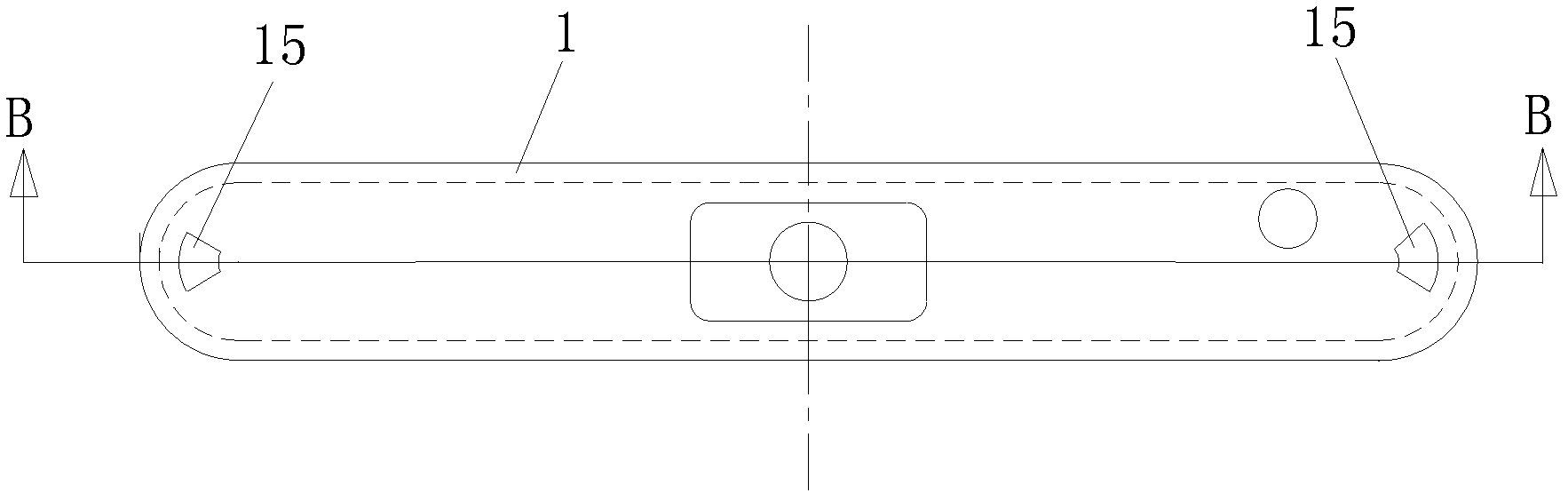

[0030] Such as figure 1 and figure 2 Shown, it is the first embodiment of lithium battery cap. The lithium battery cap includes a circular cover, the cover includes a circular substrate 1 and a circular step 5 with a height of H1, the step 5 integrally extends downward from the lower surface 12 of the substrate, and the diameter of the step 5 is smaller than the diameter of the substrate 1. A pit 15 is punched downward on the upper surface 11 of the substrate, and correspondingly, a boss 6 with a height H2 protrudes from the position corresponding to the pit on the lower surface of the step. The step 5 has a first side 51, which is used to cooperate with the casing of the lithium battery, and the first side 51 is an arc surface. The boss 6 has a second side 61, the second side 61 is an arc surface, the second side 61 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com