Guide frame and electromagnetic reversing valve

A technology of guide frame and slider, applied in the direction of sliding valve, valve detail, multi-way valve, etc., can solve the problems of small matching area between guide frame and slider, fracture, slider deformation, etc., to avoid deformation or fragmentation, The effect of increasing the mating area and reducing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

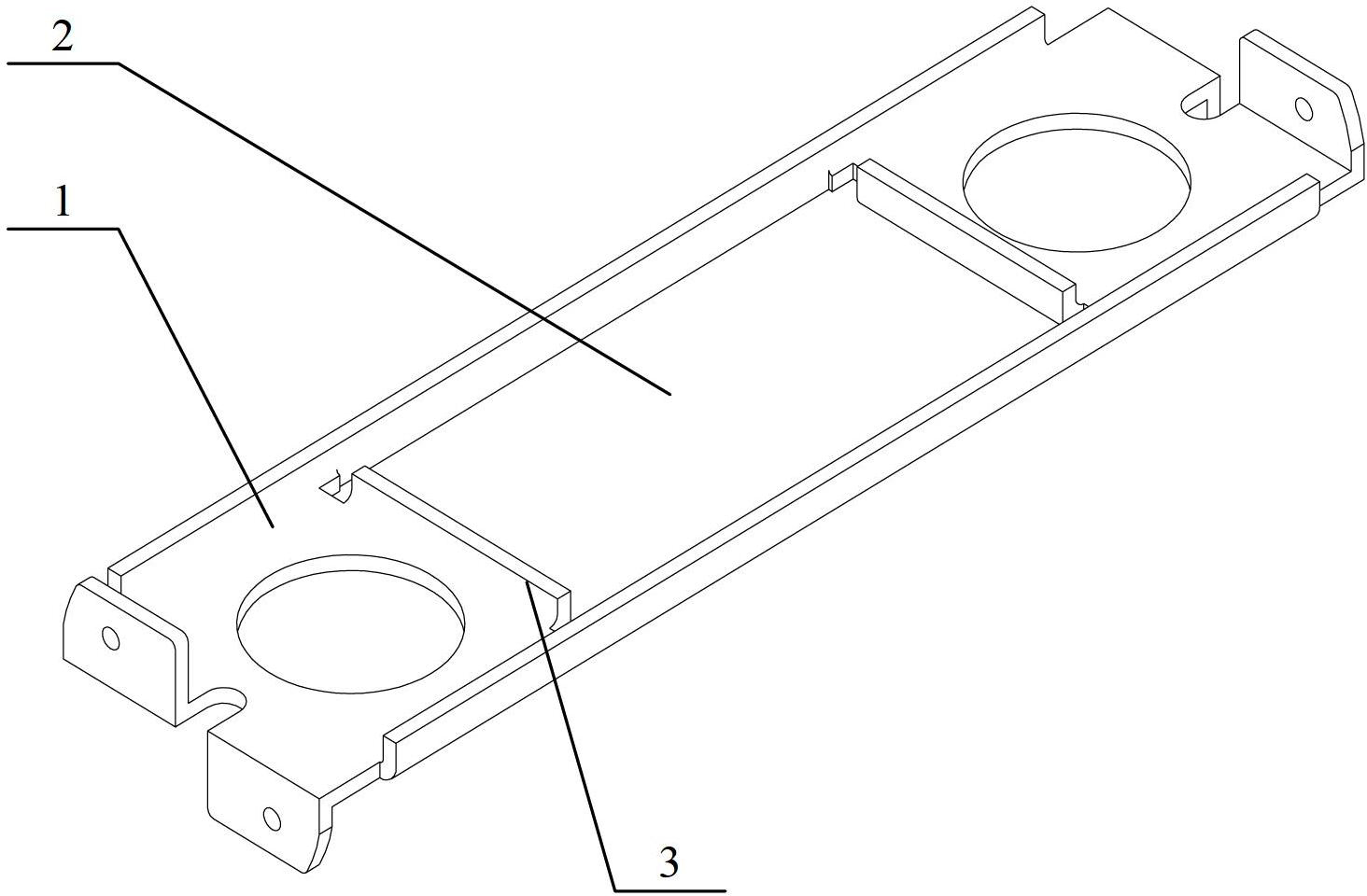

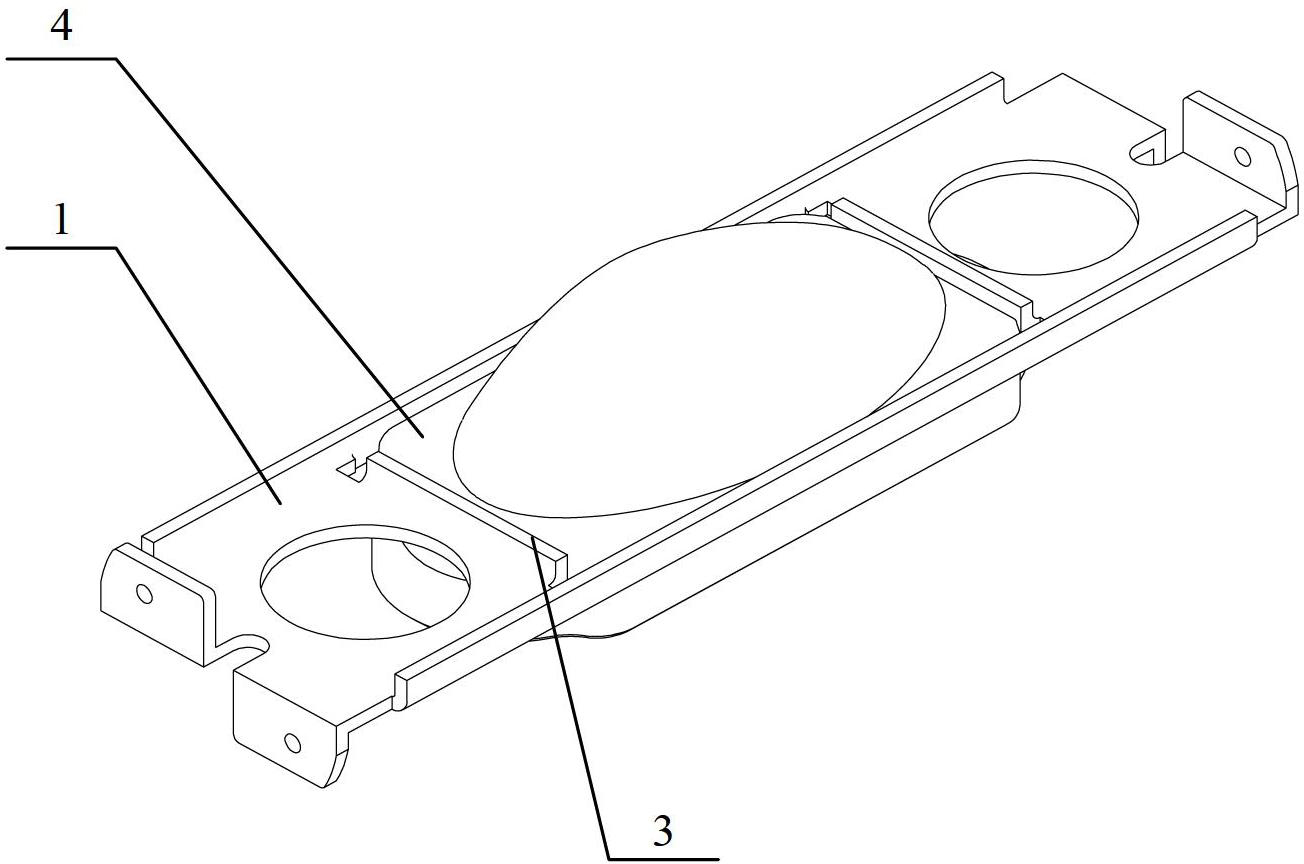

[0031] refer to figure 1 and figure 2 , figure 1 Schematic diagram of the structure of the guide frame provided by the embodiment of the present invention; figure 2 for figure 1 Schematic of the guide frame shown with the slide mounted.

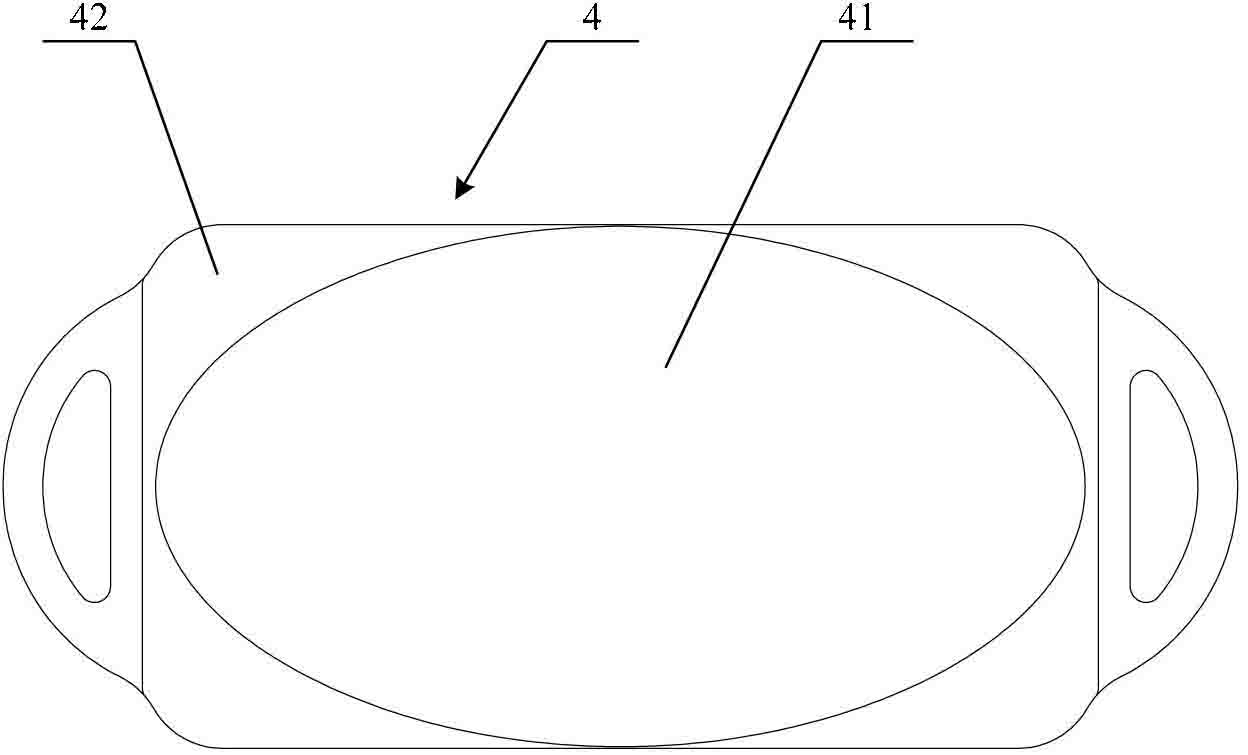

[0032] Such as figure 1 and 2 As shown, the guide frame provided by this embodiment includes a plate-shaped guide frame body 1 and a slider mounting hole 2 provided on the guide frame body 1. The slider mounting hole 2 is along the two ends of the guide frame body 1 in the length direction. The part has a slider mounting plate 3 for cooperating with the mounting part of the slider.

[0033] In the guide frame provided by this embodiment, the slider 4 is installed in the slider mounting hole 2 of the guide frame. In practical applications, pistons are installed at both ends of the guide frame, and the guide frame is arranged on the valve of the main valve of the electromagnetic reversing valve. In the chamber, the piston drives the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com