Pierced type master slice of radiator of internal combustion engine and processing method thereof

A processing method and radiator technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of radiator leakage, falling off, poor connection strength, etc., and achieve increased mating area, good welding strength, and mating area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

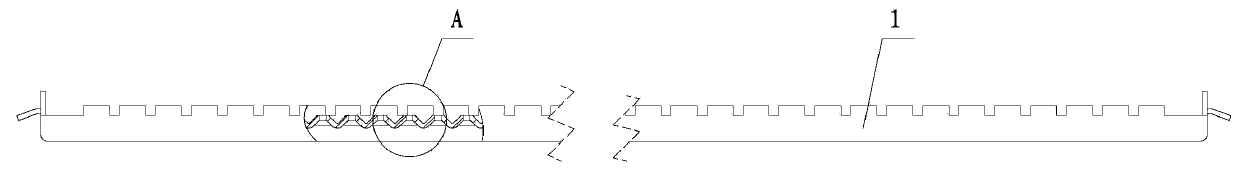

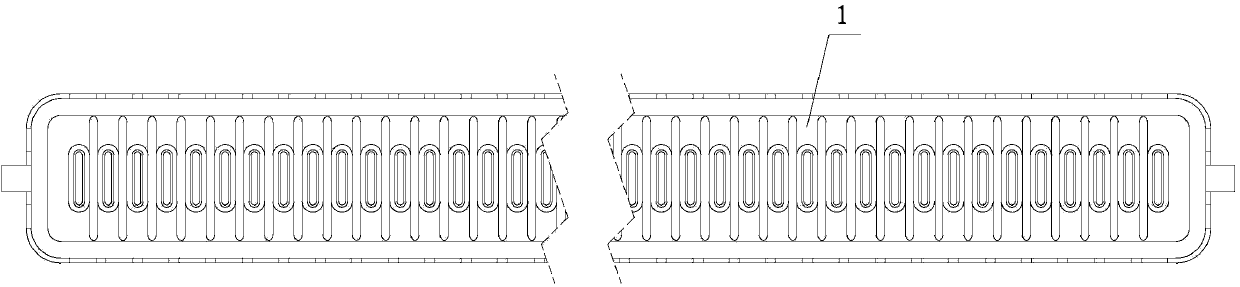

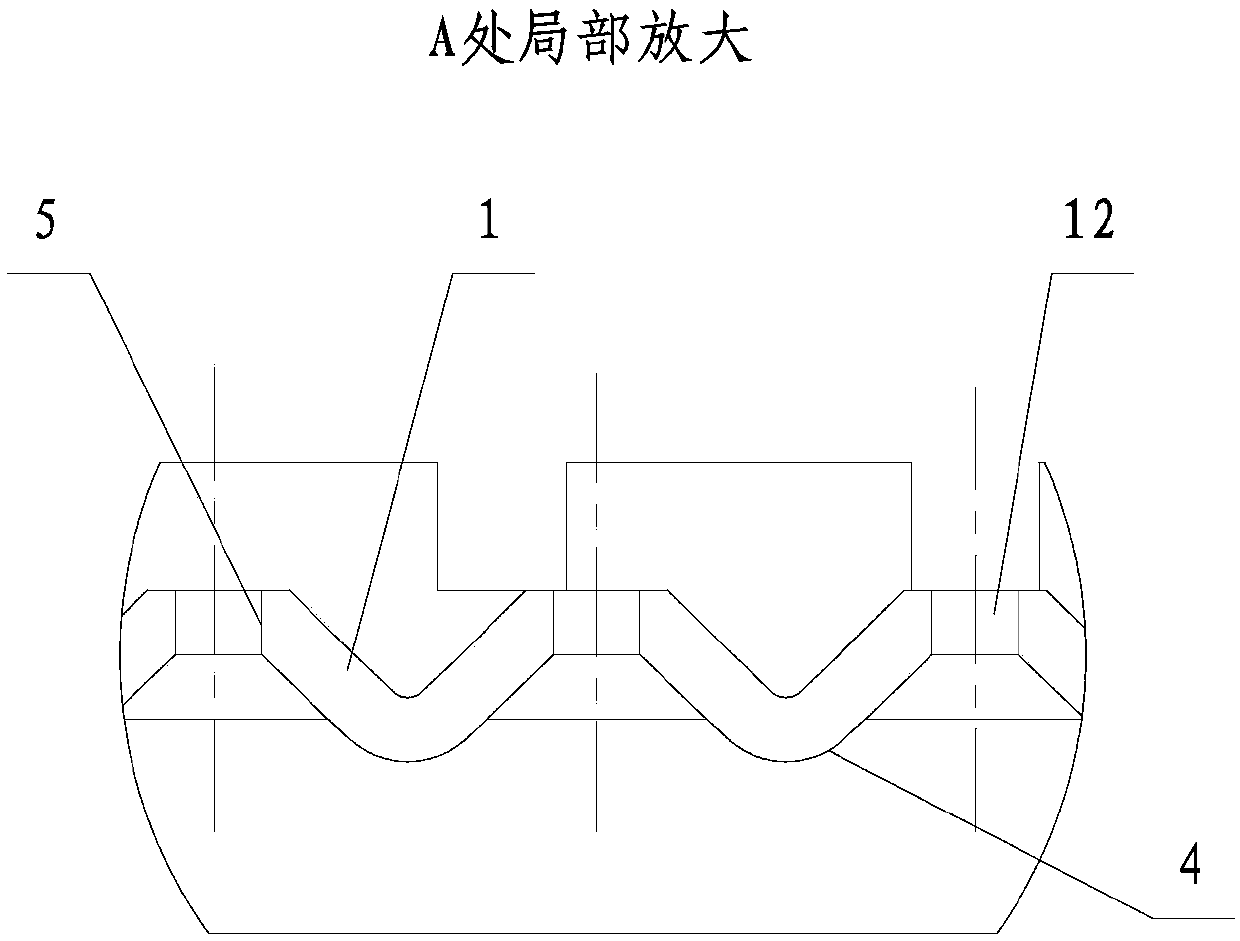

[0026] Such as Figure 5-8 As shown, the main sheet 11 of the present invention has a plurality of installation holes 12 formed by stretching and piercing evenly distributed along its length direction, and each installation hole 12 is brazed with the high-frequency welded pipe 2 . There is a solder coating 10 on the section 7 of the mounting hole 12, so that after the main sheet 11 and the high-frequency welded pipe 2 are brazed, except for the solder 6 at the root of the main sheet 11, the section 7 of the main sheet 11 also has a solder coating 10, After brazing, the main piece 11 and the high-frequency welded pipe 2 are tightly welded together, the welding area is large, and the welding strength is good, thereby solving the hidden danger of the radiator leakage caused by the main piece solder cracking and falling off under severe conditions.

[0027] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com