A power connection device with pull force detection function

A technology of power connection and tension detection, which is applied to the parts of the connection device, measuring device, connection, etc., can solve the problems of the influence of the safety distance, the increase of the connection length between the tower and the transmission line, and the increase of cost, so as to achieve stability and anti-interference Strong ability, reduced material and labor costs, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

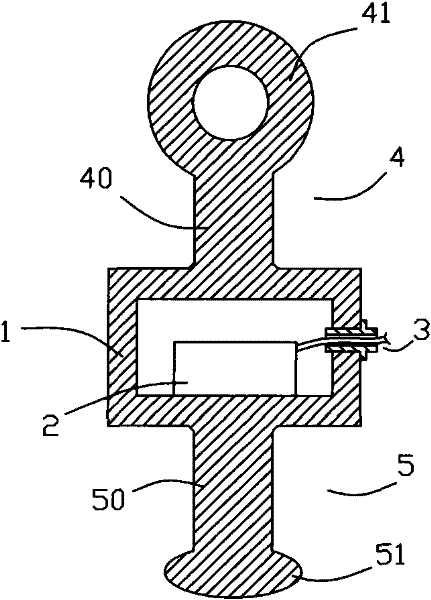

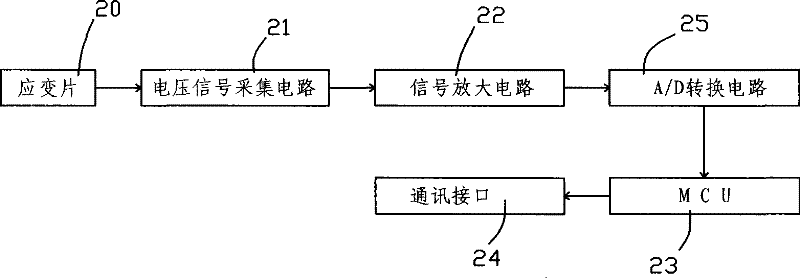

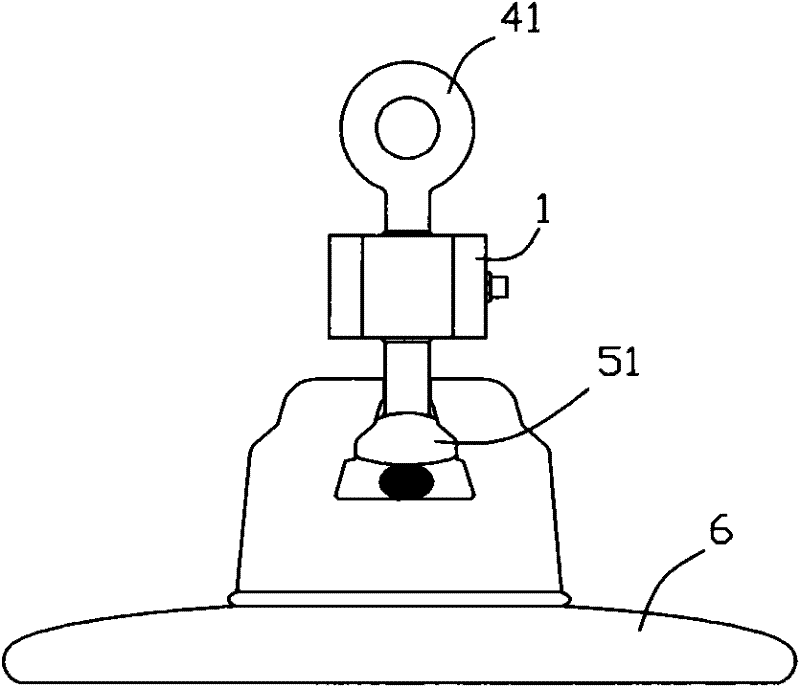

[0021] see Figure 1 to Figure 3 , shows an embodiment of a power connection device with a pull force detection function in the present invention, which includes a closed casing 1 with a cavity in the middle, and a pull force detection device 2 is built in the middle cavity of the casing 1, and the pull force detector 2 is embedded in the middle cavity during the processing of the shell 1. The side wall of the middle cavity of the shell has an inlet / outlet 3 communicating with the inner cavity of the shell. One end of the shell 1 The connection part 4 connected with the pole tower (not shown in the figure) is integrally formed, and another connection part 5 which can be connected with the insulator string (not shown in the figure) is integrally formed on the other end of the housing 1, so it not only It has a connection function and a tension detection function. The housing 1, the connection part 4 and the other connection part 5 are all made of stainless steel, so it can not ...

Embodiment 2

[0025] The housing 1 is a closed housing, and the tension detector 2 is embedded in the middle of the housing during the processing of the housing 1. One end of the housing 1 is connected to the pole tower (not shown in the figure) through a flexible connection device. The connected connecting part 4, the other connecting part 5 connected to the insulator string (not shown in the figure) by the other end of the housing 1 through a movable connection device, and the rest are the same as the first embodiment.

Embodiment 3

[0027] The shell 1 is a non-closed shell, and the tension detector 2 is embedded in the middle of the shell during the process of forming the shell 1. One end of the shell 1 is integrally formed and connected with the pole tower (not shown in the figure). The other end of the housing 1 is integrally formed with another connecting portion 5 that can be connected to an insulator string (not shown in the figure), and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com