A kind of coloring method of stainless steel surface

A surface coloring and stainless steel technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uncoordinated environment, poor adhesion of stainless steel surface, coldness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

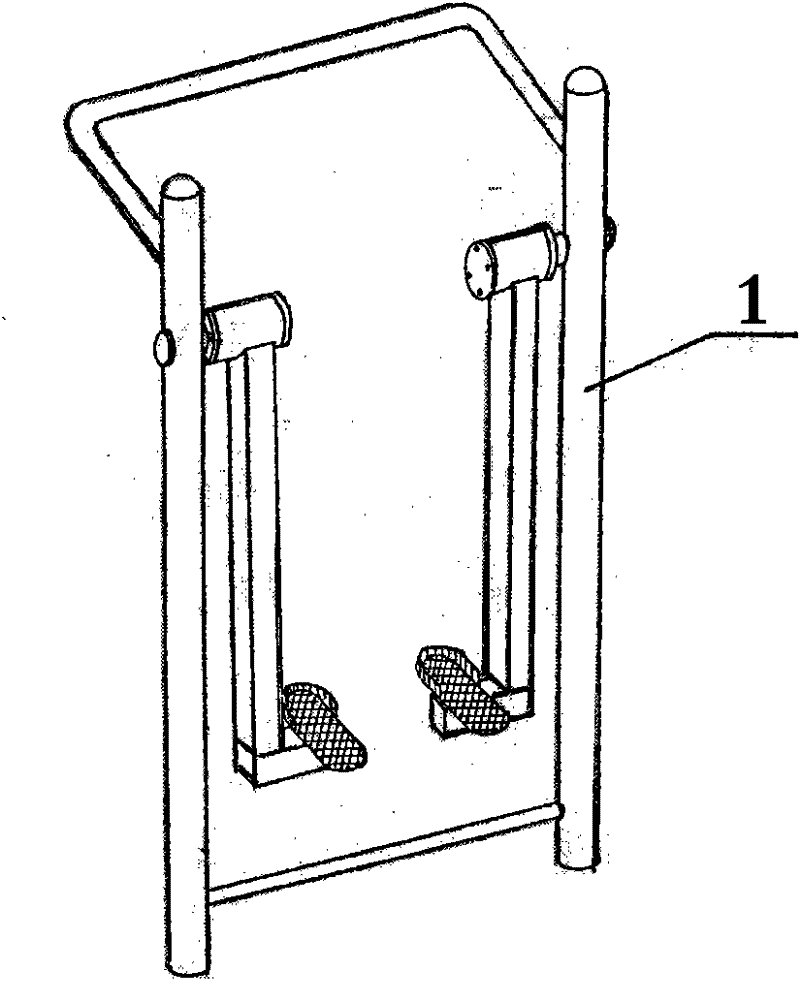

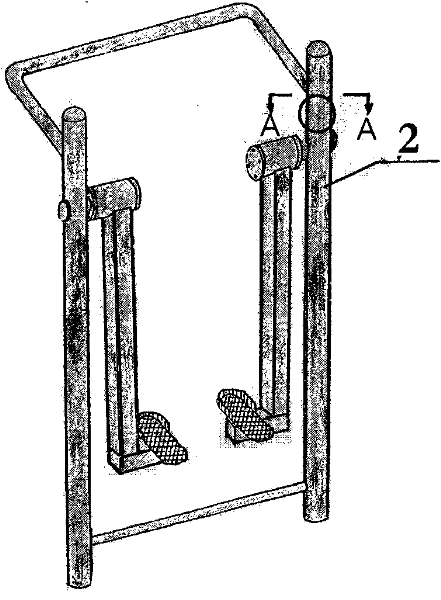

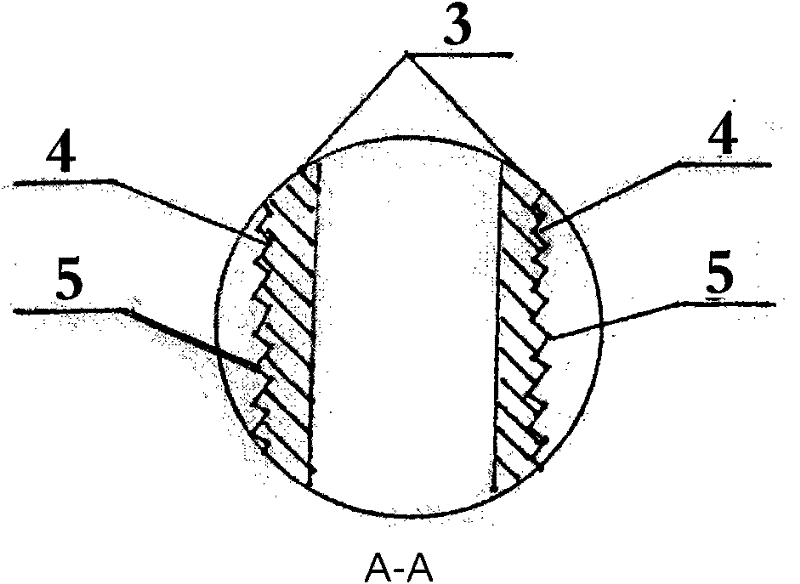

[0012] figure 1 It is an outdoor fitness equipment (walking machine) made of stainless steel, and the surface of the fitness equipment is bright. In order to change the bright and single color of the stainless steel surface, the coloring method of the stainless steel surface of the present invention is now used to carry out coloring treatment on the product. figure 2 It is the three-dimensional effect after completing the sandblasting process of the coloring method of the present invention. The surface of the product has changed from the original bright shape to uneven and rough. image 3 It can be clearly seen from the partially enlarged cross-sectional view that the outer wall of the tube 3 of the stainless steel fitness equipment presents uneven shapes, concave 4 and convex 5 . Figure 4 It is the three-dimensional effect after completing the painting process of the coloring method of the present invention, and from Figure 5 As can be seen from the partially enlarged se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com