Process method for galvanizing rubber metal part

A process method, rubber metal technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve problems such as maintaining positive galvanized layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

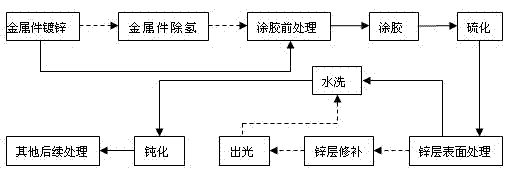

Method used

Image

Examples

Embodiment

[0028] Production of 6,534 pieces of spherical hinges with jackets, the specific process is: metal parts galvanized (without passivation), metal parts pre-treatment for gluing, gluing, vulcanization, zinc layer surface treatment, water washing, passivation. 5 pieces of unglued products (the zinc layer of these 5 products were seriously damaged in many places, and the zinc layer on the surface of the metal parts was removed and re-galvanized before the glue was unglued). The pass rate was 99.92%, and the appearance quality of the zinc layer was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com