Steamed buns with long quality guarantee period and suitable for long-distance delivery and preparation method of steamed buns

A long-distance, shelf-life technology, applied to bacteria used in food preparation, yeast-containing food ingredients, food ingredients as moisturizers, etc., can solve problems such as inability to adapt to sales radius, long sales cycle, easy cracking and peeling, etc., to achieve The effect of delaying the outward migration of moisture, inhibiting the growth of microorganisms, and ensuring the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.4kg of bio-fermentation agent and 0.5kg of compound improver to 100kg of flour, mix well, then add 48kg of water, and make dough; roll the dough into dough rolls after sheet-folding-sheet cycle, and divide the dough , Formed into raw steamed buns; after the green steamed buns are proofed for 60 minutes at a temperature of 35-38°C and a relative humidity of 85%, they are forced to be humidified under saturated humidity conditions of a temperature of 35-38°C and a relative humidity of 100% for 3 minutes; steam the moistened steamed buns for 30 minutes.

[0026] The biological fermentation agent is composed of active yeast, plant lactobacillus and acetic acid bacteria, and the weight ratio of active yeast, plant lactobacillus and acetic acid bacteria is 100:2:10; the compound improver is composed of starch hydrolase, gluconic acid-δ -Lactone and β-cyclodextrin, the weight ratio of starch hydrolase, glucono-δ-lactone and β-cyclodextrin is 7:60:50.

Embodiment 2

[0034] Add 1.5kg of bio-fermentation agent and 0.05kg of compound improver to 100kg of flour, mix well, then add 46kg of water, and make dough; roll the dough into dough rolls after sheet-folding-sheet cycle, and divide the dough rolls , Formed into steamed buns; steamed buns were proofed for 40 minutes at a temperature of 35-38°C and a relative humidity of 80%, and then forced to humidify for 5 minutes under saturated humidity conditions of a temperature of 35-38°C and a relative humidity of 100%. minutes; steam the moistened steamed buns for 25 minutes.

[0035] The biological fermentation agent is composed of active yeast, plant lactobacillus and acetic acid bacteria, and the weight ratio of active yeast, plant lactobacillus and acetic acid bacteria is 100:10:6; the compound improver is composed of starch hydrolase, gluconic acid-δ -Lactone and β-cyclodextrin, the weight ratio of starch hydrolase, glucono-δ-lactone and β-cyclodextrin is 1:20:30.

Embodiment 3

[0043] Add 1.1kg of biological leavening agent and 0.25kg of compound improver to 100kg of flour, mix well, then add 54kg of water, and knead into dough; roll the dough into rolls after sheet-folding-sheet cycle, and divide the rolls , Shaped into green steamed buns; after the green steamed buns are proofed for 50 minutes at a temperature of 35-38°C and a relative humidity of 90%, they are forced to be humidified for 4 minutes at a saturated humidity of 35-38°C and a relative humidity of 100%. ; Steam the moistened steamed buns for 20 minutes.

[0044] The biological fermentation agent is composed of active yeast, lactobacillus plantarum and acetic acid bacteria, and the weight ratio of active yeast, lactobacillus plantarum and acetic acid bacteria is 100:6:2; the compound improver is composed of starch hydrolase, gluconic acid-δ -Lactone and β-cyclodextrin, the weight ratio of starch hydrolase, glucono-δ-lactone and β-cyclodextrin is 4:40:41.

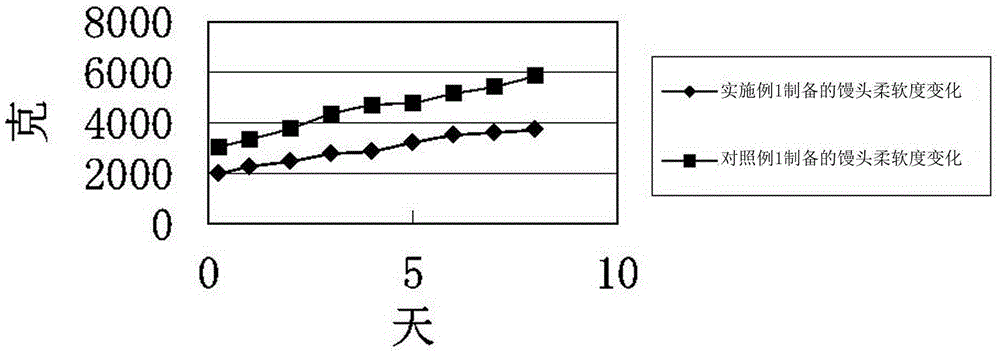

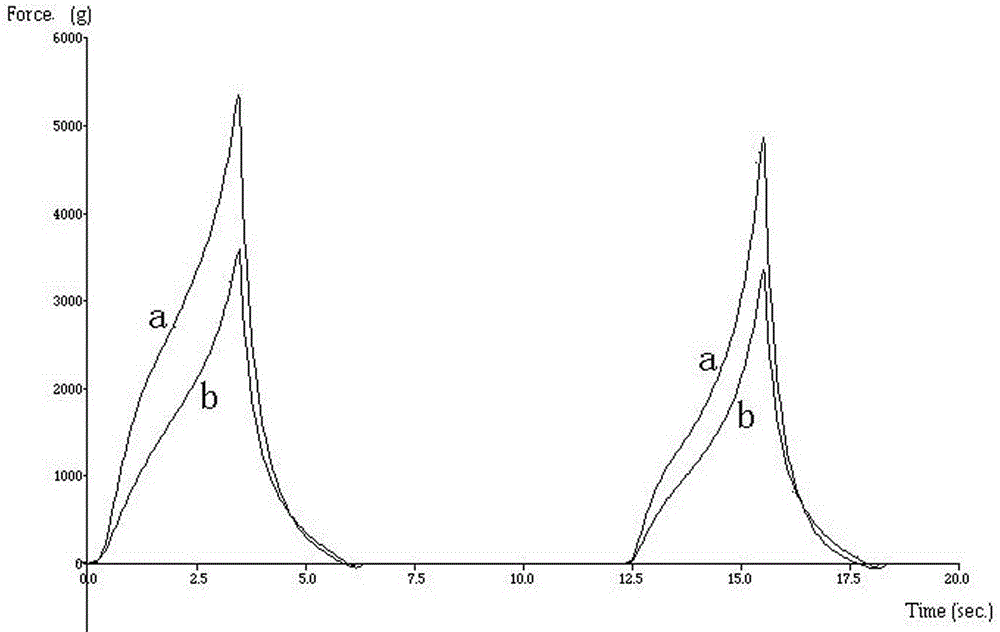

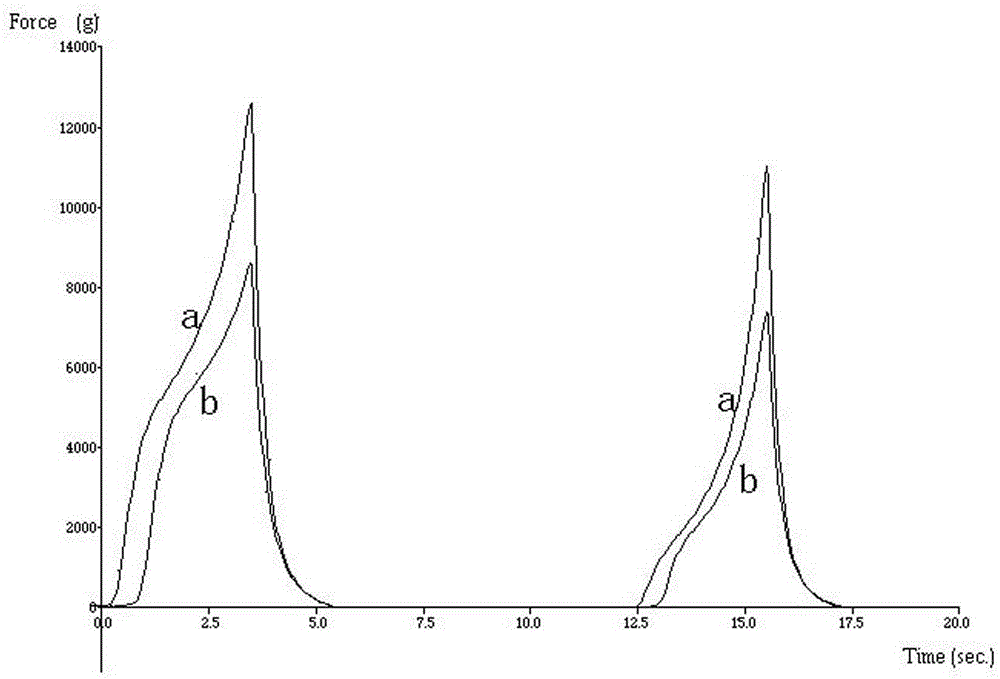

[0045] Compared with Comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com