Vulcanization ring sheet mold for tire

A technology of vulcanizing ring pieces and molds, which is applied to tires, household appliances, and other household appliances. It can solve problems that affect the appearance quality, reduce product grades, and cannot be repaired, so as to ensure the appearance quality and performance, and improve positioning accuracy. , Reduce the effect of mold processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

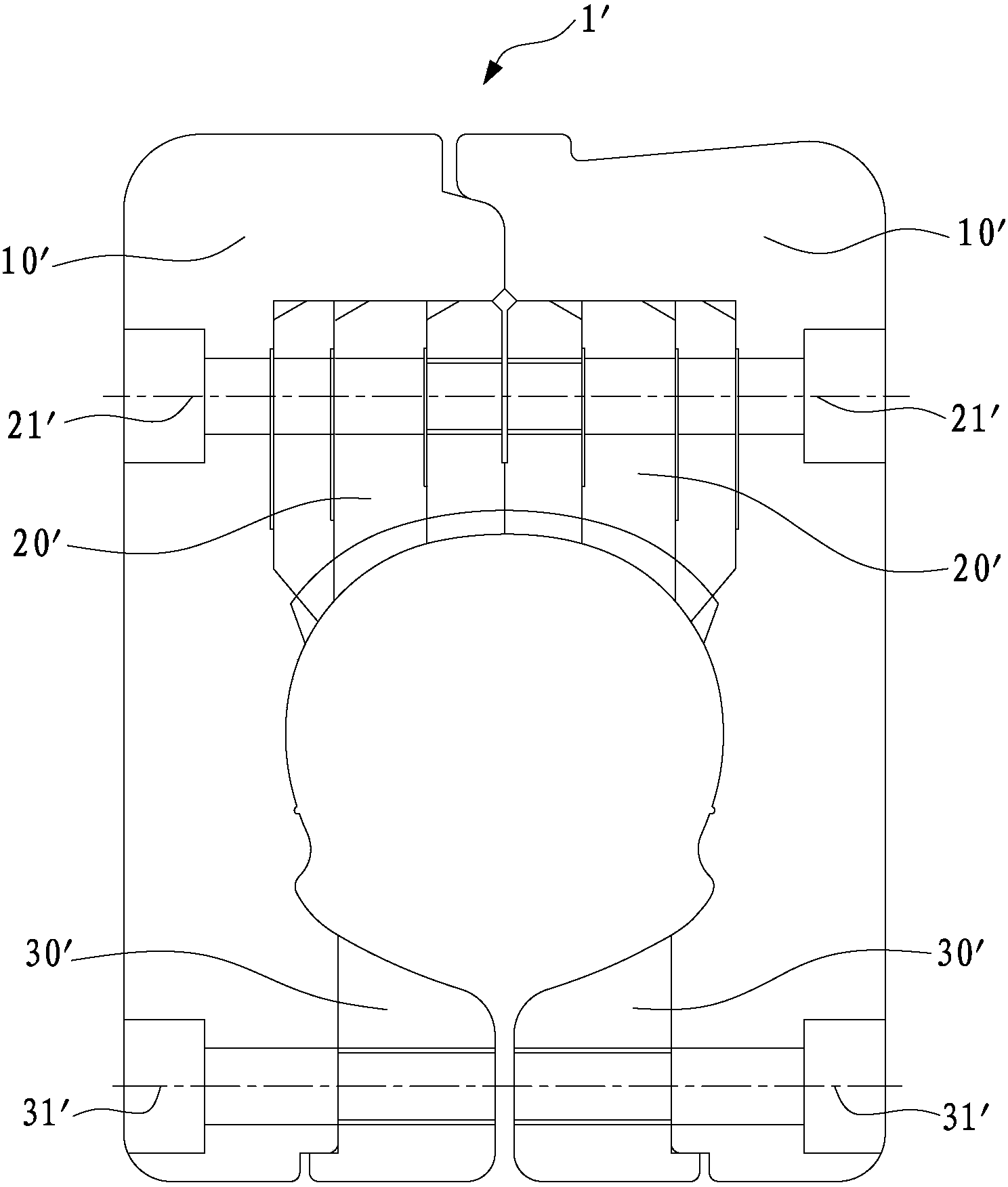

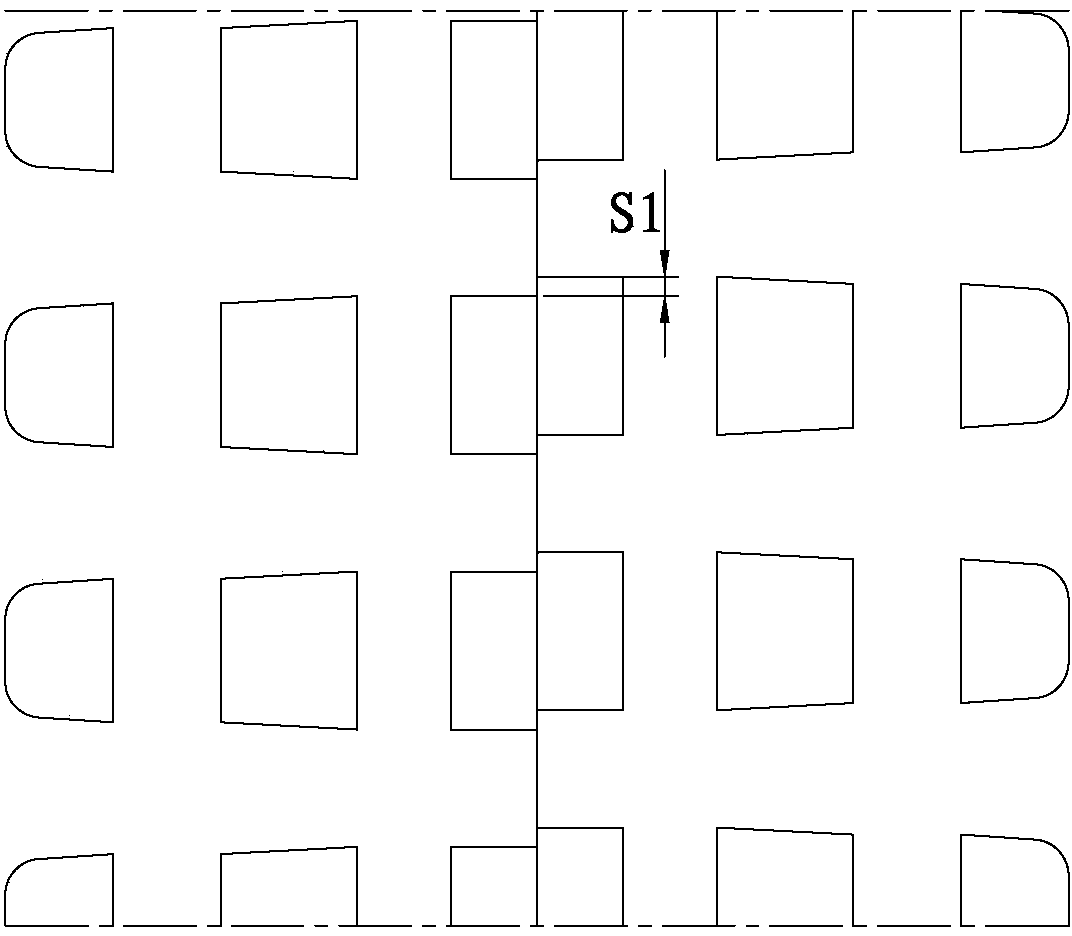

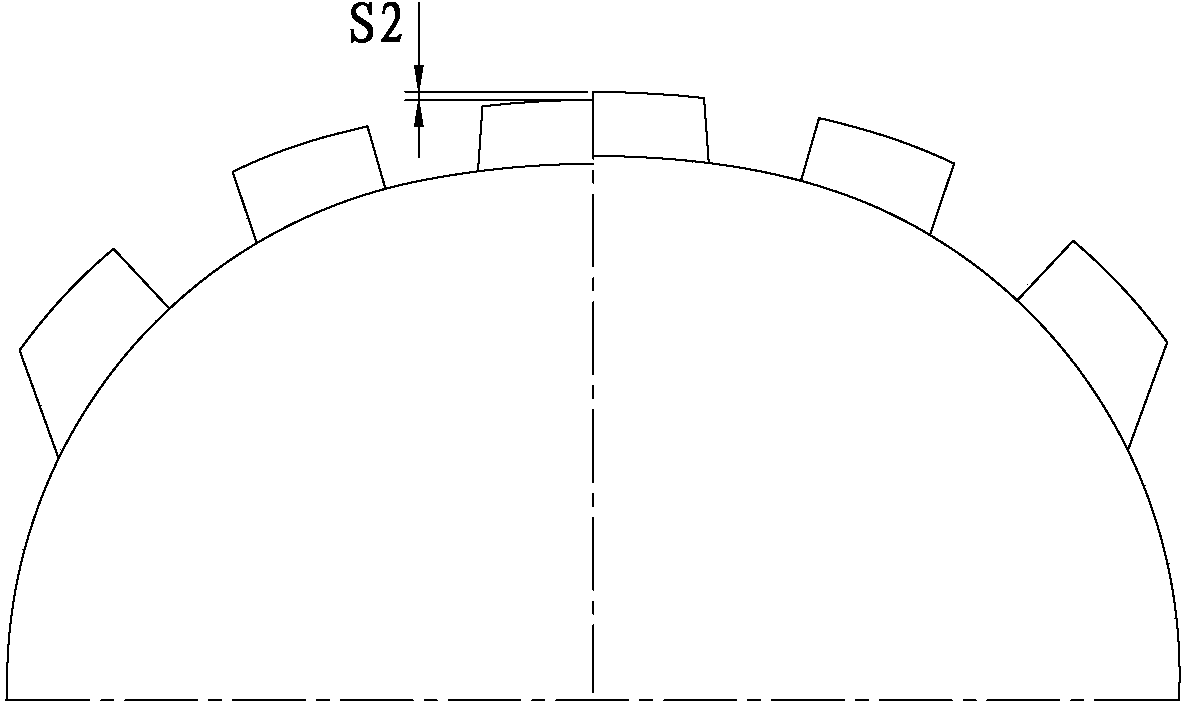

[0033] Such as Figure 4 to Figure 7 As shown, the present invention discloses a tire vulcanization ring mold. The ring mold 1 is also assembled from an upper mold and a lower mold that are symmetrical to each other. Both the upper and lower molds include a body 10 and a ring group 20 And the inner ring 30; wherein the ring sheet group 20 is composed of 2 or more than 2 ring sheets, and the ring sheet group 20 in this embodiment includes the first ring sheet 20a and the second ring sheet 20b from the center of the tire to the outside. and the third ring piece 20c, and are locked on the body 10 by bolts 21; the inner ring 30 is also locked on the body 10 by bolts 31; Several positioning pieces A are provided at intervals, and the same number of matching grooves B as each positioning piece A is provided at the outer edge of the upper and lower ring sheet sets 20 .

[0034] Cooperate Figure 4 , Figure 5 As shown, the positioning piece A processed on the inner cavity of the m...

Embodiment

[0038] The table below shows the figure 1 Existing ring die, and comparative example, the result that embodiment compares. Among them, the index value is used as the evaluation standard, and the larger the value, the better the item.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com