Flat yarn and round yarn mixed let-off mechanism for gauze weaving machine

A technology of a let-off mechanism and a knitting machine is applied in the field of gauze knitting machines, which can solve the problem of single variety of gauze and achieve the effect of satisfying social development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

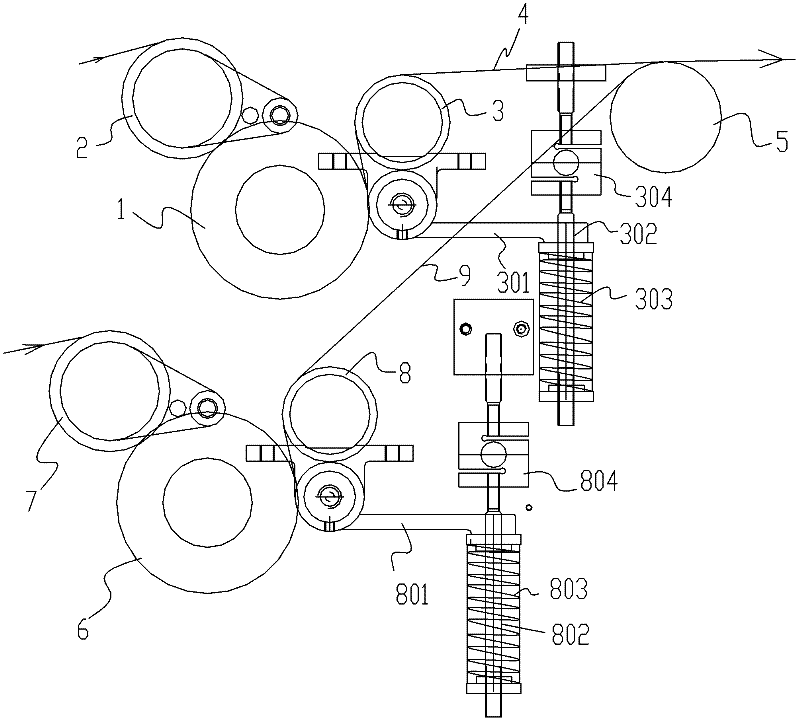

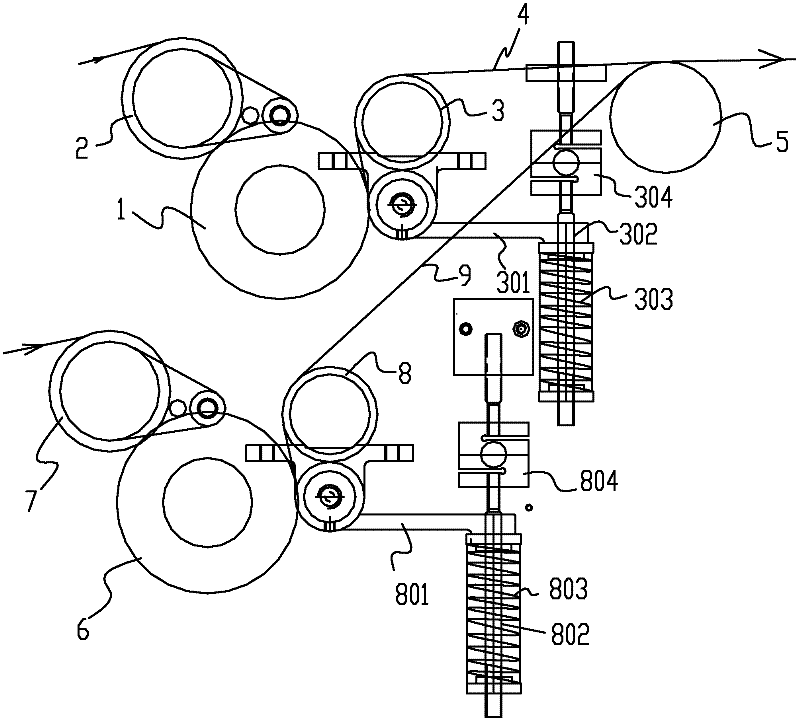

[0013] With reference to the drawings, a flat yarn and round yarn mixed warp let-off mechanism for gauze knitting machine, including flat wire let-off sub-organization and round wire let-off sub-organization, flat wire let-off sub-mechanism and round wire let-off sub-organization combination Together, share the same supporting roller. The flat wire let-off sub-mechanism and the round wire let-off sub-mechanism are preferably located on the same frame, and the main part of the round wire let-off sub-mechanism is located below the main part of the flat wire let-off sub-mechanism. As a preferred way: the main part of the above-mentioned flat wire let-off sub-mechanism includes a flat wire let-off main roller 1, a flat wire let-off pressure roller 2 located above the flat wire let-off main roller, and a flat wire let-off main roller. The flat yarn above the roll is fed through the tension buffer roller 3, and the flat yarn 4 from the flat yarn warp creel is first passed around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com