Tilter

A turning machine and turning frame technology, applied in the field of turning machines, can solve the problems of small turning load, increase the labor intensity of operators, affect the operating speed, etc., achieve the effects of reducing labor intensity, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

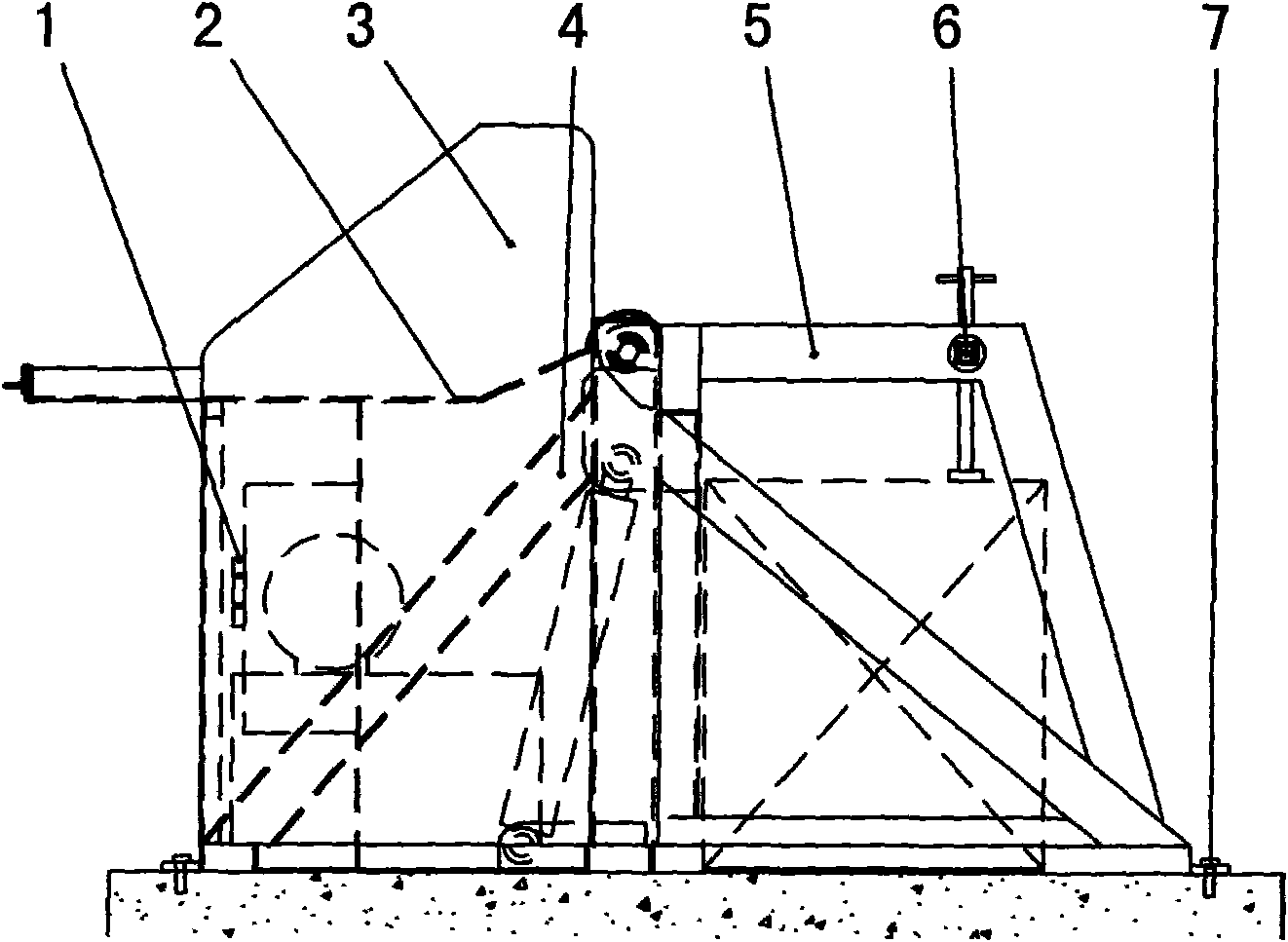

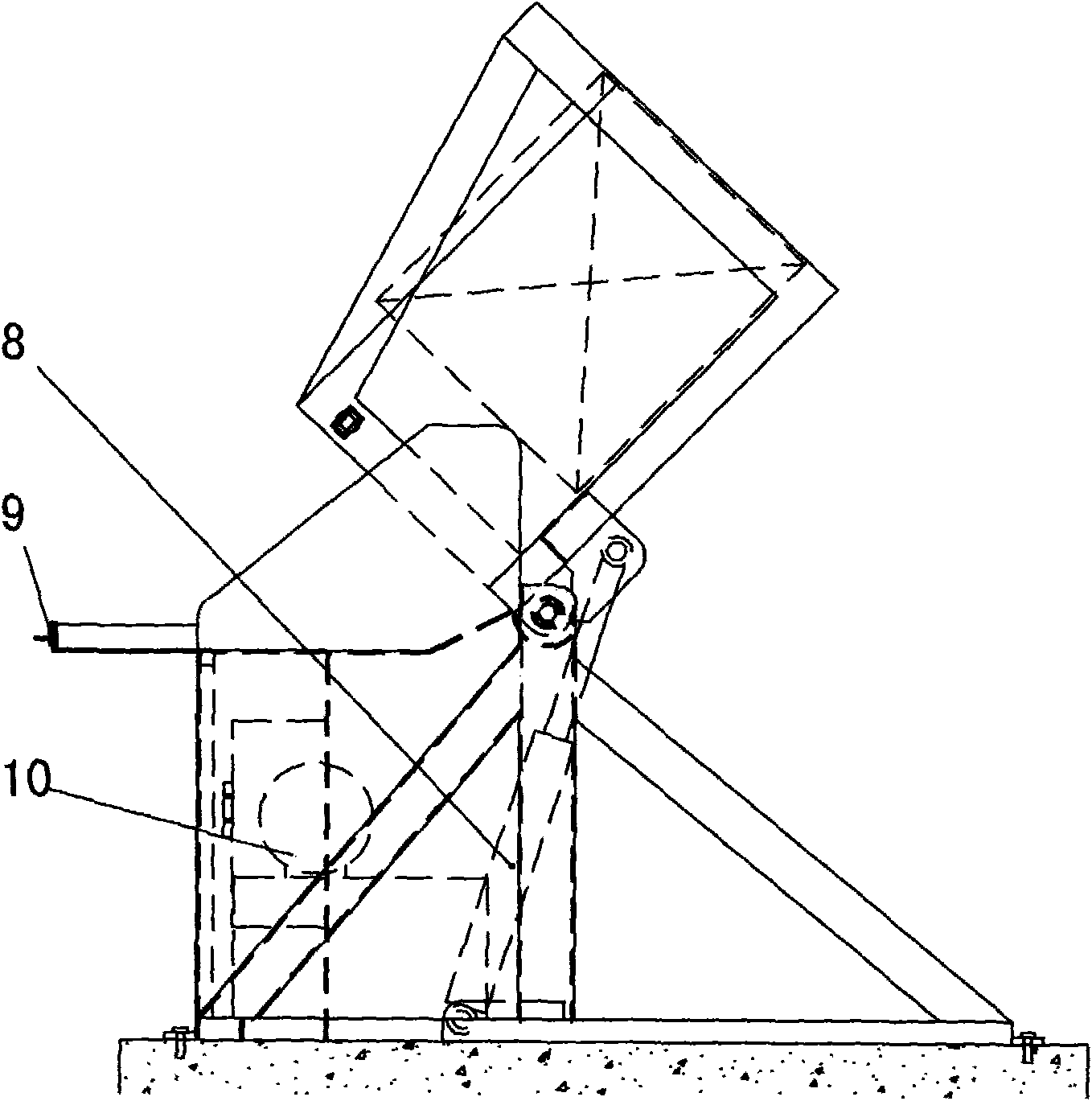

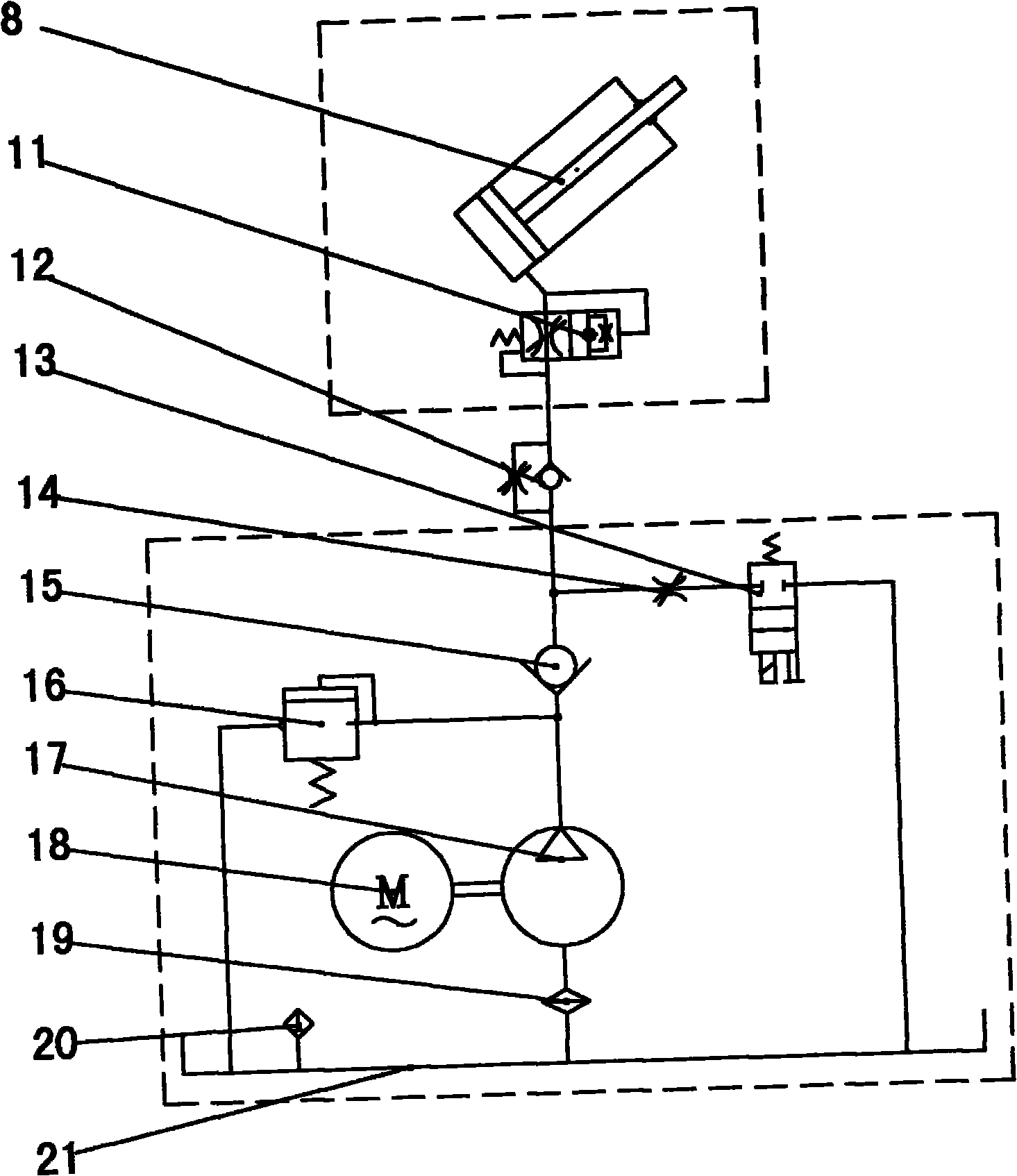

[0019] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] like figure 1 and 2 As shown, the turning machine described in the embodiment of the present invention includes a slide plate 2, left and right baffles 3, a fixed frame 4, a turning frame 5, a locking device 6, a turning cylinder 8 and a hydraulic station 10, and the fixing The frame 4 is connected to the ground through the anchor screws 7, and the left side of the fixed frame 4 is relatively provided with a left and a right baffle plate 3, and a sliding plate 2 is arranged between the left and right baffle plates 3, and a movable plate 2 is provided on the left side of the sliding plate 2. Baffle plate 9, a hydraulic station 10 is provided on the lower side of the sliding plate 2, and a control box 1 is provided on one side of the hydraulic station 10, and the operating state of the hydraulic station 10 can be controlled throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com