waste tire overflow dam

An overflow dam and waste tire technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of high engineering cost and large amount of dam building materials, and achieve good seismic resistance, small engineering volume and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

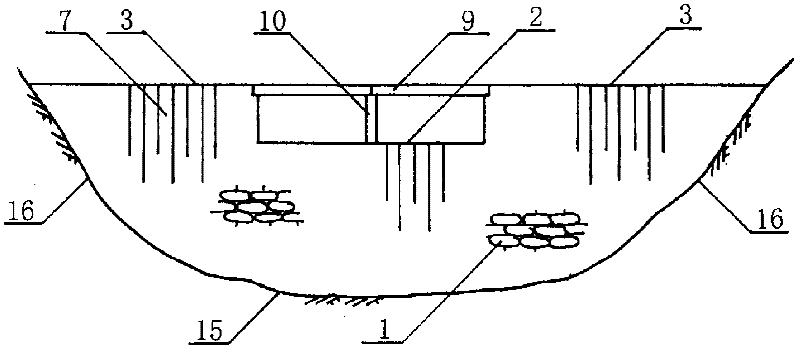

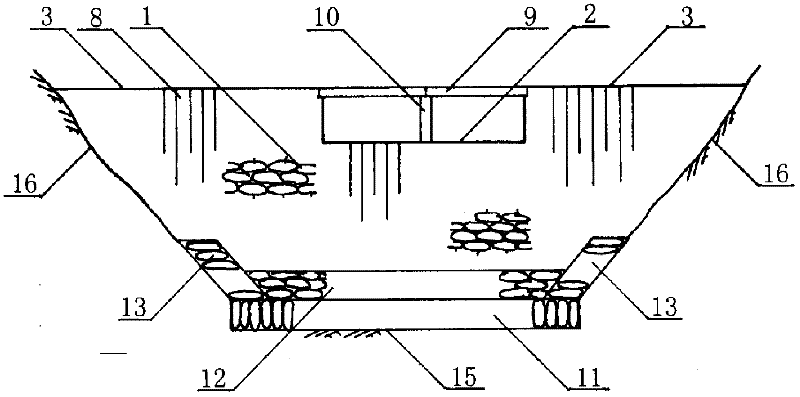

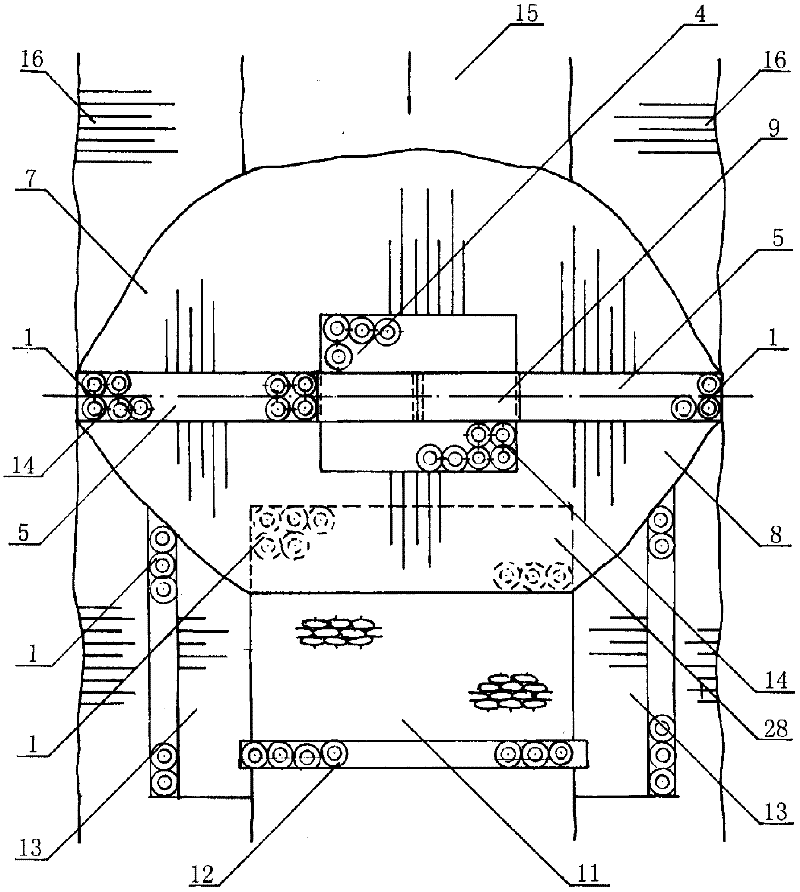

[0030] Referring to accompanying drawing, waste tire overflow dam, the riverbed 15 is provided with the retaining dam that waste rubber tire 1 masonry forms, the middle of retaining dam is overflow dam section 2, and both ends are non-overflow dam section 3, overflow dam section The elevation of the overflow surface 4 of 2 is lower than that of the dam top surface 5 of the non-overflow dam section 3. A slab bridge 9 is erected above the overflow dam section 2, and a pier 10 is supported under the slab bridge 9. The downstream slope foot of the overflow dam section 2 An apron 11 is arranged on the riverbed 15 at the place; an upstream slope protection 21, a front dam shell 22, a front reverse filter layer 23, an anti-seepage body 24, and a rear Reverse filter layer 25, rear dam shell 26, downstream slope protection 27, anti-seepage body 24 is located above the water intercepting groove 20 at the position of the dam axis, the cross section of the overflow dam section 2 is trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com