Magneto-rheological adjustable stiffness coil spring

A helical spring and magneto-rheological technology, applied in the field of helical springs, can solve the problem that the characteristic curve cannot be changed at any time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

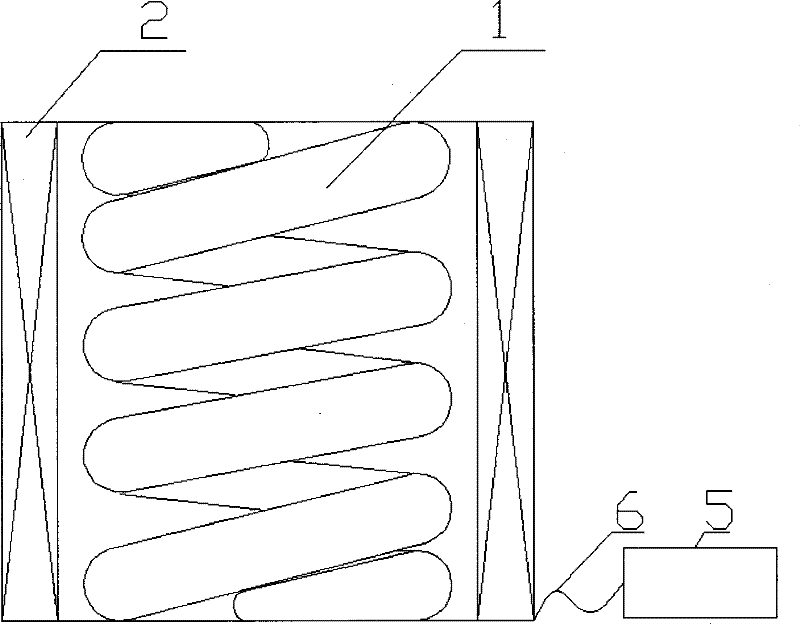

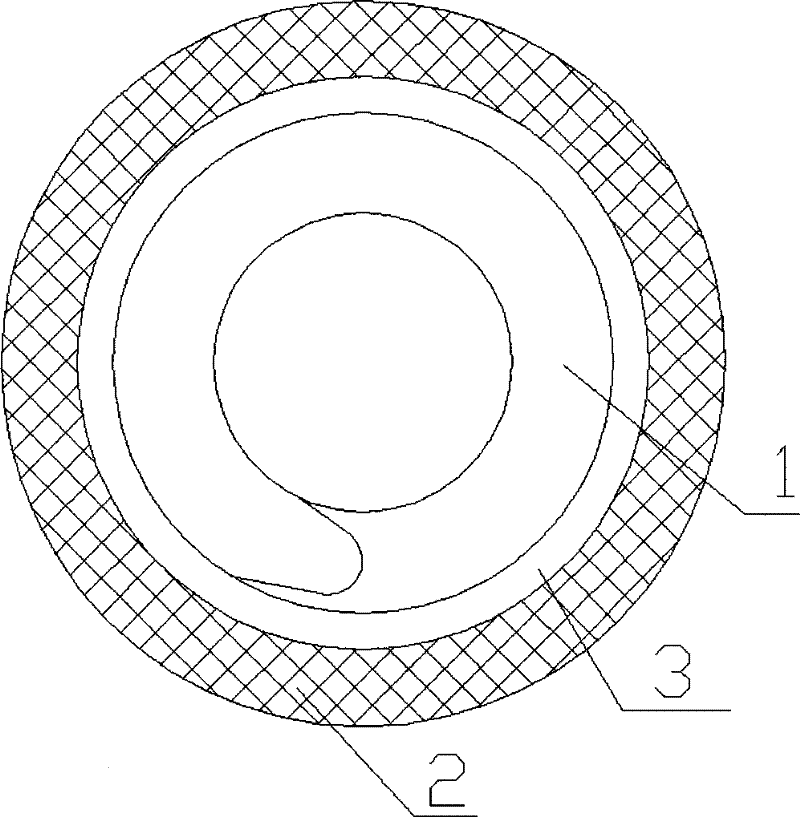

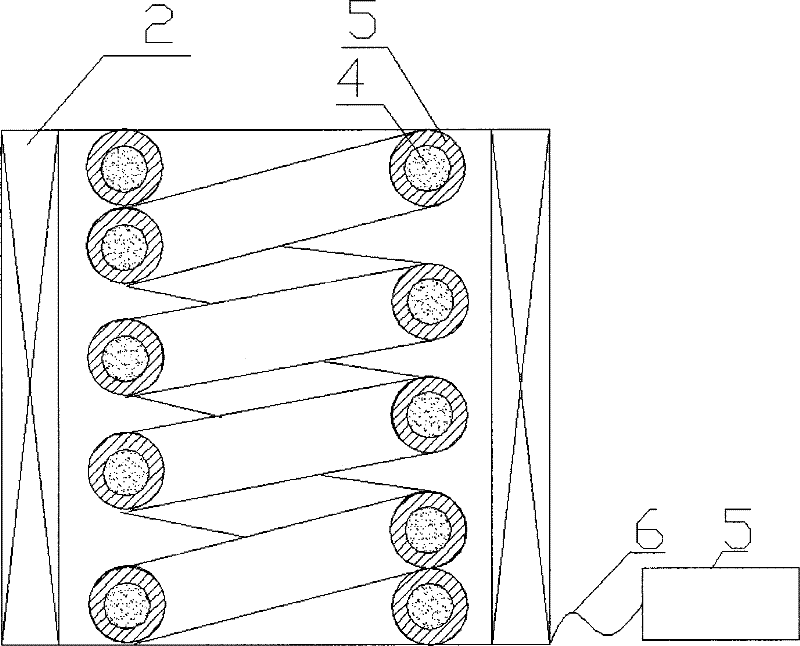

[0014] see figure 1 , figure 2 , image 3 , which is a specific structure of the present invention, the magnetorheological adjustable stiffness helical spring includes a helical spring 1 and a ring-shaped external electromagnet 2, and the reed wire of the helical spring 1 is made of a nonmagnetic polymer elastic material The hollow tube 5 is composed of a magneto-rheological fluid or magneto-rheological grease 4. The outer diameter of the coil spring 1 is smaller than the inner diameter of the ring-shaped external electromagnet 2 and a gap 3 is left. The coil spring 1 is placed In the annular external electromagnet 2 , the hollow tube 5 constituting the spring wire of the helical spring 1 is a non-magnetic conductive polymer elastic material, and the annular external electromagnet 2 is connected to the control power supply 5 through a lead wire 6 .

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com