A high-efficiency flat-plate heat collector

A heat collector and flat-plate technology, applied in the field of heat collectors, can solve the problems of heat gain efficiency difference, heat absorption efficiency reduction of heat collectors, high air heat loss of solar heat collectors, etc., to reduce heat loss, reduce heat dissipation, The effect of improving heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

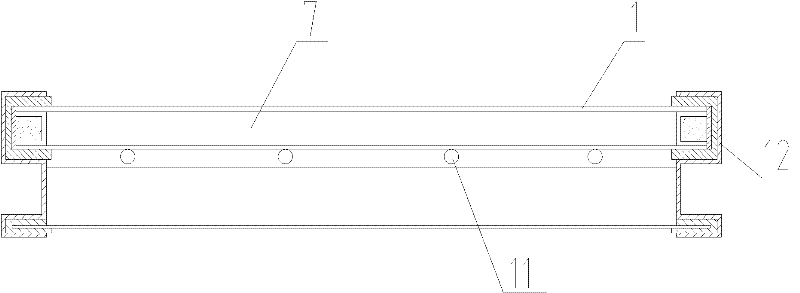

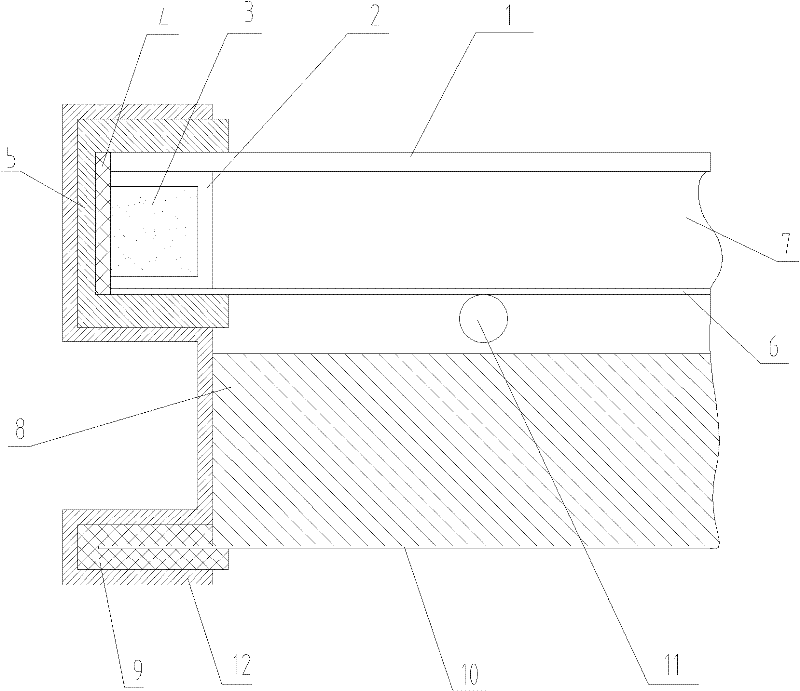

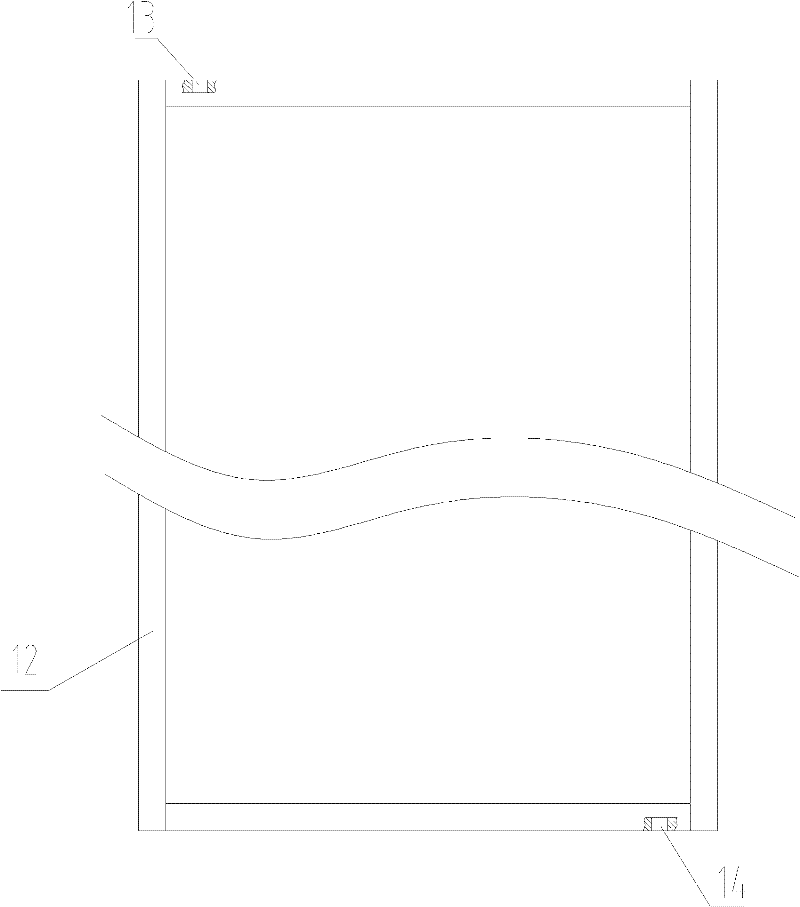

[0016] Such as figure 1 , figure 2 , image 3 As shown, a high-efficiency flat-plate heat collector includes a glass panel 1, a heat absorbing plate 6, an insulation layer 8 and a back plate 10, the glass panel 1 adopts cloth glass, and the gap between the glass panel 1 and the heat absorbing plate 6 The left and right ends of the cavity are equipped with straight-sided U-shaped aluminum alloy frames 2, the U-shaped opening of which faces the outside, and the opening is blocked by a thermal insulation sheet 4. The cavity of the aluminum alloy frame 2 is equipped with a desiccant 3, and the glass panel 1 is in contact with the heat absorber. The end side of the plate 6 is sealed by the rubber seal 5. The circulation liquid pipe 11 is fixedly connected to the bottom of the heat absorption plate 6. There is an insulation layer 8 and a back plate 10 under the circulation liquid pipe 11. The two ends of the back plate 10 are provided with composite The seal 9; the back plate 10 ...

Embodiment 2

[0020] The difference between this embodiment and the first embodiment is that nitrogen is used as the inert gas medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com