Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

A technology of impedance spectroscopy and electrodes, applied in the field of in-situ measurement of electrical quantities, to achieve the effect of solving the insulation of the sample cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

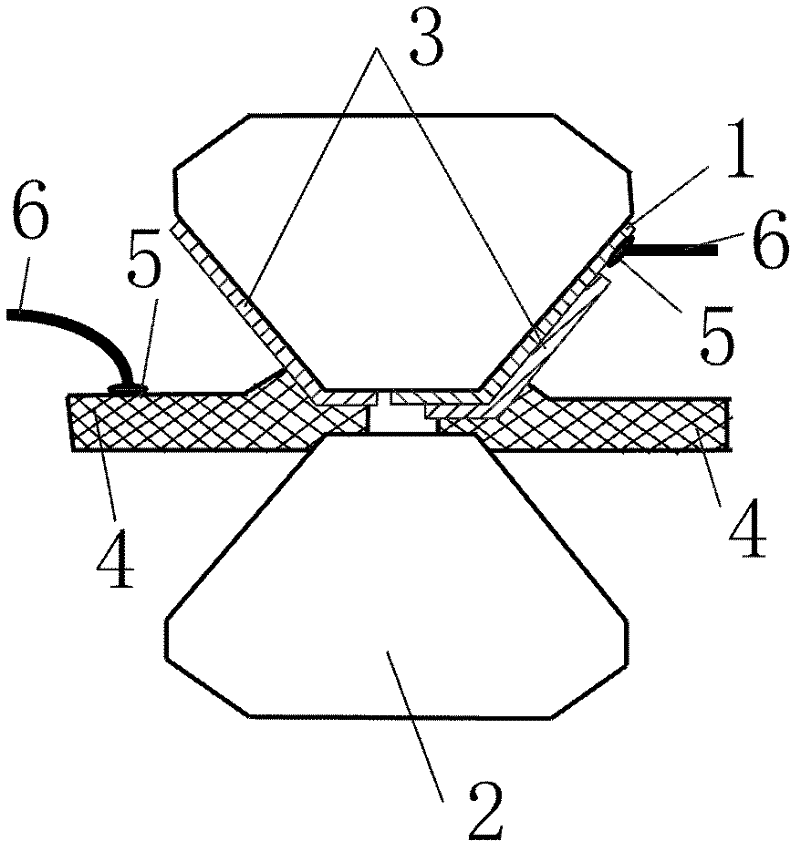

[0025] The whole device of the present invention is as figure 1 shown. Among them, 1 is a metal film electrode, 2 is a diamond anvil, 3 is an aluminum oxide protective layer, 4 is a metal gasket, 5 is a copper wire wire, and 6 is a silver paste.

[0026] The metal film electrode 1 is deposited on the anvil surface and the side surface of the diamond anvil 2, and the metal film electrode 1 is circular at one end of the anvil surface of the diamond anvil 2, and is not covered by the aluminum oxide protective layer 3; One end of the side of the anvil 2 uses silver paste 6 to bond the copper wire conductor 5 .

[0027] Metal pad 4 is used as another electrode, and silver paste 6 is also used to bond copper wire 5 .

[0028] The metal gasket 4 and the metal film electrode 1 form an axisymmetric electrode system; the two electrodes are at the sample cavity so that all the detection signals are transmitted through the sample,

Embodiment 2

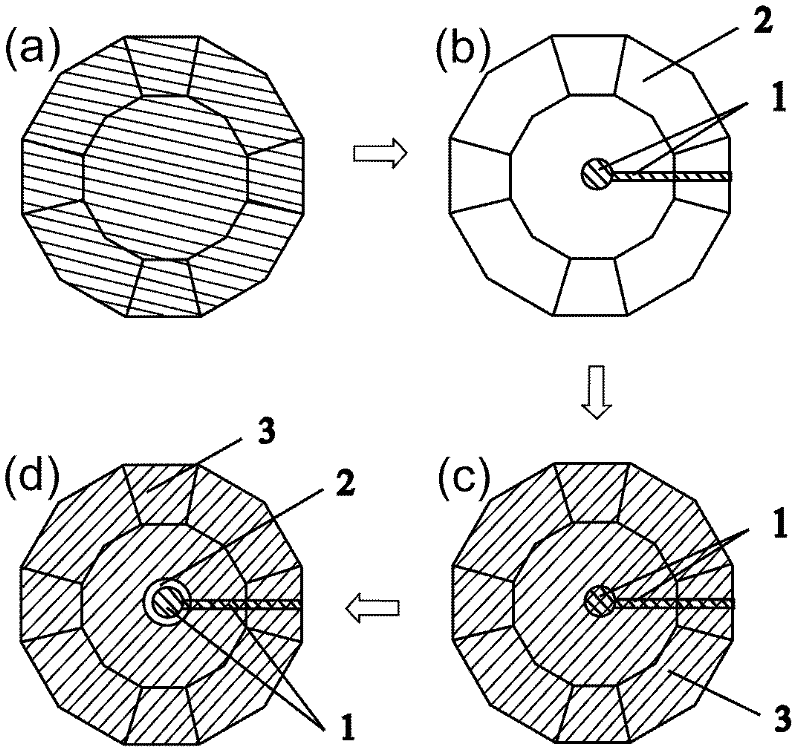

[0030] The present invention adopts following technological process [whole process is as figure 2 Shown in (a)~(d)]:

[0031] Step 1: Soak the diamond anvil in a mixed solution of acetone and alcohol (volume ratio 1:1) for 20 minutes to remove surface stains, and rinse the residual solution on the surface with deionized water after taking it out.

[0032] The second step: on the surface of the diamond anvil, a layer of metal film is plated by magnetron sputtering as an electrode material [such as figure 2 (a)]. During the sputtering process, the substrate temperature is kept at 250-300 degrees Celsius, metal materials are used as the target material, argon is used as the working gas, and the pressure in the vacuum chamber is always kept within the range of 0.8-1Pa.

[0033] Step 3: Take out the diamond anvil coated with the metal film, apply a layer of photoresist evenly on its surface, use photolithography technology to carve the shape of the electrode on the diamond anvi...

Embodiment 3

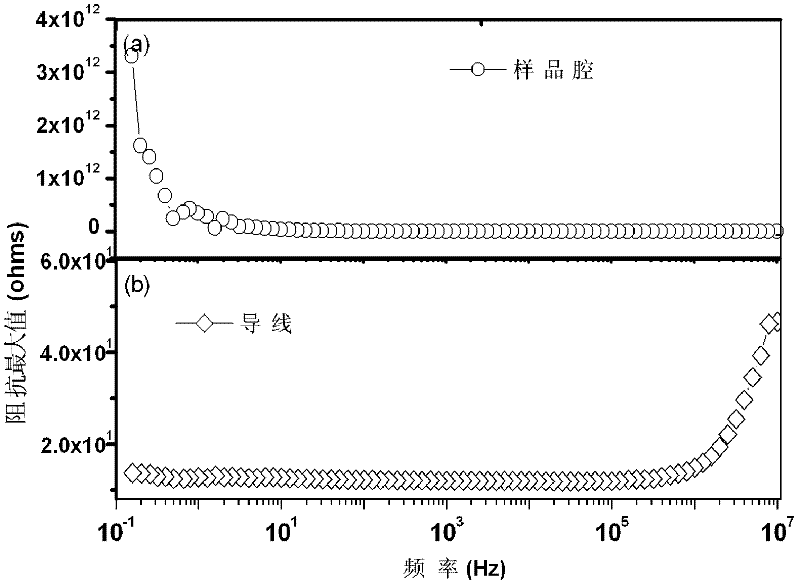

[0038] Using the electrode model designed by the invention, the impedance spectrum measurement is carried out on the nanometer ZnS. The instrument used in the experiment is a Solartron frequency response analyzer, the instrument model is 1260+1296. During the measurement, the two connection terminals are respectively connected to two thin copper wires. The input and output frequency range of the AC signal used is 10MHz-10μHz, and the amplitude of the AC voltage signal needs to be selected according to different samples. For the sample of nano-ZnS, the AC signal voltage used by the author is 0.1V.

[0039] The specific electrical quantity measurements and their results are as follows.

[0040] 1. Measurement results of parasitic capacitance and inductance of the system

[0041] Parasitic capacitance generally refers to the capacitance characteristics of inductors, resistors, chip pins, etc. under high frequency conditions. In fact, a resistor is equivalent to a capacitor, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com