Processing box

A process cartridge and photosensitive drum technology, applied in the field of process cartridges, can solve the problems of high manufacturing and installation requirements, unfavorable production cost, saving and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

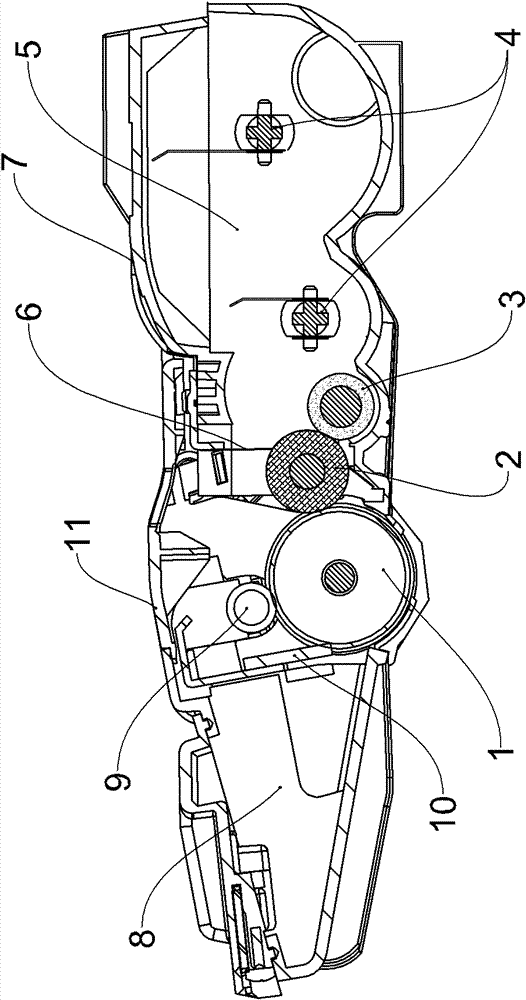

[0027] Since the main structure of the embodiment of the process box of the present invention is the same as that of the existing process box, only the improvement of the present invention to the existing process box will be highlighted.

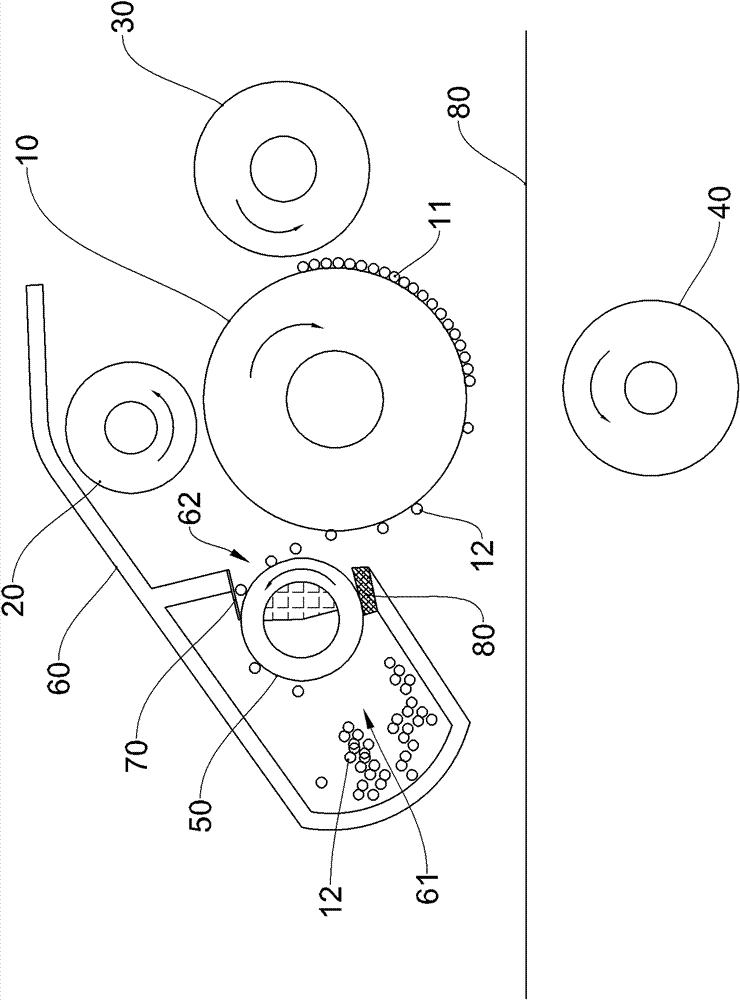

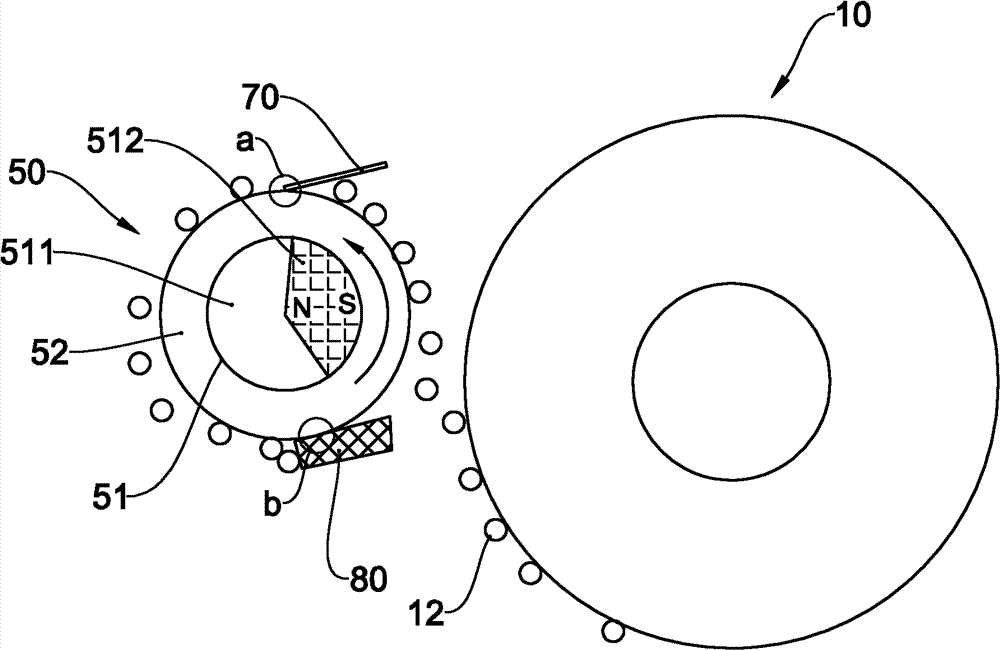

[0028] figure 2 The operation principle of the photosensitive drum cleaning device for the process cartridge of the embodiment of the present invention is shown. A photosensitive drum 10 , a waste toner bin 61 , a cleaning roller 50 and a charging roller 20 are disposed in the cleaning frame 60 . The developing roller 30 forms a toner image 11 on the surface of the photosensitive drum 10 through a developing operation. As the photosensitive drum 10 rotates, when passing through the imaging medium 80 , such as paper, the toner image 11 is transferred to the imaging medium 80 by the transfer operation of the transfer roller 40 to form a printed image. After the photosensitive drum 10 has been transferred, the surface of the photosensitive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com