Upper bracket and manufacturing method thereof

A technology of inner fittings in the circumferential direction, which is applied in the field of upper brackets, and can solve the problems of fixing difficult inner fittings 202 and rebound stop fittings 208, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

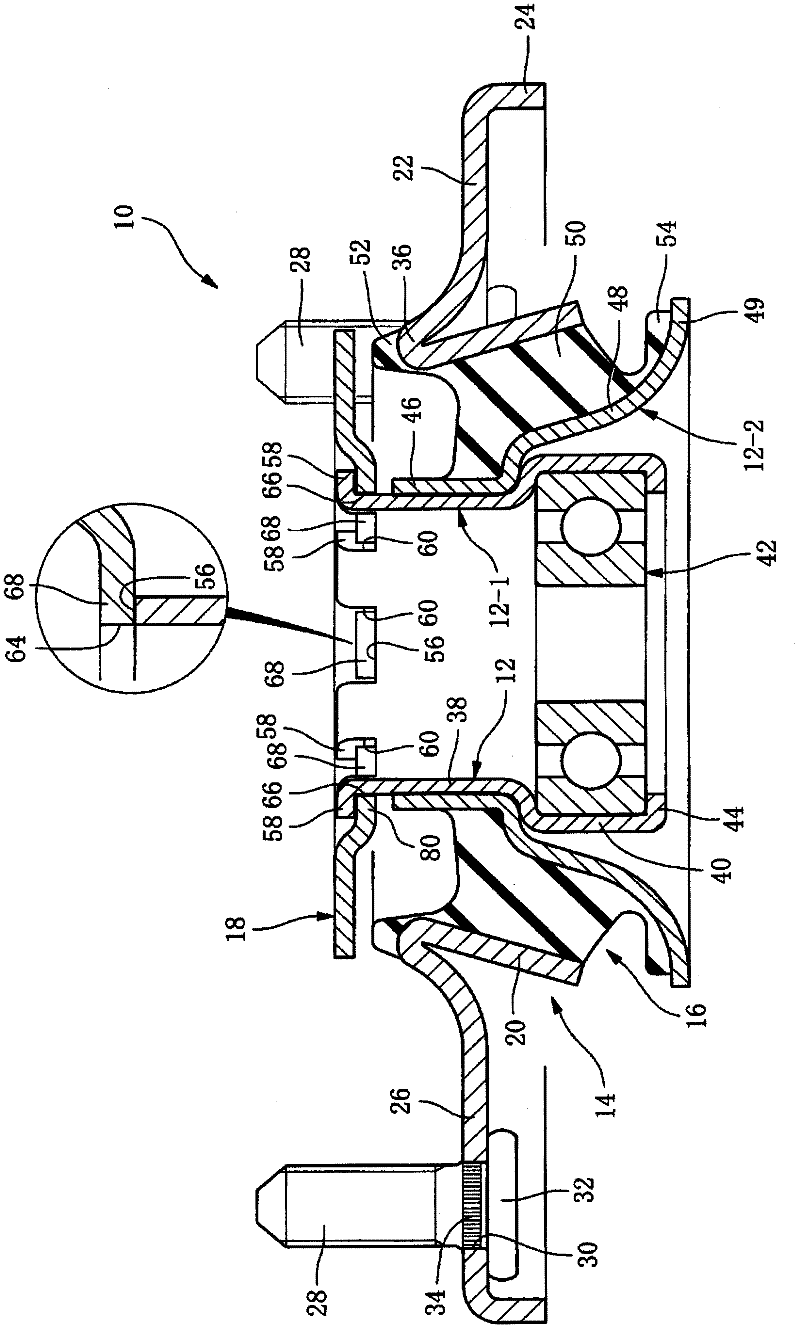

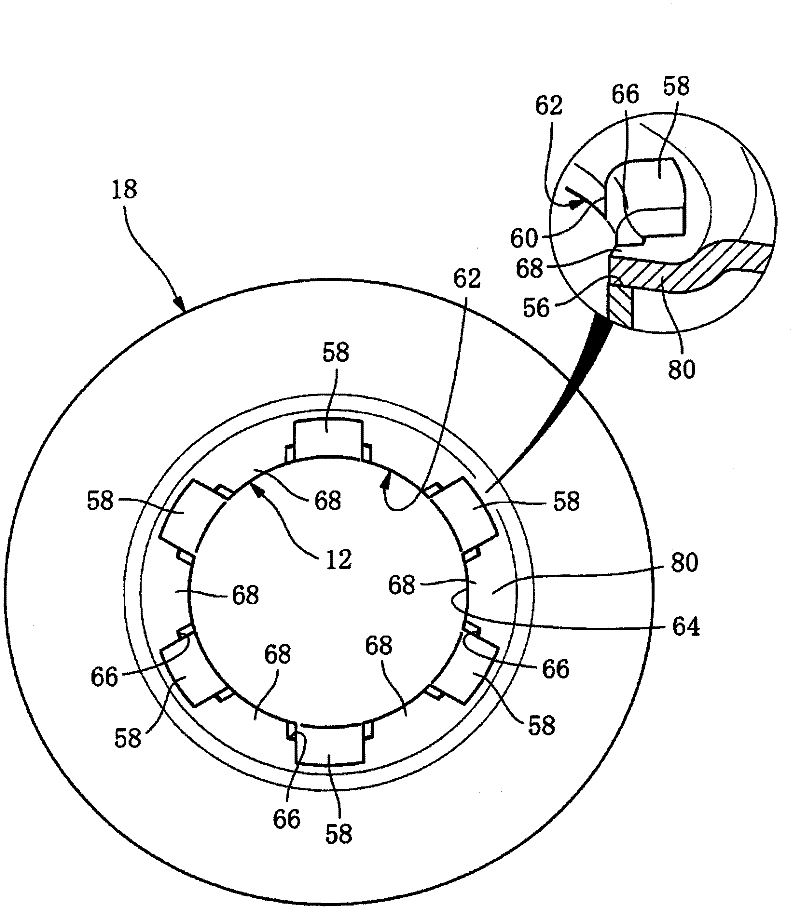

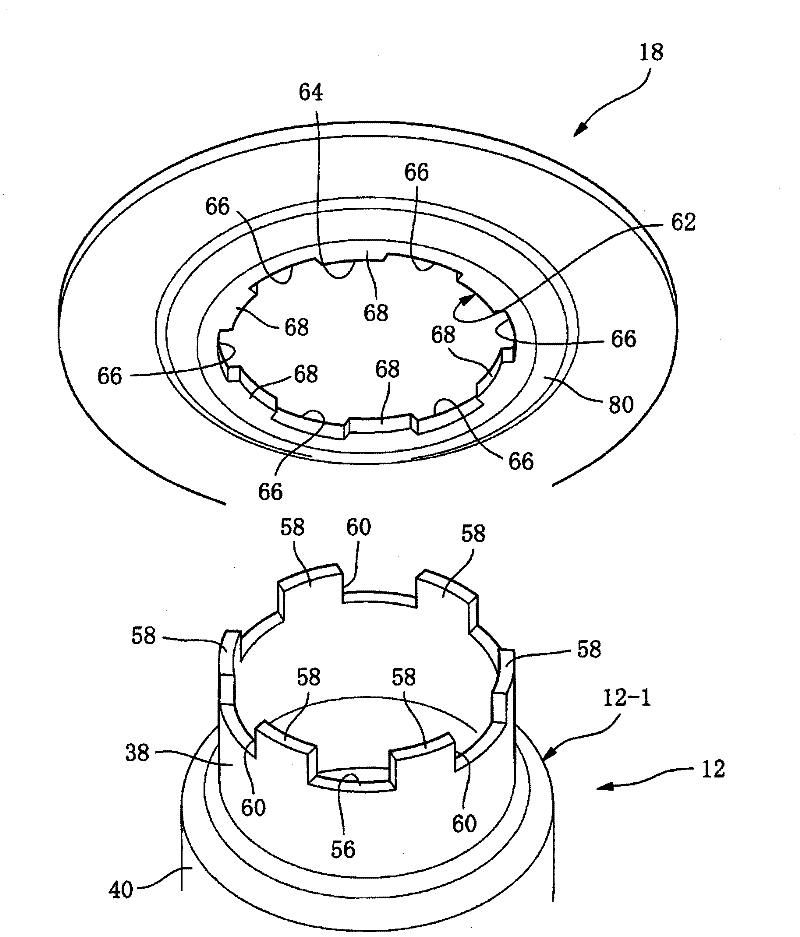

[0080] exist figure 1 Among them, the reference numeral 10 is an upper bracket that elastically connects the piston rod of the shock absorber and the vehicle body and plays a role of vibration isolation between the piston rod and the vehicle body. It has a cylindrical inner fitting 12 and is configured The outer fitting 14 on the radially outer side of the inner fitting 12, the rubber elastic body 16 integrally vulcanized and bonded to these inner fittings 12 and the outer fitting 14 in a state of elastically connecting them, and the rebound stop fitting 18, The springback stop fitting 18 is formed in a plate shape independently of the inner fitting 12 , fixed to the upper end of the inner fitting 21 by riveting, and moves up and down together with the inner fitting 12 , and acts as a stopper when rebounding.

[0081]The upper bracket 10 is fixed to the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com