Motor stator or rotor segment

A segment and stator technology, applied in the segment field of stator or rotor, can solve the problem of inflexible winding, etc., and achieve the effect of good pluggability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

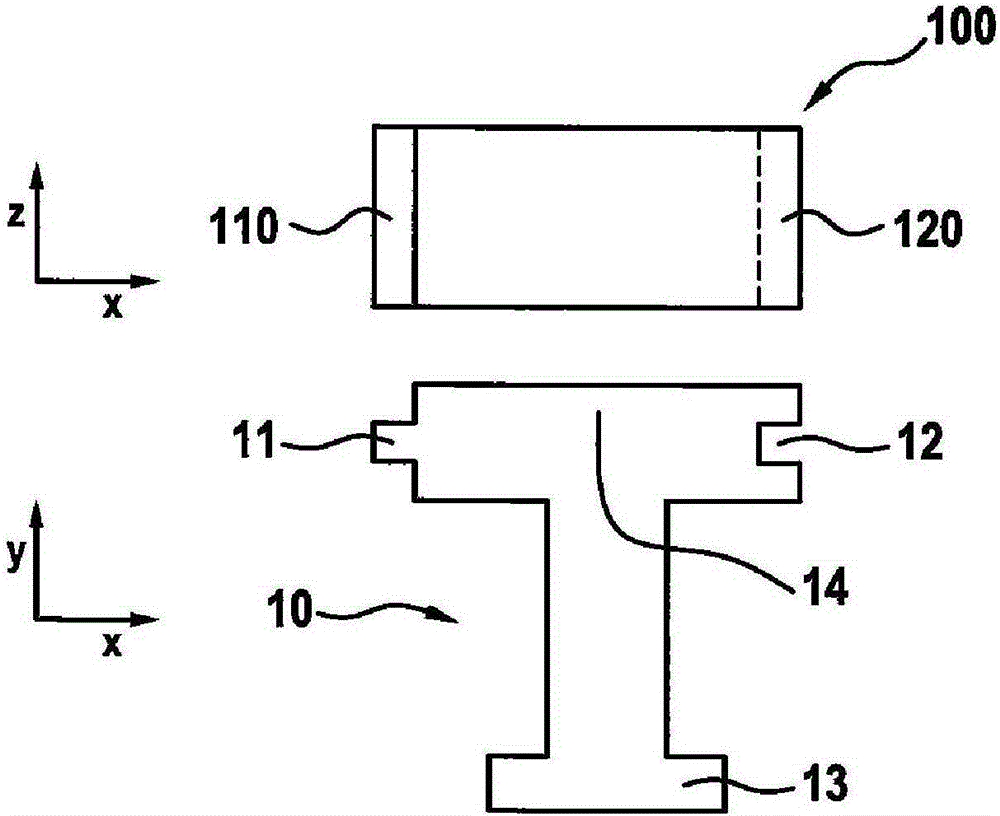

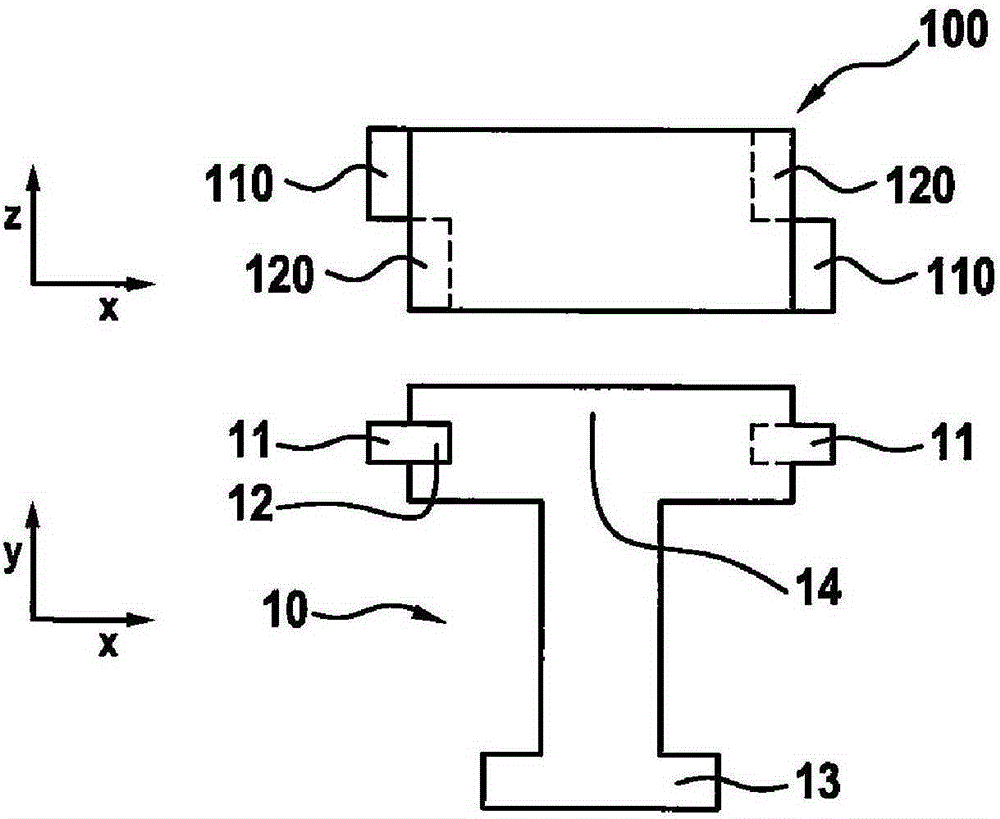

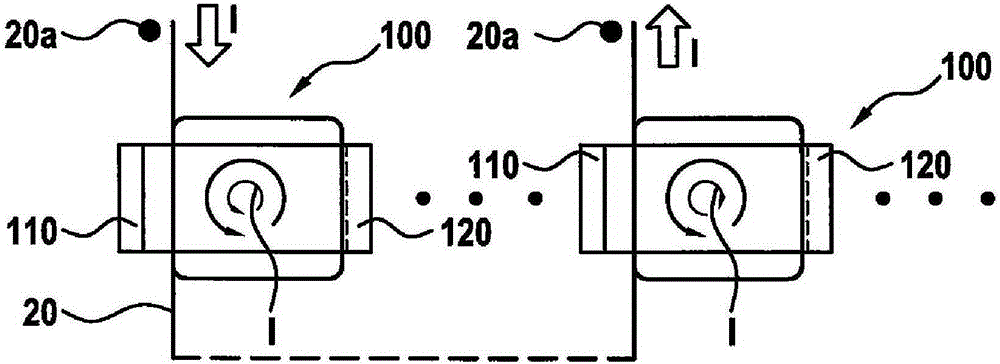

[0032] Figure 1a A conventional segment 100 for a stator 200 (not shown) or a rotor 210 (not shown) of an electric machine 300 is shown in two views, which may consist of a thin electrical connection having a thickness of 0.5 mm or, for example, 0.35 mm. Tablets (Elektroblech) Composition. Other strengths (or thicknesses) of the lugs are likewise possible. An x-y and an x-z coordinate system are shown for the orientation, which should indicate the geometrical orientation of the segment 100 .

[0033] Segment 100 has a plurality of teeth 10 and is preferably formed from punched sheets which are first punched and then pressed into groups of punched sheets in the form of segment 100 . Alternatively, it is also possible to produce the tooth 10 by means of a casting process, ie to cast it. The length of the punched segment 100 is related here to the structural length of the electric machine 300 in the axial direction. It can be seen that in the segment 100 in the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com