Limited heavy hammer for crane anti-overwinding switch

A crane and position-limiting technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of inconvenient separation of the left half limit block and the right half limit block, and easy loss of connecting parts such as bolts and nuts. , to achieve the effects of quick replacement, quick disassembly, and reduced time for replacement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

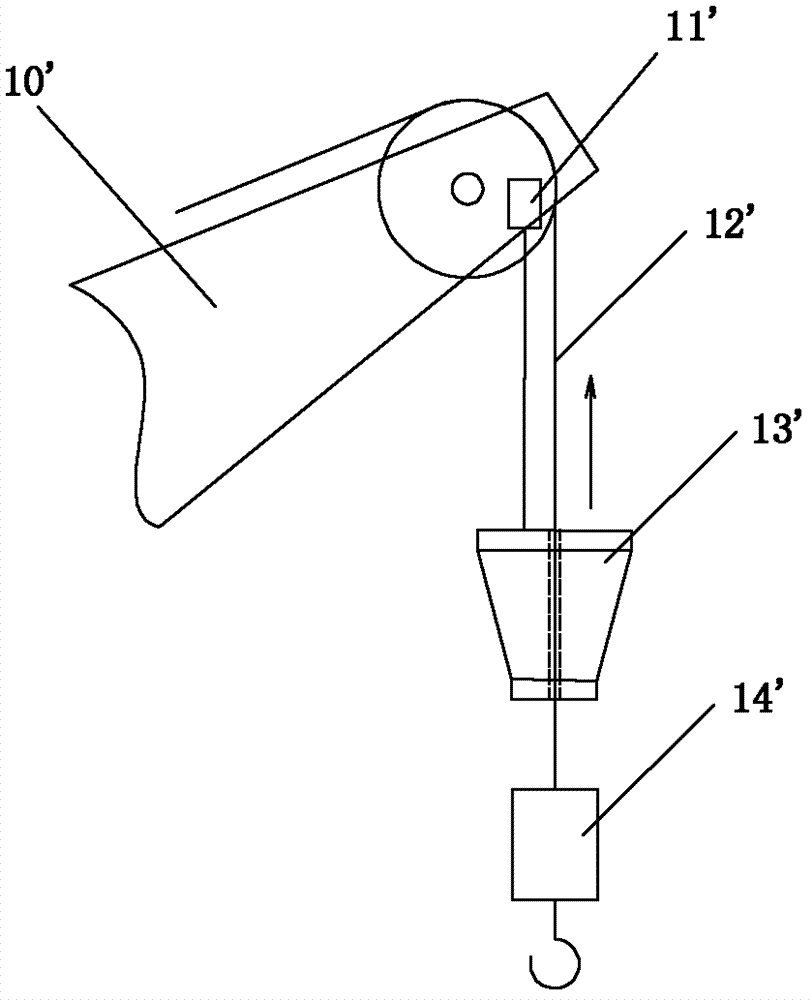

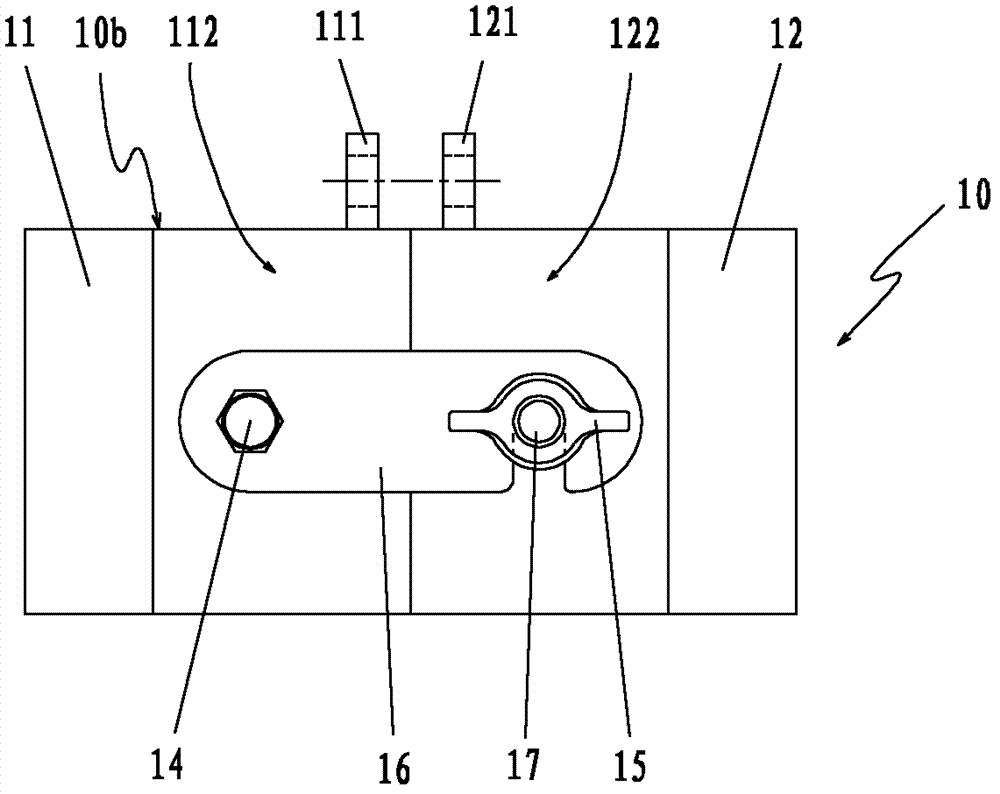

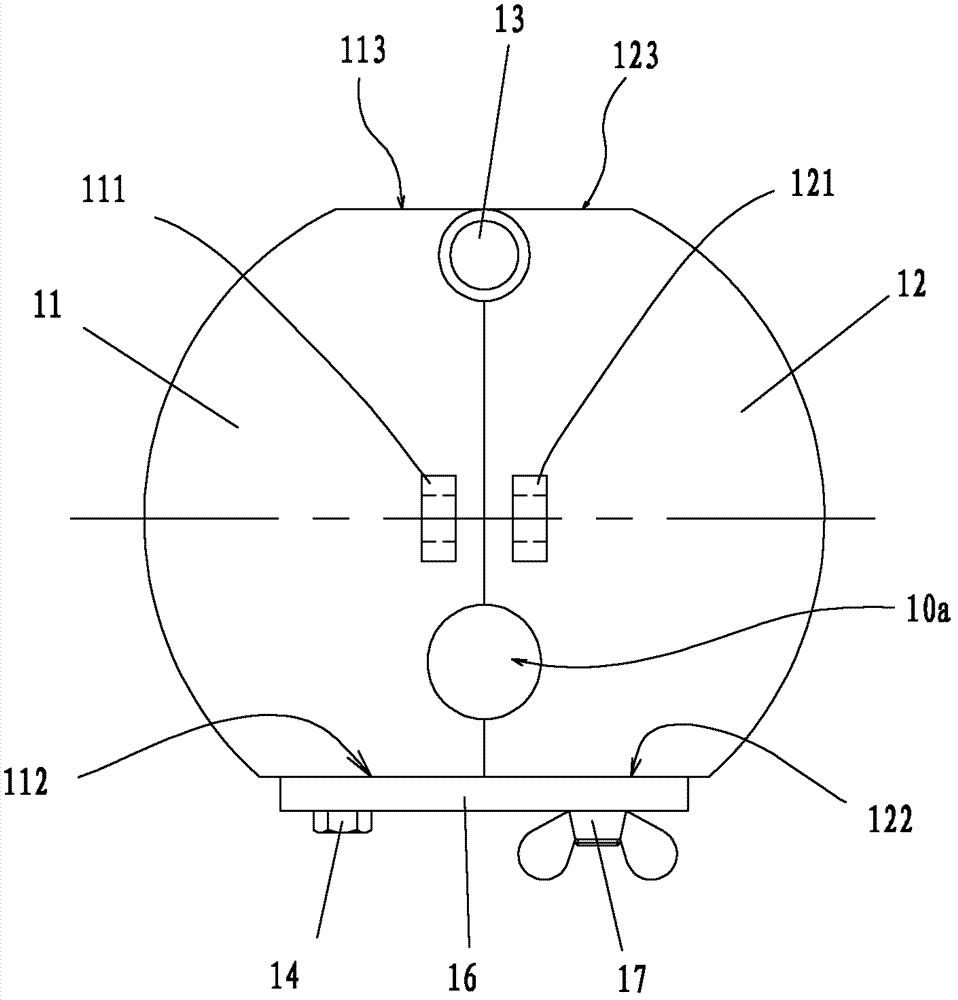

[0027] Figure 2 to Figure 4 It shows a side view structural schematic diagram of the limit weight of the anti-rollover switch of the crane according to the present invention. combined reference Figure 2 to Figure 4 , the limit weight 10 of the present invention includes: a left half limit block 11, a right half limit block 12, a pin shaft 13 that pivotally connects the left half limit block 11 and the right half limit block 12, and a fixed connection The bolt 14 on the left half limit block 11, the lock column 15 that is fixedly connected on the right half limit block 12, and the lock plate 16 that is pivoted on the bolt 14 and is used to lock the lock column 15, and is screwed on the lock The wing nut 17 used to lock the lock plate 16 on the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com