Method and system for installing foundation components in an underwater formation

A technology for installing foundations and components, applied in foundation structure engineering, architecture, sheet pile walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

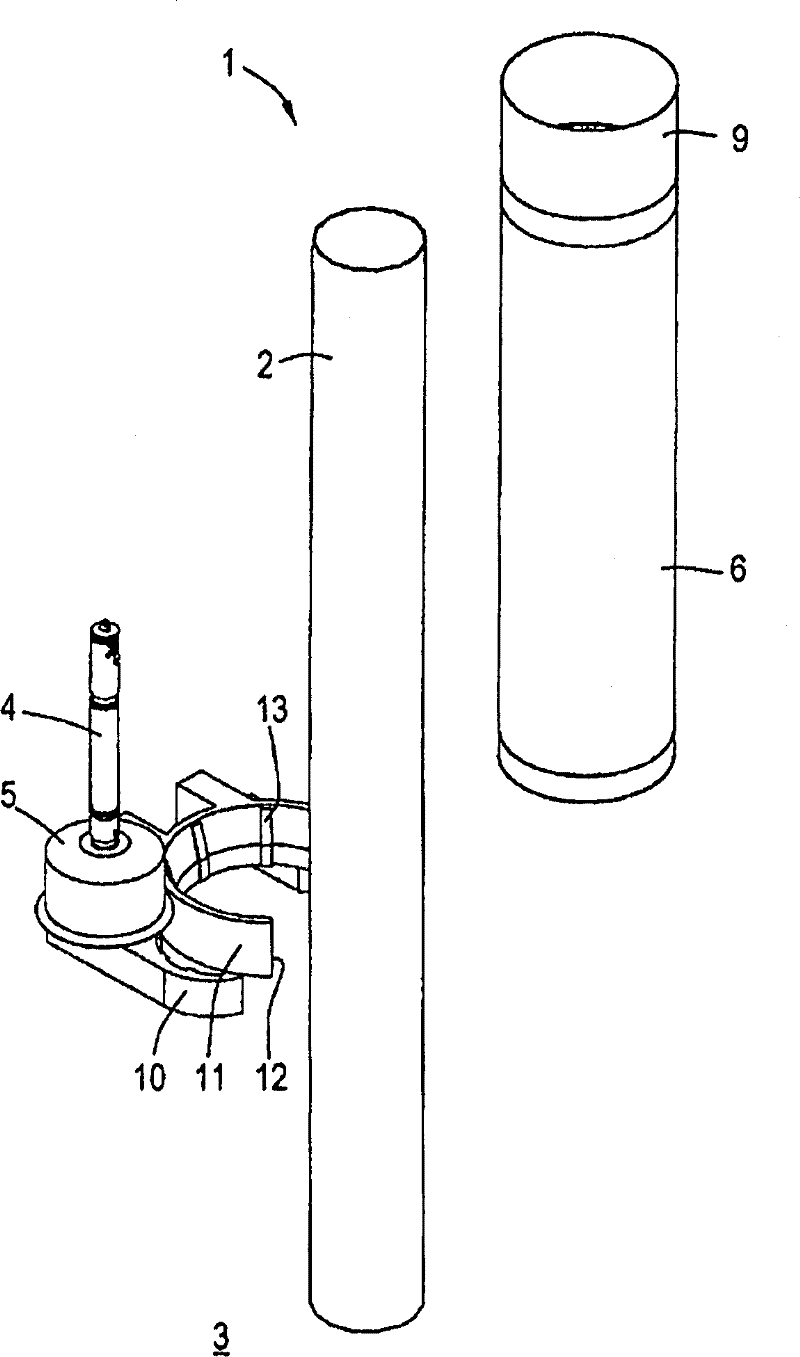

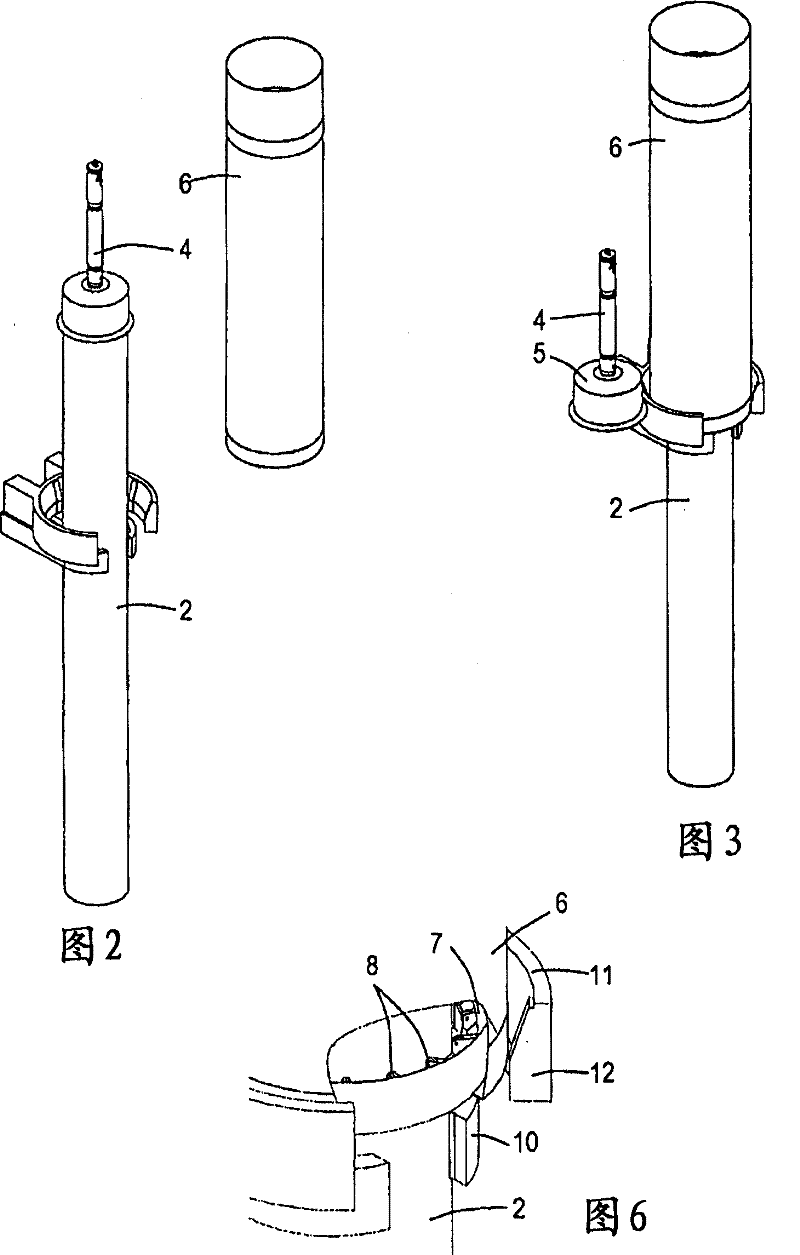

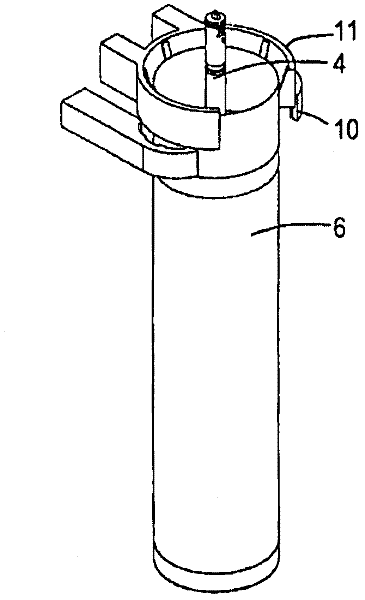

[0021] figure 1 An embodiment of a system 1 according to the invention for installing a monopile 2 in an underwater formation 3 , such as the sea bottom, is shown. In this example, the monopile 2 has a circular cross-section and is five (5) meters in diameter, which will serve as the foundation for the wind turbine after installation is complete.

[0022] The system 1 comprises: a hydraulic pile driver 4 (eg IHC Hydraulic Hammer S-1800), which is connected to a power unit on a surface vessel such as a jack-up barge (not shown); The pile driver sleeve 5 for firmly installing the pile driver on the monopile; and the anvil (covered by the pile driver sleeve and unable to see) for transferring the impact energy of the pile driver 4 to the monopile.

[0023] The system further comprises a sound insulating sleeve 6, for example of steel, which is placed around the foundation member and on the submerged formation to reduce the noise input from the pile driver into the surrounding wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com