A method and device for testing the concentrating performance of a solar dish concentrator

A test method and a test device technology, which are applied in the direction of testing optical properties, etc., can solve problems such as difficulty and complexity in implementation, and achieve the effects of clear physical meaning, small quantity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

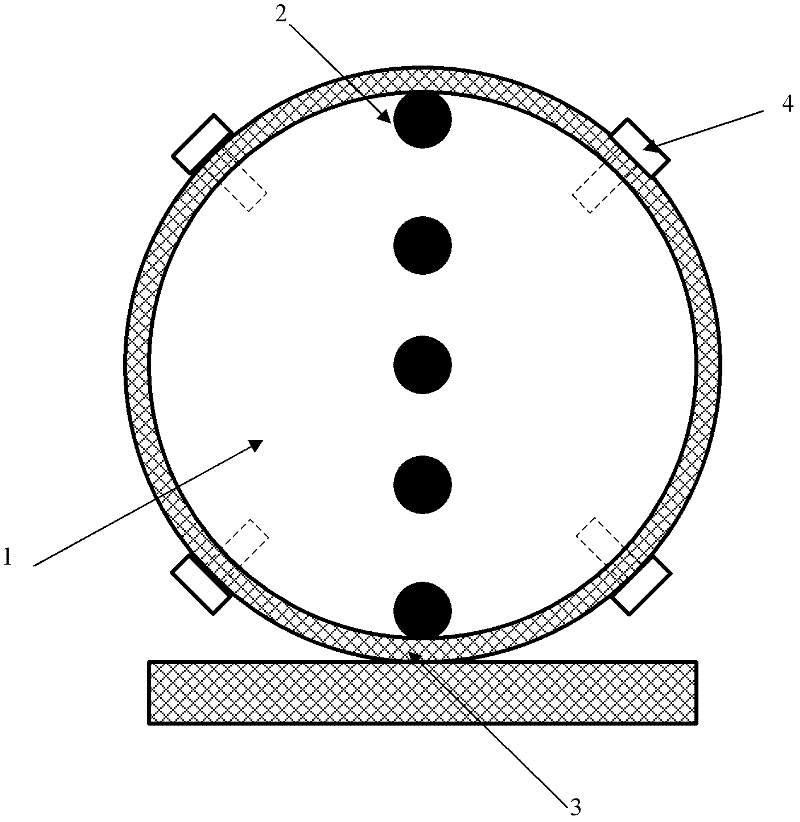

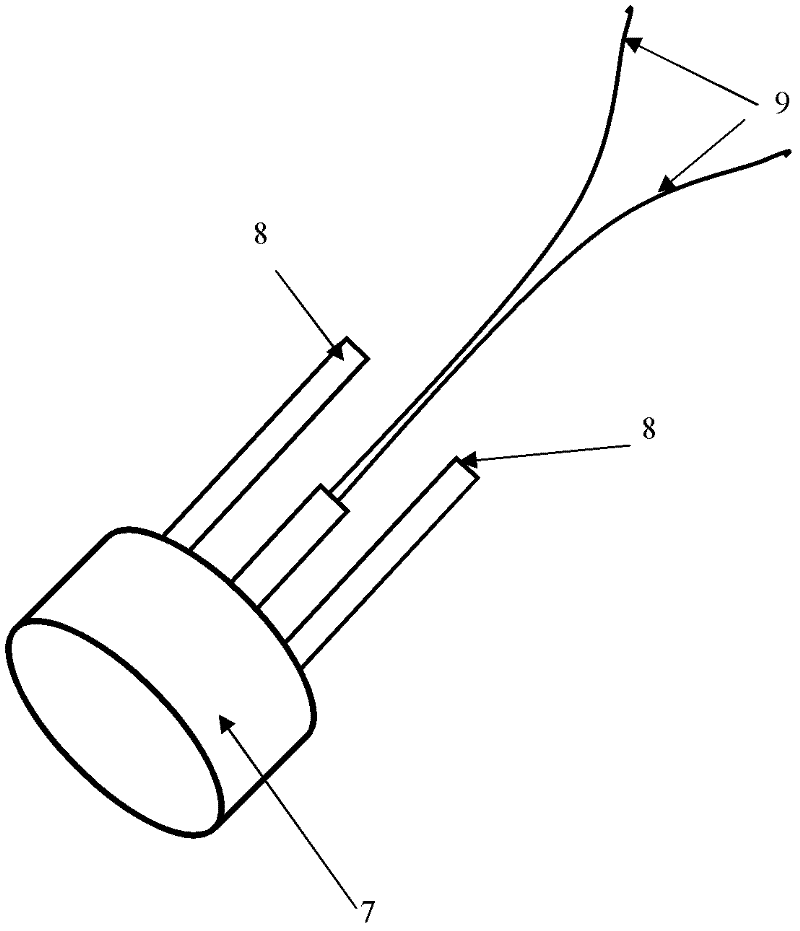

[0024] figure 1 The light concentrating performance test device of the dish concentrator shown. Such as figure 1 As shown, the device is composed of a rotating substrate 1 , a heat flow sensor 2 and a fixed frame 3 . The fixed frame 3 is located at the outermost layer of the test device and surrounds the rotating base plate 1 . The rotating base plate 1 and the fixed frame 3 are connected by bolts, and the heat flow sensor 2 is installed on the rotating base plate 1 .

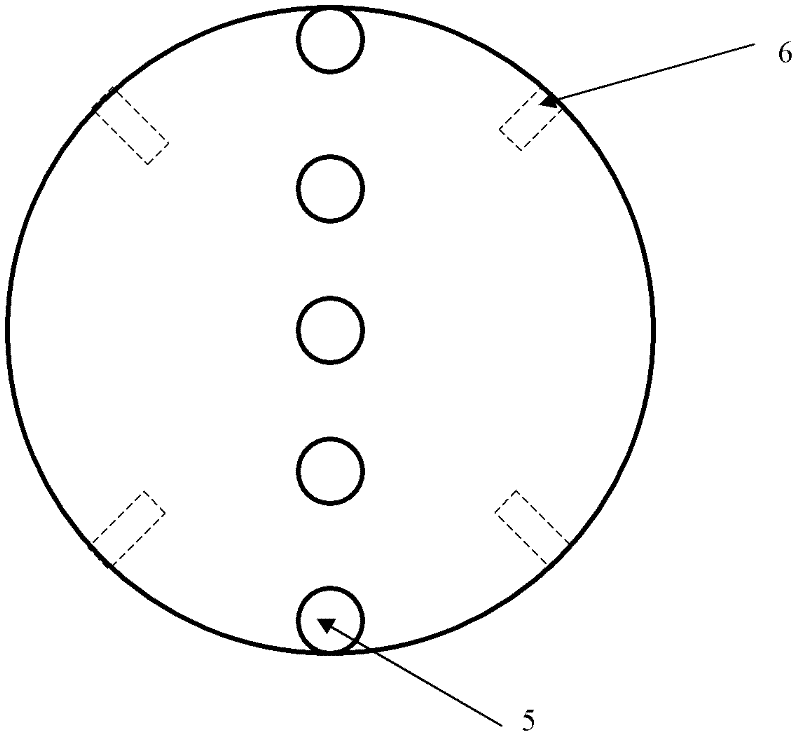

[0025] The rotating base plate 1 is disc-shaped. The rotating base plate 1 can be integrally formed by refractory materials. The rotating base plate 1 has a heat flow sensor installation hole 5 reserved for installing the heat flow sensor 2. The side of the rotating base plate 1 is preset with 4 base plates for fixing. The holes 6 and the substrate fixing holes 6 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com