Power assembly positioning system and positioning method

A technology of powertrain and positioning system, applied in the field of positioning system, can solve the problems of difficulty in observation, time-consuming, small space in the power cabin, etc., and achieve the effect of simple and convenient installation and positioning, and rapid hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

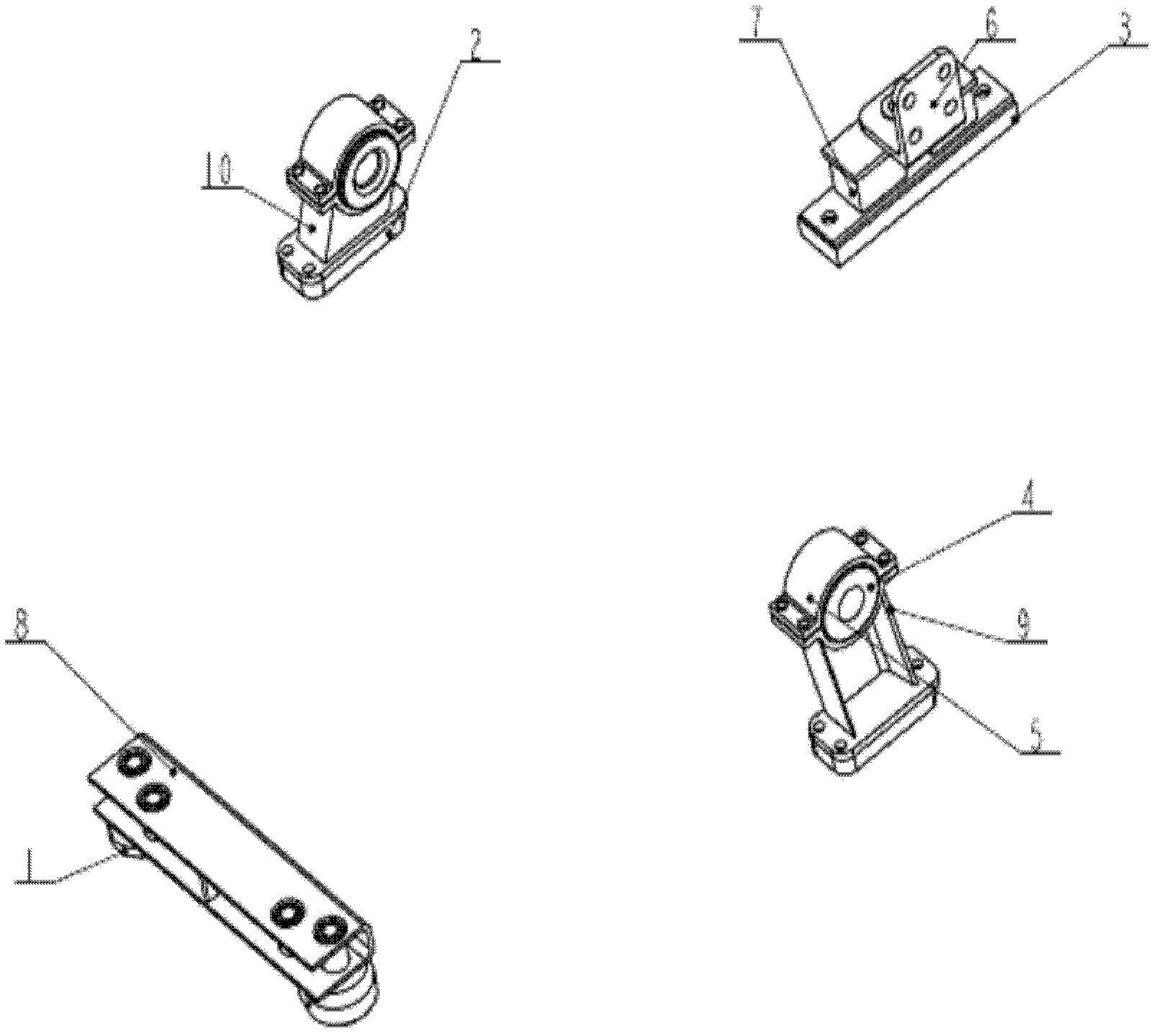

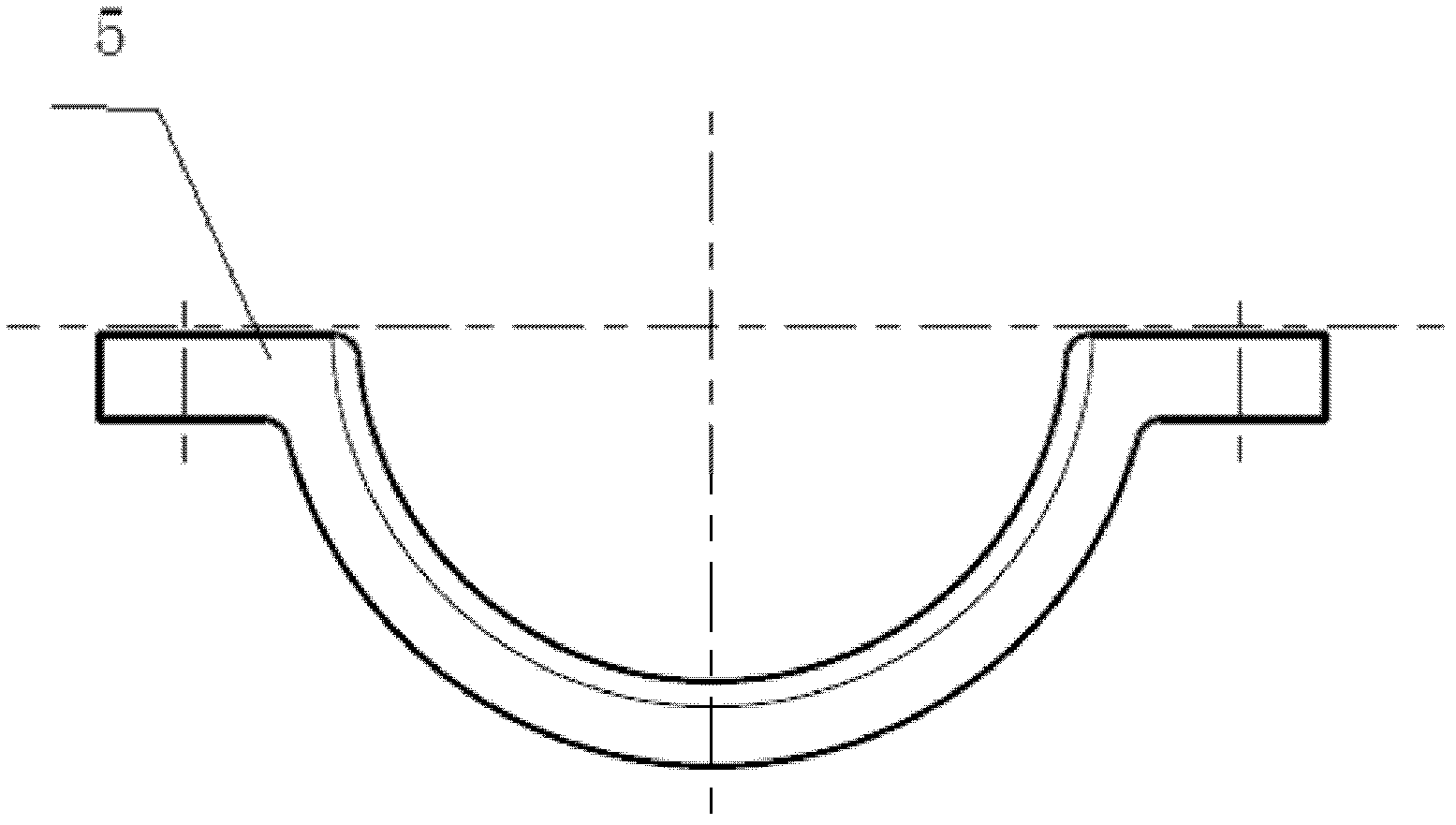

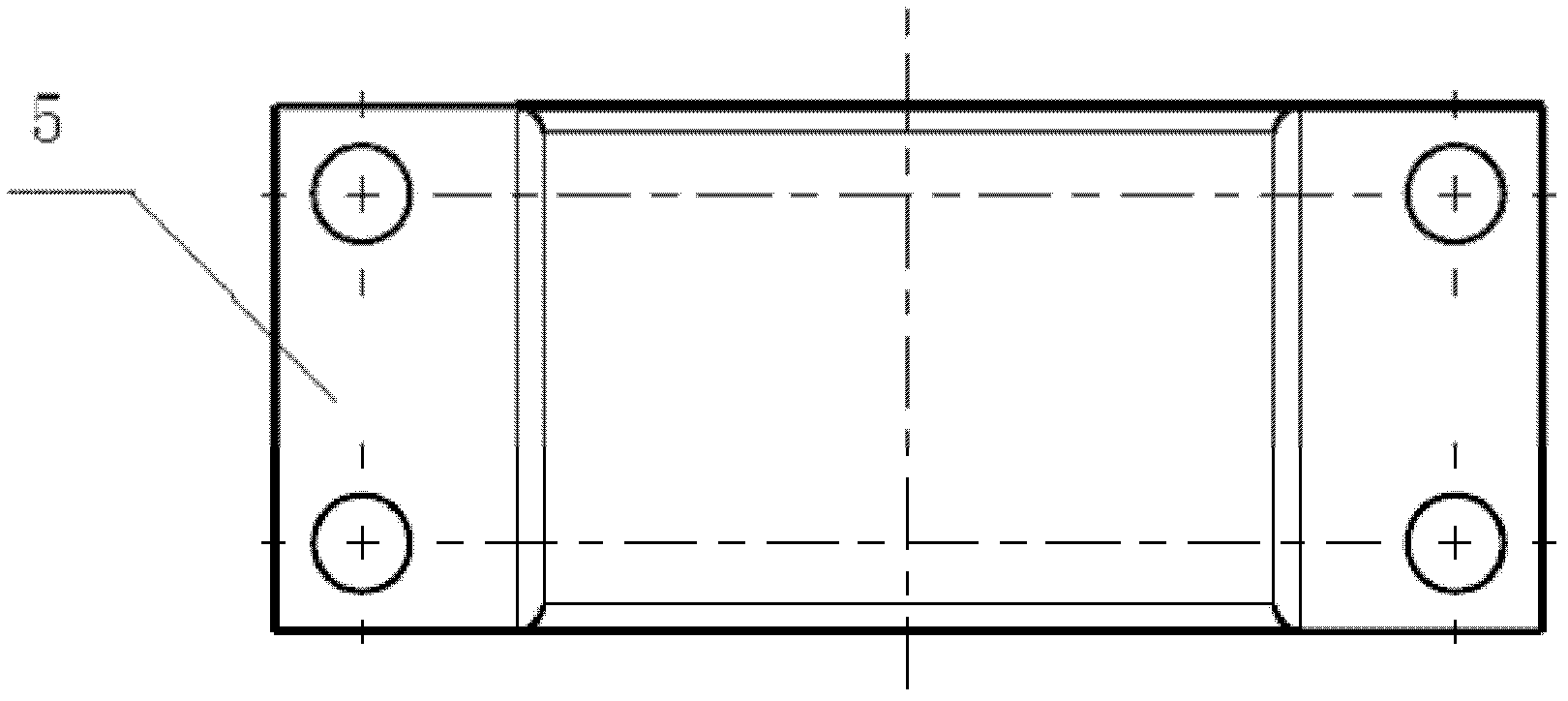

[0029] Such as Figure 1-11 As shown, a powertrain positioning system and a positioning method of the present invention include an engine installed on the vehicle body, a powertrain gearbox, and a gearbox bracket 6, and a transition bracket 8 is connected to the free end of the engine. The semi-cylindrical positioning structure of the bracket 8 has a positioning hole on the transition bracket 8, and a positioning attachment 1 is provided on the car body. The positioning attachment 1 matches the positioning hole on the transition bracket 8, and the positioning attachment 1 and the positioning hole The connection is a conical structure; the flywheel housings at the left and right ends of the engine are connected with a rear mount 4, and the rear mounts 4 at the left and right ends are respectively arranged on the upper ends of the rear mount left upper bracket 9 and the rear mount right upper bracket 10, and the rear mount The left upper bracket 9 and the rear suspension upper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com